High-performance magnesia carbon brick and preparation method thereof

A magnesia-carbon brick and high-performance technology, which is applied in the field of magnesia-carbon brick processing, can solve the problems of large thermal expansion coefficient, affect performance, and large expansion coefficient, and achieve the effects of improving corrosion resistance, reducing thermal shock damage and improving performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

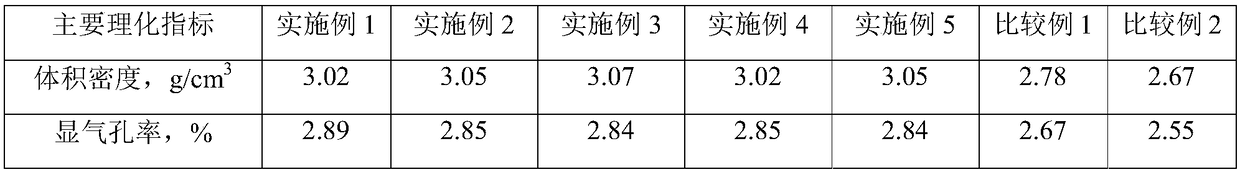

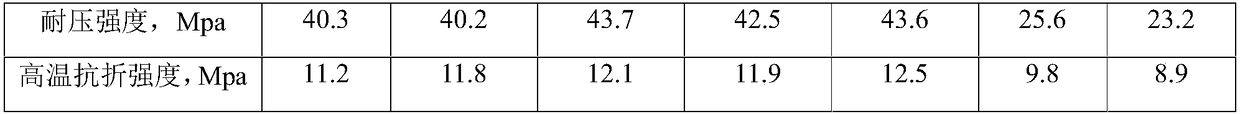

Examples

Embodiment 1

[0037] (1) Mixing: first add the fused magnesia particles to the mixer for dry mixing for 4 minutes, then slowly add the binder and mix for 4 minutes, then add flake graphite and mix for 8 minutes, and finally add fused magnesia fine powder, metal Aluminum powder and spinel-calcium aluminate composite material were mixed for 35 minutes and discharged;

[0038] (2) Molding: Add the mud material that has been kneaded into the mold and press it to form a semi-finished brick adobe, with a pressure of 6300KN;

[0039] (3) Baking: put the pressed semi-finished brick adobe into a drying kiln to bake and solidify, the baking temperature is 200°C, and the baking time is 16 hours;

[0040] In this example, according to the mass parts, the proportion of each component is 60 parts of fused magnesia particles, and the fused magnesia particles are three kinds of particles of 3mm, 1mm, and 0.075mm mixed in a mass ratio of 3:3:2 Formed, the mass percentage of chemical composition is MgO≧96.5...

Embodiment 2

[0047] (1) Mixing: first add the fused magnesia particles to the mixer for dry mixing for 5 minutes, then slowly add the binder and mix for 5 minutes, then add flake graphite and mix for 10 minutes, and finally add fused magnesia fine powder, metal Aluminum powder and spinel-calcium aluminate composite material were mixed for 30 minutes and discharged;

[0048] (2) Forming: Add the mixed mud material into the mold and press it into a semi-finished brick adobe, with a pressure of 10000KN;

[0049] (3) Baking: put the pressed semi-finished brick adobe into a drying kiln to bake and solidify, the baking temperature is 180°C, and the baking time is 24h;

[0050] In this embodiment, according to the mass parts, the proportion of each component is 75 parts of fused magnesia particles, and the fused magnesia particles are three kinds of particles of 5mm, 3mm and 1mm mixed with a mass ratio of 5:5:4. Composition, the mass percentage of chemical composition is MgO≧96.5%, CaO2 3 ;

[...

Embodiment 3

[0057] (1) Mixing: first add the fused magnesia particles to the mixer for dry mixing for 5 minutes, then slowly add the binder and mix for 5 minutes, then add flake graphite and mix for 10 minutes, and finally add fused magnesia fine powder, metal Aluminum powder and spinel-calcium aluminate composite material were mixed for 40 minutes and discharged;

[0058] (2) Molding: Add the mud material that has been kneaded into the mold and press it into a semi-finished brick adobe, with a pressure of 7000KN;

[0059] (3) Baking: put the pressed semi-finished brick adobe into a drying kiln to bake and solidify, the baking temperature is 250°C, and the baking time is 12 hours;

[0060] In this embodiment, according to the mass parts, the proportion of each component is 70 parts of fused magnesia particles, and the fused magnesia particles are three kinds of particles of 5mm, 3mm and 1mm mixed with a mass ratio of 5:5:4. Composition, the mass percentage of chemical composition is MgO≧...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com