Self-circulating crystallizer and multistage continuous crystallization method

A crystallizer and crystallization technology, which is applied in the fields of chemical industry and medicine, can solve the problems of small product particle size, short operation cycle, pipeline blockage, etc., achieve large product particle size and improve the effect of small product particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

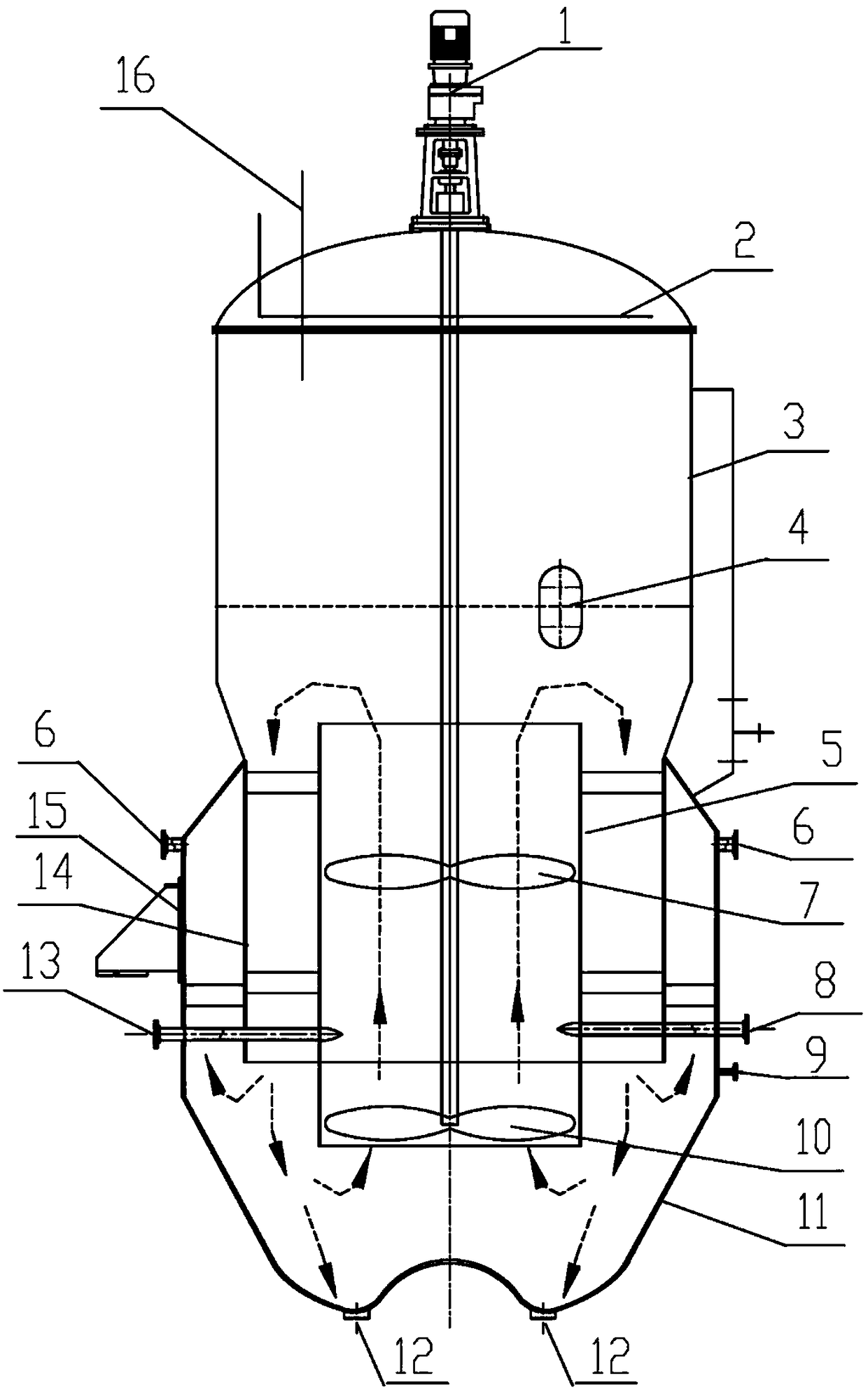

[0043] as attached figure 1 A typical crystallizer schematic diagram disclosed by the present invention shown, as shown in the figure, is provided with steam outlet and / or feeding port on the still head of the crystallizer, and the bottom of the still head is provided with annular spray pipe 2, toward the crystallizer inner wall direction Open the hole and wash the scale near the liquid level on the inner wall of the crystallizer. The diameter of the cylinder body 3 on the crystallizer is 1.2-1.3 times of the diameter of the middle straight barrel section 14, and the height is 0.7-1.4 times of the height of the middle straight barrel section 14, and the height of the middle straight barrel section 14 is 0.5-1.2 times of its own diameter. The cylinder and the middle straight barrel are connected with variable diameters. The diameter of the guide tube 5 is 0.6-0.8 times the diameter of the middle straight barrel section 14, and the height is 1.1-1.3 times the height of the middl...

Embodiment 2

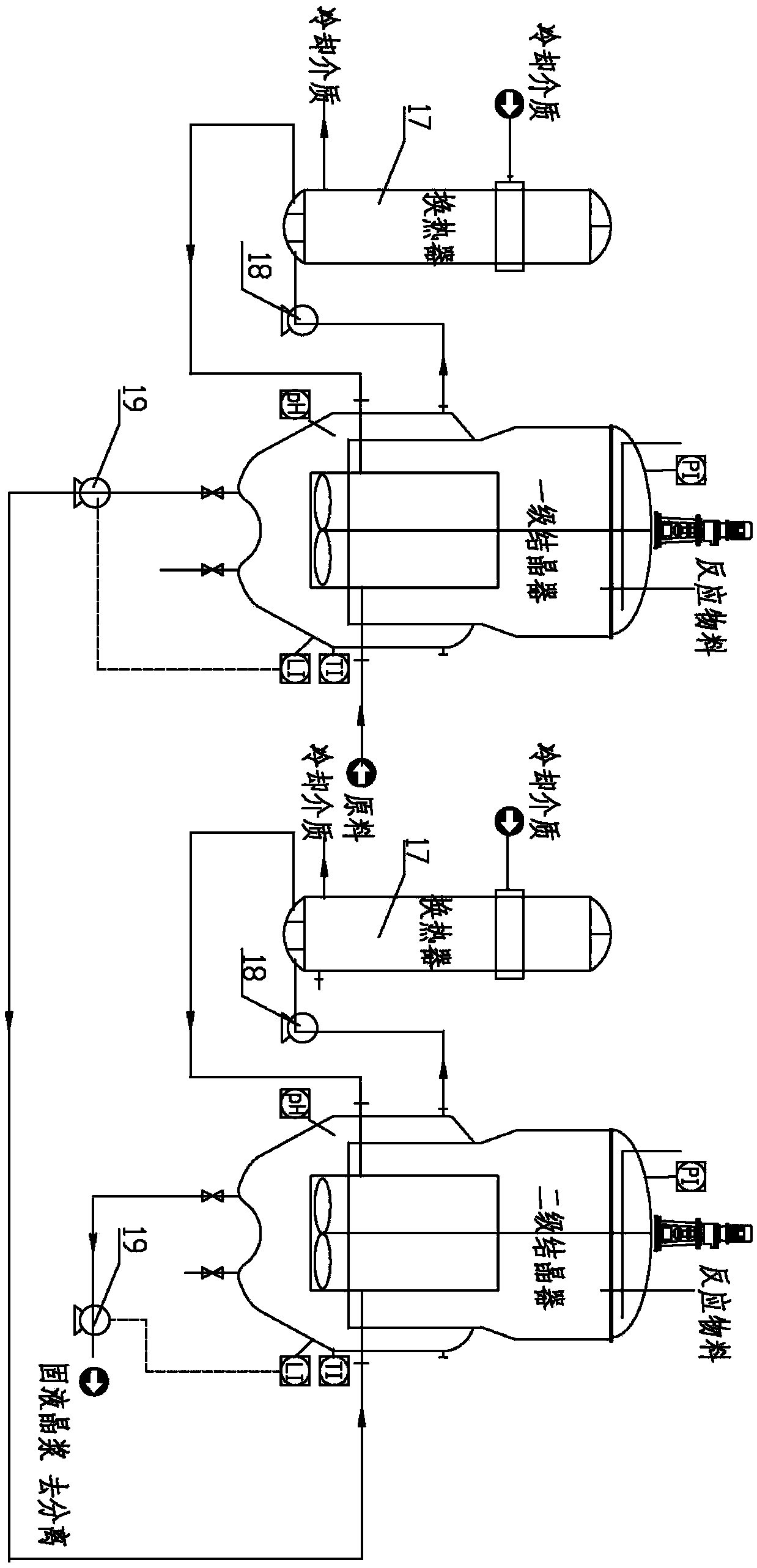

[0047] For the system in which the solid mass in the final crystallization slurry feed liquid accounts for 10% to 25% of the total feed liquid mass, a two-stage continuous crystallization process can be used. Such as figure 2 Shown is a two-stage continuous reaction crystallization device and process for cephalexin, which consists of two-stage crystallizers connected in series. Brief technical process: under normal pressure, the cephalexin feed solution is dissolved and clarified when the pH is less than 1.5, and then crystals are precipitated by adding ammonia water. The temperature of the primary crystallizer is controlled at 25°C. Due to the exothermic reaction, the primary crystallizer needs an external cooling heat exchanger. In order to improve the process yield, the temperature of the secondary crystallizer is controlled at 15°C. The secondary crystallization requires an external cooling heat exchanger. device. Due to the fast reaction crystallization rate, in order ...

Embodiment 3

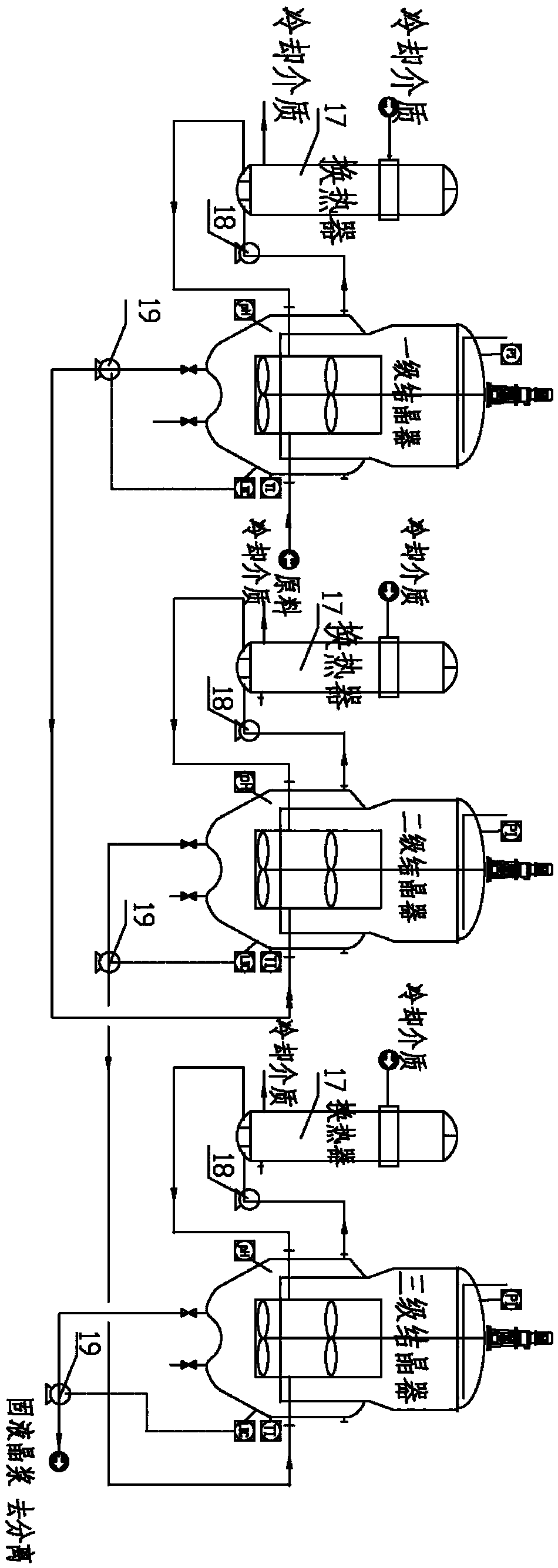

[0053] For the system in which the solid mass in the final crystallization slurry feed liquid accounts for 25% to 40% of the total feed liquid mass, a three-stage continuous crystallization process can be used. Such as image 3 Shown is a three-stage continuous cooling crystallization device for continuous cooling and crystallization of vitamin C, which consists of three crystallizers connected in series. Brief technical process: under normal pressure, prepare a vitamin C aqueous solution with a concentration of 45-55%, heat up to 60°C to dissolve, cool down to 10°C and discharge. According to the solubility characteristics of vitamin C, the solid content and operating temperature of crystallizers at all levels are adjusted. The temperature of the primary crystallizer is controlled at 45°C, and its solid content is ~5%. The temperature of the secondary crystallizer is controlled at 33°C, and its solid content is ~20%. The temperature of the three-stage crystallizer is control...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com