Spouted circulating fluidized bed

A circulating fluidized bed and spouted fluidized bed technology, applied in chemical/physical processes, chemical instruments and methods, etc., can solve the problems of easy occurrence of short circuits and channeling, large back mixing, and lowering the yield of target products, etc. Achieve the effect of eliminating and easy-bonding particle agglomeration, avoiding delamination or junction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

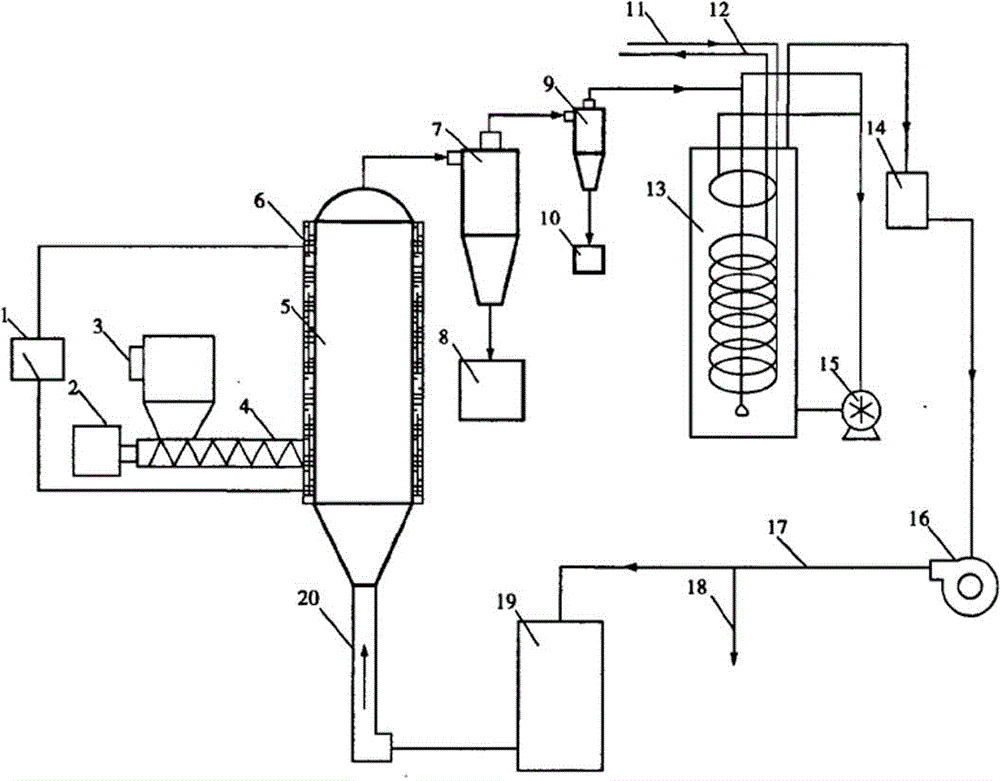

[0018] A spouted circulating fluidized bed is composed of a monitoring system 1, a feed system, a main reactor, a gas-solid separation system, a filter 14, a gas purification system, a gas recovery system, and a preheating system 20 connected end to end in sequence. The main reactor is the spouted fluidized bed reactor 5. The feeding system is a vibrating feeder 3, and is connected with a spouted fluidized bed reactor 5 through a screw 4. The spouted fluidized bed reactor 5 is covered with a layer of heater 6 . The gas-solid separation system is divided into two-stage separation devices connected in sequence, namely the first-stage cyclone separator 7 and the first-stage cyclone separator 9 . The bottom of the primary cyclone separator 7 is connected to the primary carbon collection box 8 , and the bottom of the secondary cyclone separator 9 is connected to the secondary carbon collection box 10 . The condensing system is a bubbling secondary spray condenser 13, and is provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com