Crushing and grinding process for treating nickel copper sulfide ore

An ore, nickel-copper technology, applied in the field of grinding process for processing nickel-copper sulfide ore, can solve the problems of personnel health impact, high production cost, large number of equipment, etc., and achieve easy automatic control, less equipment and less investment. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

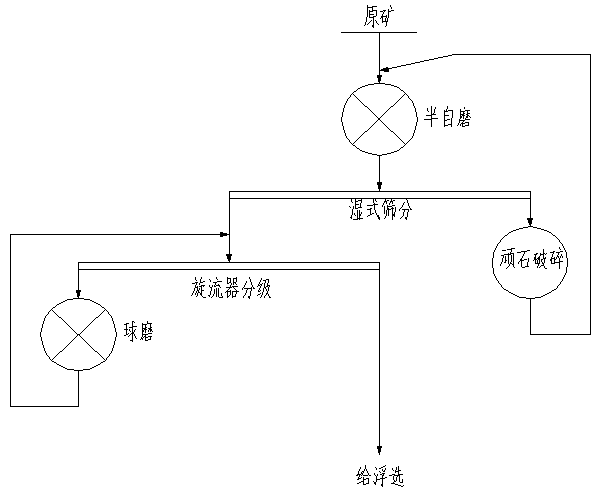

[0032] The ore feeding rate is 460 tons / hour, the ore feeding particle size is 100-250 mm, accounting for 30%, the nickel grade of the ore is 0.85%, and the Platinum hardness of the ore is 12.5.

[0033] Step (1): First, the nickel-copper sulfide ore with the above particle size and hardness is fed into the semi-autogenous mill for grinding with a belt conveyor. The grinding power index is 17.65 Kwh / t, and the medium filling rate is 15%. The water supply pressure is 0.45Mpa. Output semi-autogenous mill discharge ore, the semi-autogenous mill discharge ore is the pulp with a weight percentage concentration of 70%;

[0034] Step (2): The semi-autogenous mill in step (1) is fed into the wet sieving machine for sieving. On the sieve are stubborn stones that are difficult to grind, and on the sieve are fine-grained products. Among the fine-grained products Ore particles with particle size ≤ 6mm accounted for 80%;

[0035] Step (3): Feed the cobblestone (amount on the sieve) in st...

Embodiment 2

[0043] The ore feeding rate is 460 tons / hour, the ore feeding particle size is 100-250 mm, accounting for 25%, the nickel grade of the ore is 0.78%, and the Platinum hardness of the ore is 12.

[0044] Step (1): First, the nickel-copper sulfide ore with the above particle size and hardness is fed into the semi-autogenous mill for grinding with a belt conveyor. The grinding power index is 16.7 Kwh / t, and the medium filling rate is 12%. The water supply pressure is 0.43Mpa. Output semi-autogenous mill discharge ore, the semi-autogenous mill discharge ore is a slurry with a concentration of 68% by weight;

[0045] Step (2): The semi-autogenous mill in step (1) is fed into the wet sieving machine for sieving. On the sieve are stubborn stones that are difficult to grind, and on the sieve are fine-grained products. Among the fine-grained products Ore particles with particle size ≤ 6mm accounted for 85%;

[0046]Step (3): Feed the cobblestone (amount on the sieve) in step (2) into ...

Embodiment 3

[0054] The ore feeding rate is 460 tons / hour, the ore feeding particle size is 100-250 mm, accounting for 20%, the nickel grade of the ore is 0.65%, and the Platinum hardness of the ore is 11.7.

[0055] Step (1): First, the nickel-copper sulfide ore with the above particle size and hardness is fed into the semi-autogenous mill for grinding with a belt conveyor. The grinding power index is 17.65 Kwh / t, and the medium filling rate is 10%. The water supply pressure is 0.41Mpa. Output semi-autogenous mill discharge ore, the semi-autogenous mill discharge ore is a slurry with a concentration of 65% by weight;

[0056] Step (2): The semi-autogenous mill in step (1) is fed into the wet sieving machine for sieving. On the sieve are hard stones that are difficult to grind, and on the sieve are fine-grained products. Among the fine-grained products Ore particles with particle size ≤ 6mm accounted for 90%;

[0057] Step (3): Feed the cobblestone (the amount on the sieve) in step (2) i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com