Grinding classification method

A classification method and ore grinding technology, which is applied in the direction of the device where the axial direction of the swirl can be reversed, the swirl device, etc., can solve the problems of large consumption of spare parts and materials, low classification efficiency, and complicated classification system, and achieve classification The parameters remain stable, the slurry pressure remains stable, and the effect of high classification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The above-mentioned content of the present invention will be further described in detail below through specific implementation in the form of examples, to illustrate but not limit the present invention.

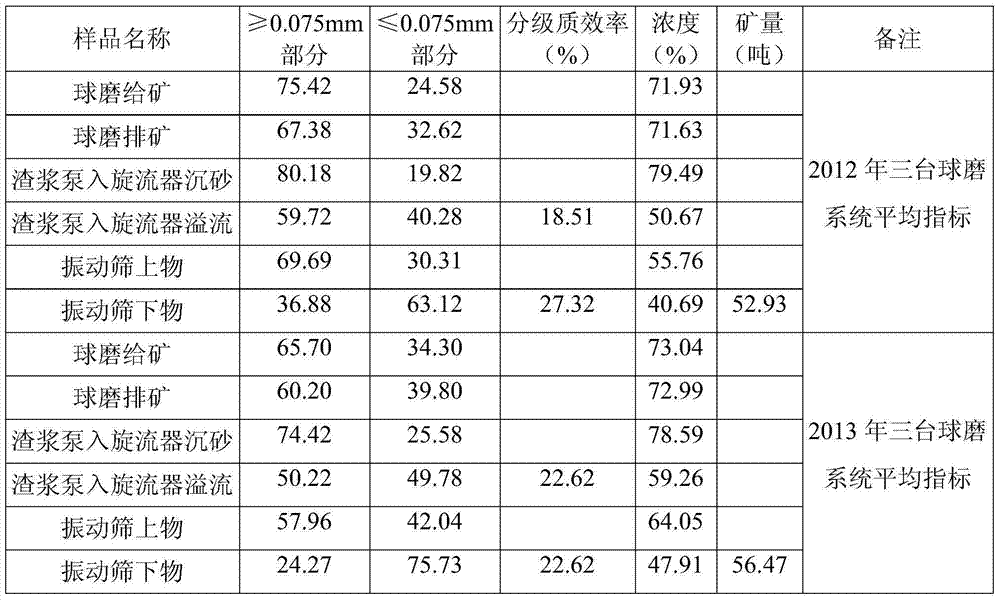

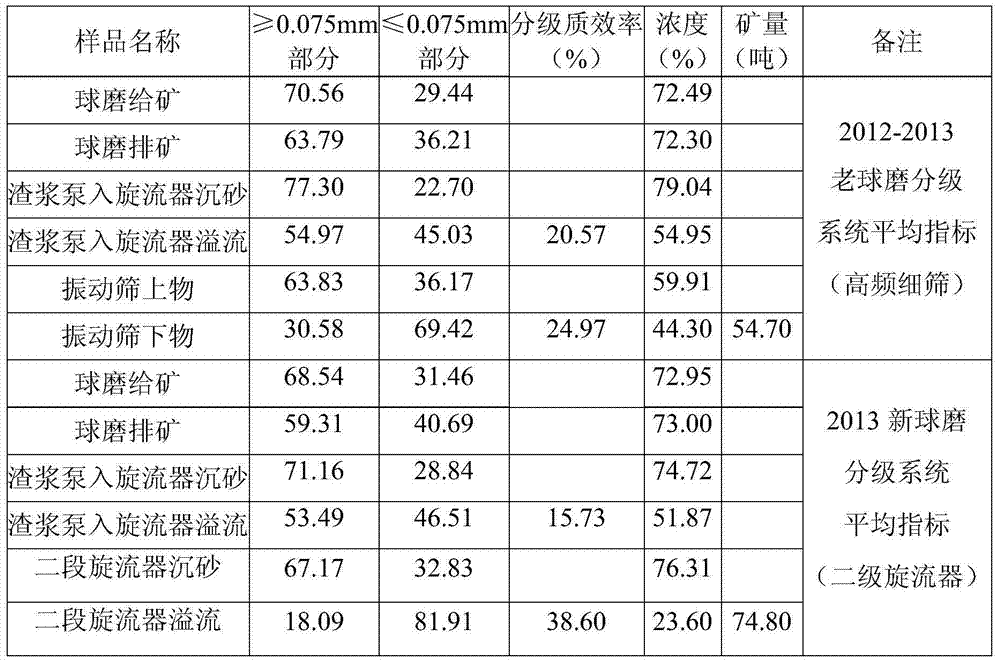

[0044] Regarding the original process, take the target mineral size of -200 mesh to account for more than 75% as an example.

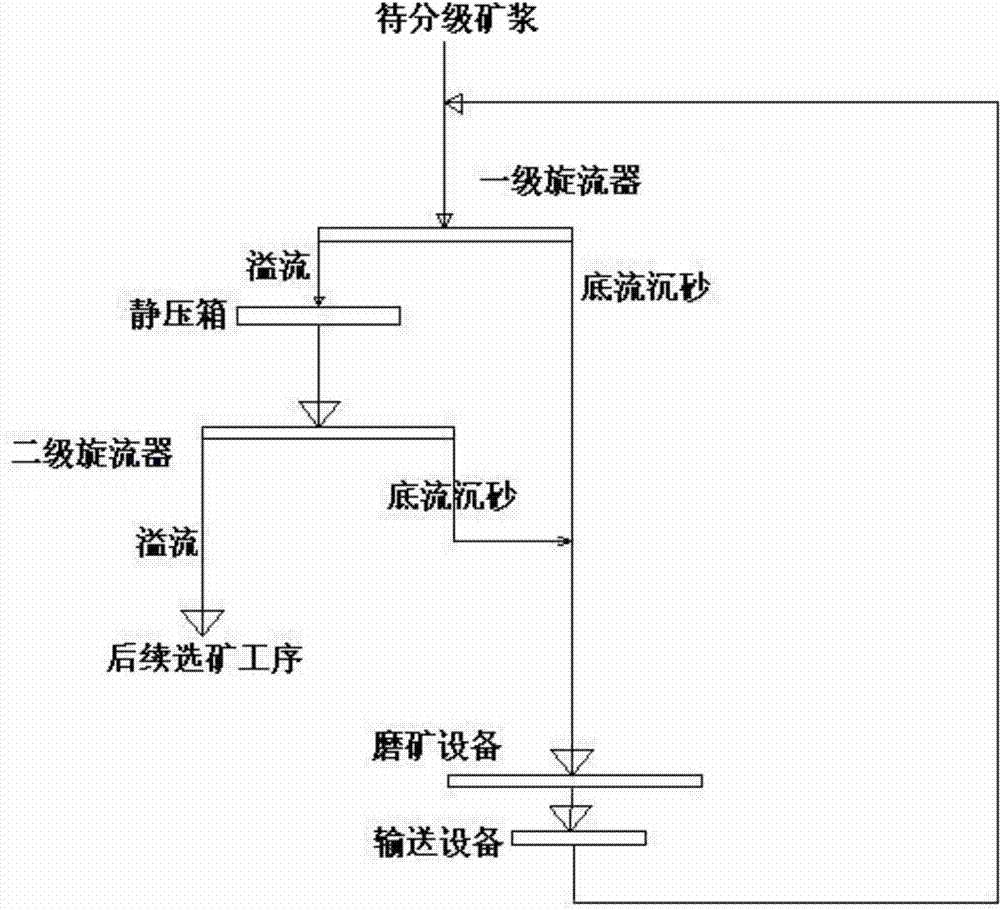

[0045] The original classification process of the applicant’s iron selection section is as follows: the ore discharge of the ball mill and the first-stage magnetic separation concentrate are mixed and transported to the first-stage cyclone through the pump, and the overflow of the cyclone is screened by a high-frequency fine sieve, and the underscreen is regarded as a qualified product Go directly to the second and third stages of magnetic separation and concentration, and the sieve material is then subjected to dehydration magnetic separation. The concentrate of dehydration magnetic separation is mixed with the first stage of cyclone sand settl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com