Modification method of cerium-tin compound oxide coated lithium-rich manganese-based positive material

A composite oxide, lithium-rich manganese-based technology, applied in nanotechnology for materials and surface science, positive electrodes, active material electrodes, etc., can solve problems such as irreversible oxygen loss, achieve high efficiency for the first time, and rapid synthesis method The effect of simplicity and stable crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

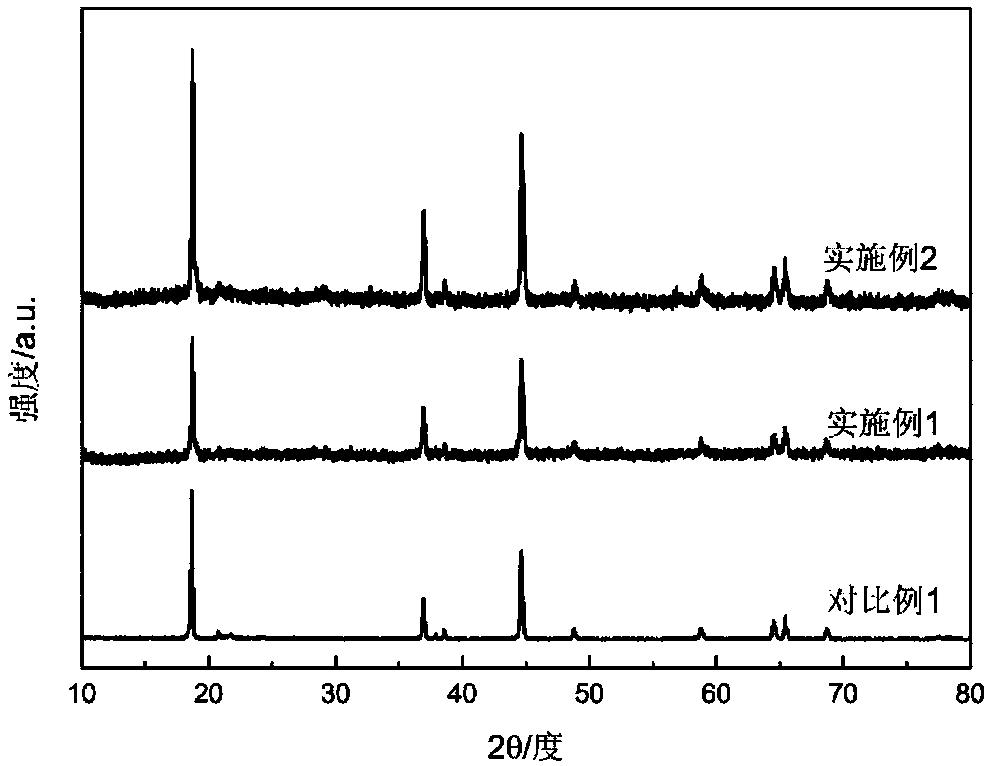

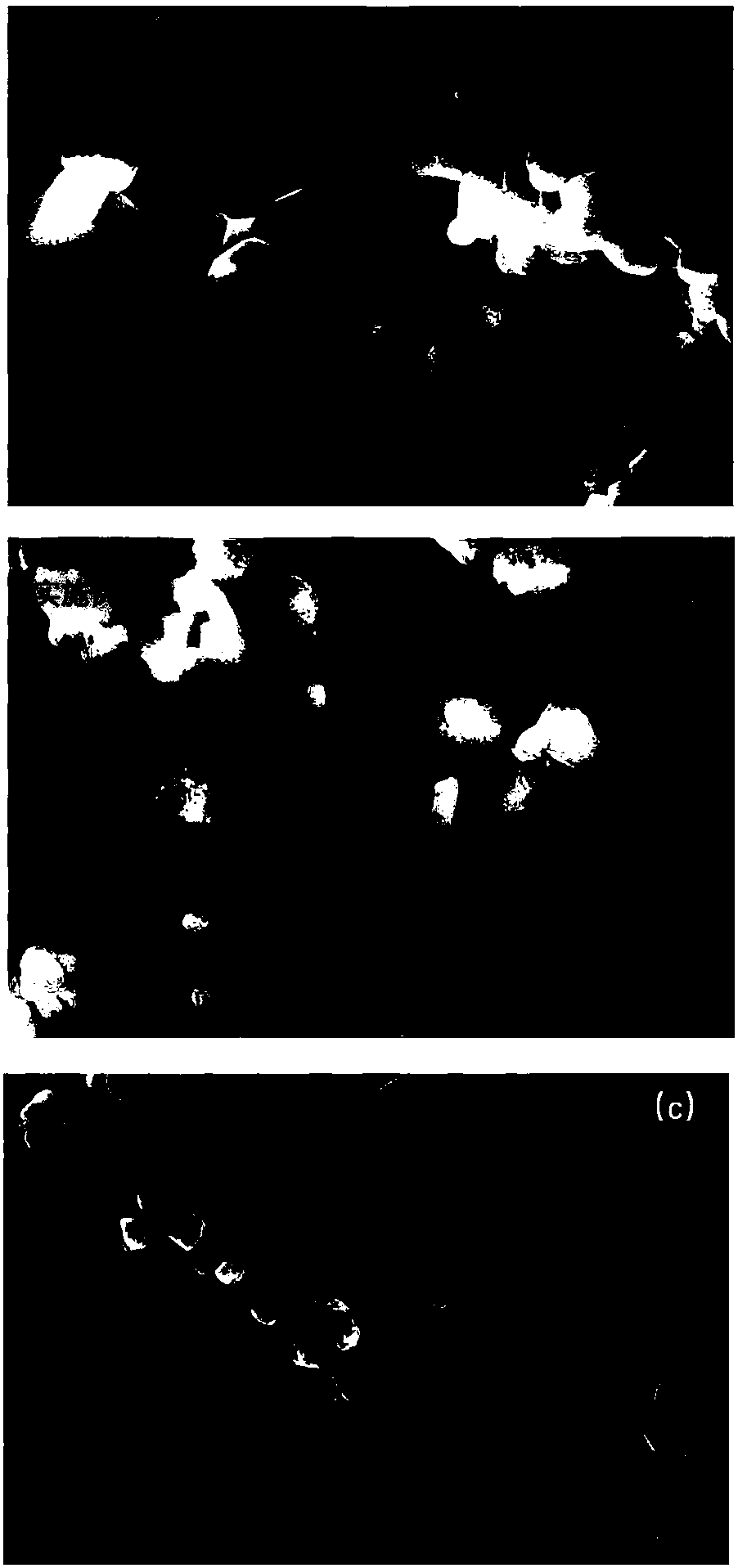

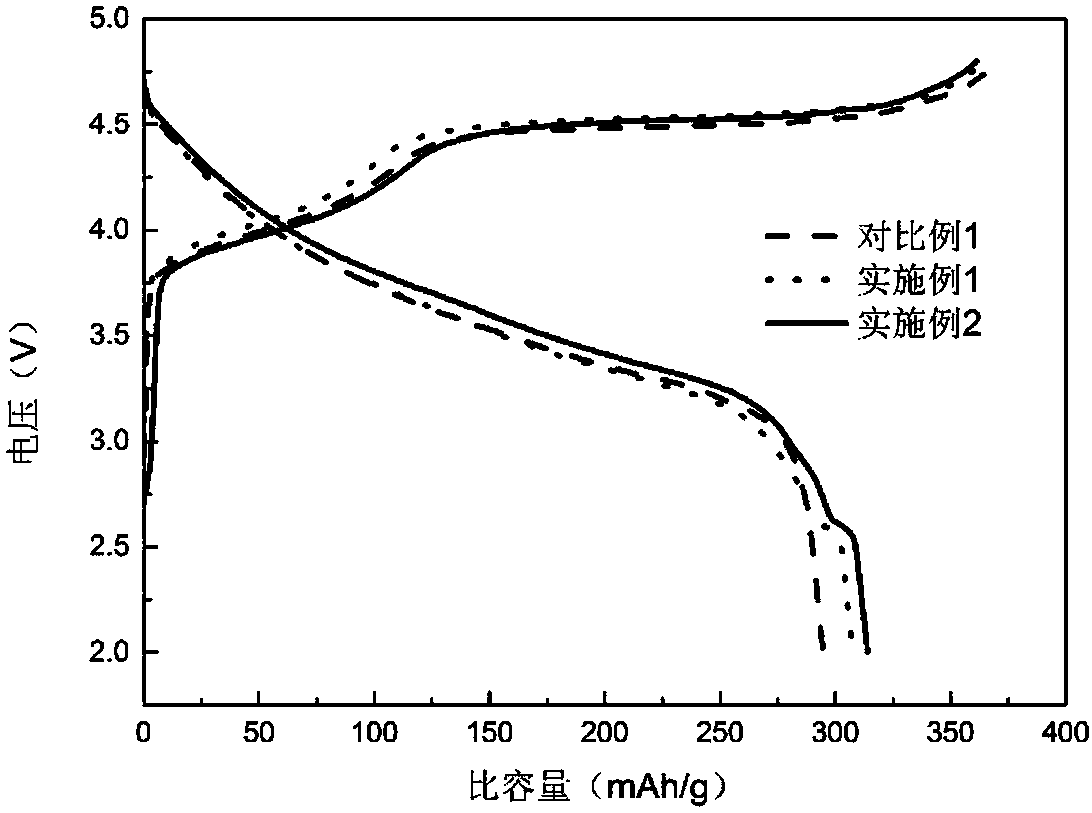

Embodiment 1

[0029] The lithium-rich manganese-based positive electrode material that contains the cerium-tin composite oxide coating of the present embodiment is that the chemical formula is Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 The surface of the lithium-rich manganese-based positive electrode material is coated with cerium-tin composite oxide; in the example, the coating amount of ceria is 4% by mass.

[0030] Its preparation method is:

[0031] (1) Disperse 0.5g of lithium-rich manganese-based positive electrode material into 50mL of secondary water solvent, form a uniform mixed solution through ultrasonic vibration, and record it as solution A;

[0032](2) 0.052g cerium nitrate hexahydrate Ce(NO 3 ) 3 ·6H 2 Disperse O into 20mL secondary water solvent, add 1.0M NaOH solution, adjust the pH of the solution to 12, and record it as B solution;

[0033] (3) Mix the A solution in the step (1) and the B solution in the step (2) evenly, then place it in a reactor for hydrothermal tr...

Embodiment 2

[0036] The lithium-rich manganese-based positive electrode material that contains the cerium-tin composite oxide coating of the present embodiment is that the chemical formula is Li[Li 0.2 mn 0.54 Ni 0.13 co 0.13 ]O 2 The surface of the lithium-rich manganese-based positive electrode material is coated with cerium-tin composite oxide; in the embodiment, the coating amount of ceria is 4% by mass, and the molar ratio of cerium and tin elements is 8:2.

[0037] Its preparation method is:

[0038] (1) Disperse 0.5g of lithium-rich manganese-based positive electrode material into 50mL of secondary water solvent, form a uniform mixed solution through ultrasonic vibration, and record it as solution A;

[0039] (2) 0.052g cerium nitrate hexahydrate Ce(NO 3 ) 3 ·6H 2 O and 0.012 g tin tetrachloride pentahydrate SnCl 4 ·5H 2 Disperse O into 20mL of secondary water solvent, add 1.0M NaOH solution, adjust the pH of the solution to 12, and record it as solution B;

[0040] (3) Mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| First discharge specific capacity | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com