Patents

Literature

71results about "Cascade evaporators" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

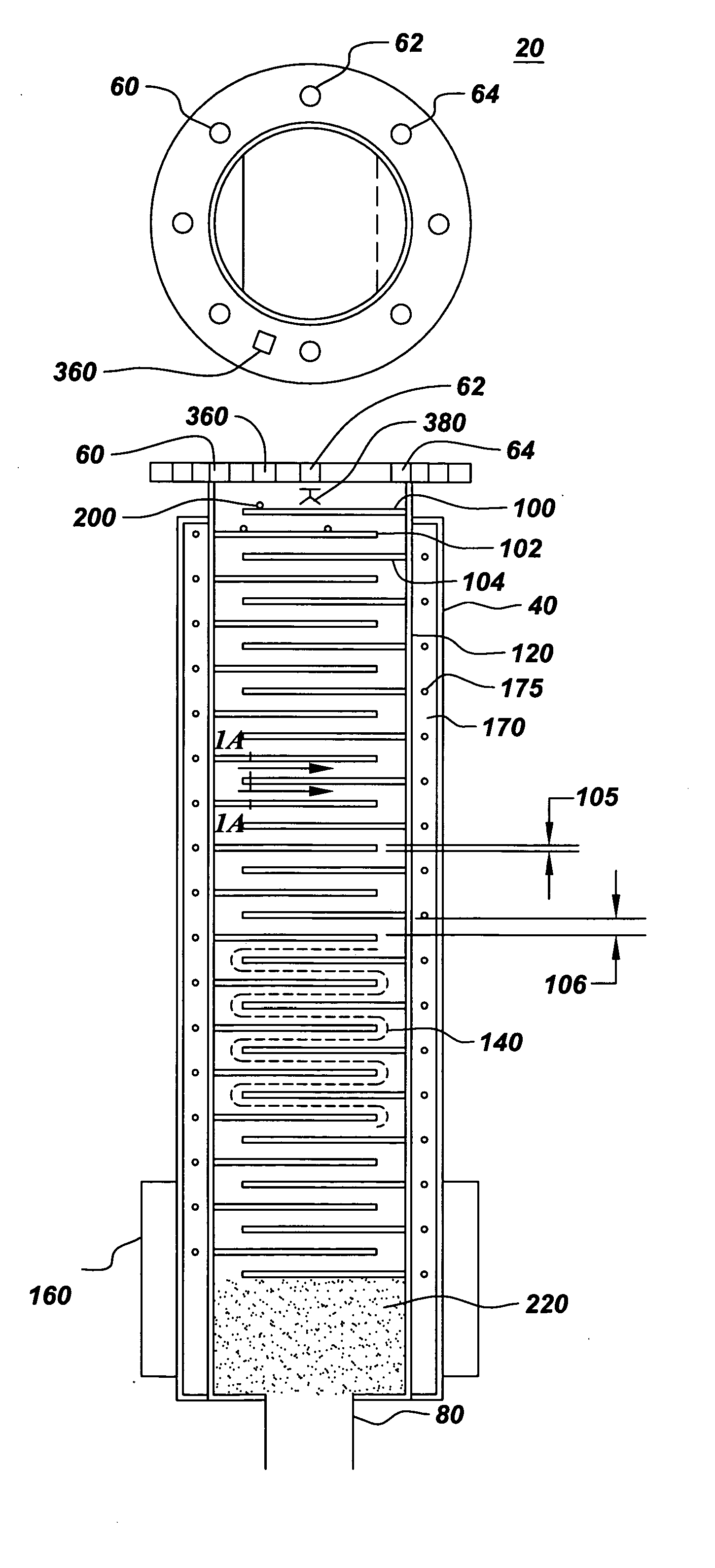

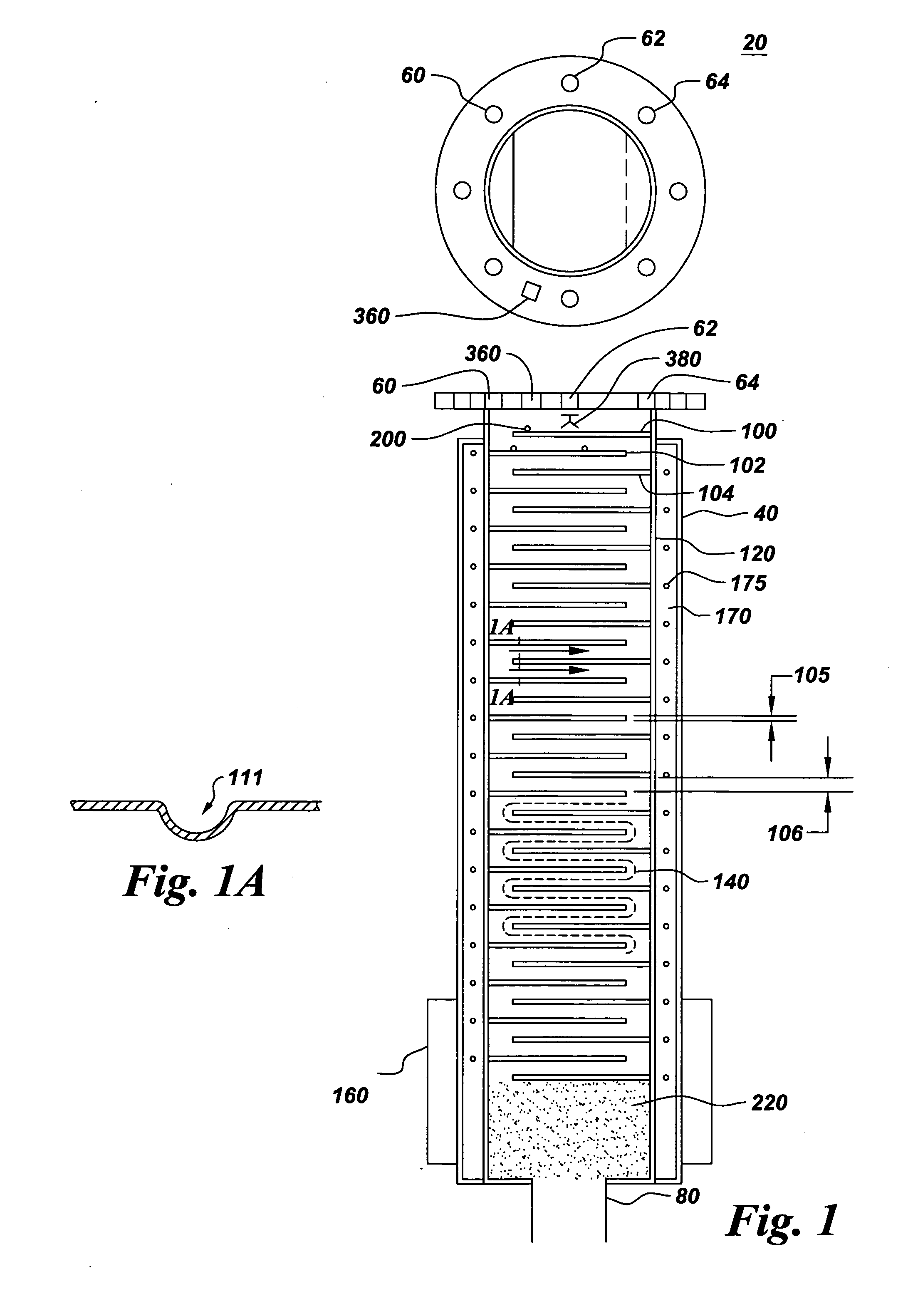

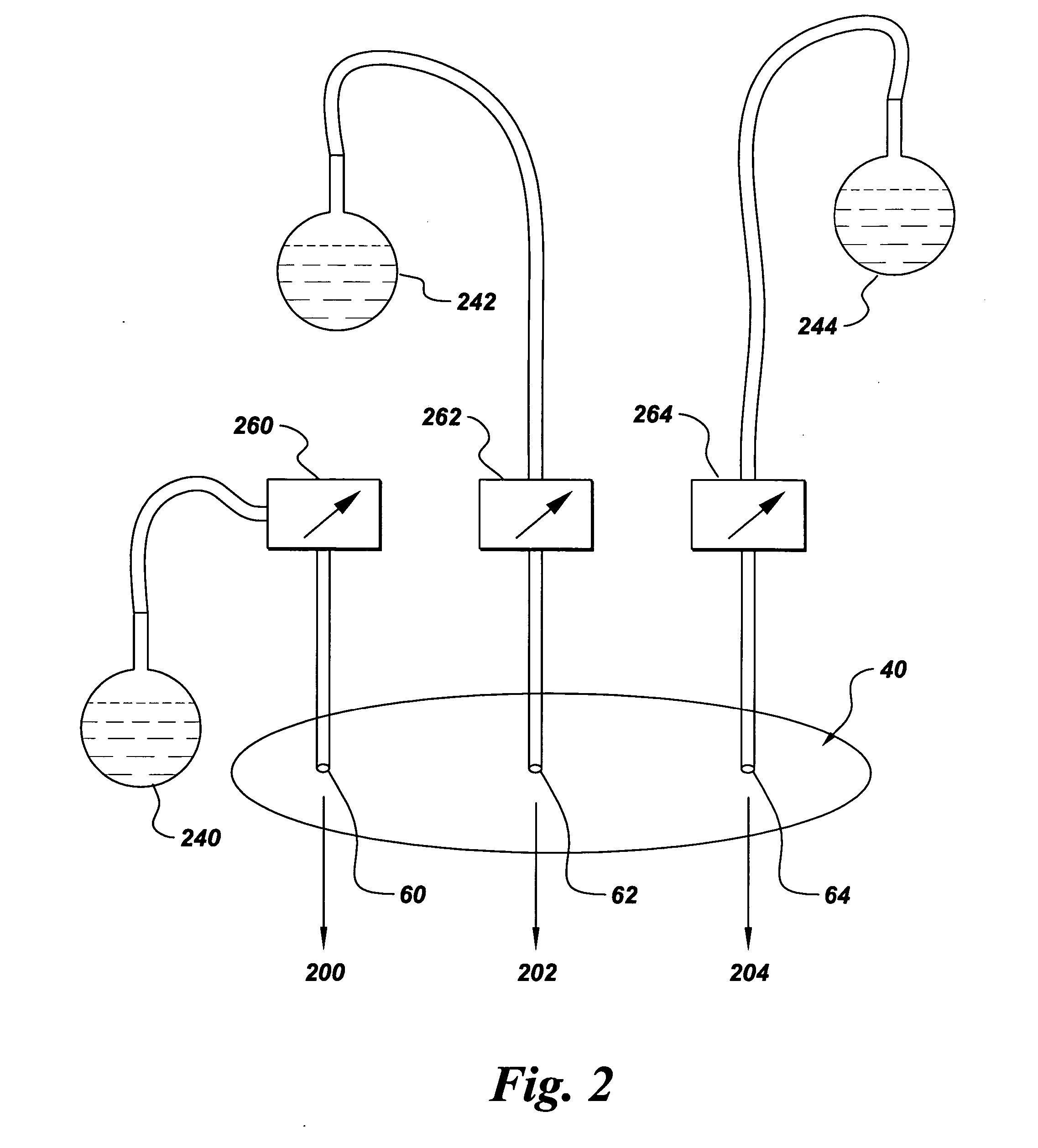

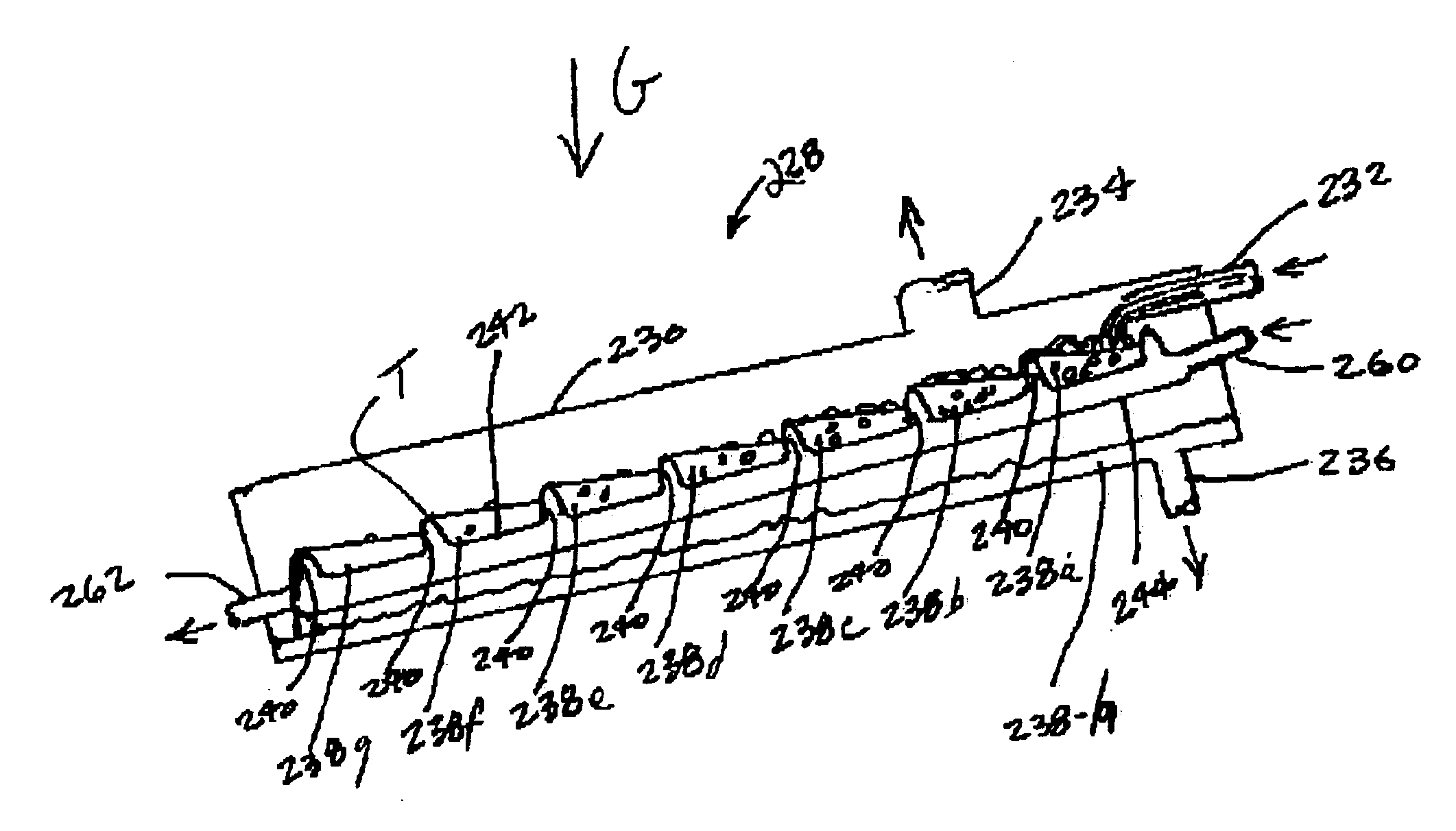

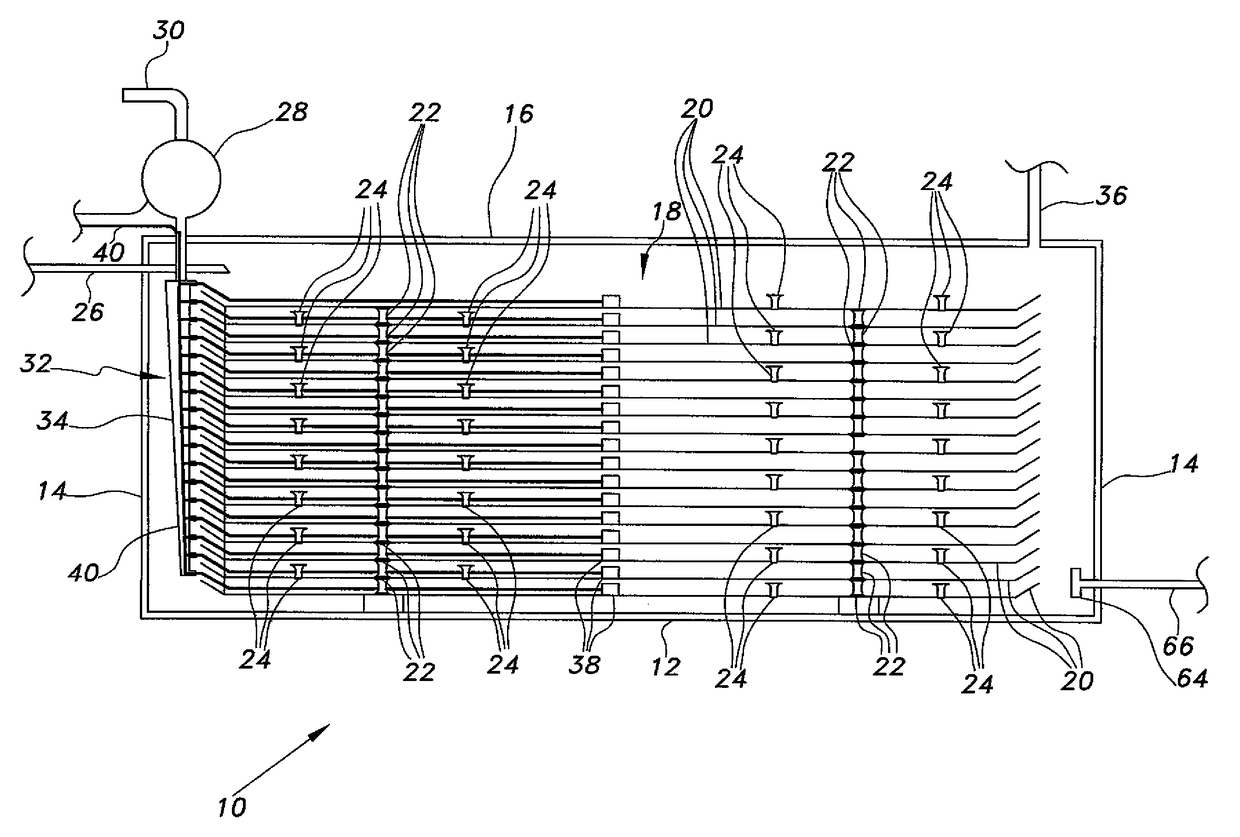

Apparatus for the evaporation of aqueous organic liquids and the production of powder pre-forms in flame hydrolysis processes

InactiveUS20050205215A1Drying using combination processesEvaporator liquid feederOrganic liquidsEvaporation

An organic liquid evaporation system is disclosed. The organic liquid evaporation system comprises a housing having at least one inlet and at least one outlet. At least a first evaporator plate radially extending from a sidewall of the housing, and at least a second evaporator plate radially extending from a sidewall of the housing define a serpentine flow path within the housing. A heating source is in thermal communication with the first evaporator plate and the second evaporator plate, wherein the heating source provides heat to the first and second evaporator plates to evaporate organic liquid introduced within the inlet to produce a vapor through the outlet. A method for preparing powder pre-forms and oxide soot using the organic liquid evaporation system is also disclosed.

Owner:GENERAL ELECTRIC CO

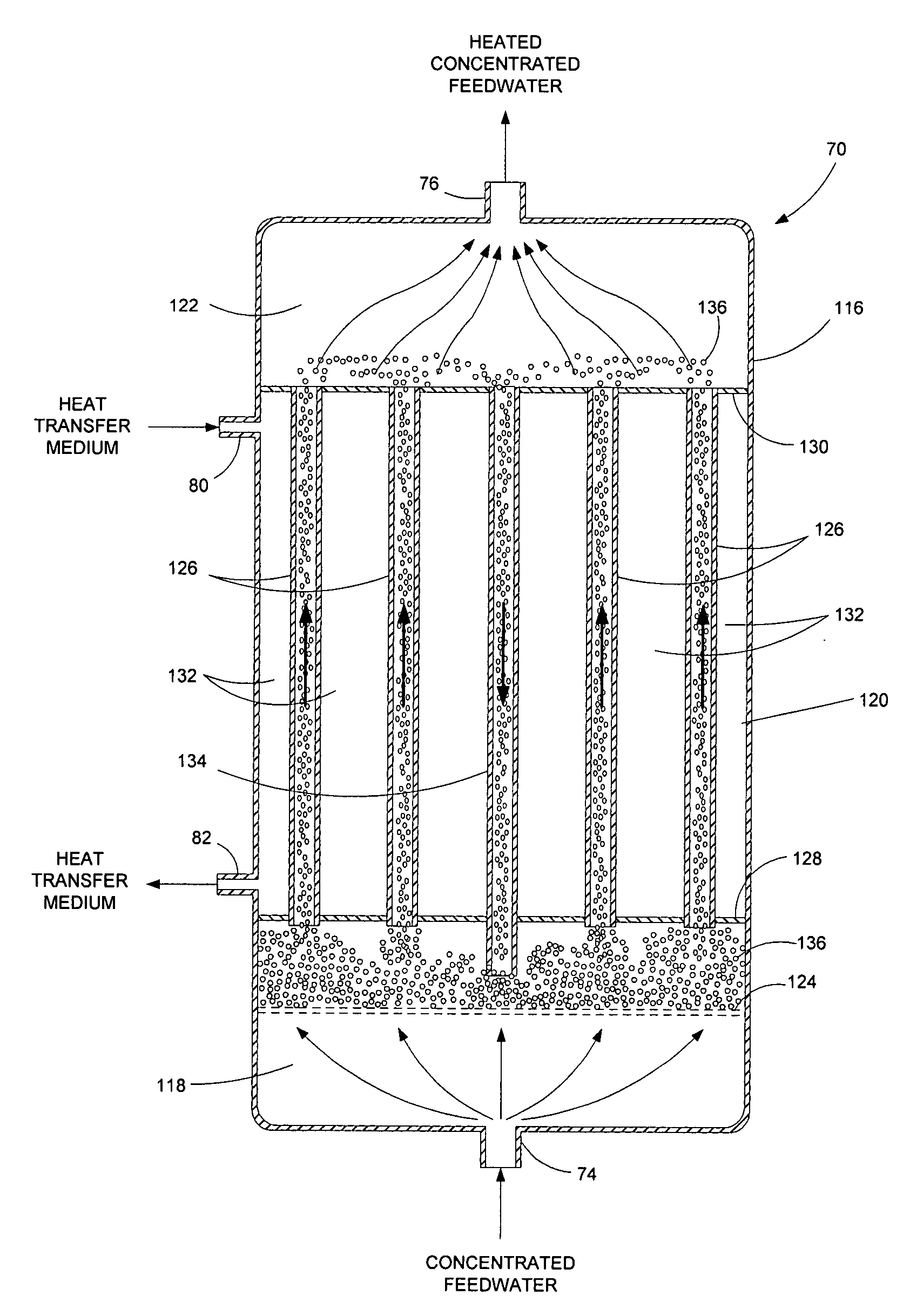

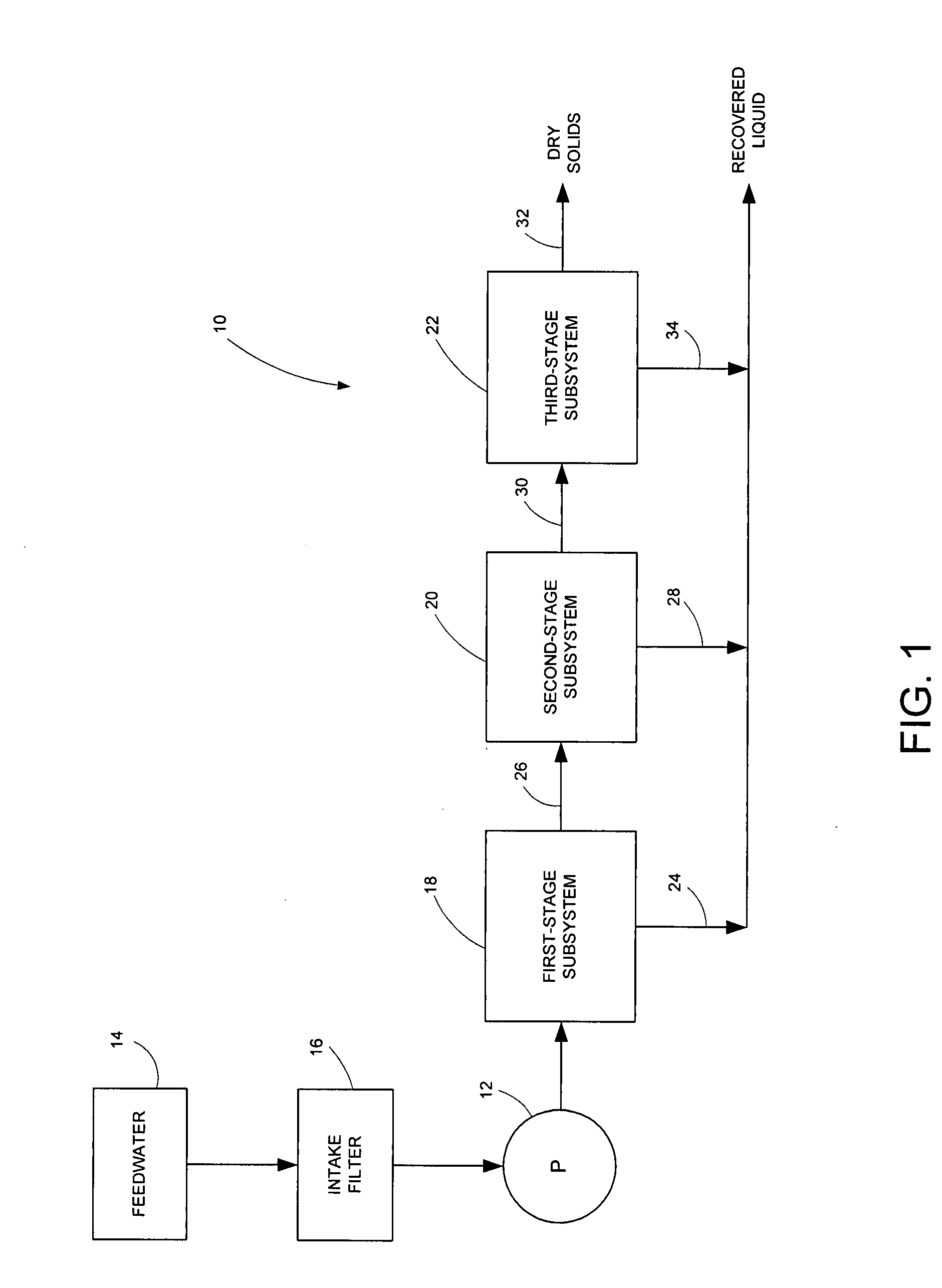

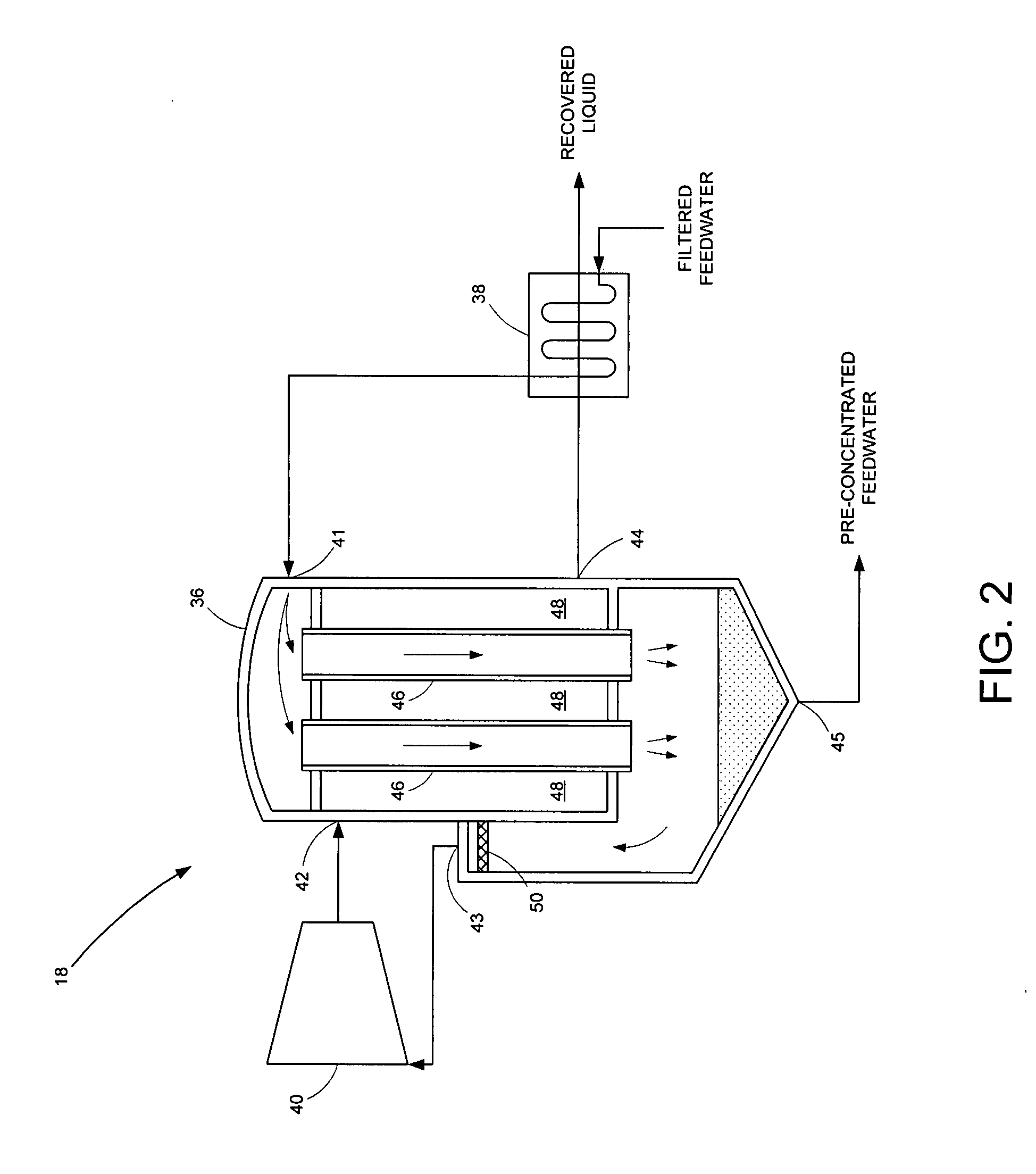

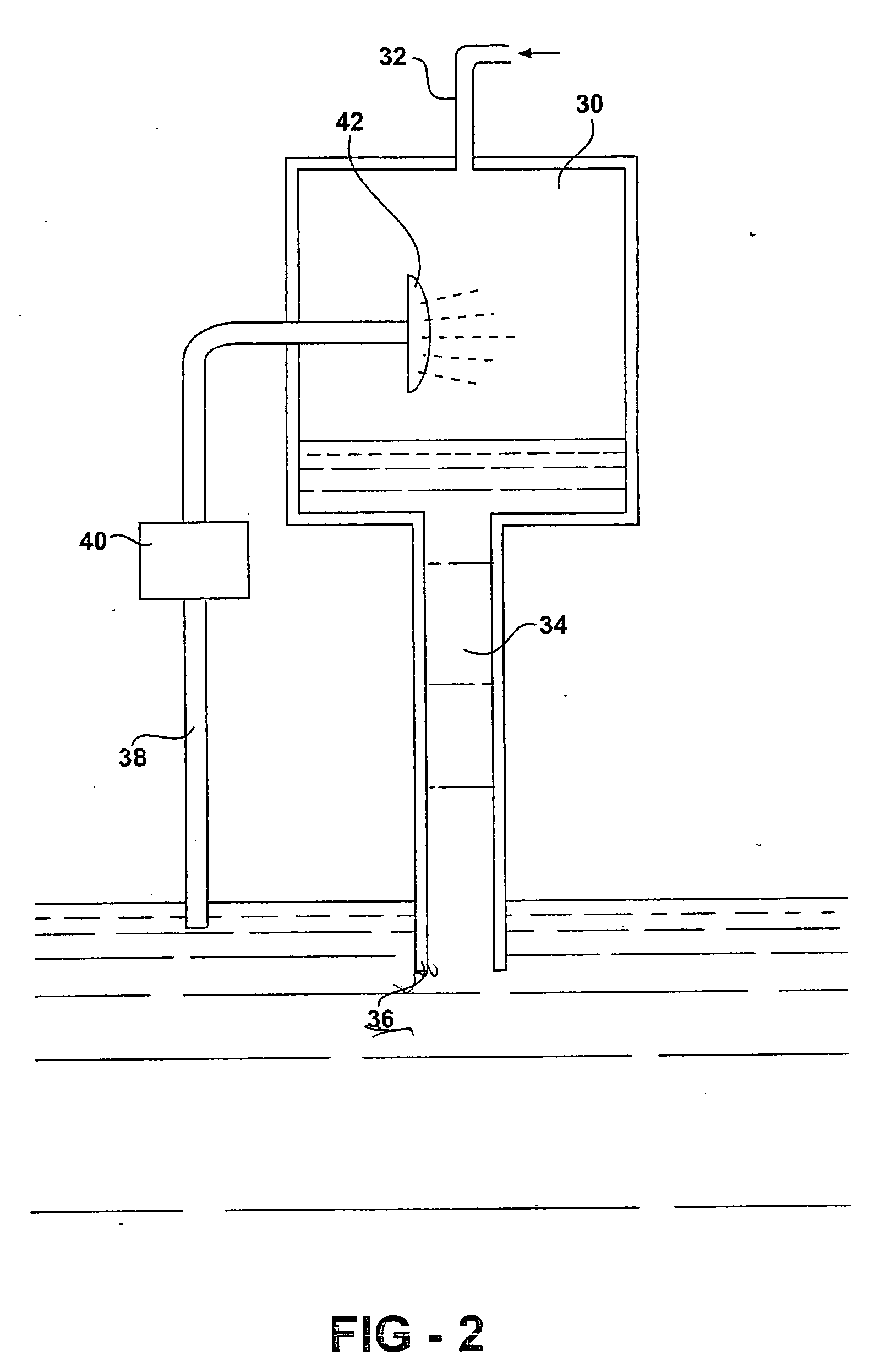

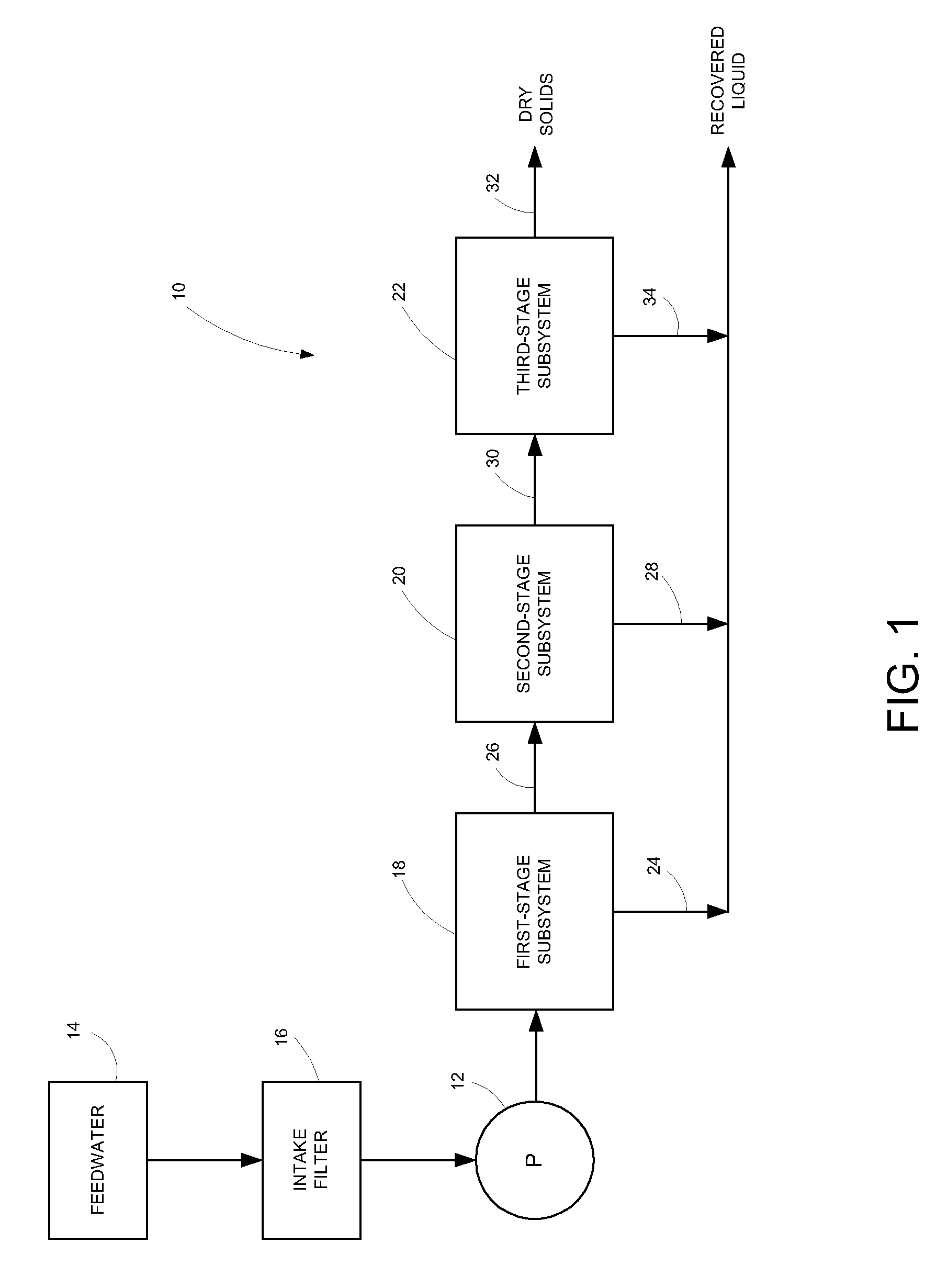

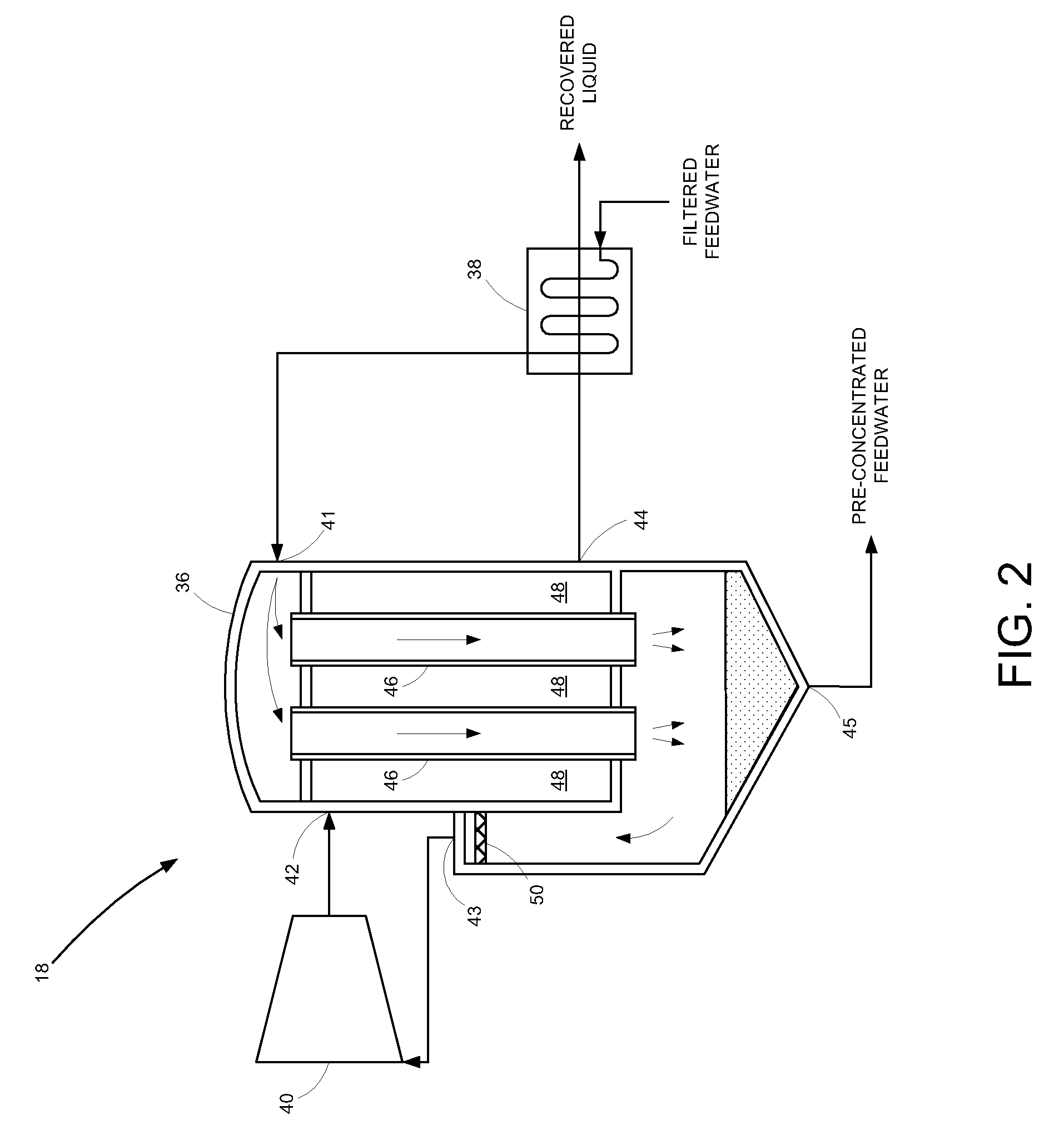

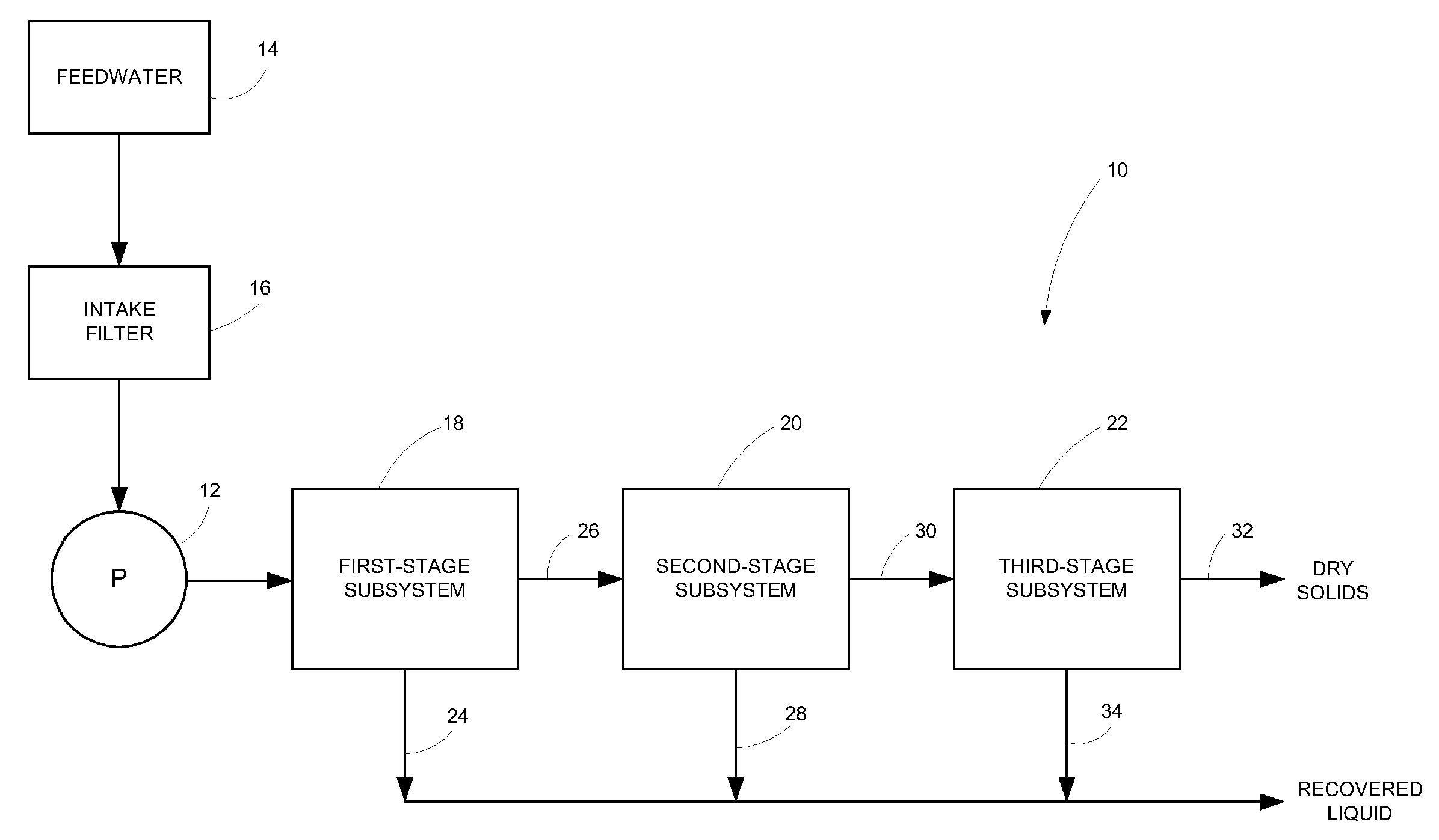

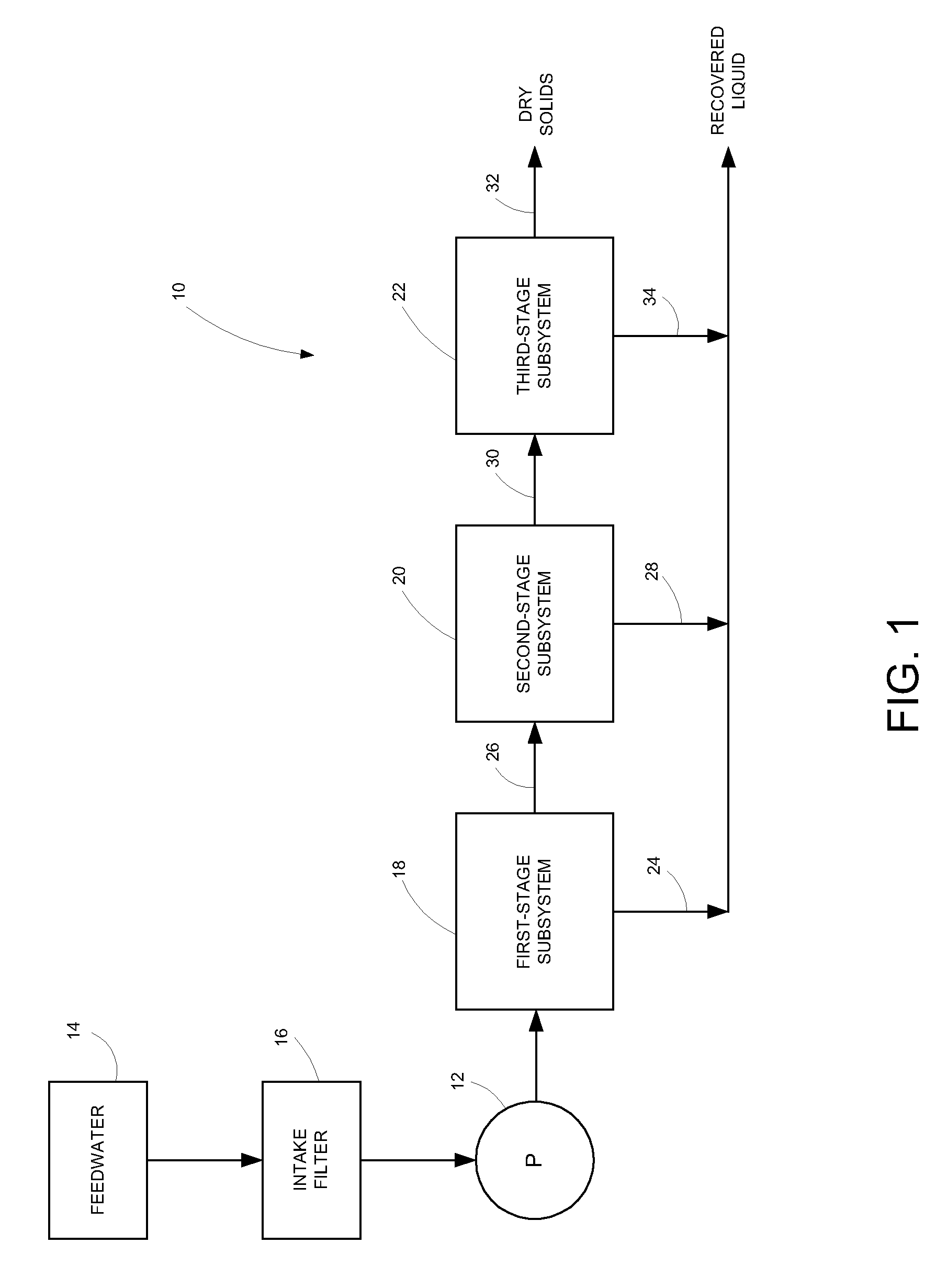

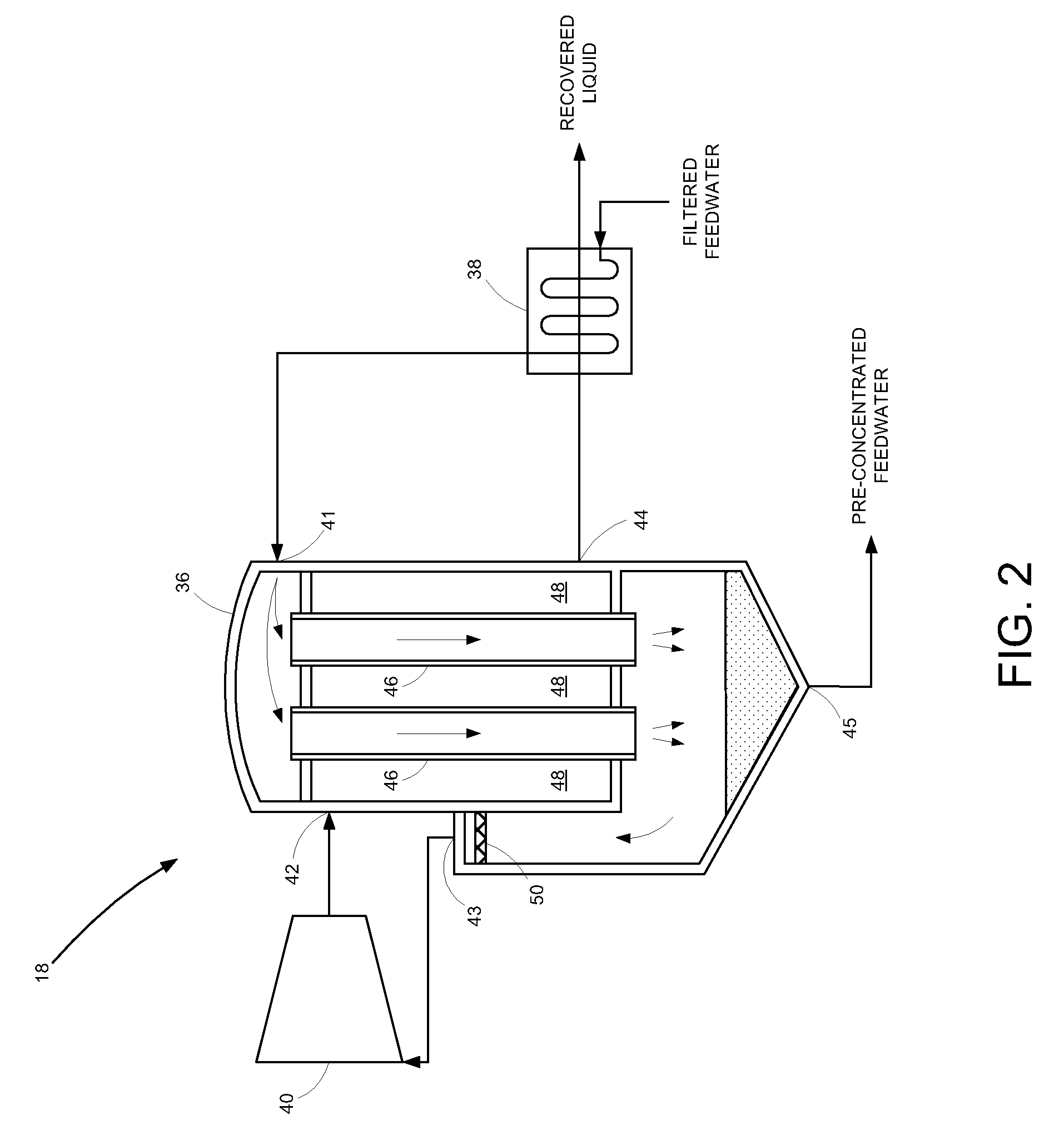

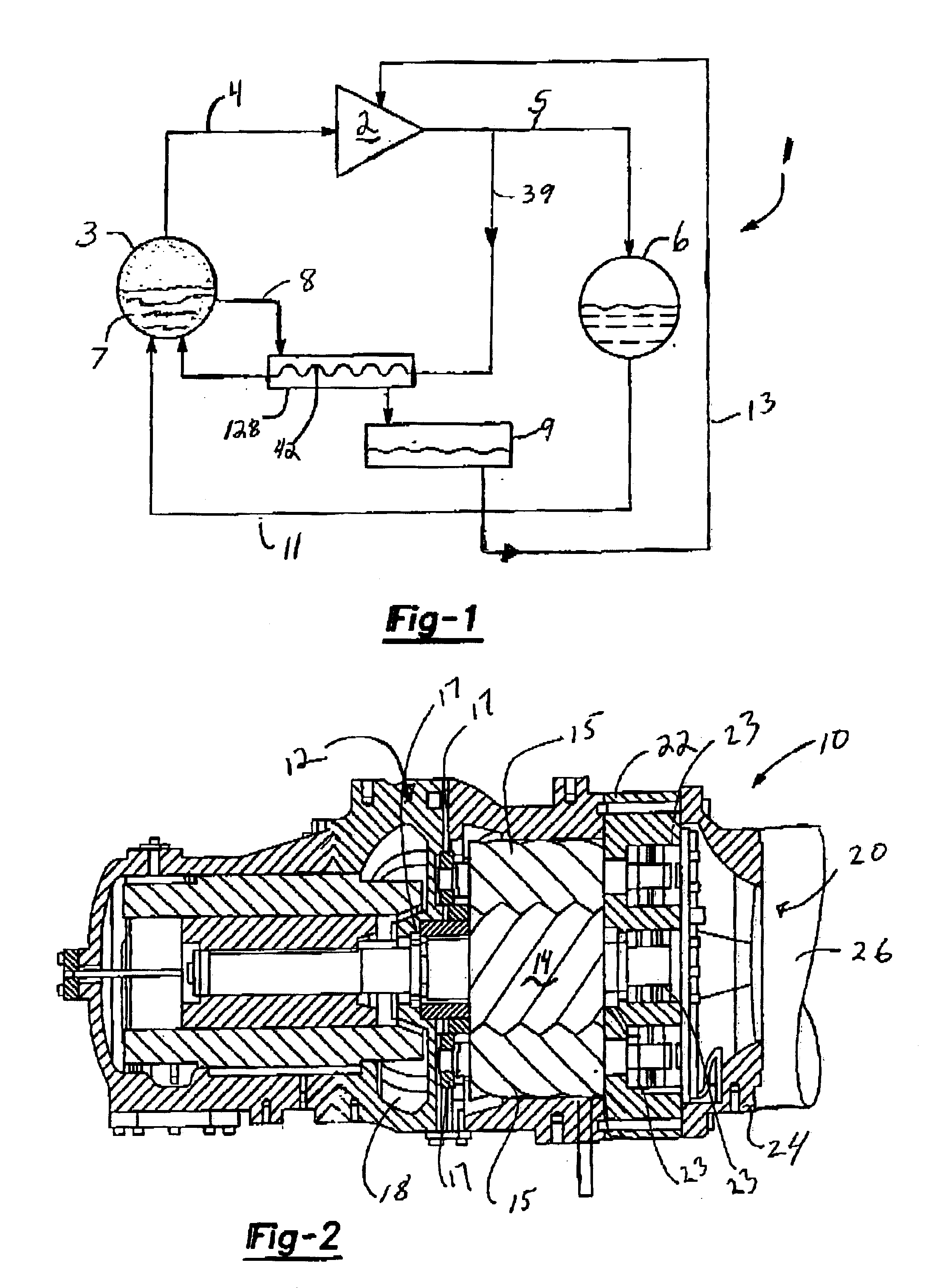

Method and system for treating feedwater

InactiveUS20090020481A1Easy to understandLiquid degasificationSedimentation separationFluidized bedSlurry

A system for treating feedwater includes a fluidized bed heat exchanger unit connected to receive feedwater and a flash concentrator column connected to receive feedwater discharged from the fluidized bed heat exchanger unit. A spray dryer is provided to receive a solids / liquid slurry discharged from the flash concentrator column. Feedwater can be treated by converting dissolved solids in the feedwater to suspended solids, vaporizing a portion of the feedwater to produce a solids / liquid slurry, and separating solids from the solids / liquid slurry.

Owner:WATERVAP +1

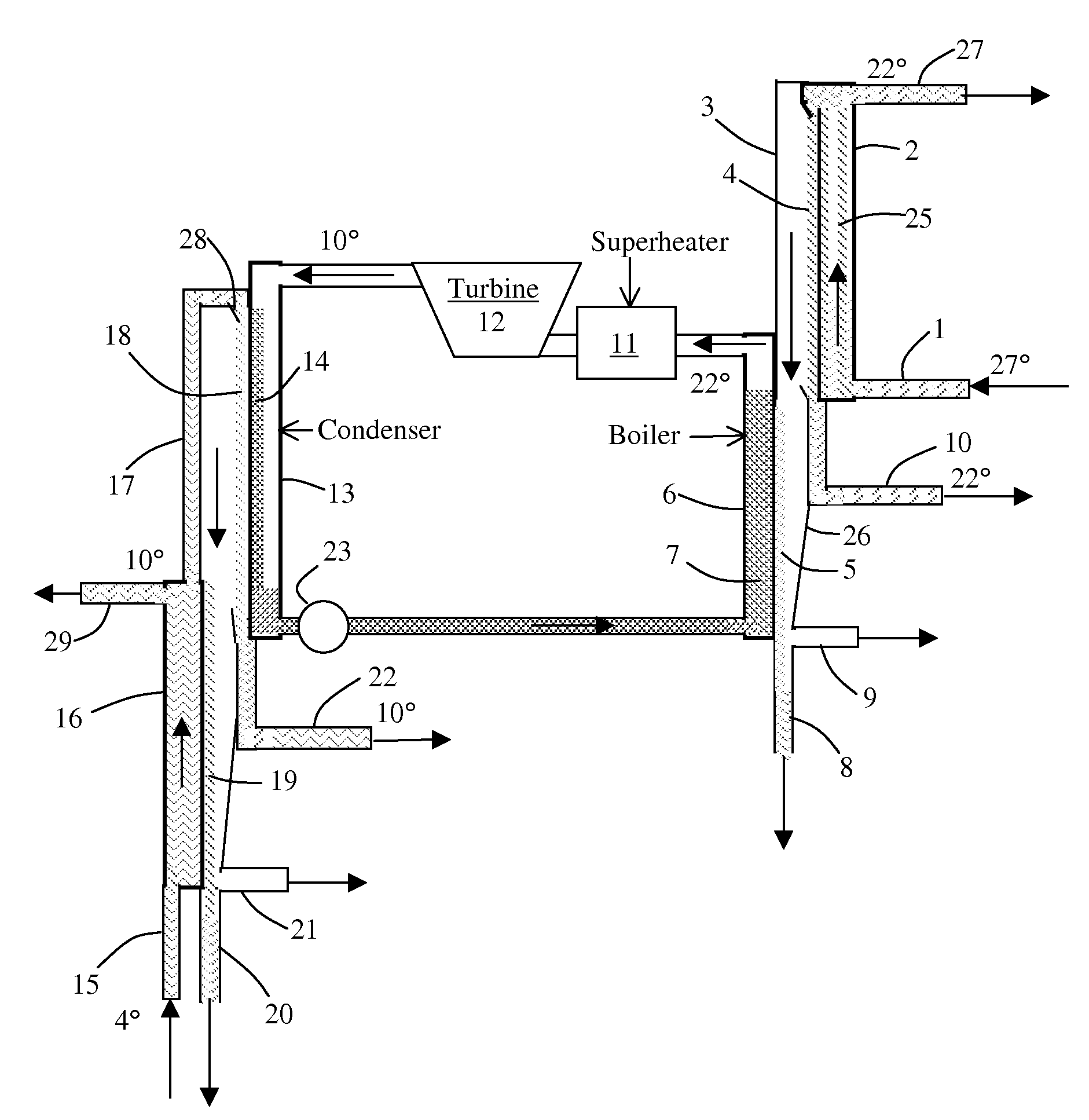

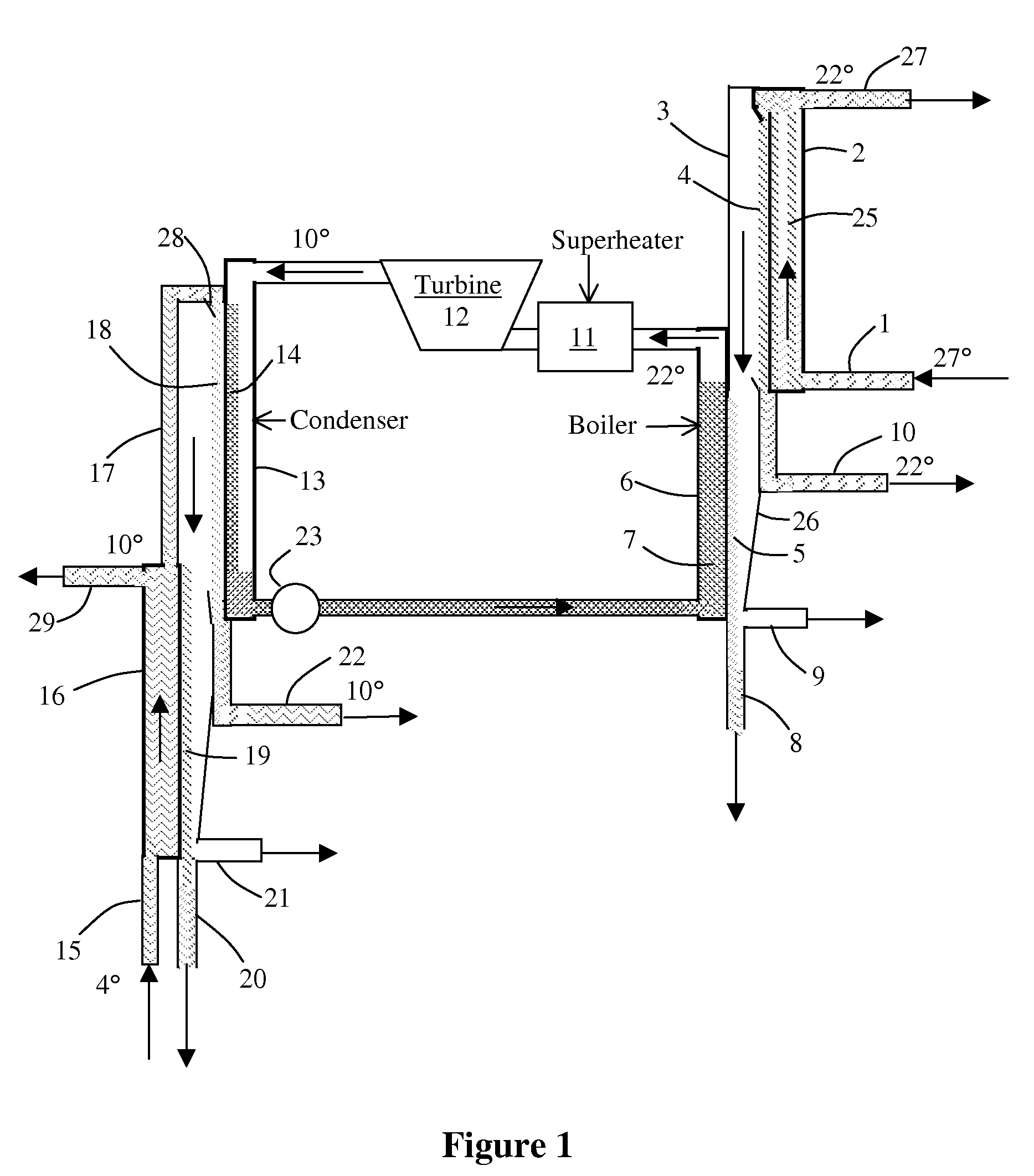

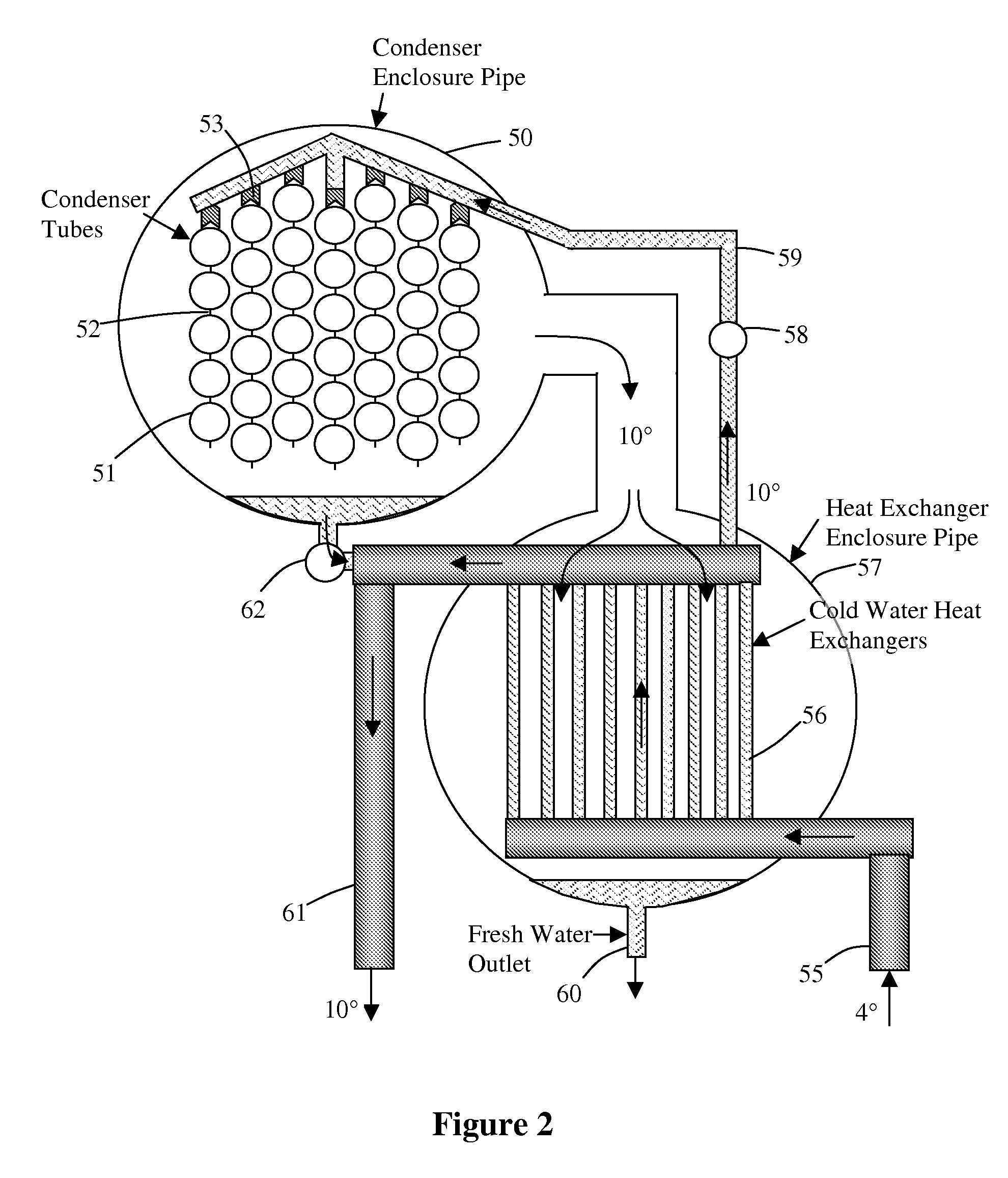

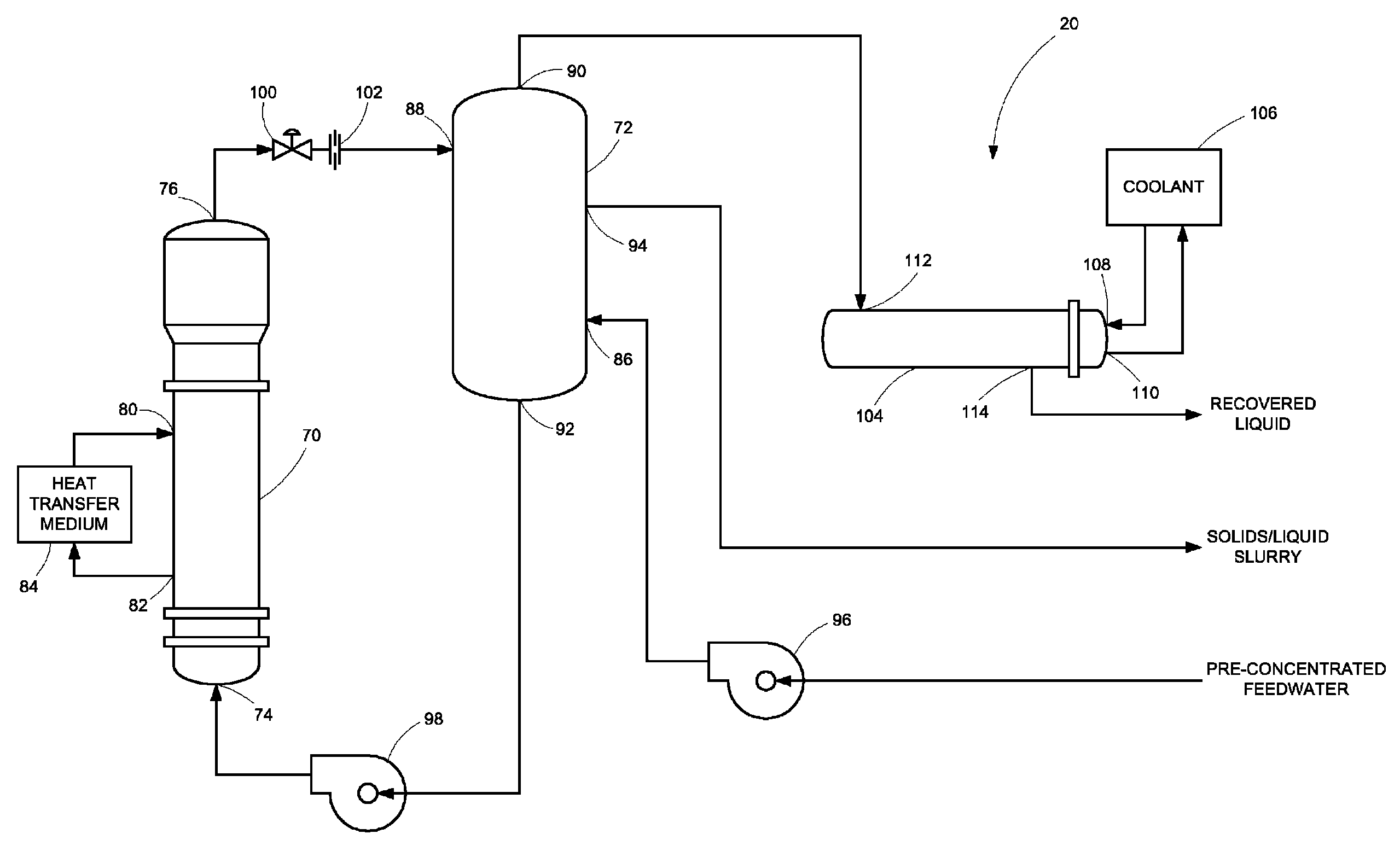

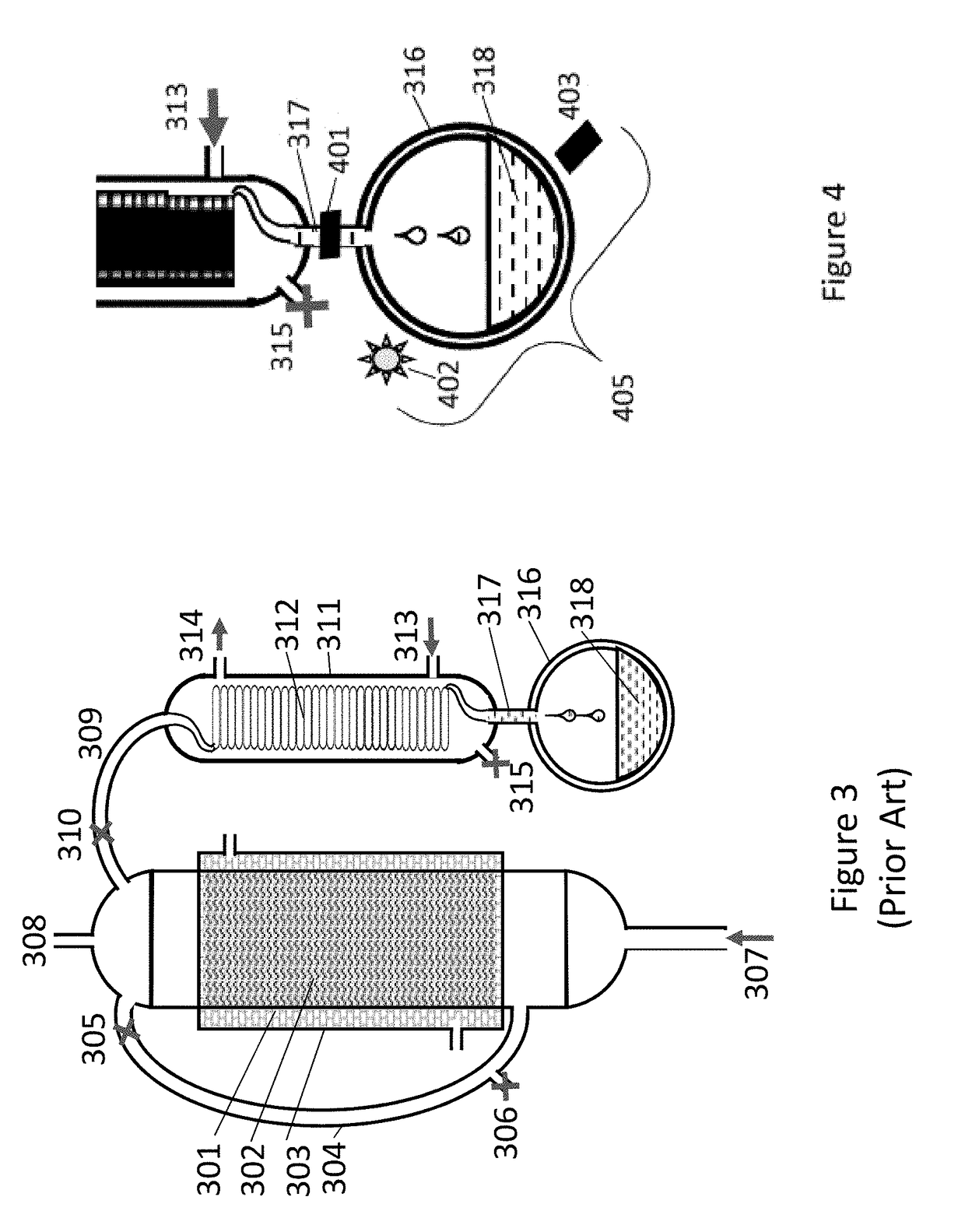

Heat Transfer Methods for Ocean Thermal Energy Conversion and Desalination

InactiveUS20090077969A1Eliminate scalingPrevent buildupGeneral water supply conservationBarometric condensationOcean thermal energy conversionWater discharge

A means is provided to produce fresh water from seawater on both the boiler side and the condenser side of an OTEC power plant. Part of the warm ocean surface water is evaporated, and its vapor transfers heat to the working-fluid boiler as the vapor condenses. The condensation of the vapor provides fresh water. On the condenser side, the condensation of the working-fluid vapor from the turbine in the condenser releases heat that evaporates seawater that runs down the outside of the condenser surfaces. The vapor from the seawater is condensed by a heat exchanger that uses input from colder seawater. As the cold seawater accepts heat from the condensing vapor, it becomes slightly warmer and provides the source of seawater that accepts heat from the condenser. The condensing vapor on the heat exchanger becomes fresh water that is drawn out as potable water. To provide additional fresh water, a multi-stage desalination unit uses the warm water discharge and the cold-water discharge from the OTEC plant to provide a temperature gradient that causes evaporation and condensation in each stage of the unit.

Owner:PRUEITT MELVIN L

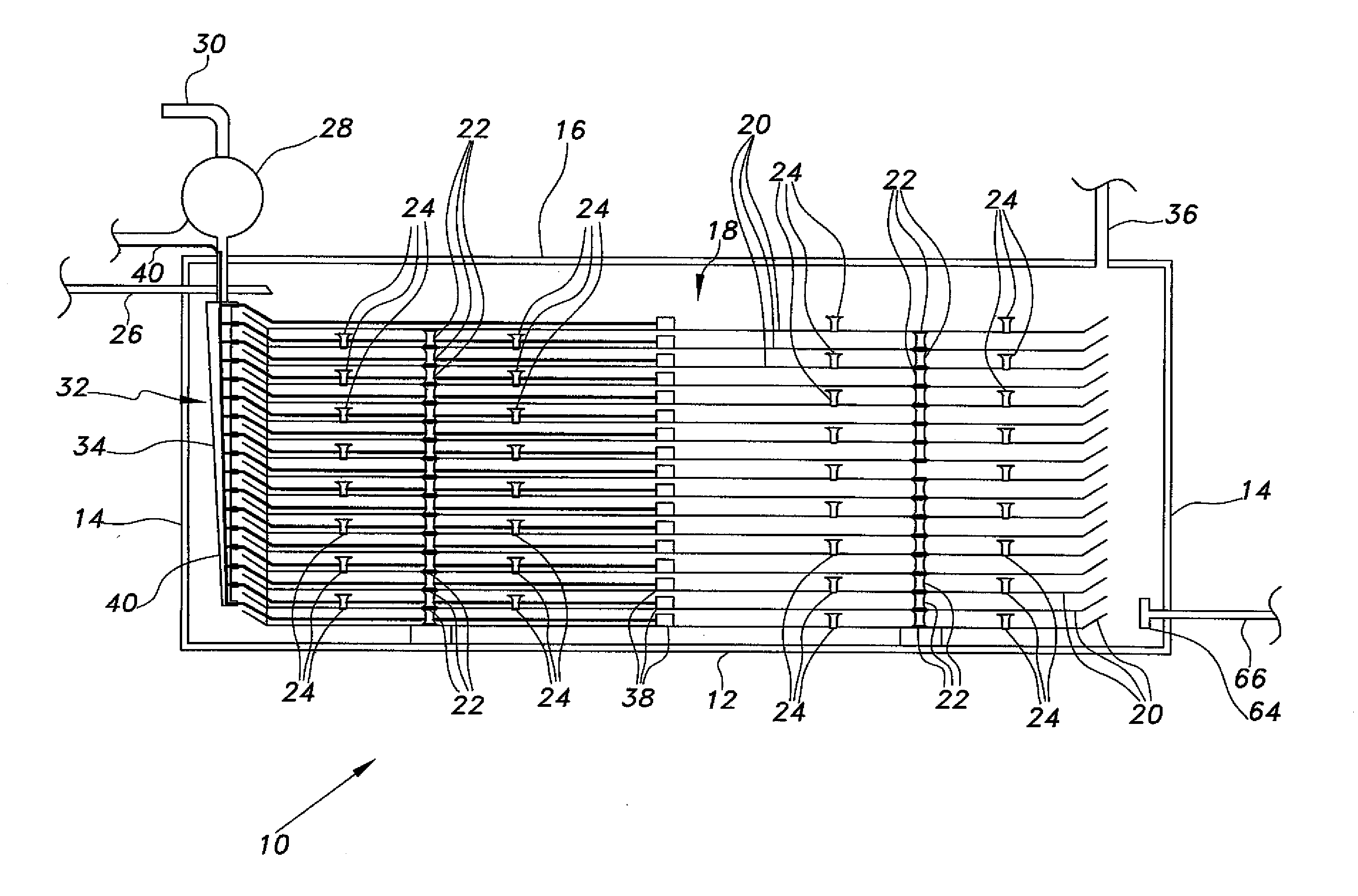

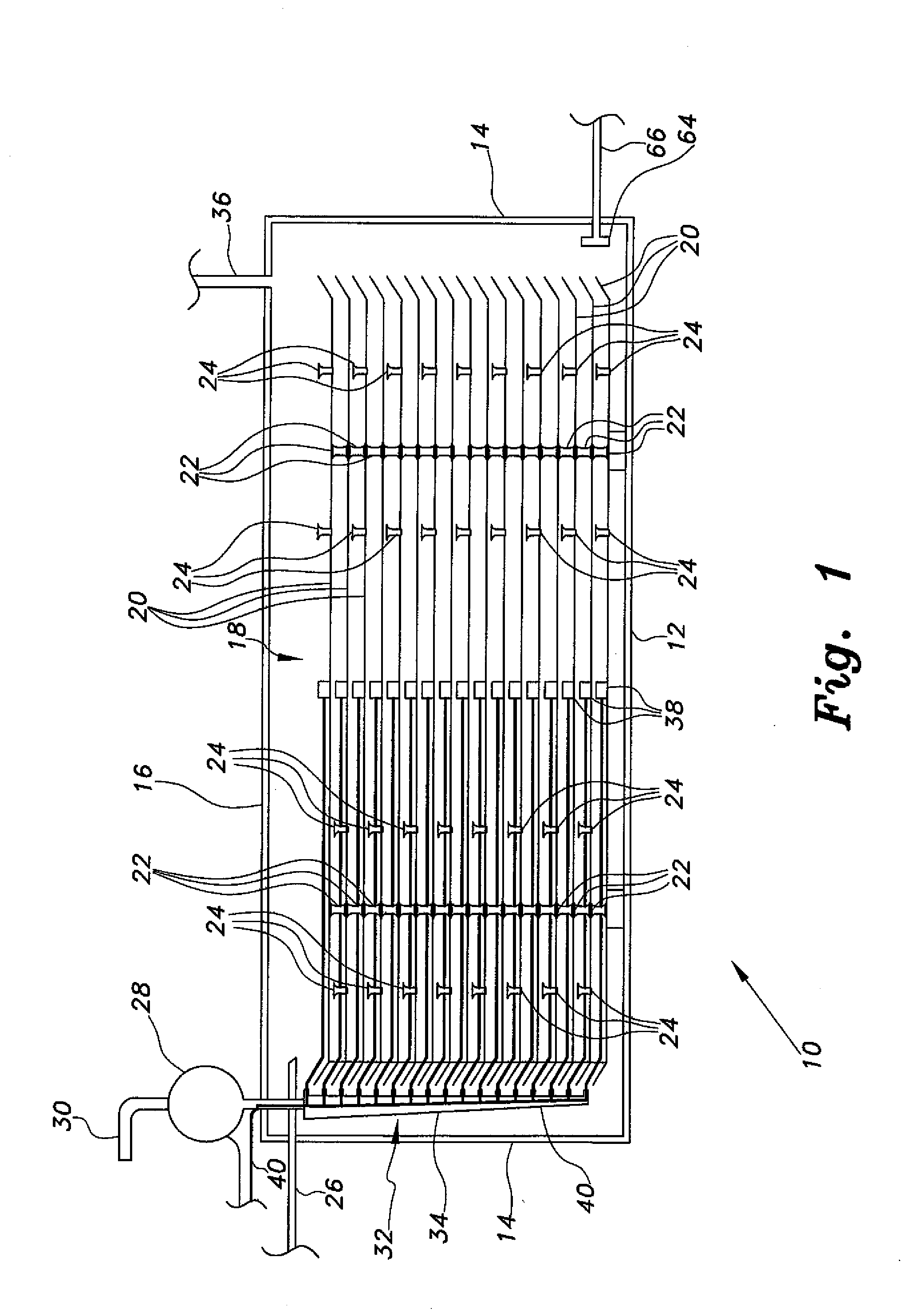

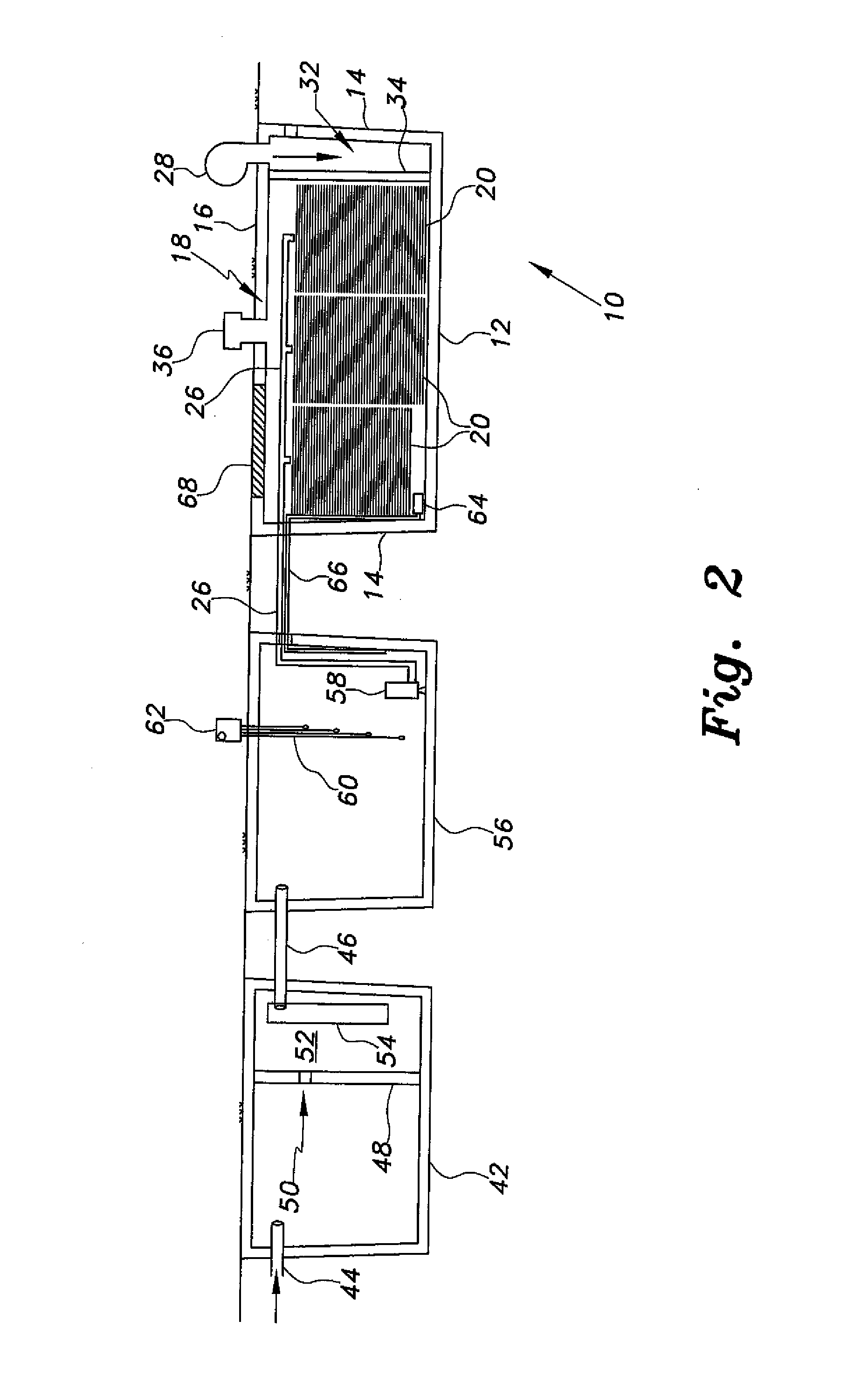

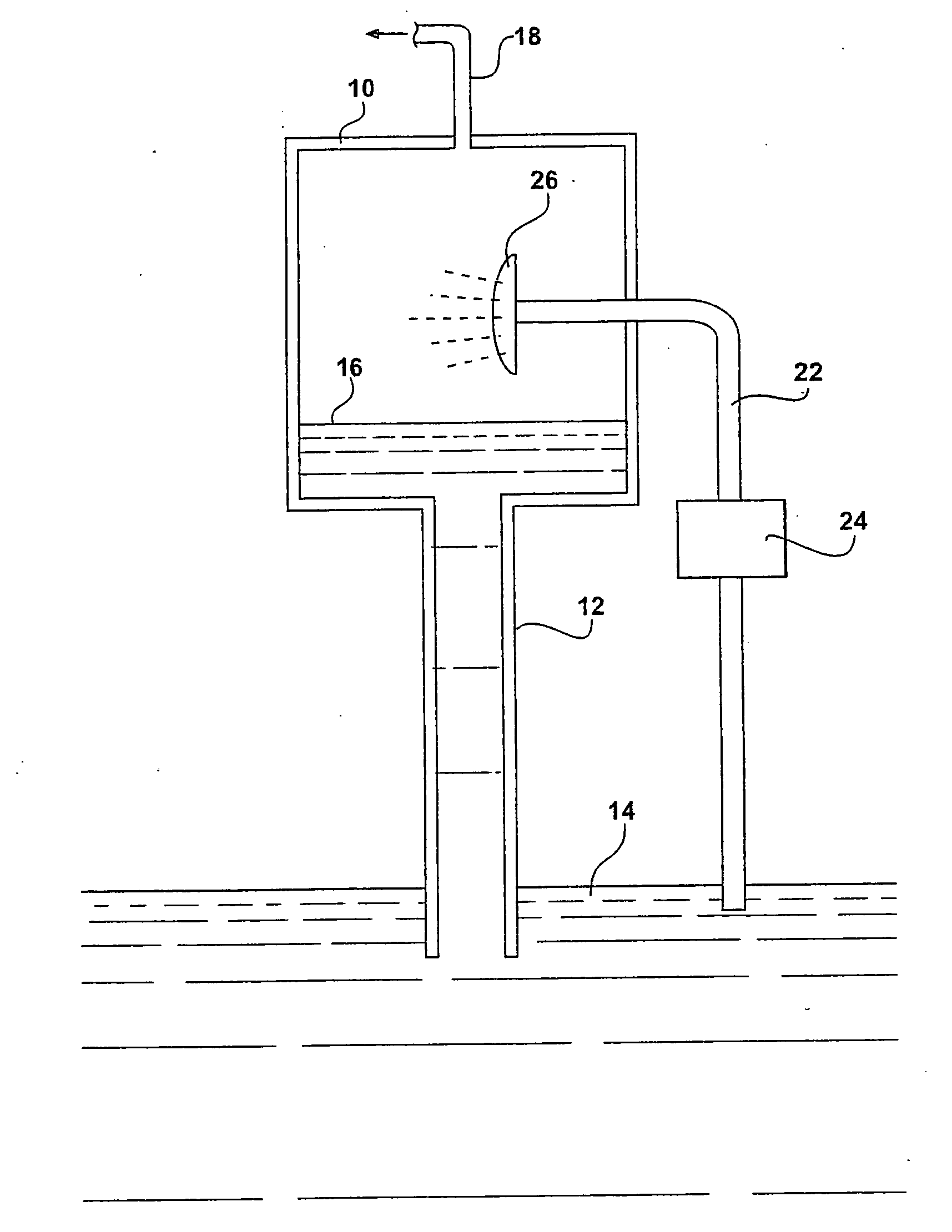

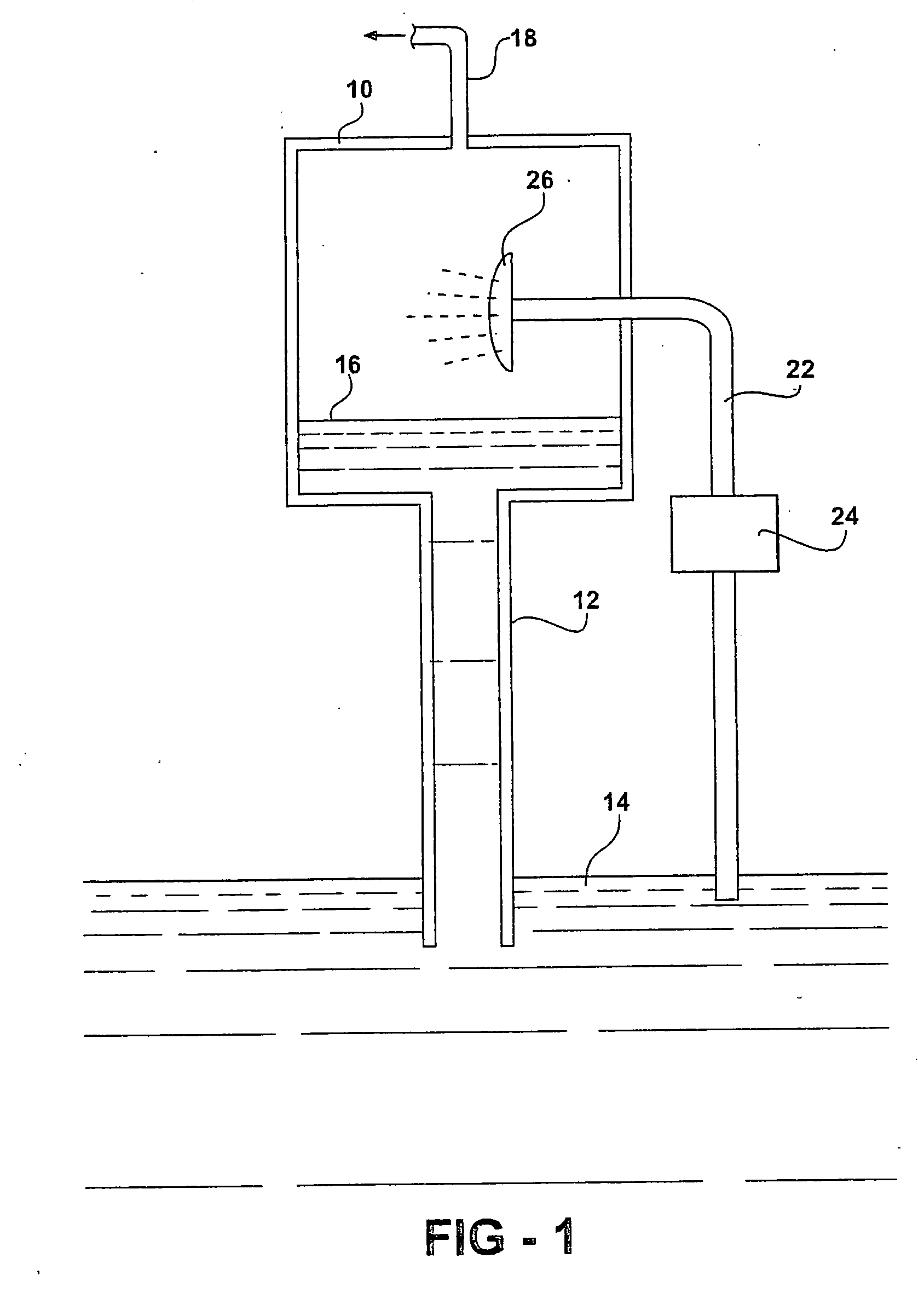

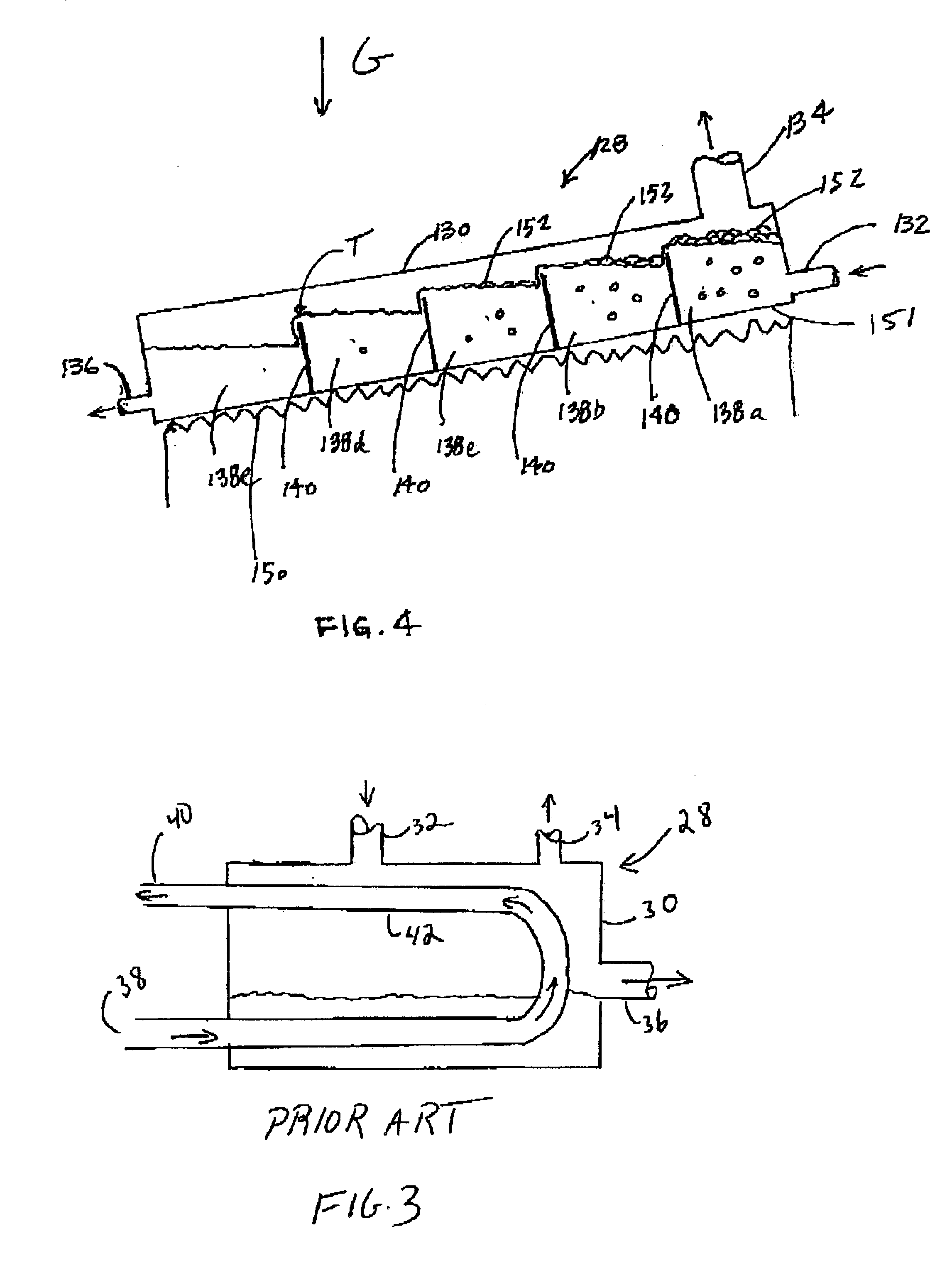

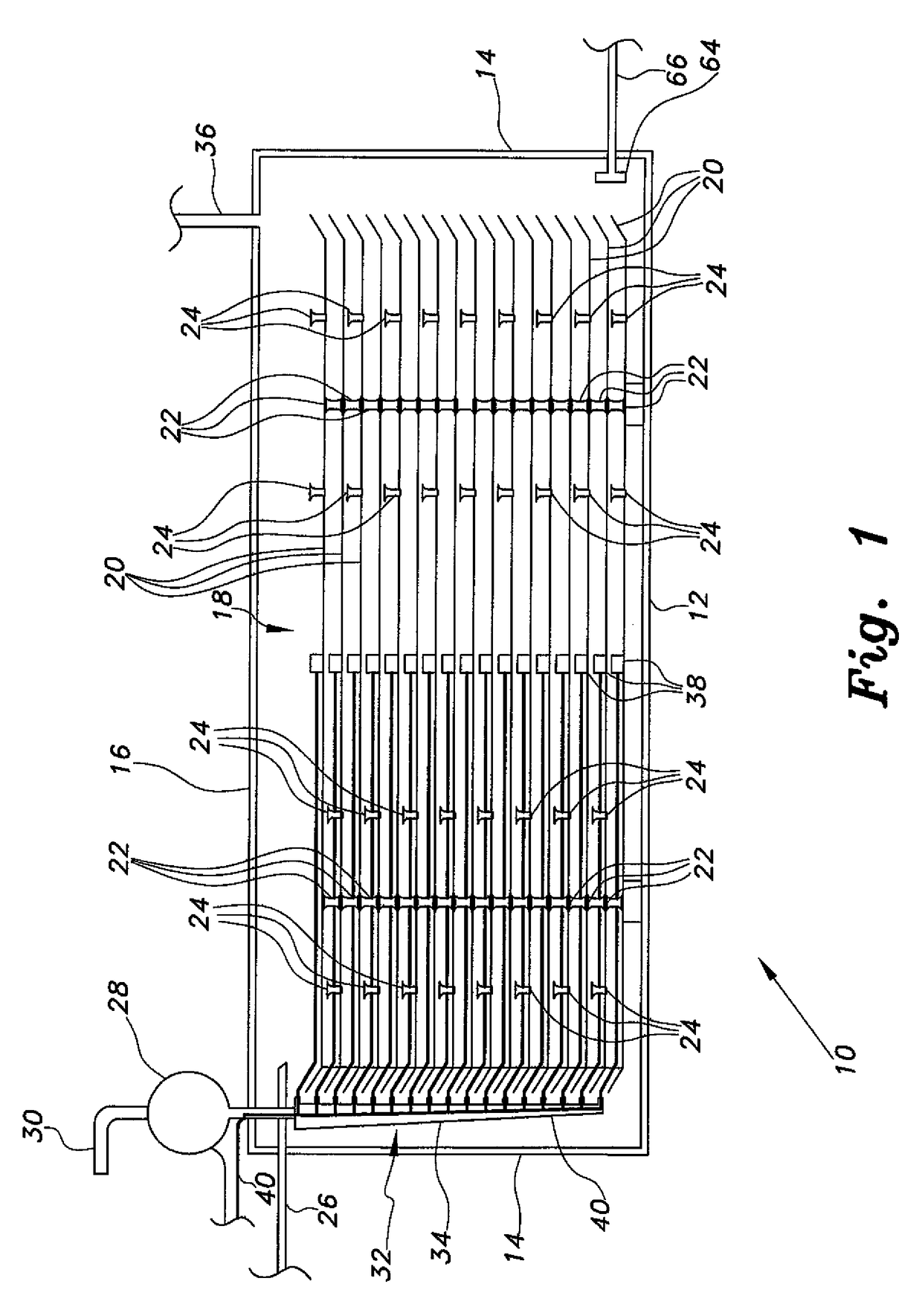

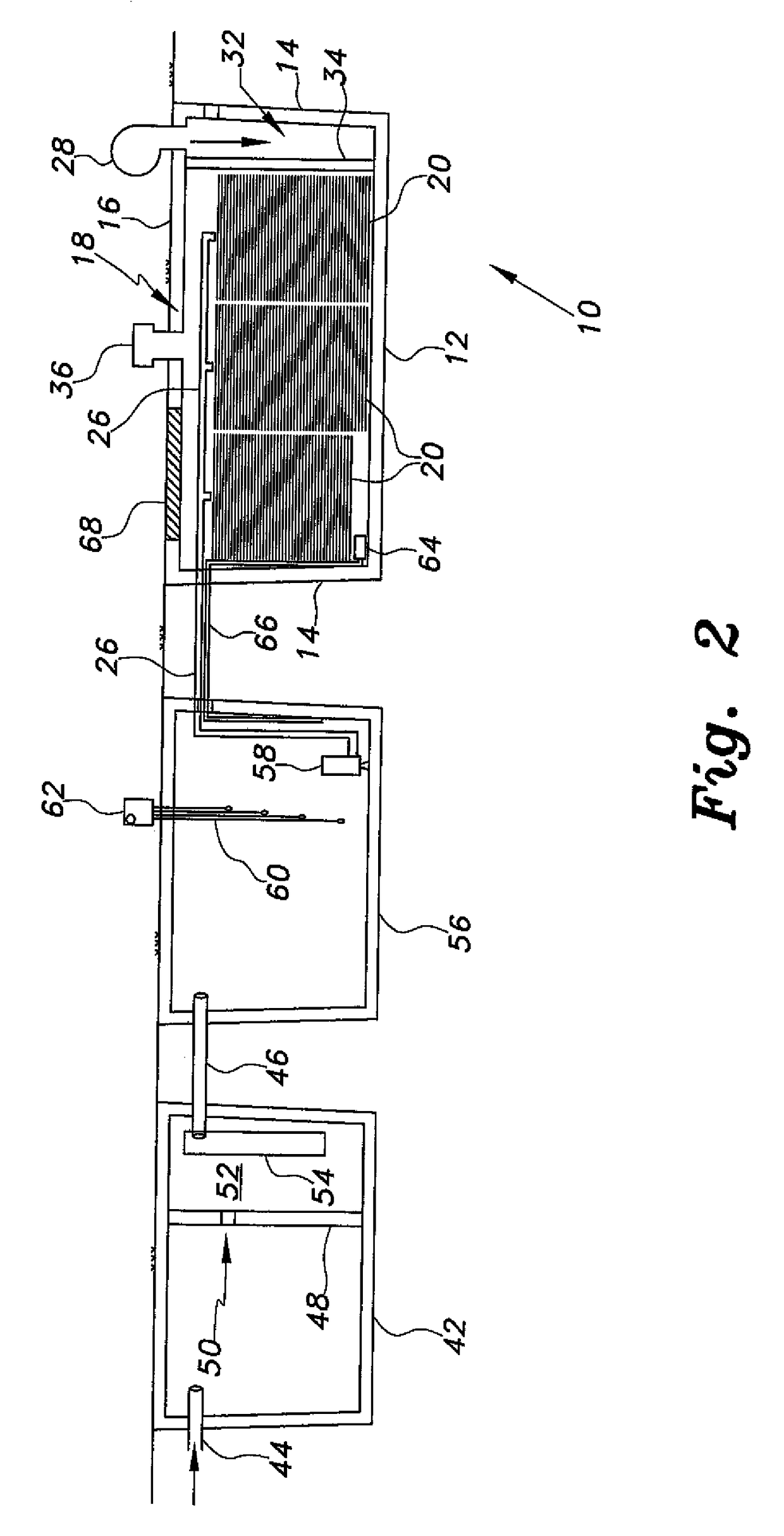

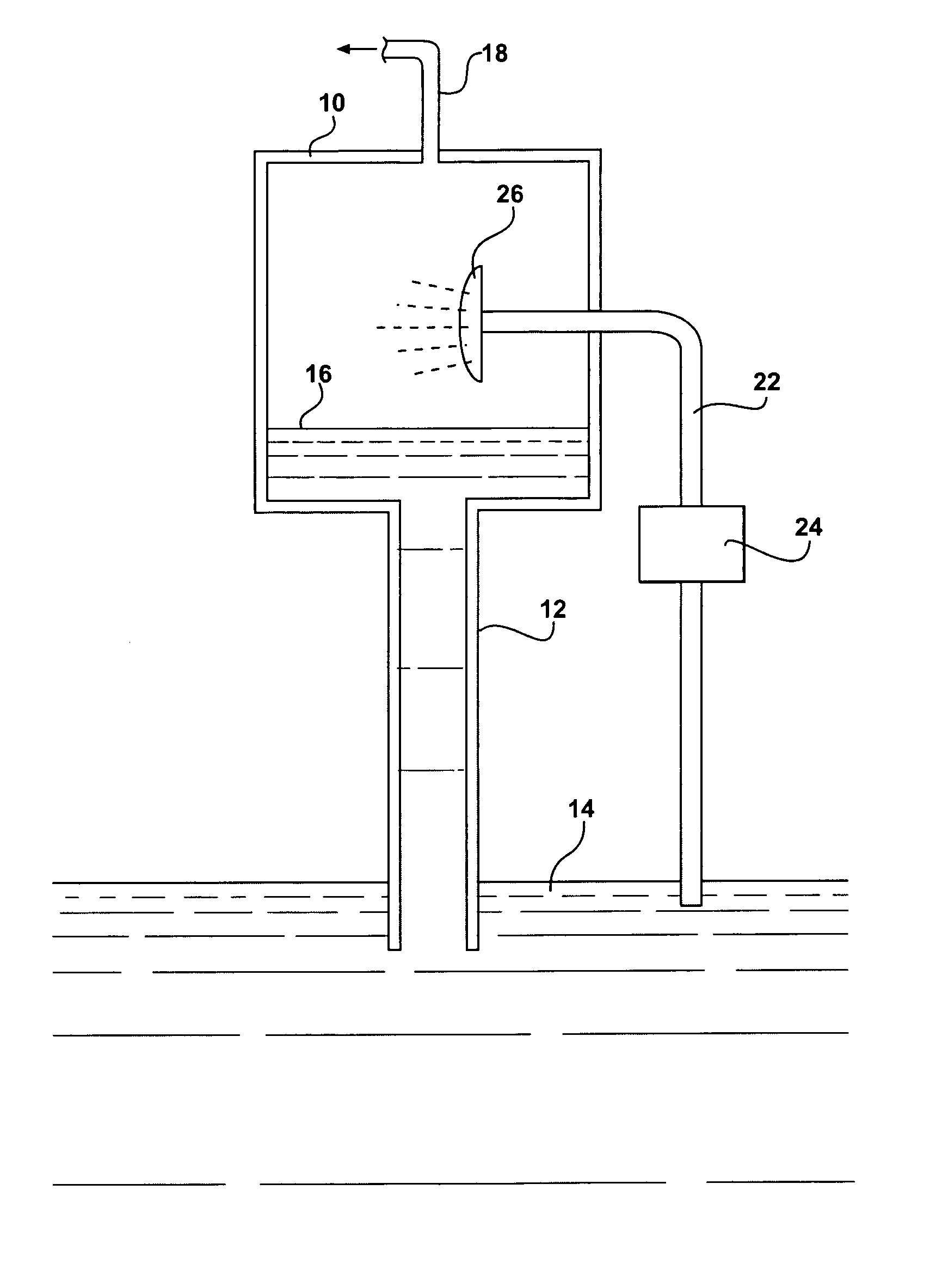

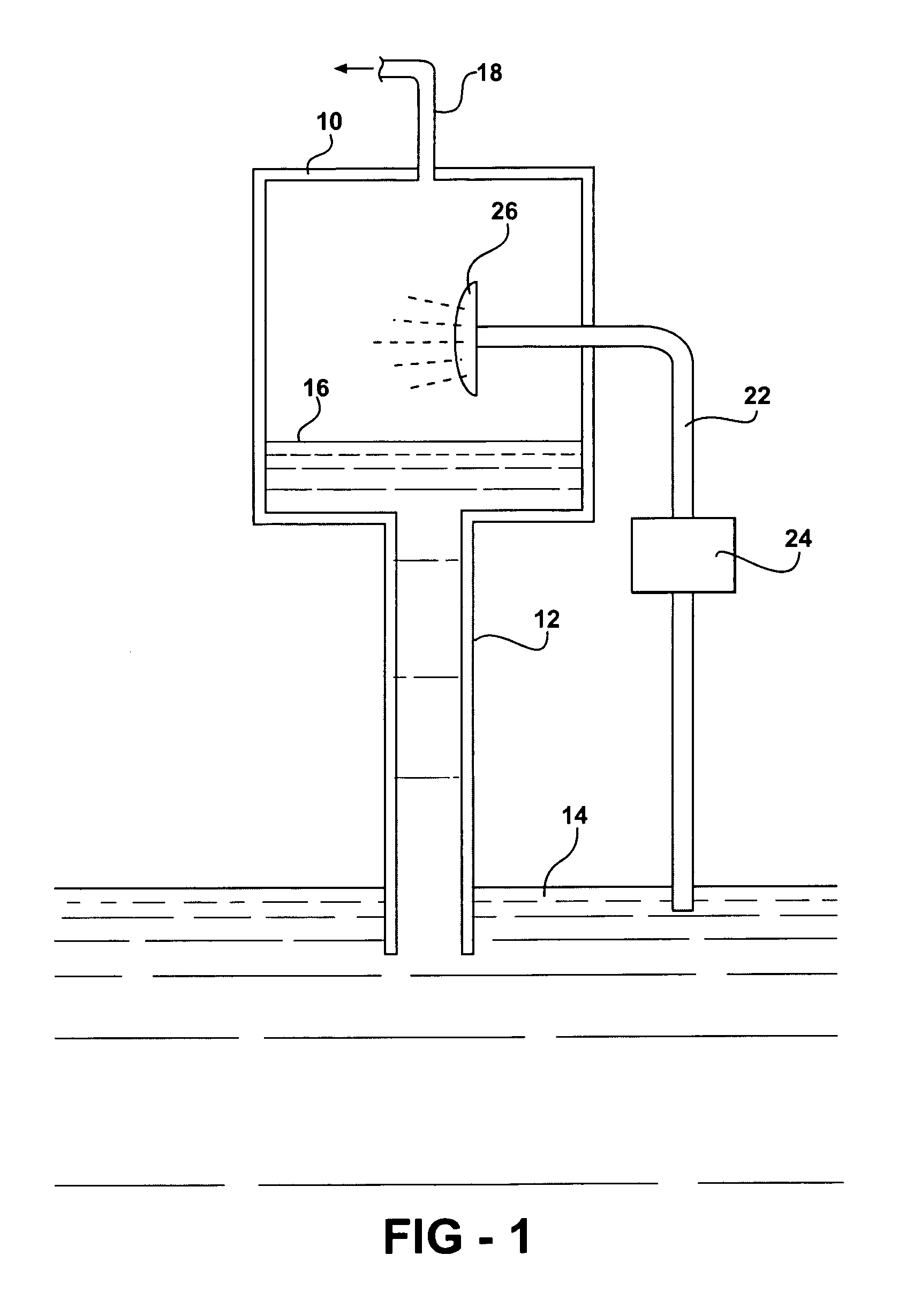

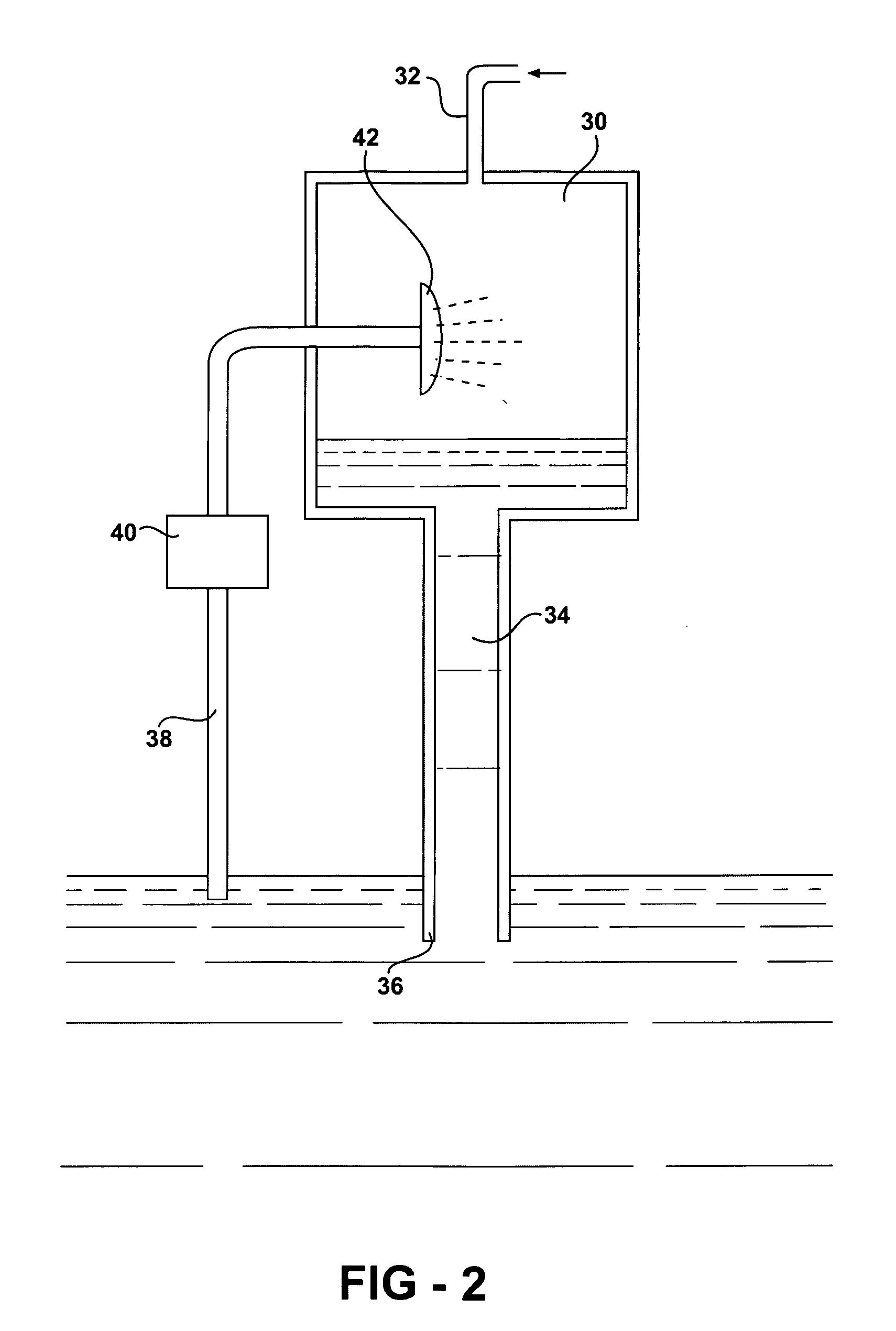

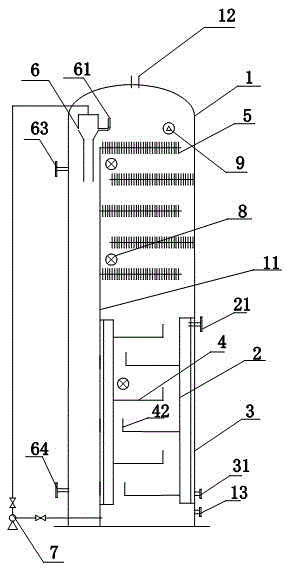

Wastewater evaporator

ActiveUS20140014277A1Increase surface areaSpeed up evaporationWater treatment parameter controlDistillation by vibrationWastewaterEvaporation

The wastewater evaporator provides for effluent evaporation in a septic system to eliminate need for a drain field. The evaporator tank contains a plurality of evaporator trays in a vertical array. Solids settle in the septic tank, and liquid effluent flows from the septic tank to the evaporator tank and cascades sequentially from the uppermost to the lowermost tray. The multiple trays increase the surface area of liquid contained therein, thereby greatly enhancing evaporation. An above-surface air pump and vent may be provided for air flow through the evaporator tank. An ultrasonic generator may be installed in each tray to increase the surface area of the effluent to enhance evaporation. An additional intermediate pump tank may be provided between the septic tank and the evaporator tank to control effluent flow and delivery to the evaporator tank. A sump pump in the pump tank periodically delivers effluent to the evaporator tank.

Owner:CLARK GRETCHEN B +1

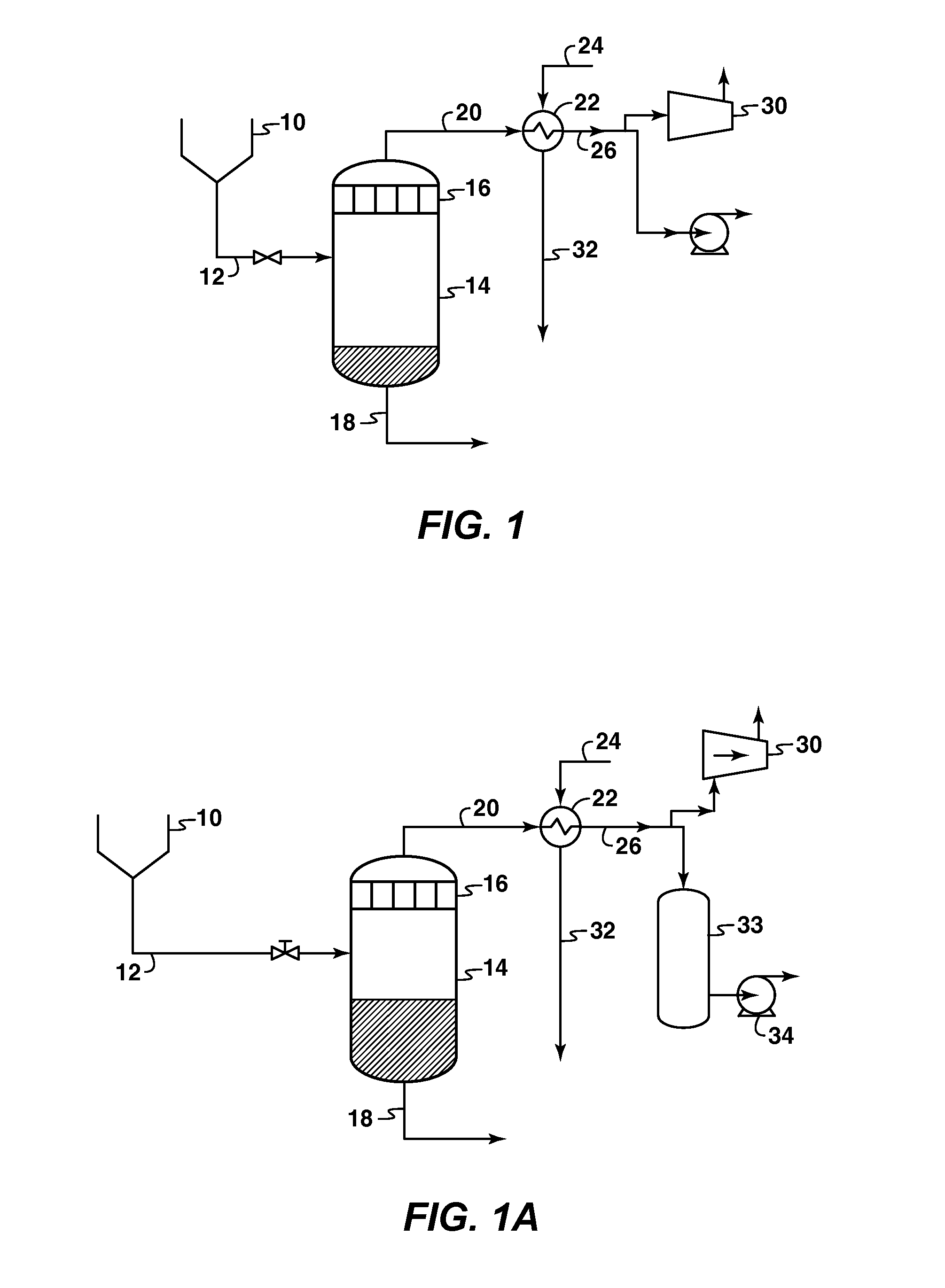

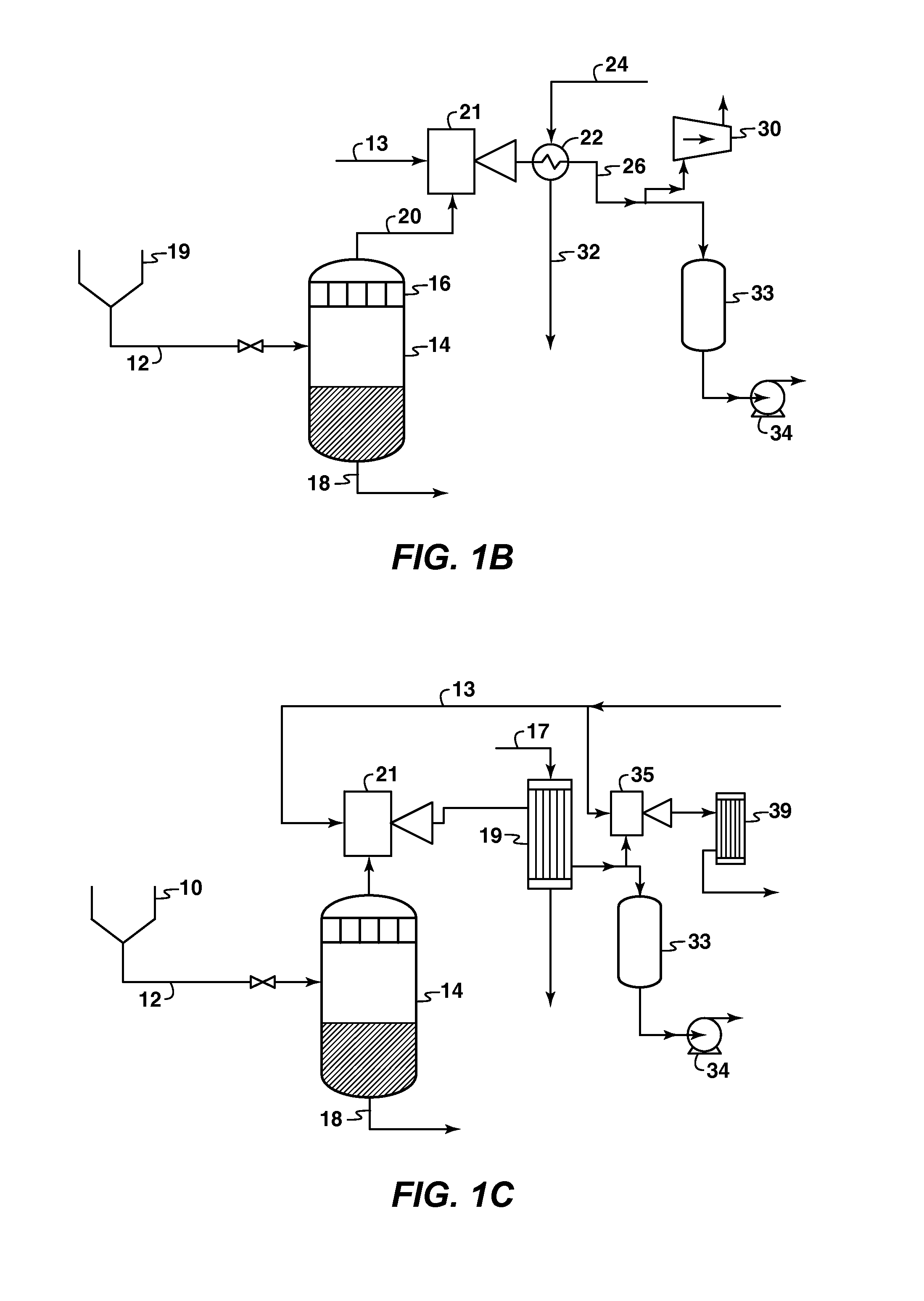

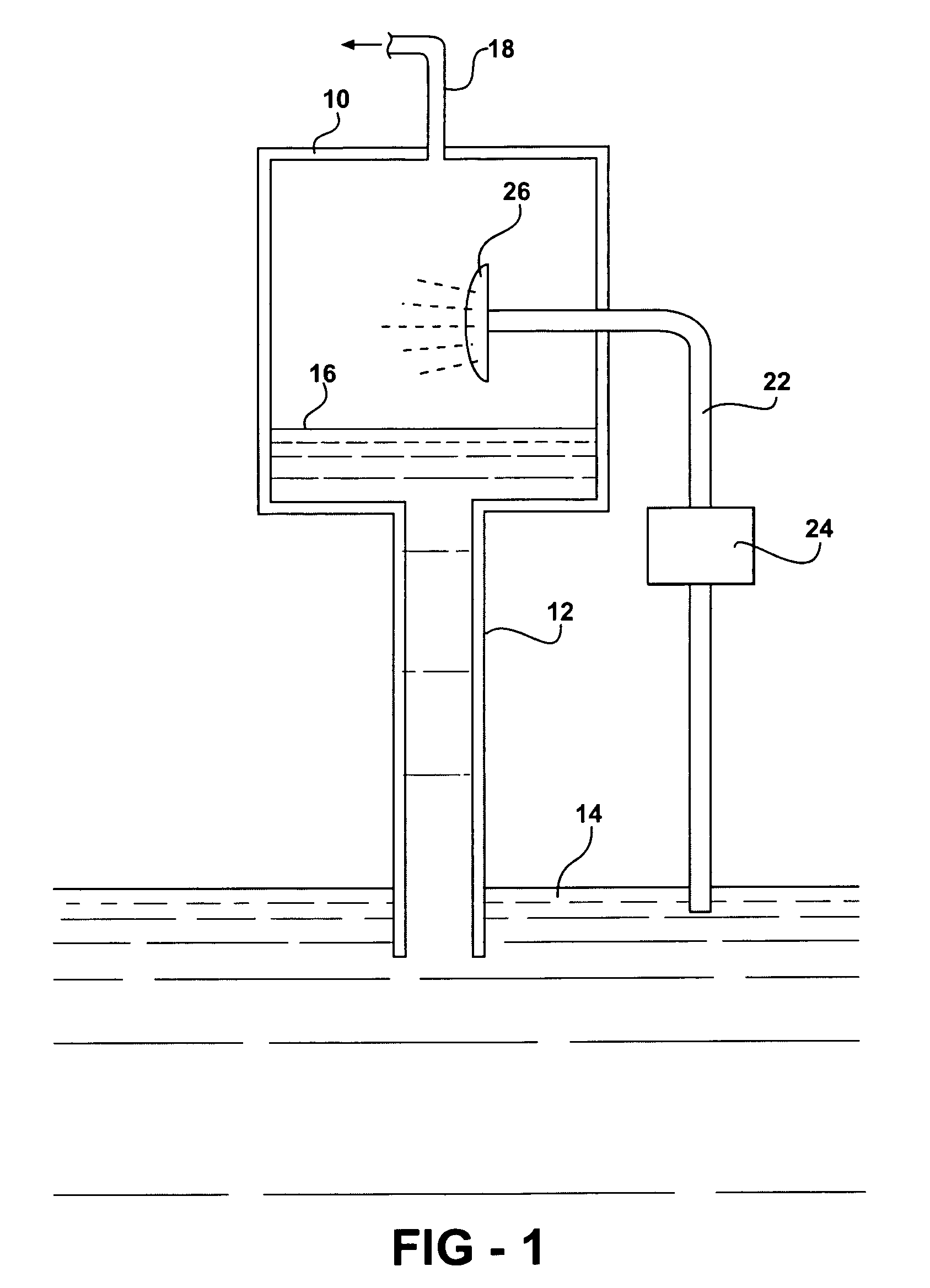

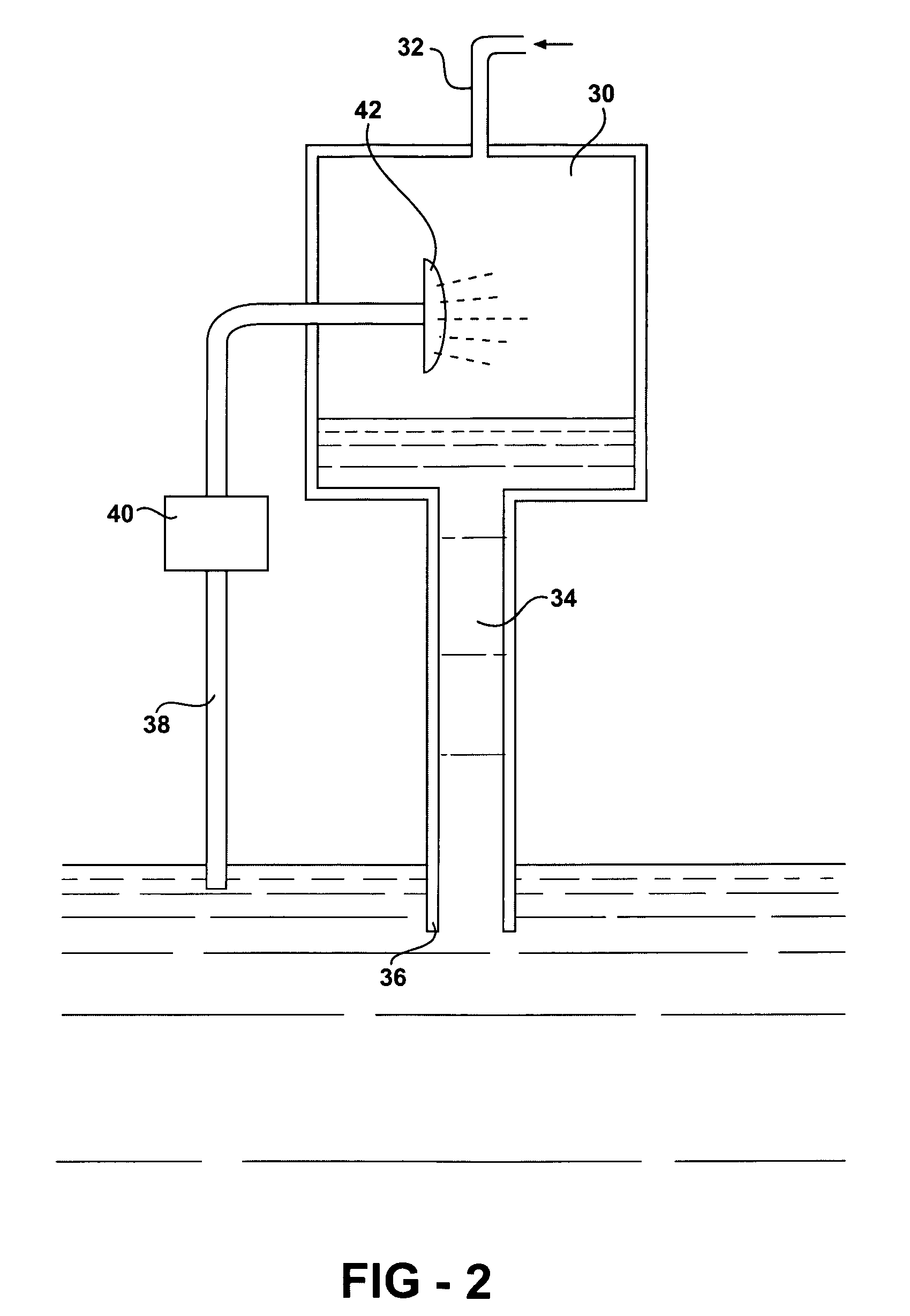

Low energy vacuum distillation method and apparatus

InactiveUS20060157335A1Lower initial costMaintenance freeLiquid degasificationGeneral water supply conservationDegasserWater source

A subatmospheric pressure desalinating still employs a closed top, open bottom pipe filled with source water to be distilled, such as seawater, having a height greater than the height of a column of seawater that can be supported by the pressure at the bottom of the tank so that a subatmospheric pressure volume is formed at the top. Water from the source is also pumped into the subatmospheric volume and passed through an evaporator which enlarges its surface volume. A small percentage of the water is vaporized and the balance is cooled to provide the heat of vaporization and falls into the top of the seawater column, creating a downward flow. The vapor is drawn from the vacuum and condensed, preferably in a second subatmospheric volume above a column of fresh water. A degasser for the water to be distilled prevents the accumulation of gases dissolved in the seawater or the like in the subatmospheric volume.

Owner:LEVINE MICHAEL R +4

Method and system for treating feedwater

Owner:AHT SOLUTIONS +1

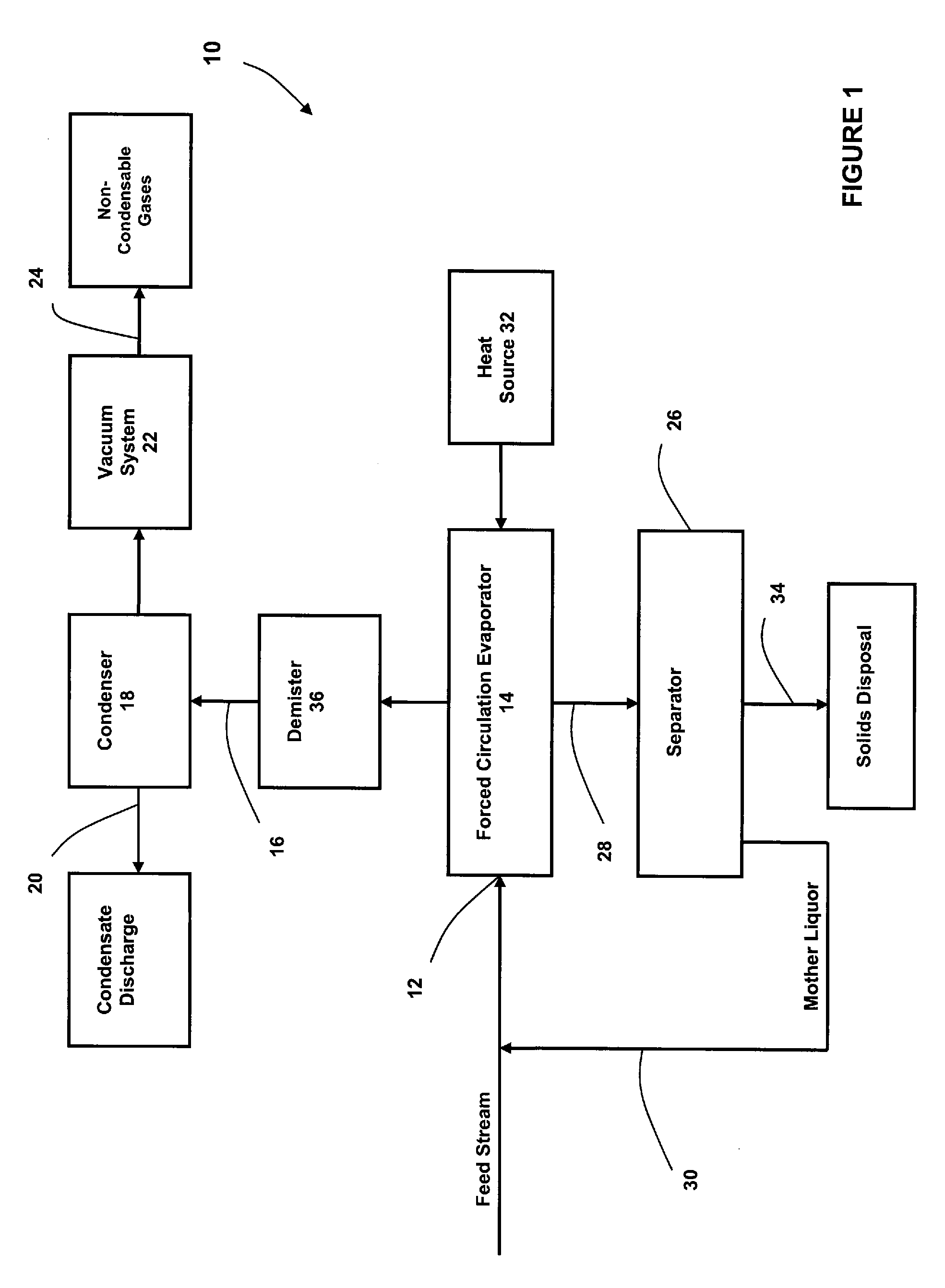

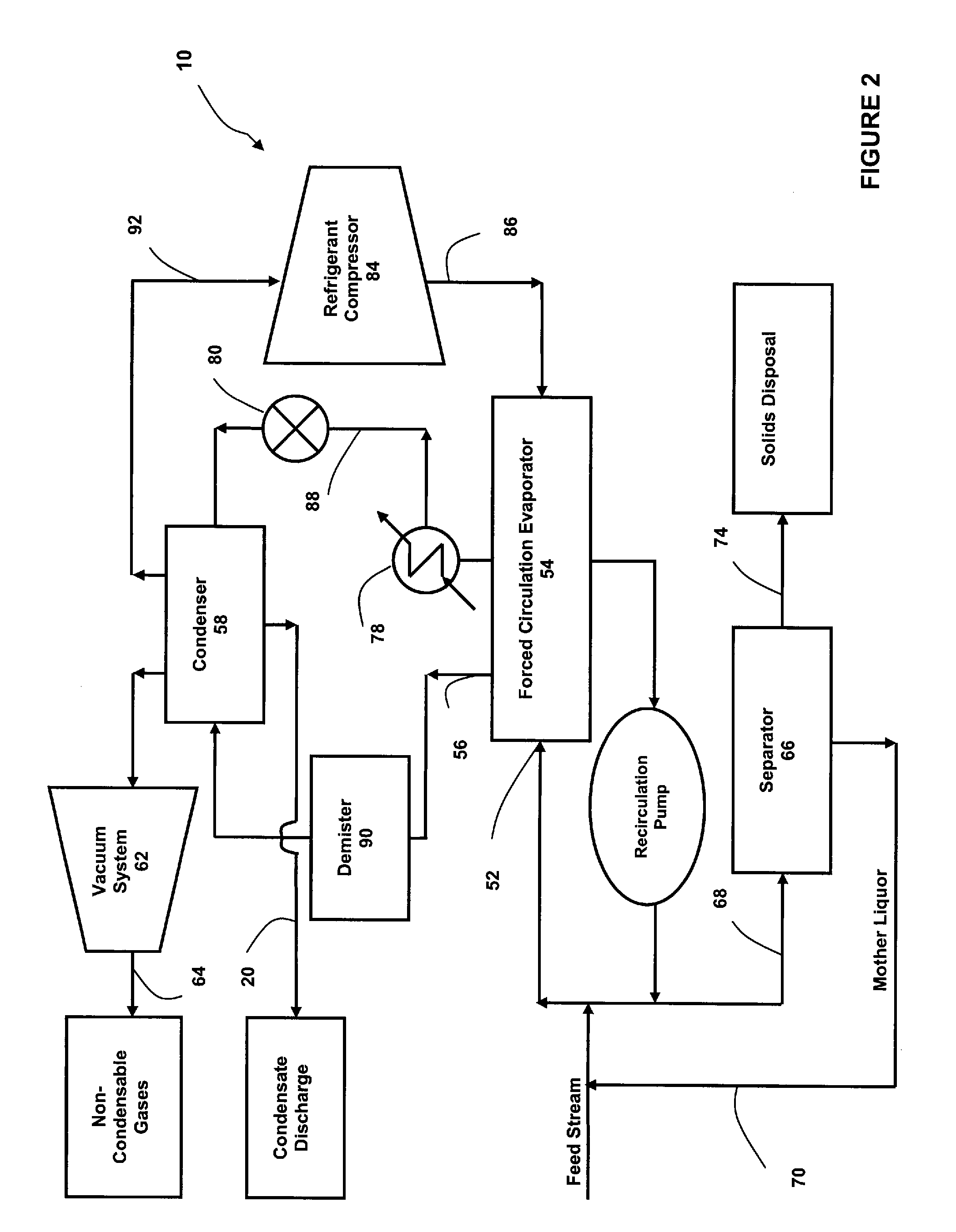

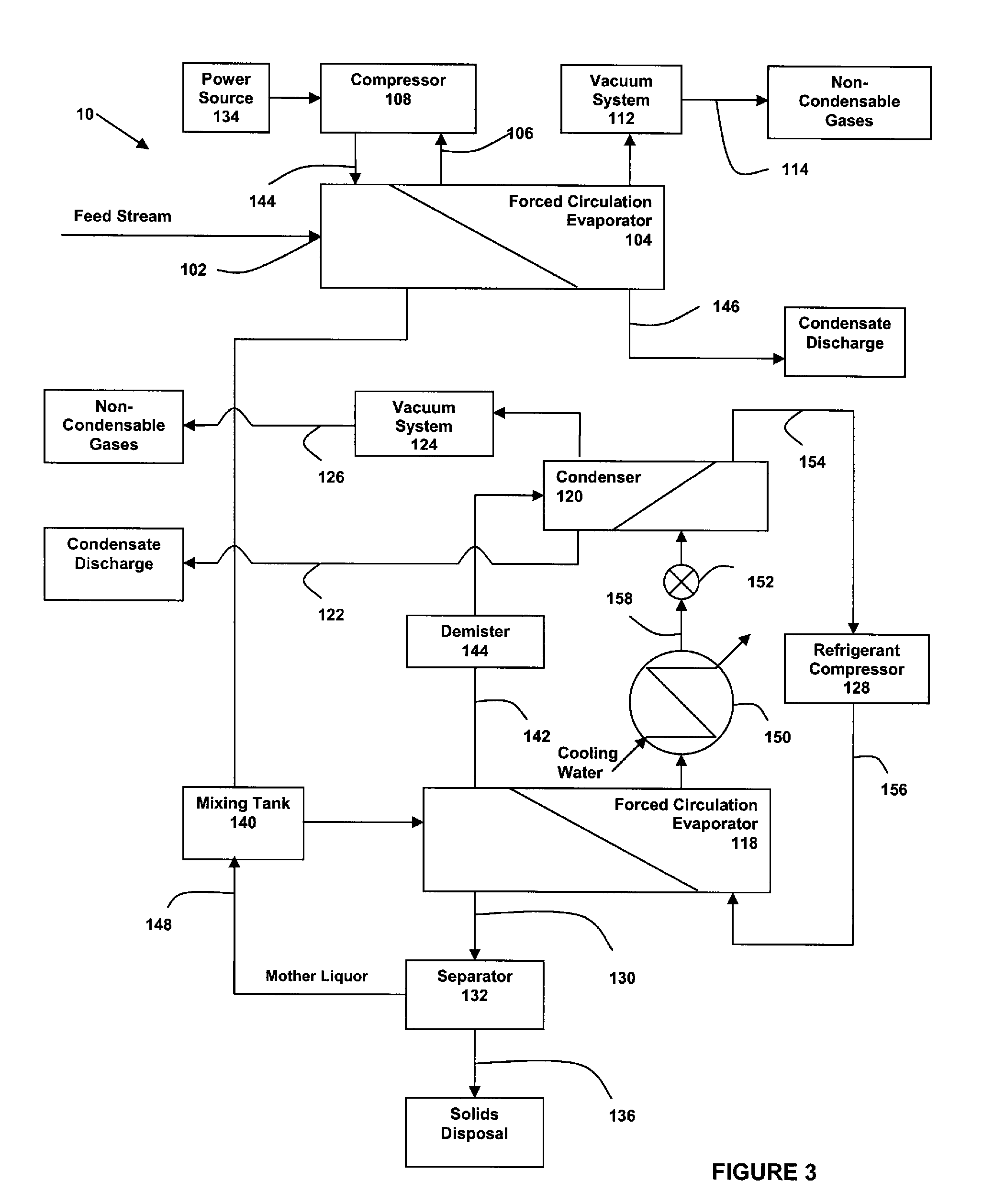

Method for removing dissolved solids from aqueous waste streams

ActiveUS8052763B2Sedimentation separationWaste water treatment from gaseous effluentsWaste streamBoiling point

A method for removing dissolved solids from a waste stream, such as that produced in flue gas scrubbing, through an evaporation-crystallization process operated at relatively low temperature. A waste stream is directed into an evaporator and heated at a temperature of less than 60° C. at a pressure below atmospheric pressure. The waste stream is concentrated through the evaporation process and forms a slurry stream having crystallized solids. At the low temperature of evaporation, the solids crystallize at substantially lower temperature and the solution has a substantially lower boiling point elevation than at atmospheric pressure. The slurry stream is directed to a solid-liquid separator where the crystallized solids in the slurry stream are separated, producing a solid cake and mother liquor.

Owner:VEOLIA WATER TECH INC

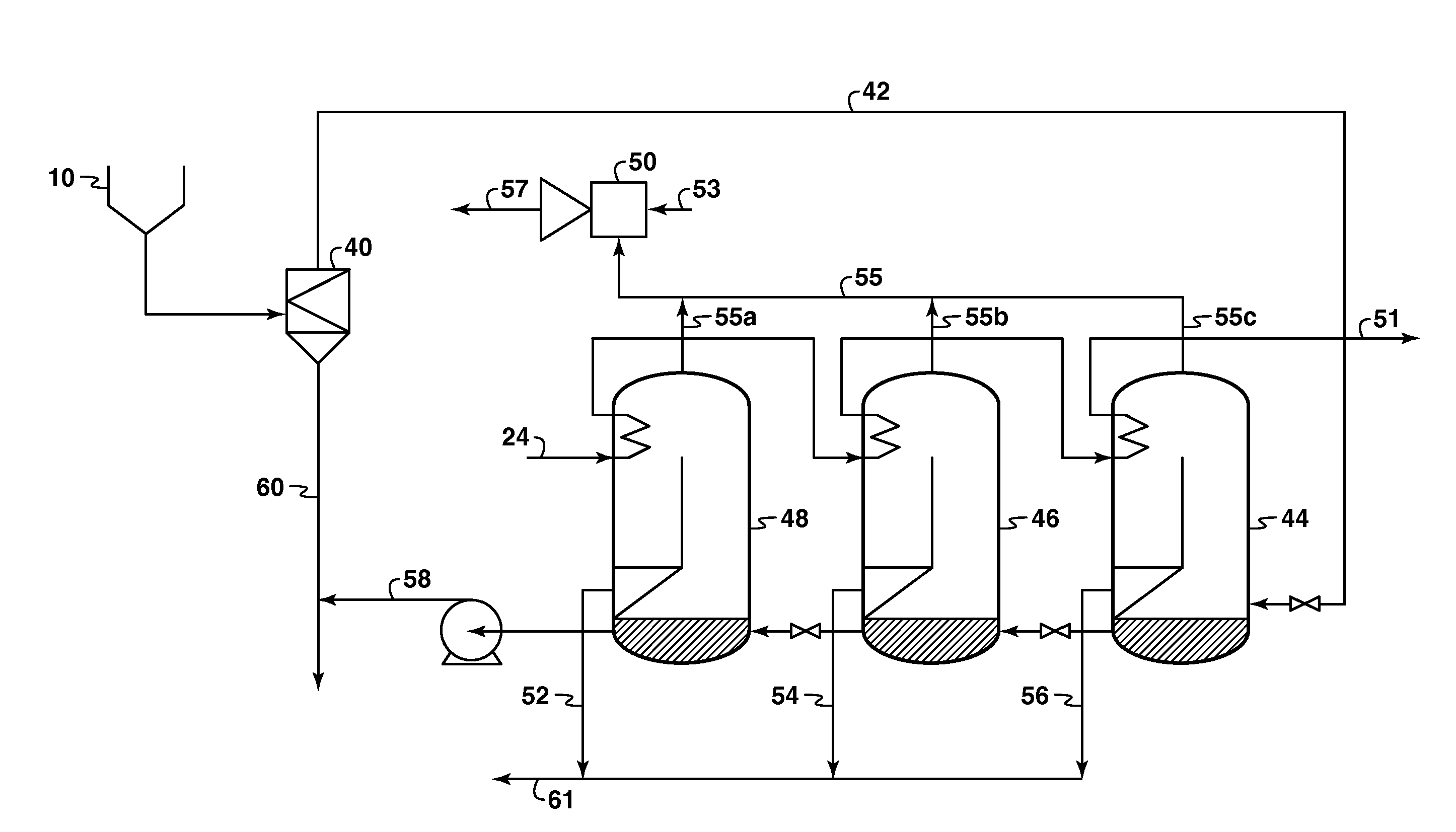

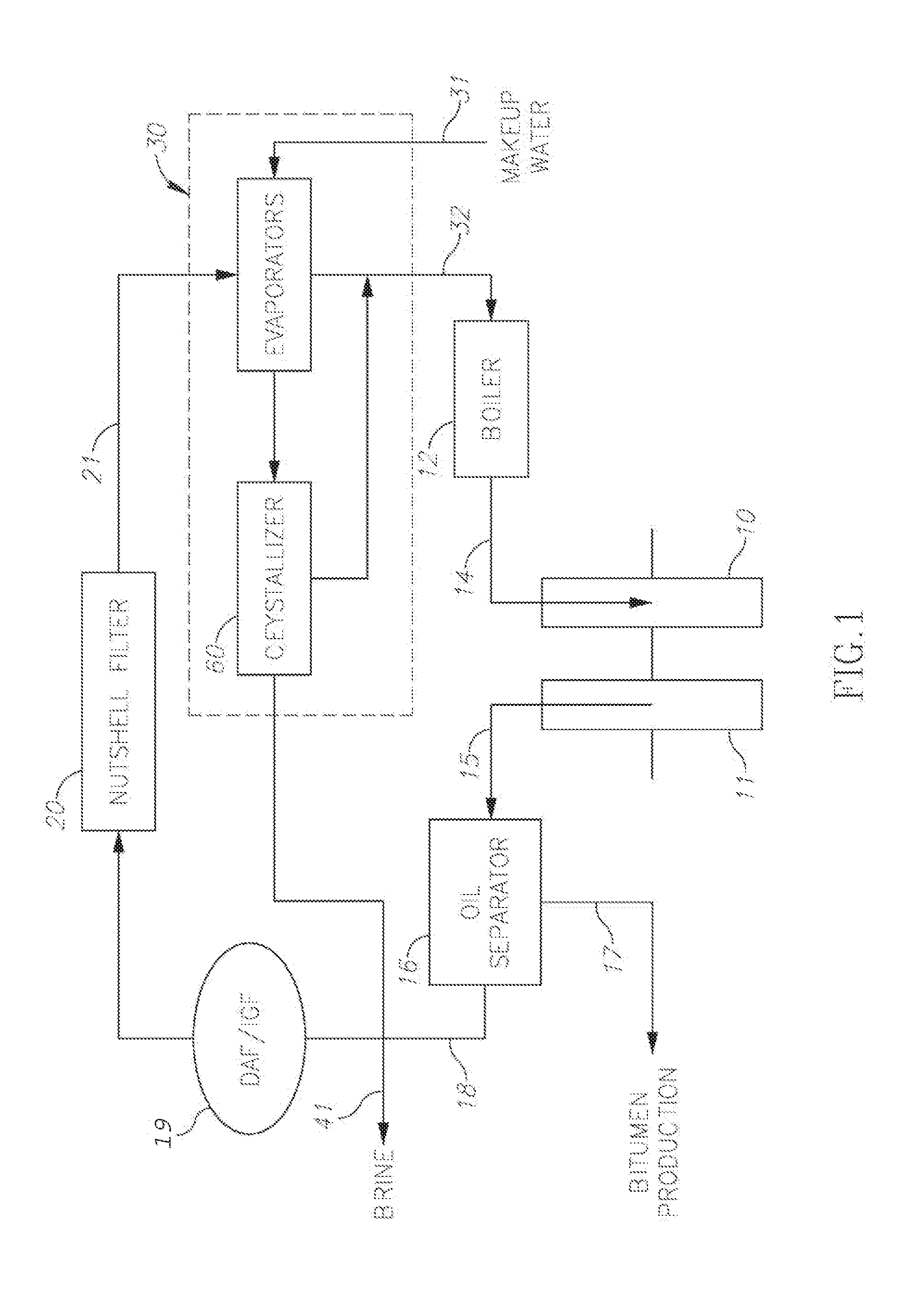

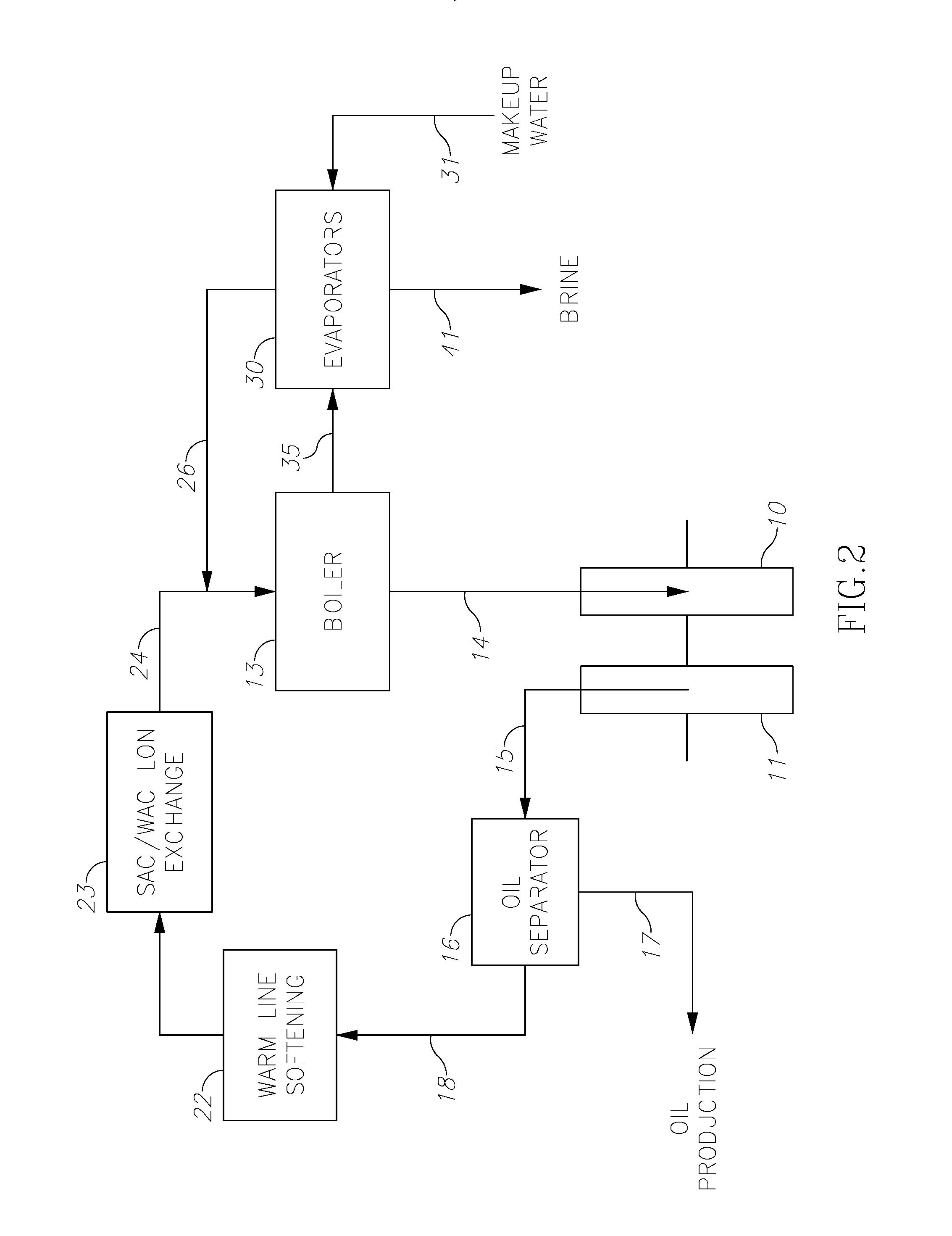

System and method of recovering heat and water and generating power from bitumen mining operations

InactiveUS20100275600A1Improve environmental performanceReducing greenhouse gas emissionThermal non-catalytic crackingAuxillariesEngineeringSlurry

A method recovering heat and water from a warm slurry, such as warm tailings from a oil sands extraction mining operation, is provided. The method comprises providing the tailings to a vacuum vessel, removing, from the vacuum vessel, warm vapor derived from the tailings, condensing the warm vapor in a condenser to produce water, and recovering the water from the condenser. Cool river or pond water can be warmed with the heat from the vapor for additional uses in the mining operation. Essentially pure water can be obtained in the process. This can also be achieved using one or flash vessels in series to condense the vapor. Power can also be generated from the vapor using a turbine.

Owner:EXXONMOBIL UPSTREAM RES CO

Method and system for treating feedwater

A system for treating feedwater includes a fluidized bed heat exchanger unit connected to receive feedwater and a flash concentrator column connected to receive feedwater discharged from the fluidized bed heat exchanger unit. A spray dryer is provided to receive a solids / liquid slurry discharged from the flash concentrator column. Feedwater can be treated by converting dissolved solids in the feedwater to suspended solids, vaporizing a portion of the feedwater to produce a solids / liquid slurry, and separating solids from the solids / liquid slurry.

Owner:AHT SOLUTIONS +1

Lubricant still and reservoir for refrigeration system

InactiveUS6904759B2High viscosityHigh trafficStationary conduit assembliesEvaporators with heating coilsRefrigerationRefrigerant

A lubricant still for use in a compressor for separating oil from refrigerant, includes a vessel having an inlet for incoming oil laden refrigerant, an outlet for gaseous refrigerant, and an outlet for refrigerant laden oil. A separating structure is provided for separating transitioning oil laden refrigerant from the incoming oil-laden refrigerant, wherein the oil laden refrigerant progressively changes to the refrigerant laden oil closer to the outlet for refrigerant laden oil. A heating device is used for heating the incoming oil laden refrigerant and transitioning oil laden refrigerant, for facilitating the formation of the gaseous refrigerant and the refrigerant laden oil.

Owner:CARRIER CORP

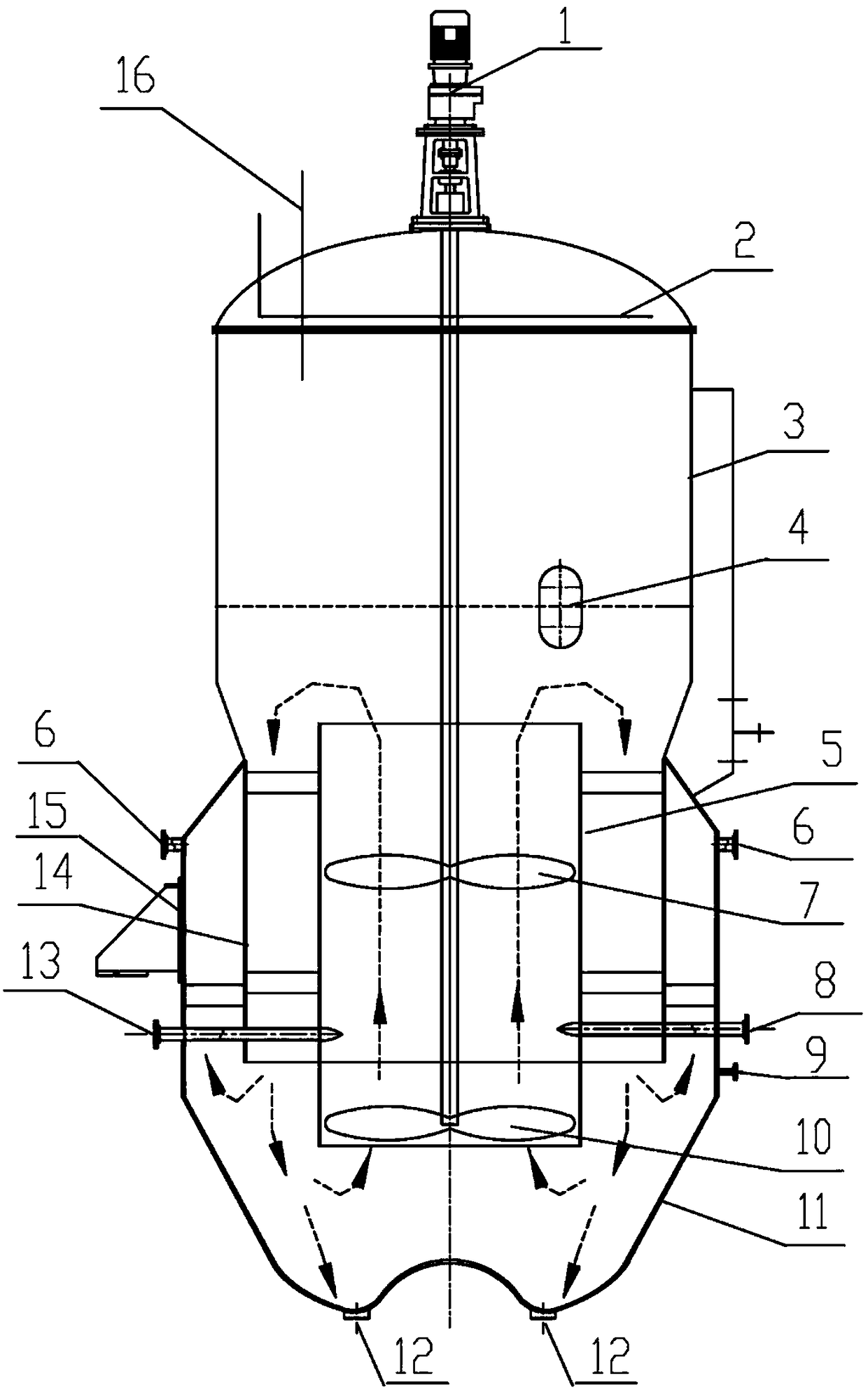

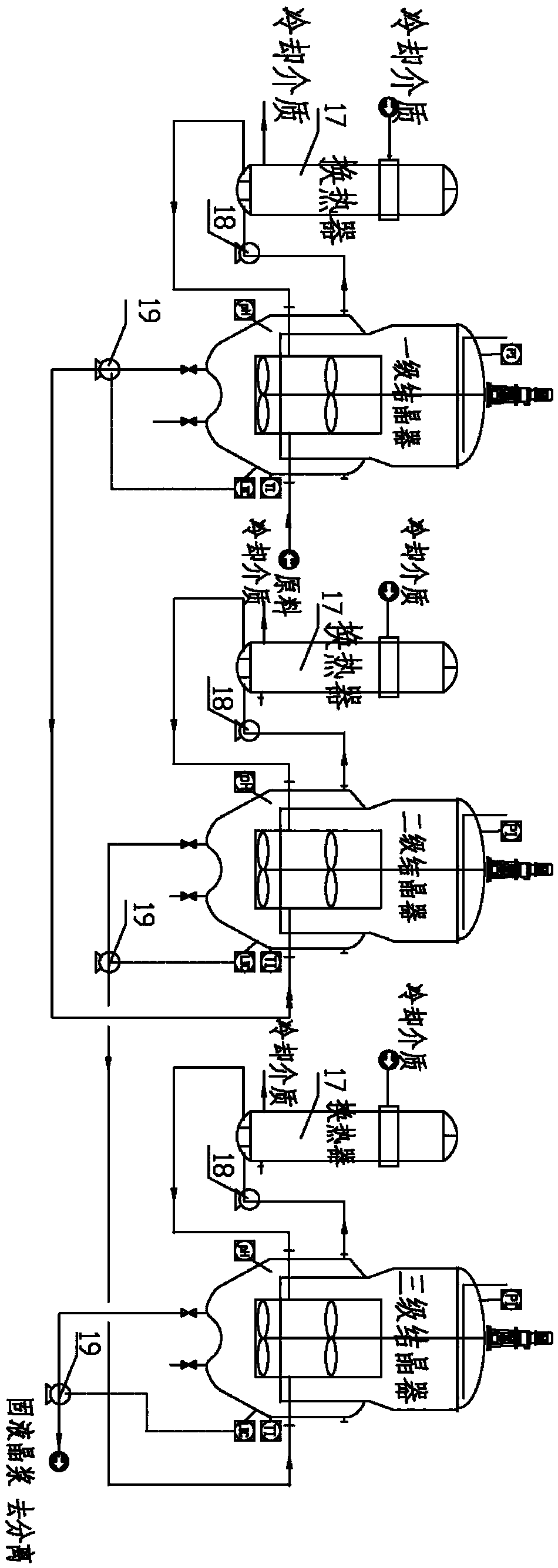

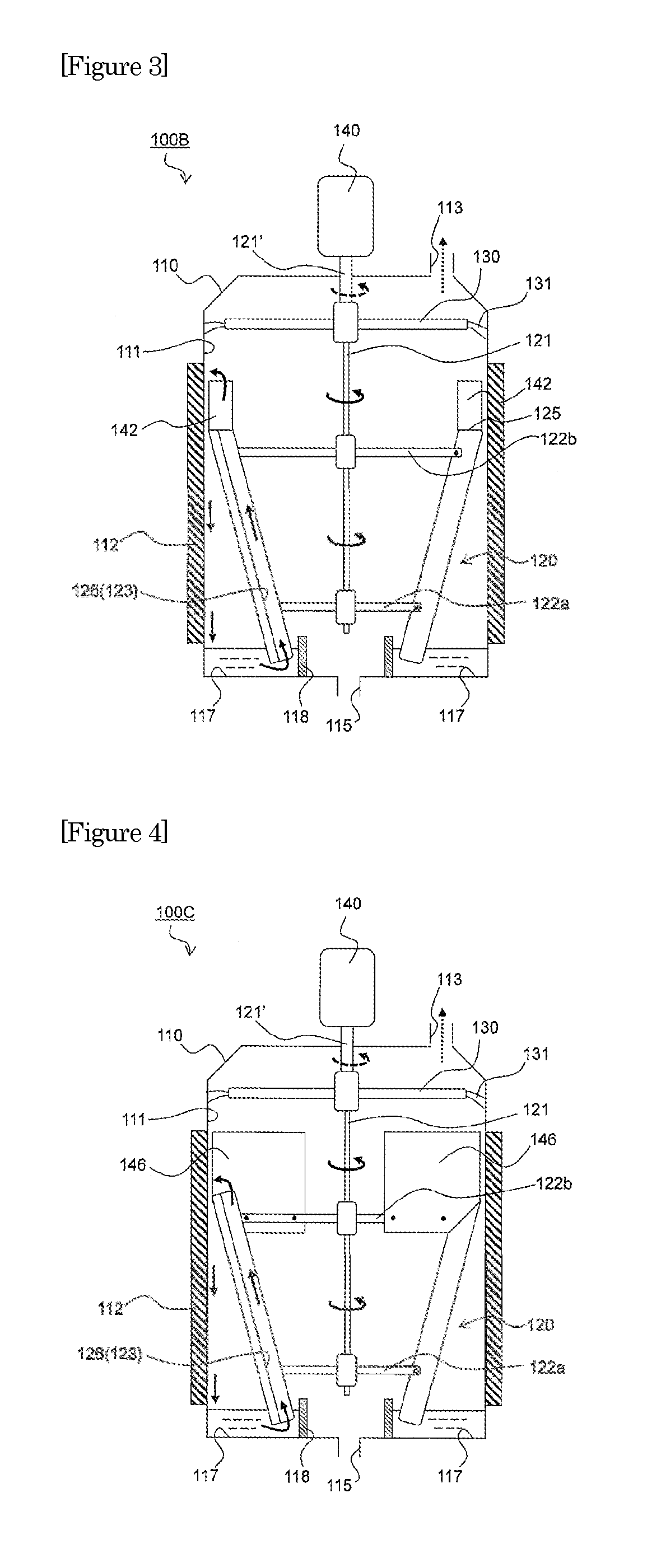

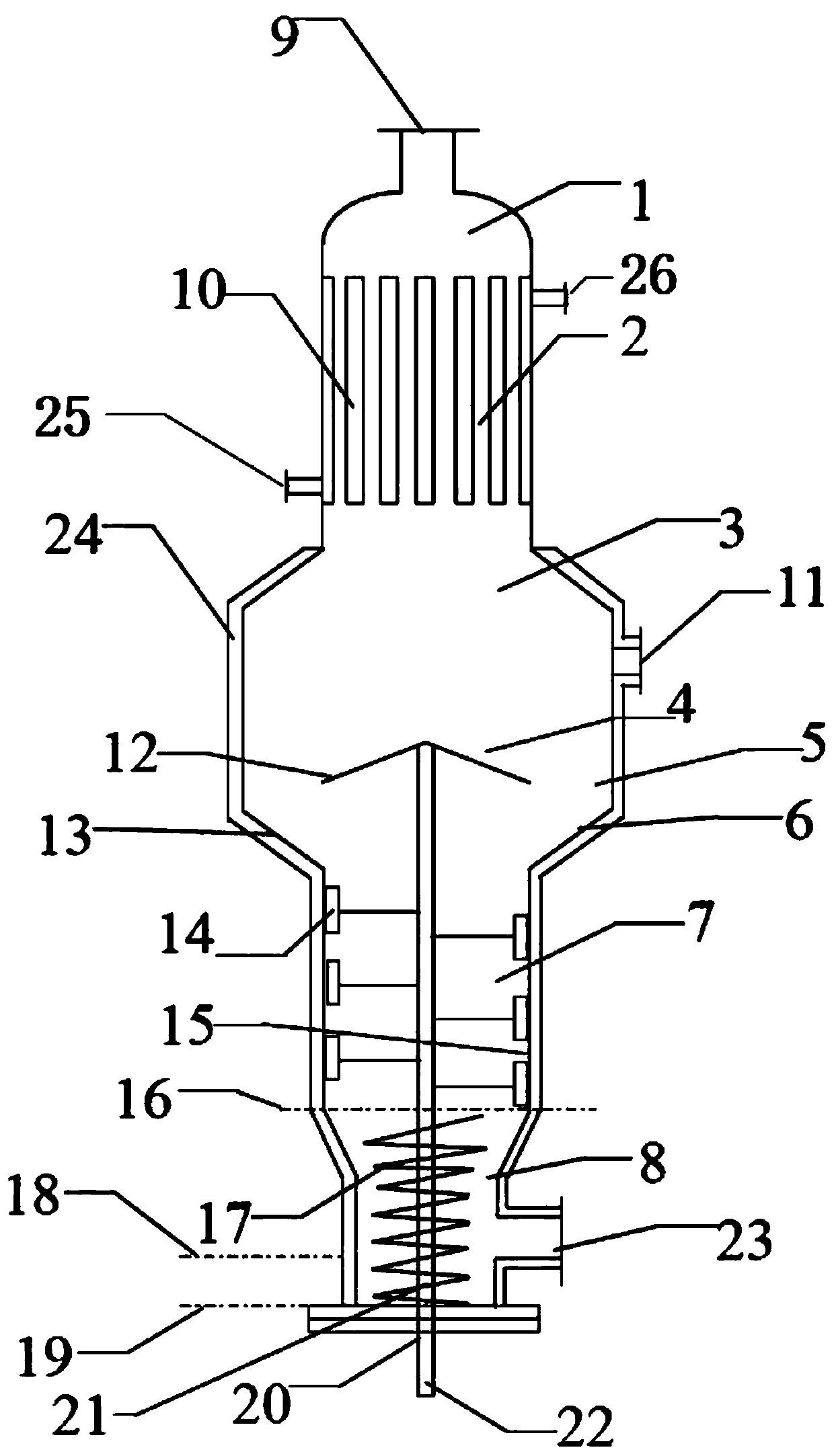

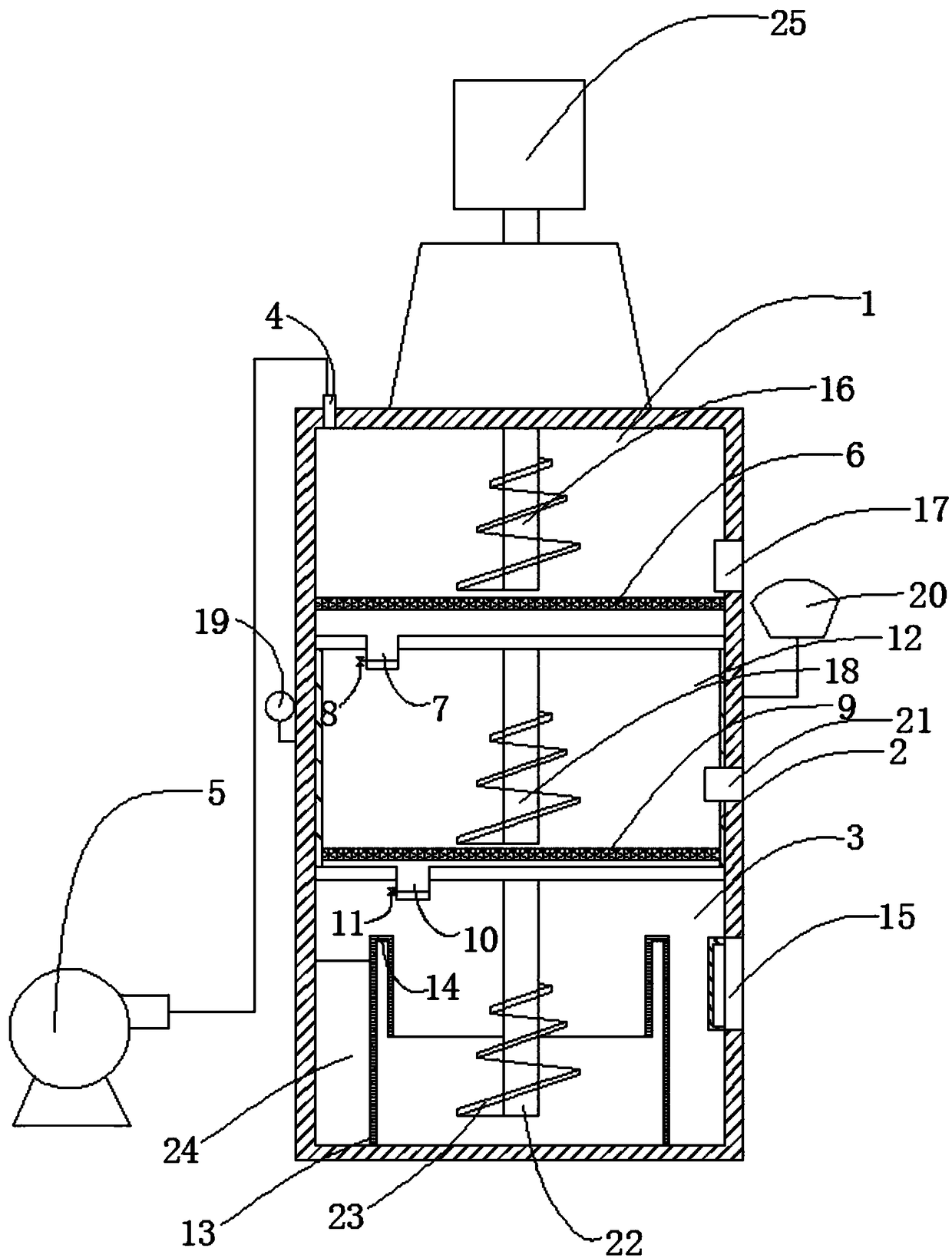

Self-circulating crystallizer and multistage continuous crystallization method

ActiveCN108939599AReduce the chance of collision nucleationStable particle sizeEvaporator accessoriesSolution crystallizationGranularityEvaporation

The invention relates to a self-circulating crystallizer and a multistage continuous crystallization method. The crystallizer sequentially comprises a kettle head, an upper cylinder body, a middle cylinder body and a bottom hole-shrinkage cylinder body with a W-shaped bottom from top to bottom, wherein a steam outlet and / or a feeding hole are / is arranged on the kettle head, an annular spraying pipe is arranged at the lower part of the kettle head; a middle straight cylinder section is arranged in the middle cylinder body, a flow guiding cylinder is arranged in the middle straight cylinder section, and a stirrer is arranged in the flow guiding cylinder; the diameter of the middle cylinder body is larger than that of the upper cylinder body, and the diameter of the upper cylinder body is larger than that of the middle cylinder body; and the lower part of the upper cylinder body and the upper part of the middle cylinder body are respectively connected with the circumference of the top ofthe middle straight cylinder section via a hole-shrinkage transition section, and a discharging hole is formed in the W-shaped bottom. The invention provides the method for realizing multistage continuous evaporation, cooling or reaction crystallization through the series connection of the crystallizer, the prepared crystals are large in granularity and uniform in particle size, the problems thatthe product granularity is small, equipment is seriously scaled, a pipeline is blocked, and the like in the continuous crystallization process are improved, and the operation period of the continuouscrystallization process is prolonged.

Owner:TIANJIN UNIV

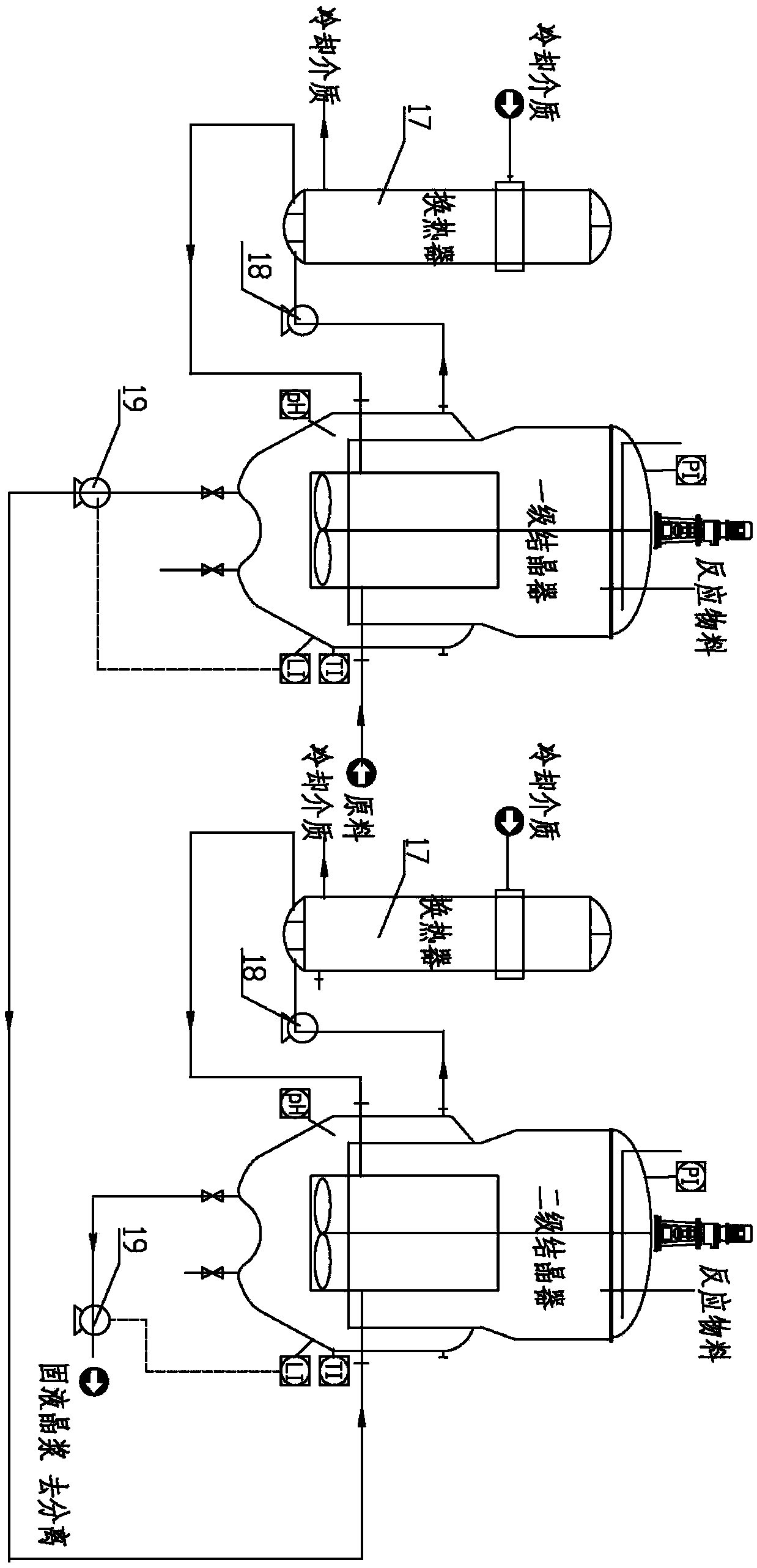

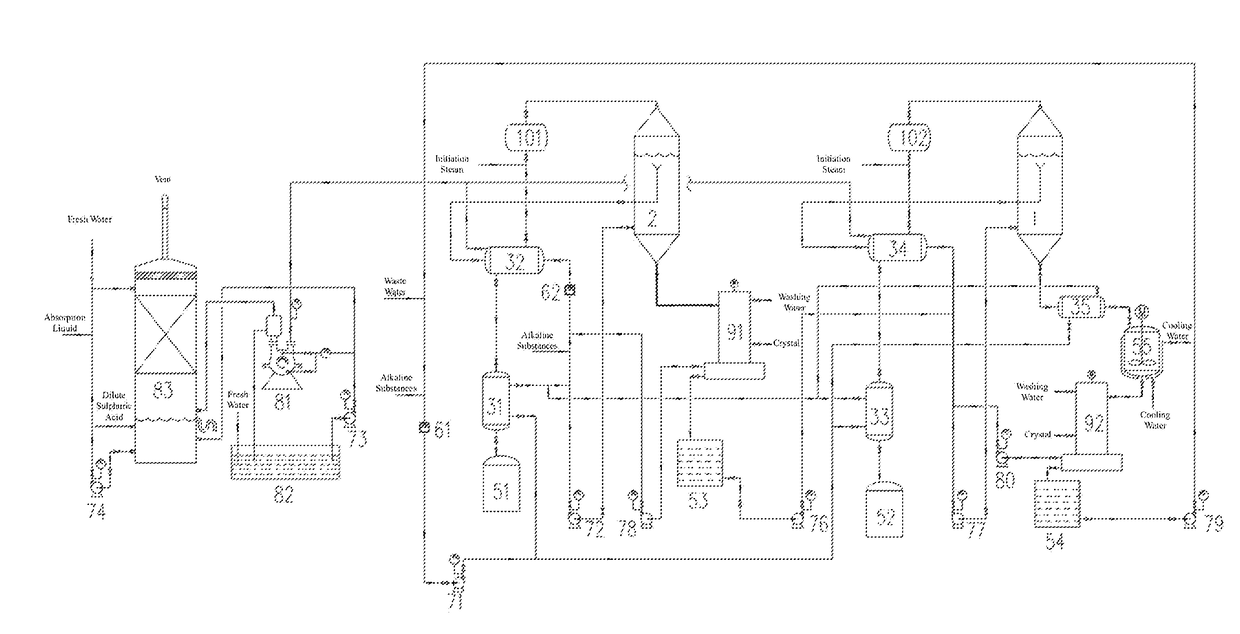

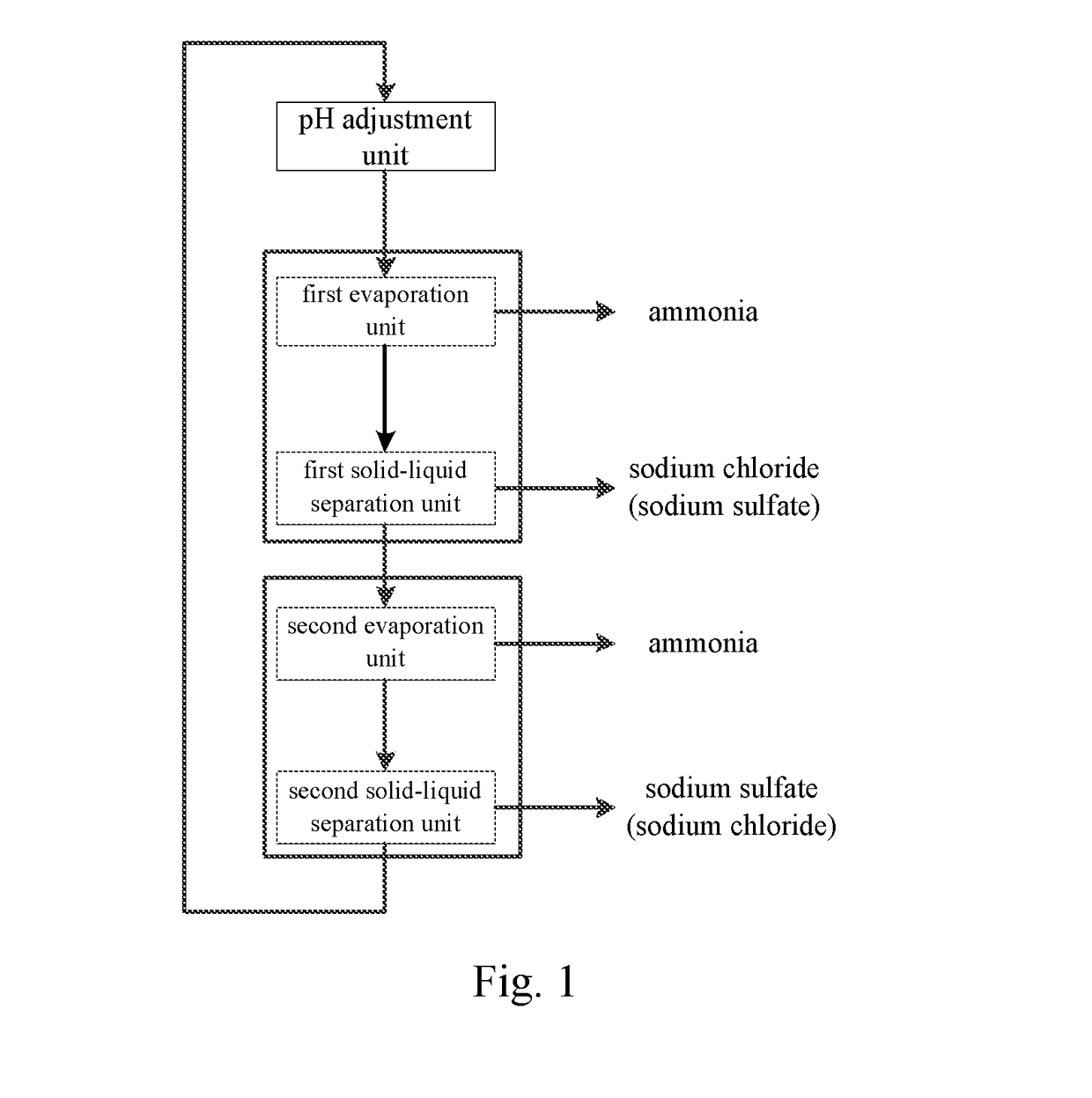

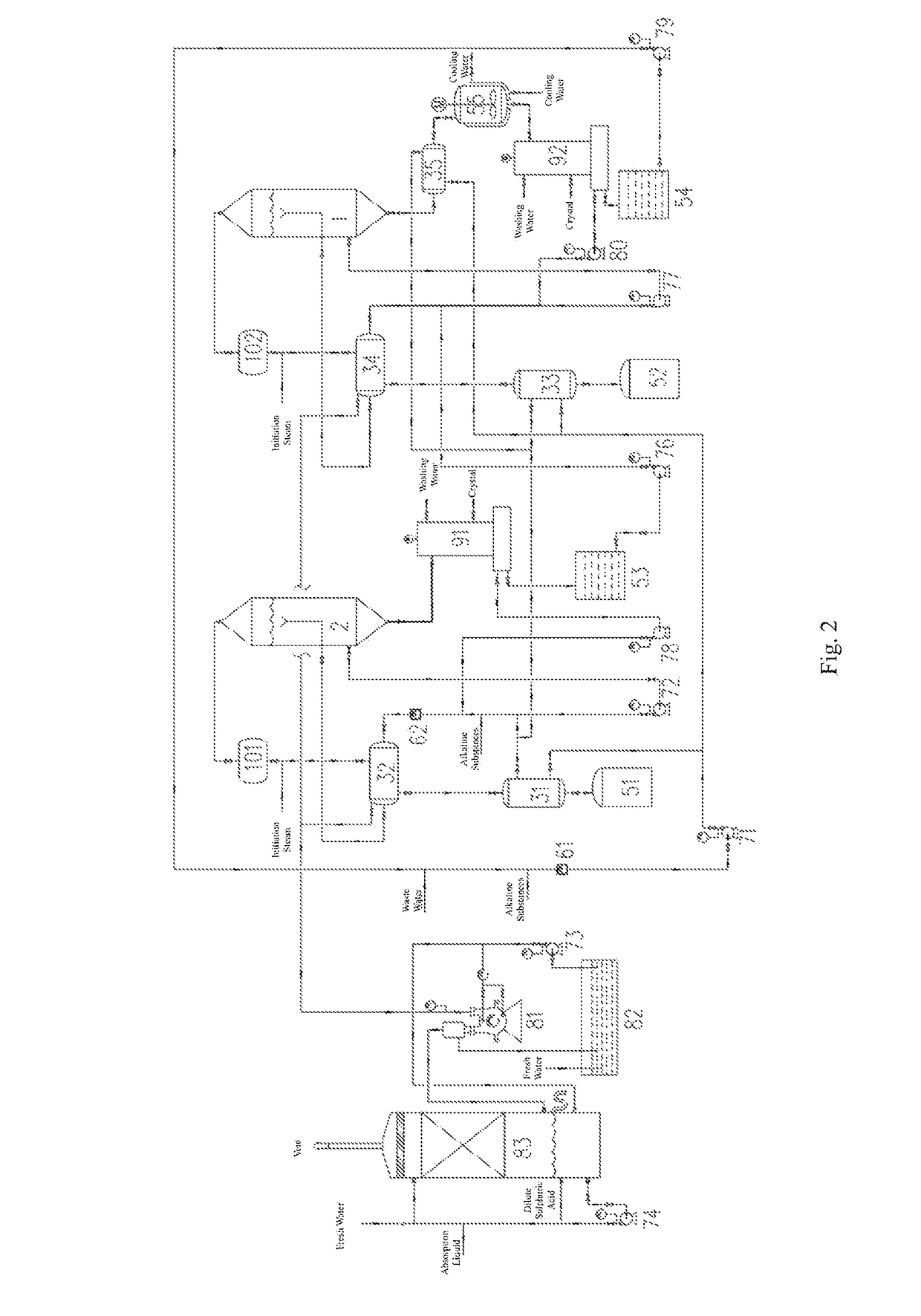

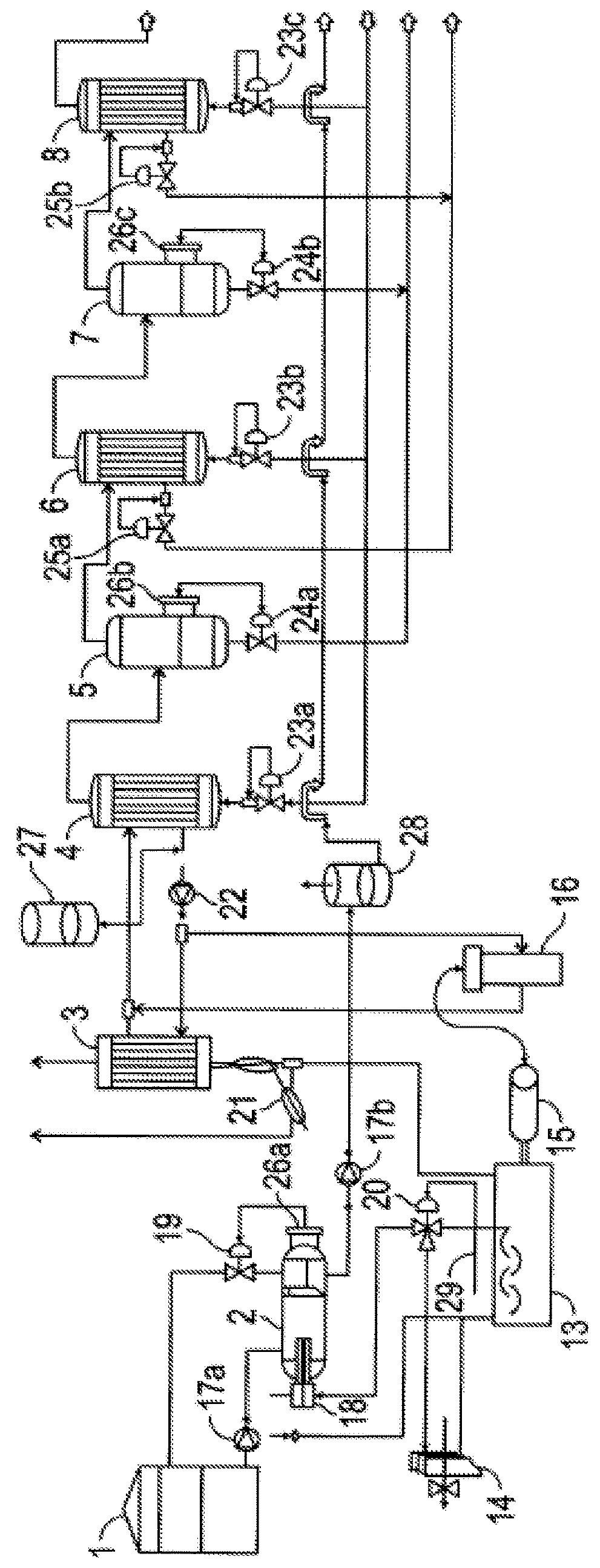

Apparatus and Method for Treating Waste Water Containing Ammonium Salts

ActiveUS20180305221A1Waste of resourceOvercomes drawbackWater treatment parameter controlEvaporation with vapour compressionEvaporationWastewater

The present invention relates to the waste water treatment field, and discloses apparatus and method for treating waste water containing ammonium salts, which contains NH4+, SO42−, Cl−, and Na+. In the method of the present invention, the pH value of the waste water to be treated is adjusted to a specific range in advance; sodium sulfate crystal and relatively concentrated ammonia are obtained by first evaporation, and then sodium chloride crystal and relatively dilute ammonia is obtained by second evaporation; alternatively, sodium chloride crystal and relatively concentrated ammonia is obtained by third evaporation, and then sodium sulfate crystal and relatively dilute ammonia are obtained by fourth evaporation. The method of the present invention can recover ammonia, sodium sulfate, and sodium chloride from the waste water respectively, so that the resources in the waste water can be reused as far as possible.

Owner:CHINA PETROCHEMICAL CORP +1

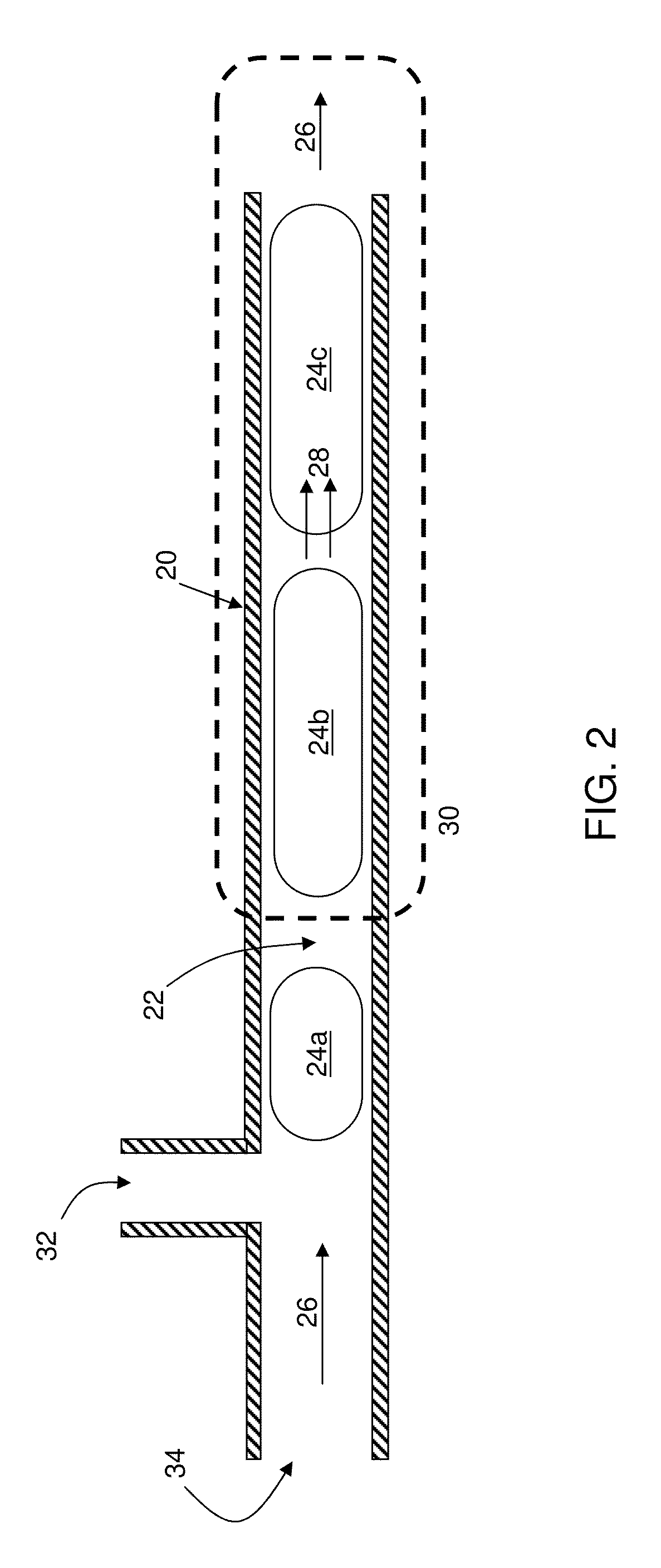

Low energy vacuum distillation method and apparatus

A sub-atmospheric pressure desalinating still employs a closed top, open bottom pipe filled with source water to be distilled, such as seawater, having a height greater than the height of a column of seawater that can be supported by the pressure at the bottom of the tank so that a subatmospheric pressure volume is formed at the top. Water from the source is also pumped into the subatmospheric volume and passed through an evaporator which enlarges its surface volume. A small percentage of the water is vaporized and the balance is cooled to provide the heat of vaporization and falls into the top of the seawater column, creating a downward flow. The vapor is drawn from the vacuum and condensed, preferably in a second subatmospheric volume above a column of fresh water.

Owner:SMART VCR PARTNERSHIP

Wastewater evaporator

ActiveUS9593025B2Increase surface areaSpeed up evaporationWater treatment parameter controlDistillation by vibrationEvaporationWastewater

The wastewater evaporator provides for effluent evaporation in a septic system to eliminate need for a drain field. The evaporator tank contains a plurality of evaporator trays in a vertical array. Solids settle in the septic tank, and liquid effluent flows from the septic tank to the evaporator tank and cascades sequentially from the uppermost to the lowermost tray. The multiple trays increase the surface area of liquid contained therein, thereby greatly enhancing evaporation. An above-surface air pump and vent may be provided for air flow through the evaporator tank. An ultrasonic generator may be installed in each tray to increase the surface area of the effluent to enhance evaporation. An additional intermediate pump tank may be provided between the septic tank and the evaporator tank to control effluent flow and delivery to the evaporator tank. A sump pump in the pump tank periodically delivers effluent to the evaporator tank.

Owner:CLARK GRETCHEN B +1

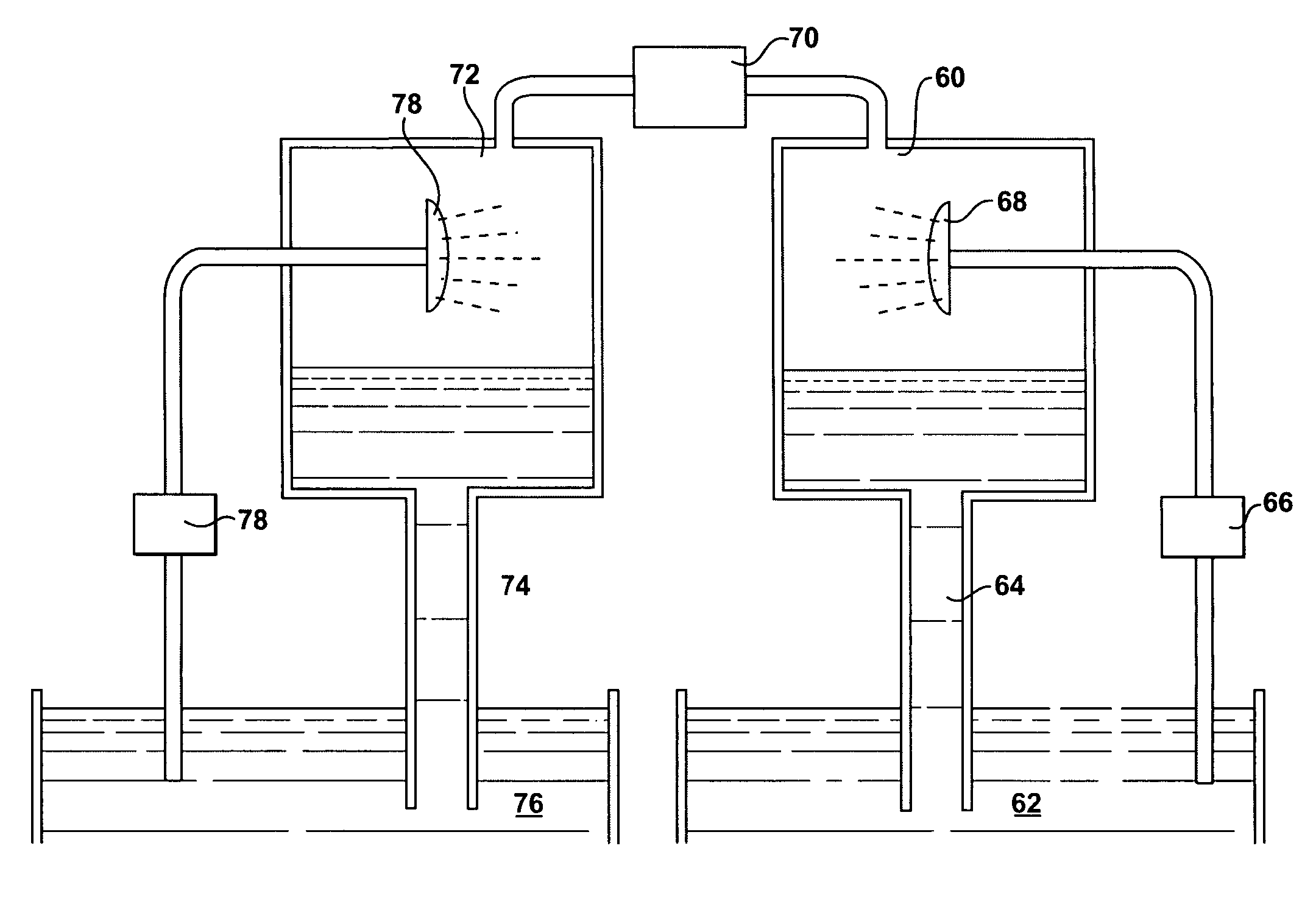

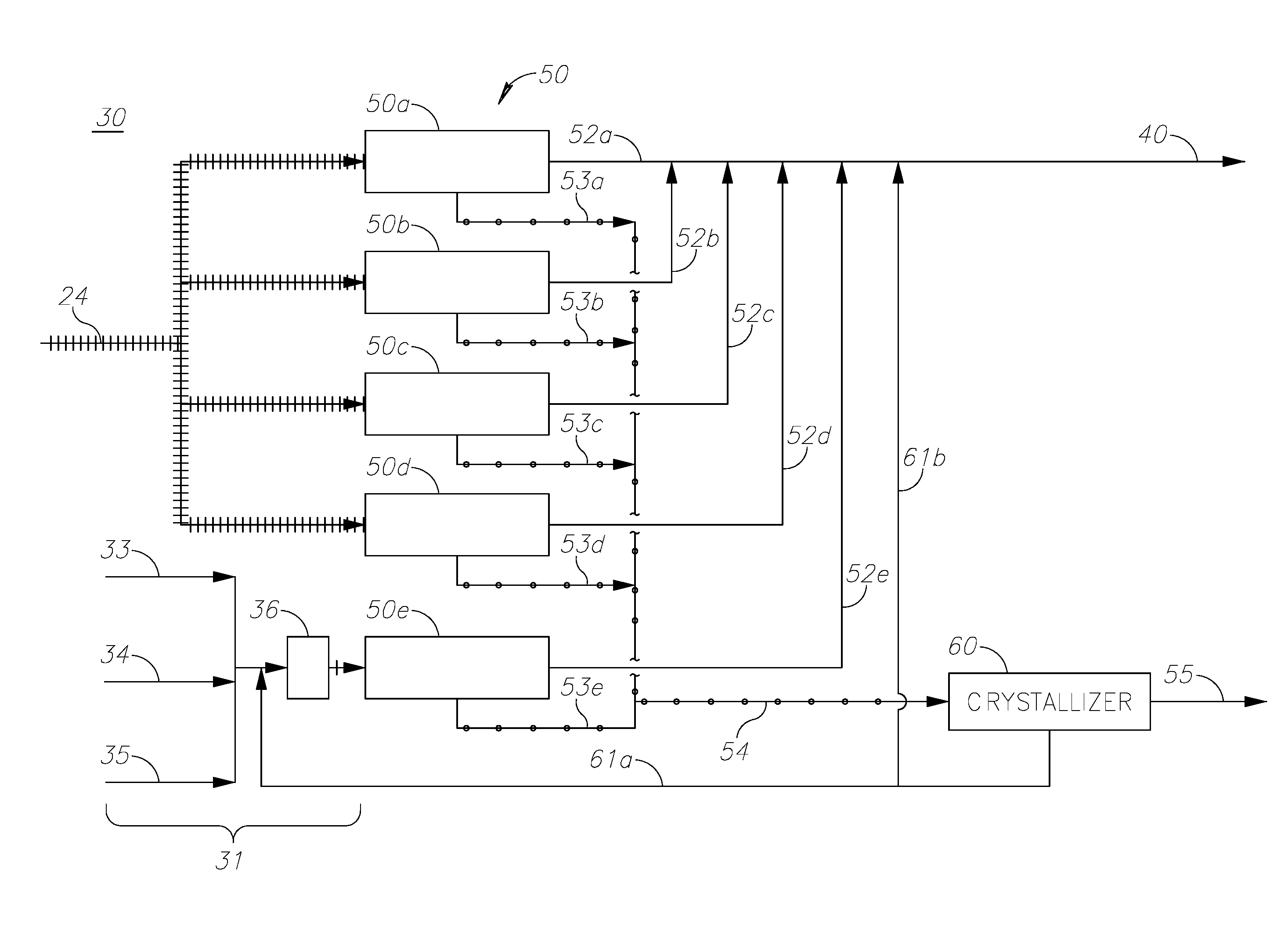

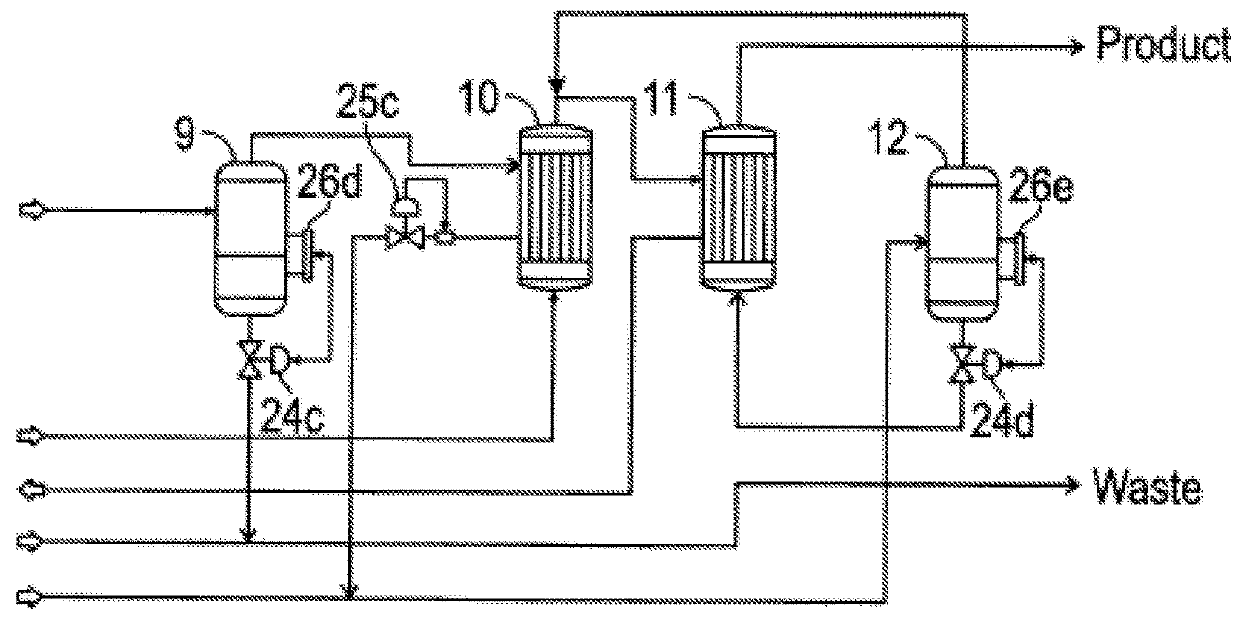

Evaporator array for a water treatment system

ActiveUS9499413B2Waste water treatment from quariesWater treatment parameter controlWater treatment systemEngineering

An evaporator array for a water treatment system, the evaporator array comprising a produced water feed and a first evaporator to receive produced water from the produced water feed, a makeup water feed and a second evaporator to receive makeup water from the makeup water feed, an output feed to receive distillate from the first evaporator and the second evaporator, and a blowdown feed to receive blowdown from the first evaporator and the second evaporator, wherein the first evaporator and the second evaporator each have a working pH, the working pH of the first evaporator being higher than that of the second evaporator.

Owner:I D E PROJECTS LTD

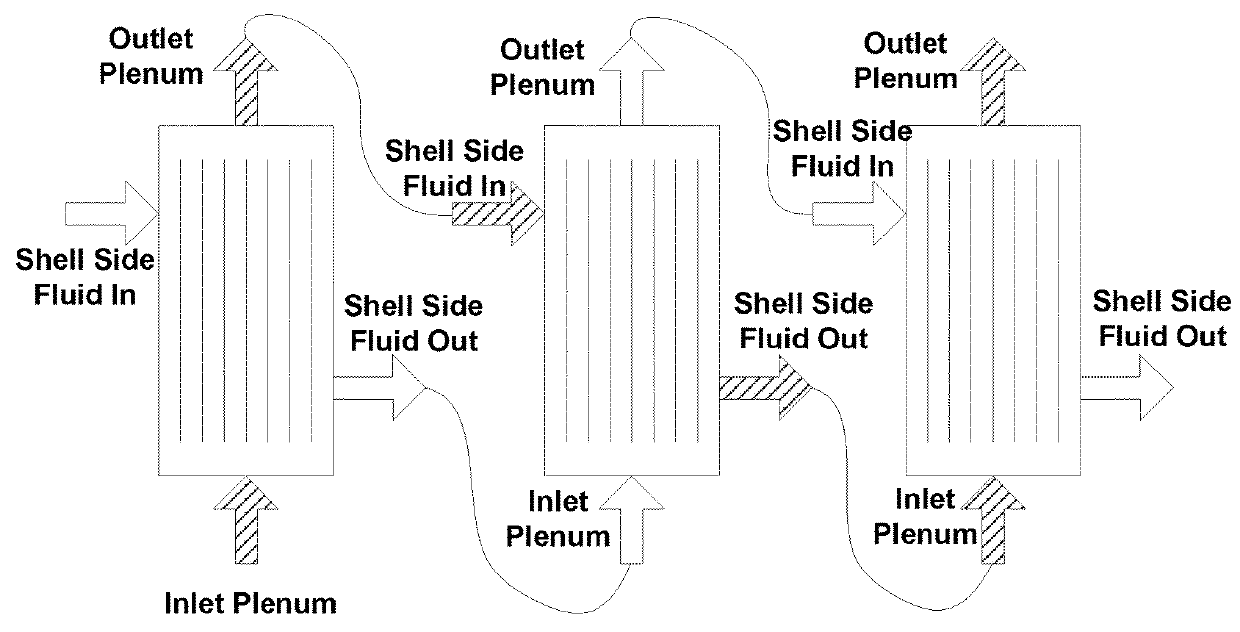

Production Water Desalinization Via a Reciprocal Heat Transfer and Recovery

ActiveUS20180272246A1Waste water treatment from quariesFatty/oily/floating substances removal devicesSaline waterParallel product

A system for brine water desalinization includes a first heat exchanger having an inlet plenum and an outlet plenum for a first fluid comprising a concentrate in a liquid. The first heat exchanger includes a shell side fluid inlet and a shell side fluid outlet for a second fluid comprising a higher concentrated liquid than the first fluid. The system also comprises pipes configured to direct the first fluid from the outlet plenum to a shell side fluid inlet of a second heat exchanger and to direct the second fluid from the shell side fluid outlet to an inlet plenum of the second heat exchanger. The system further includes pipes configured to produce desalinized water by a serial distillation of multiple steams from an nth number of heat exchangers into respective distillates thereof and a parallel product of brine waste thereof from the heat exchangers.

Owner:POLNISCH FRED

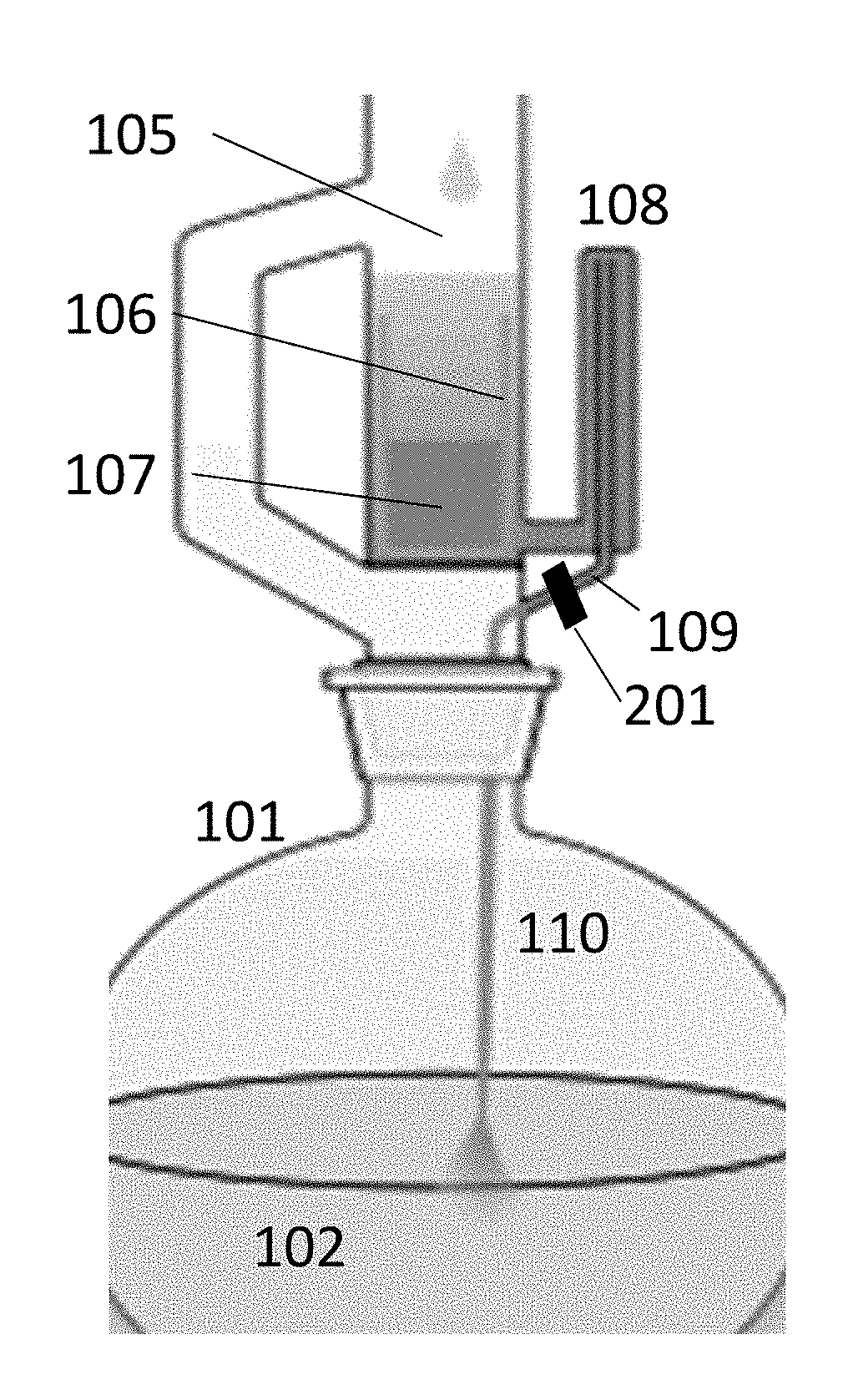

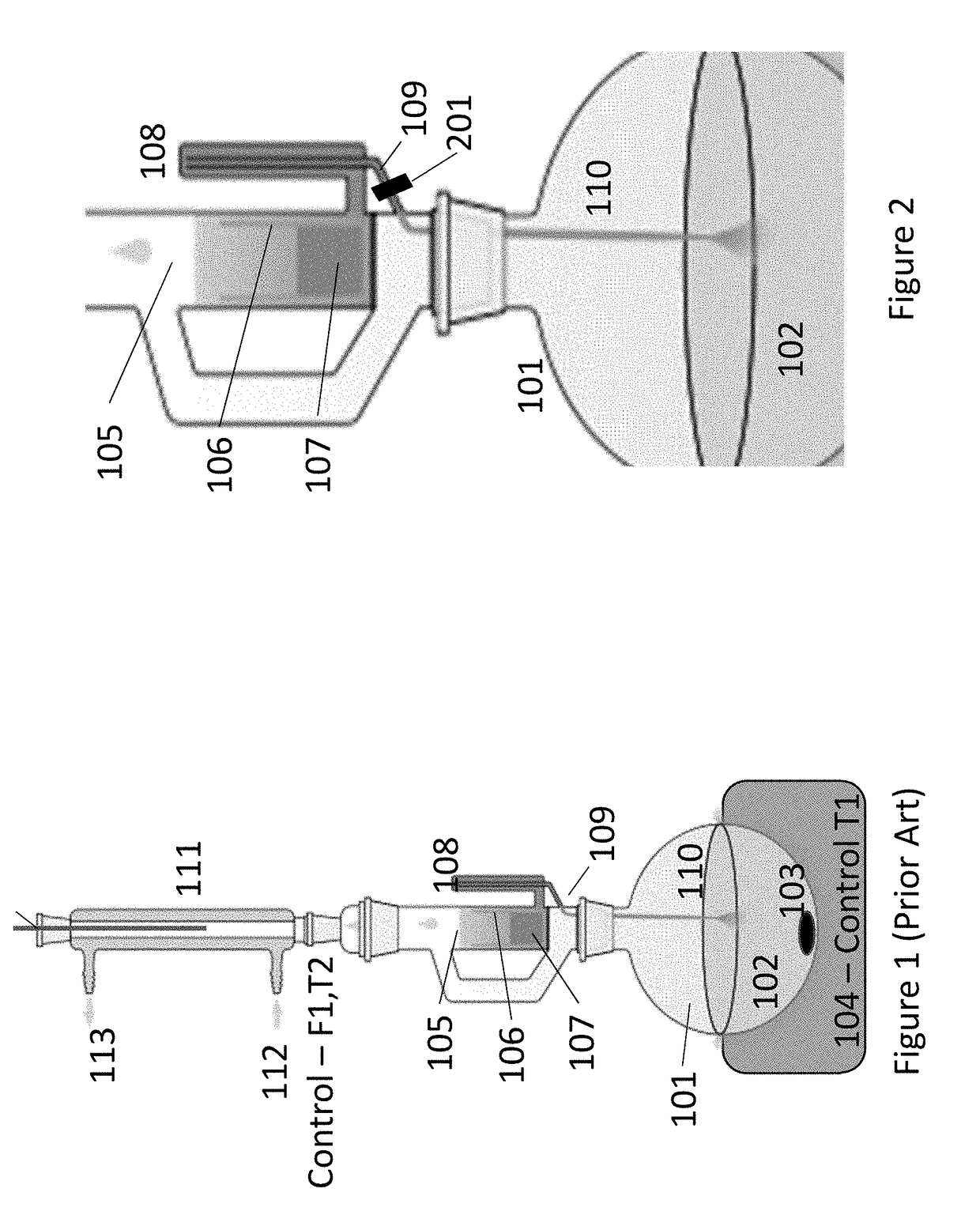

Device, system and method for in-situ optical monitoring and control of extraction and purification of plant materials

ActiveUS20180306708A1Distillation regulation/controlPolarisation-affecting propertiesPhotoluminescenceTurbidity

In-situ optical spectroscopic monitoring, characterization and feedback control of extraction and purification processes of compounds such as oils, alkaloids, flavonoids, terpenes and cannabinoids derived from plant material are described. Liquids from an extraction or purification process flow down an optically transparent tube, such as one made of glass. An in-situ optical monitoring assembly is configured to be mounted onto the tube to measure optical properties of the liquid extract or liquid condensate as it flows in the tube. Optical properties of the flowing liquid may include optical transmittance, reflectance, photoluminescence, scattering, absorbance, turbidity, nephelometry, polarimetry and colorimetry. The output of the optical monitoring assembly can be used to display spectral and other about the flowing liquid, set alarms to notify an operator of a predetermined condition such as a set point, and used to control extraction or purification process.

Owner:AROMETRIX INC

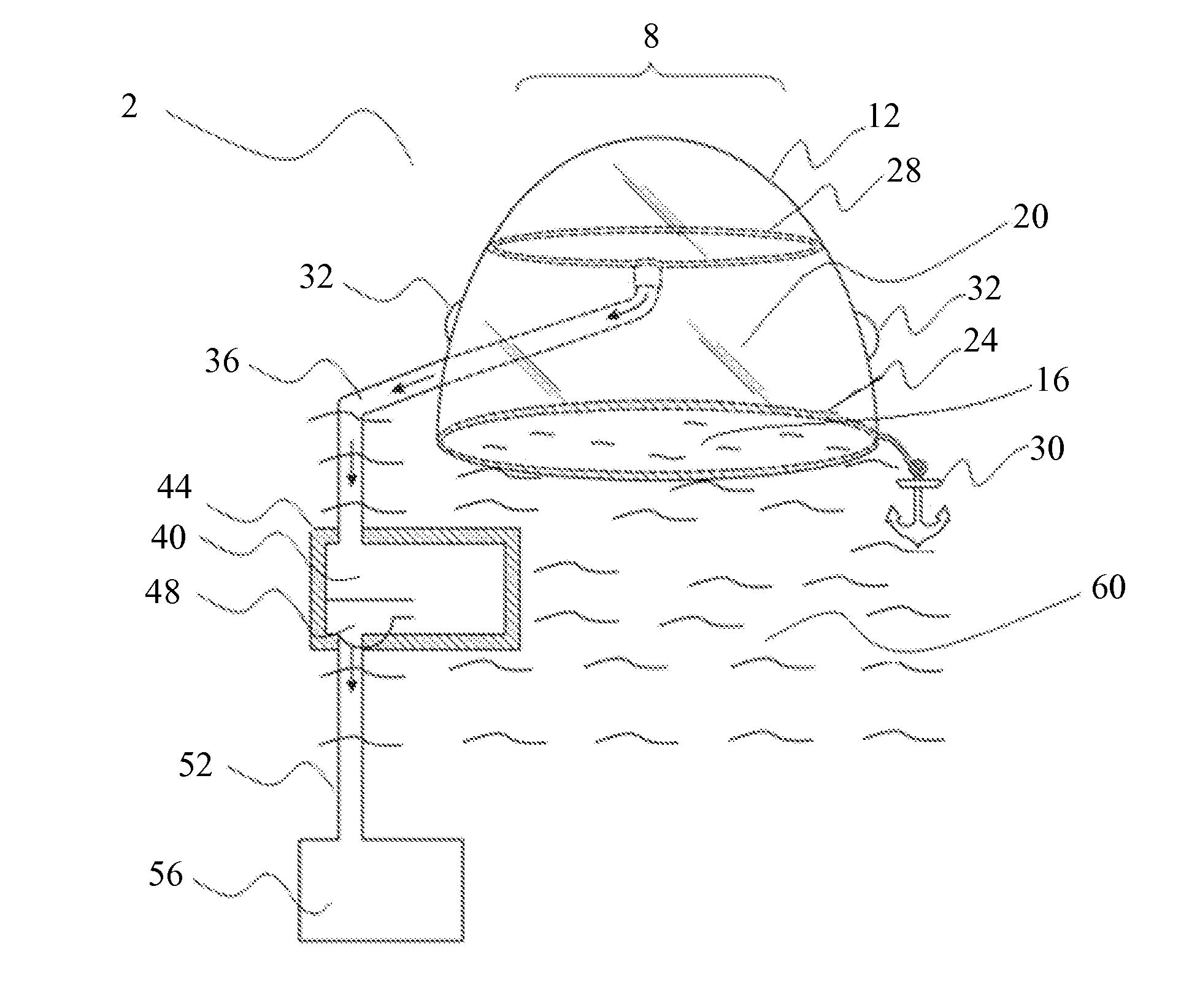

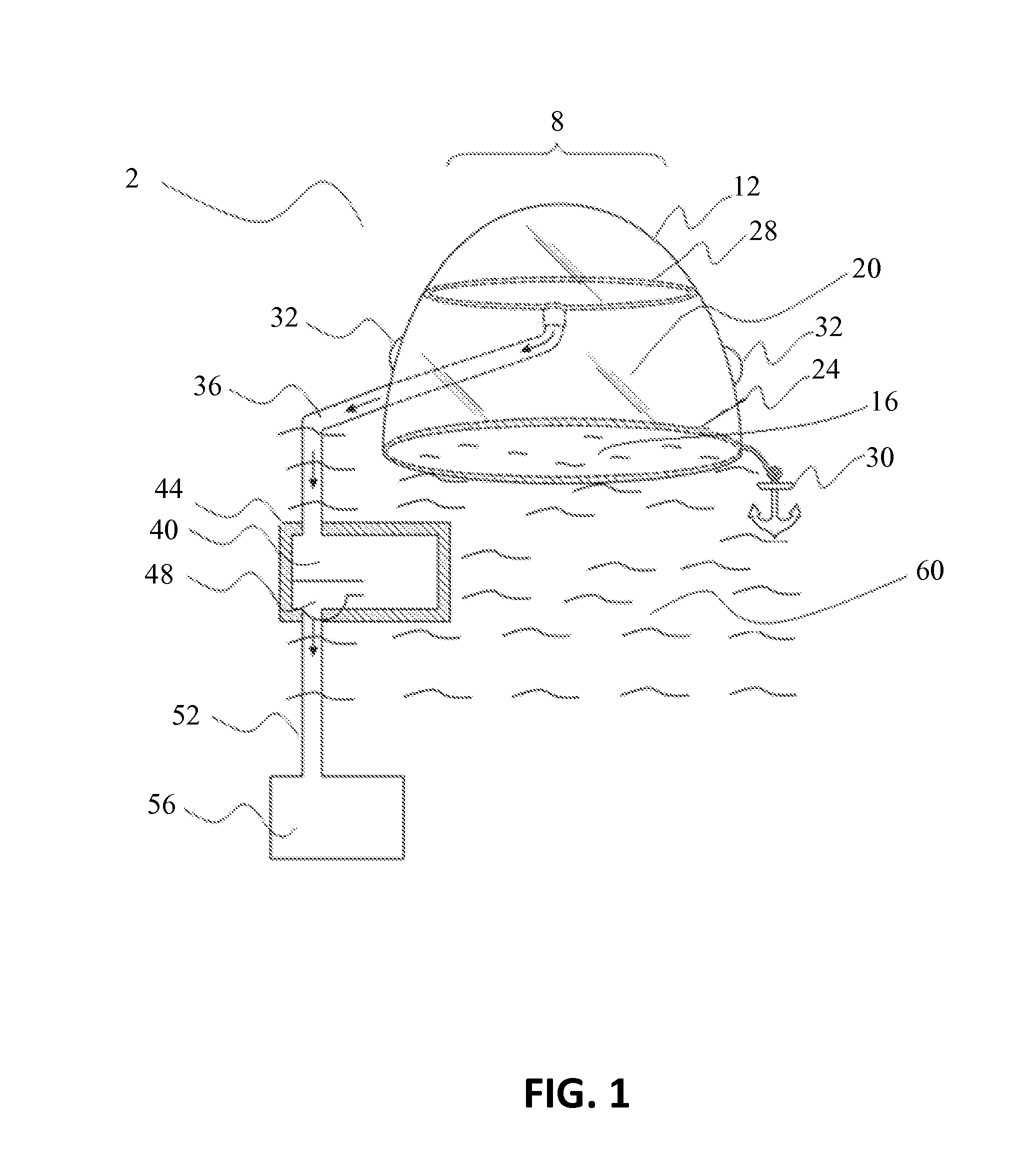

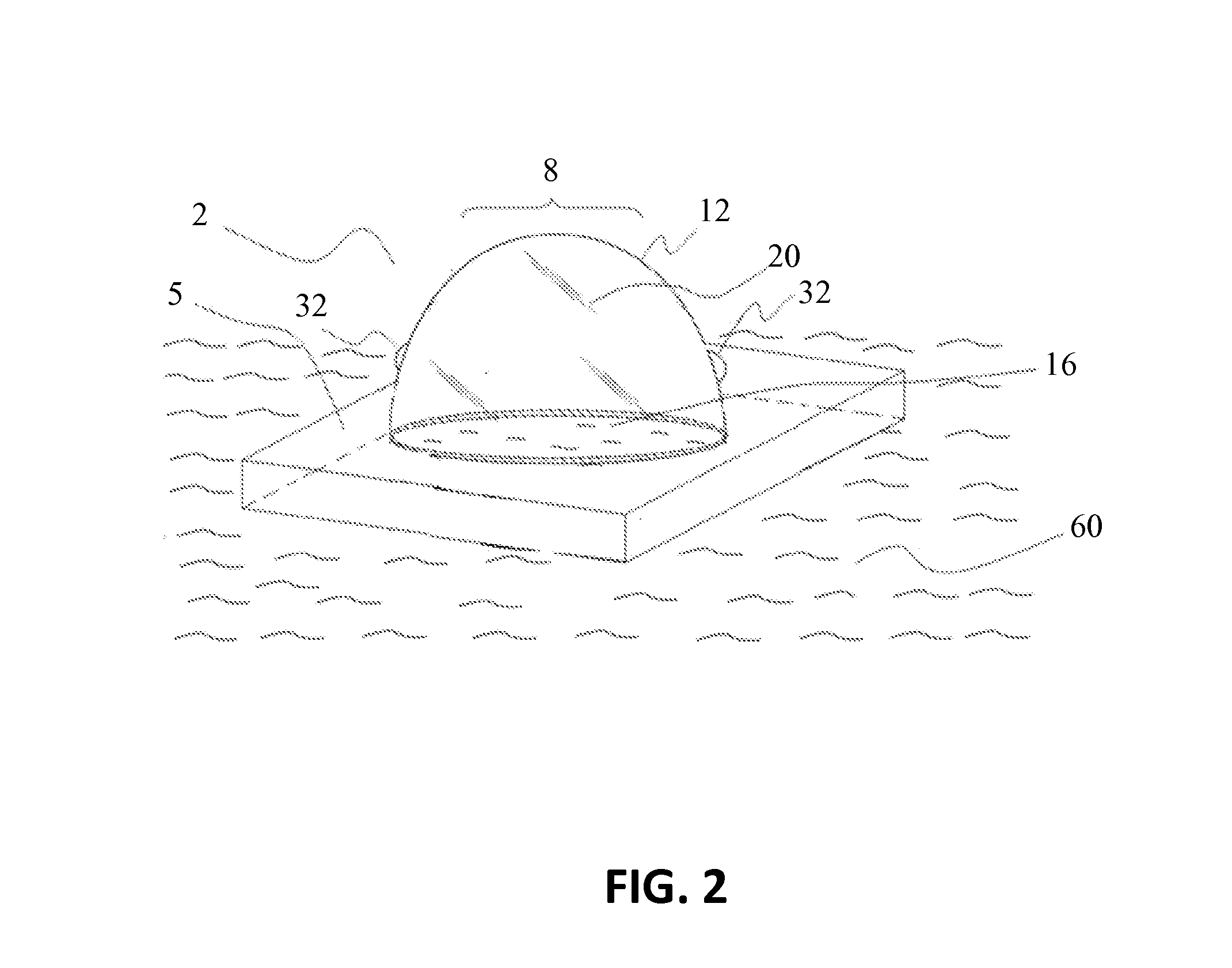

Solar Still System And Related Water Transportation Apparatus

There is provided a water transportation system comprising evaporation zones for converting water into water vapour; condensation zones for condensing the water vapour into condensed water, the condensation zones being in fluid communication with the evaporation zones; water vapour conduits adapted to enable the fluid communication of the water vapour between the evaporation zones and the condensation zones; condensed water conduits adapted to enable the fluid communication of condensed water between the condensation zones and the evaporation zones; wherein the evaporation zones and the condensation zones alternate in position along a water transportation path between a water source site and a water destination site for enabling the transport of water from the water source site to the water destination site through alternating processes of evaporation-condensation and condensation-evaporation of the water.

Owner:ALKHAZRAJI SAEED ALHASSAN

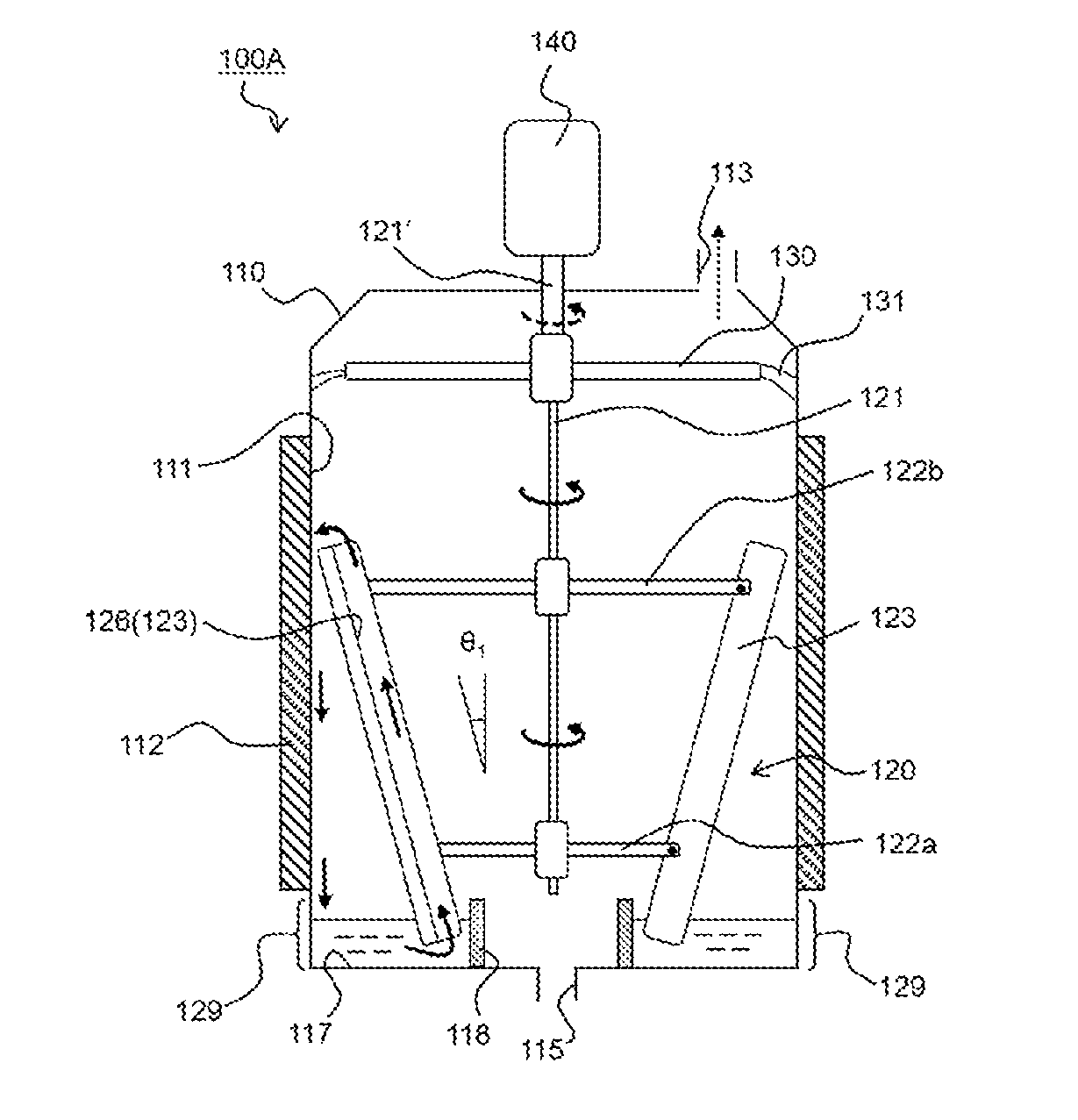

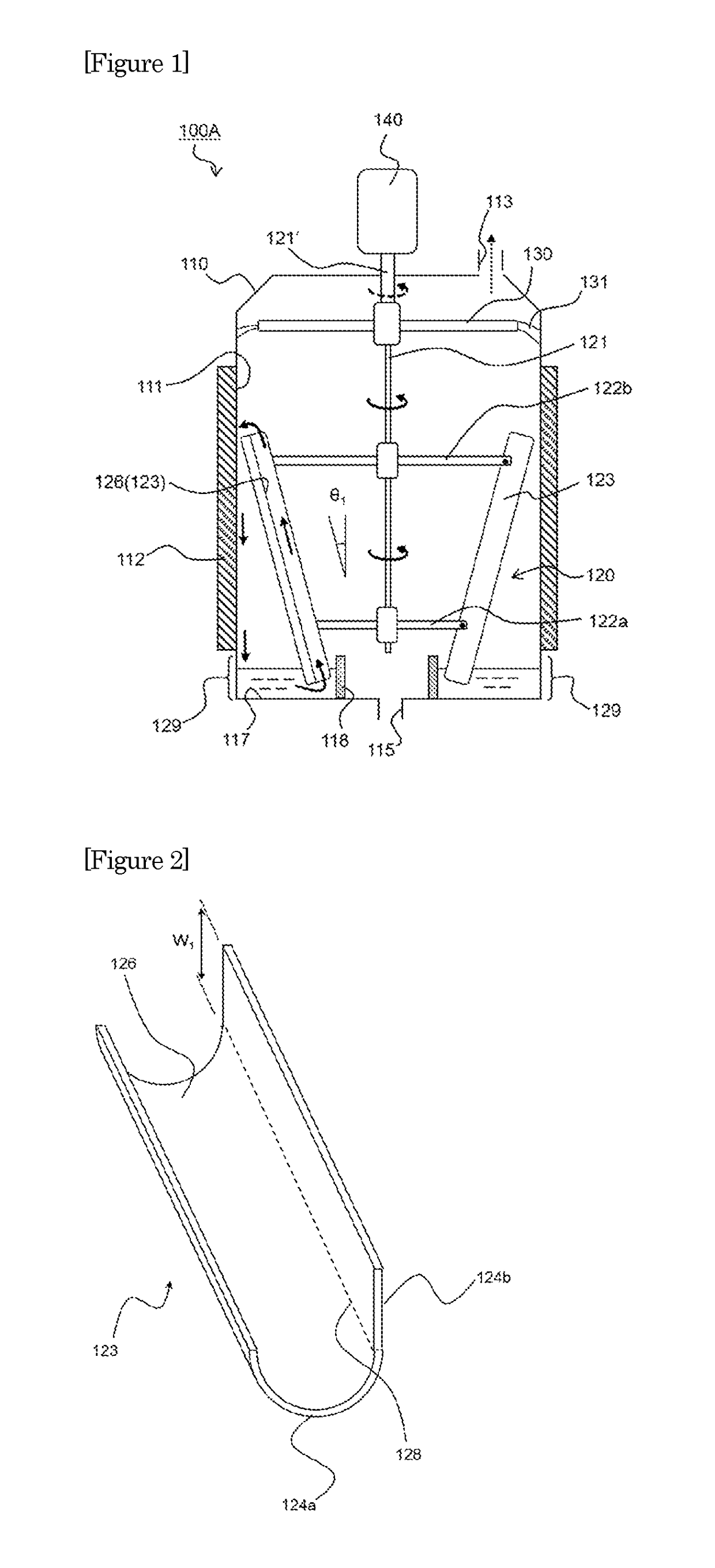

Evaporation device

ActiveUS20180015386A1Efficient evaporationAvoid possibilityRotary stirring mixersTransportation and packagingEvaporationEngineering

An evaporation device including an agitation vessel to which raw material liquid is supplied. The agitation vessel has a volatile component outlet and a concentrate outlet, a jacket provided on an outer circumference and configured to heat an inner wall, and a liquid-distributing portion configured to cause the raw material liquid to flow down the inner wall. The agitation vessel includes storage portion surrounded by a bottom, the inner wall, and a partition wall portion configured to temporarily store the raw material liquid that flows down, the liquid-distributing portion is constituted by a rotating shaft and at least one channel part having a flow passage which, as the rotating shaft rotates, the raw material liquid temporarily stored in the storage portion flows upward from a lower side of the agitation vessel. The channel part is mounted to the rotating shaft, and the concentrate outlet is provided in the bottom.

Owner:KANSAI CHEM ENG CO LTD

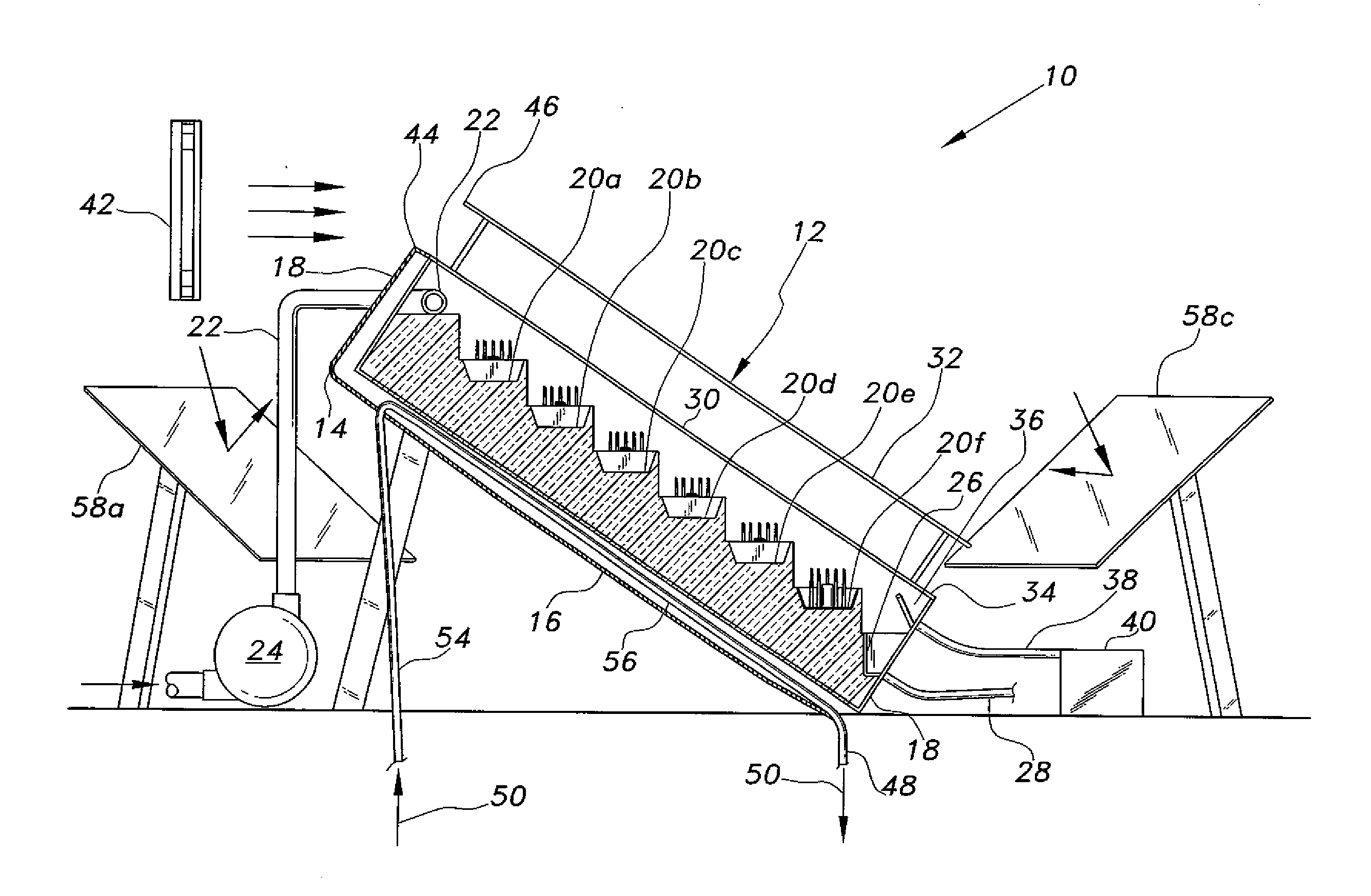

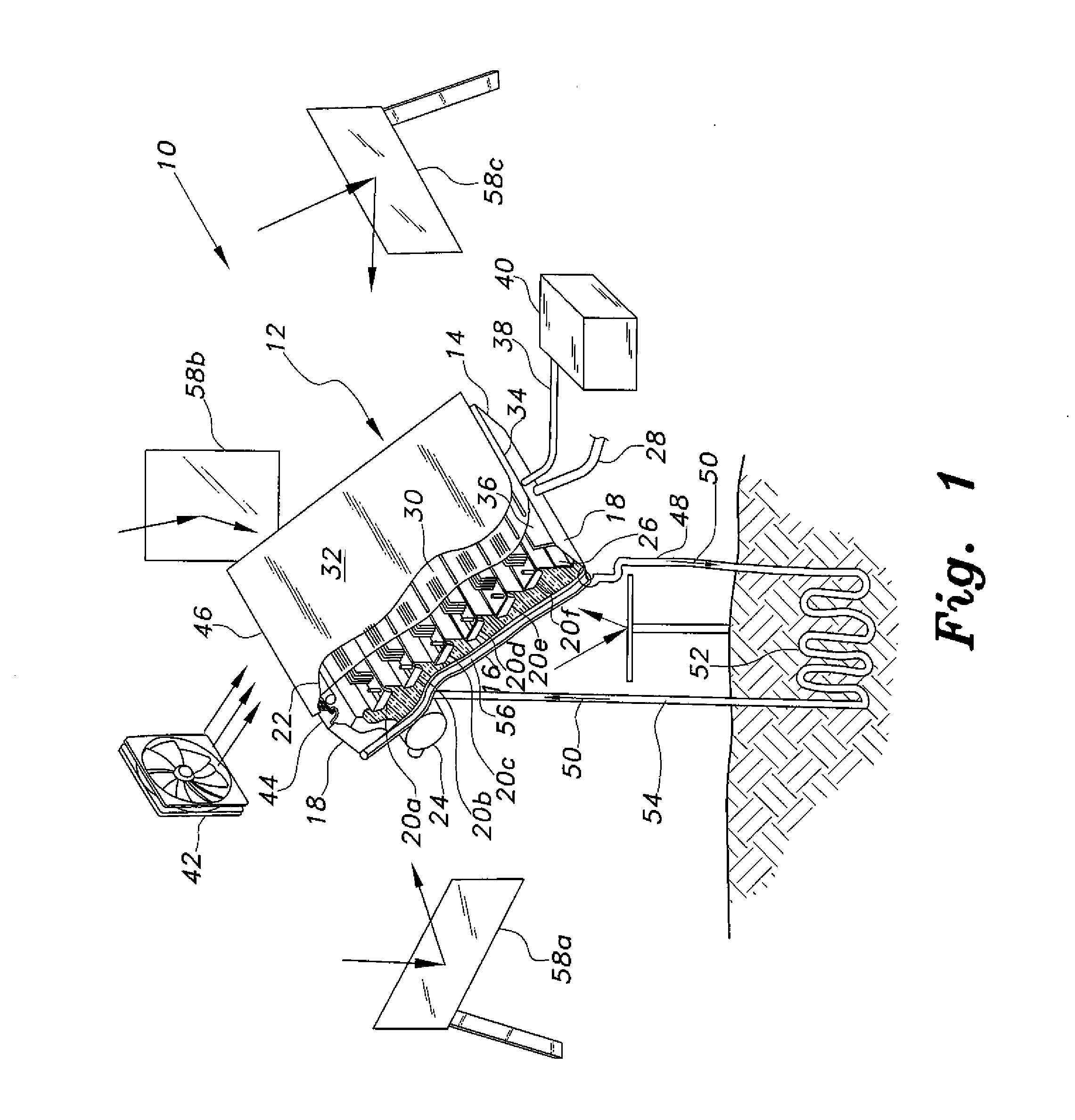

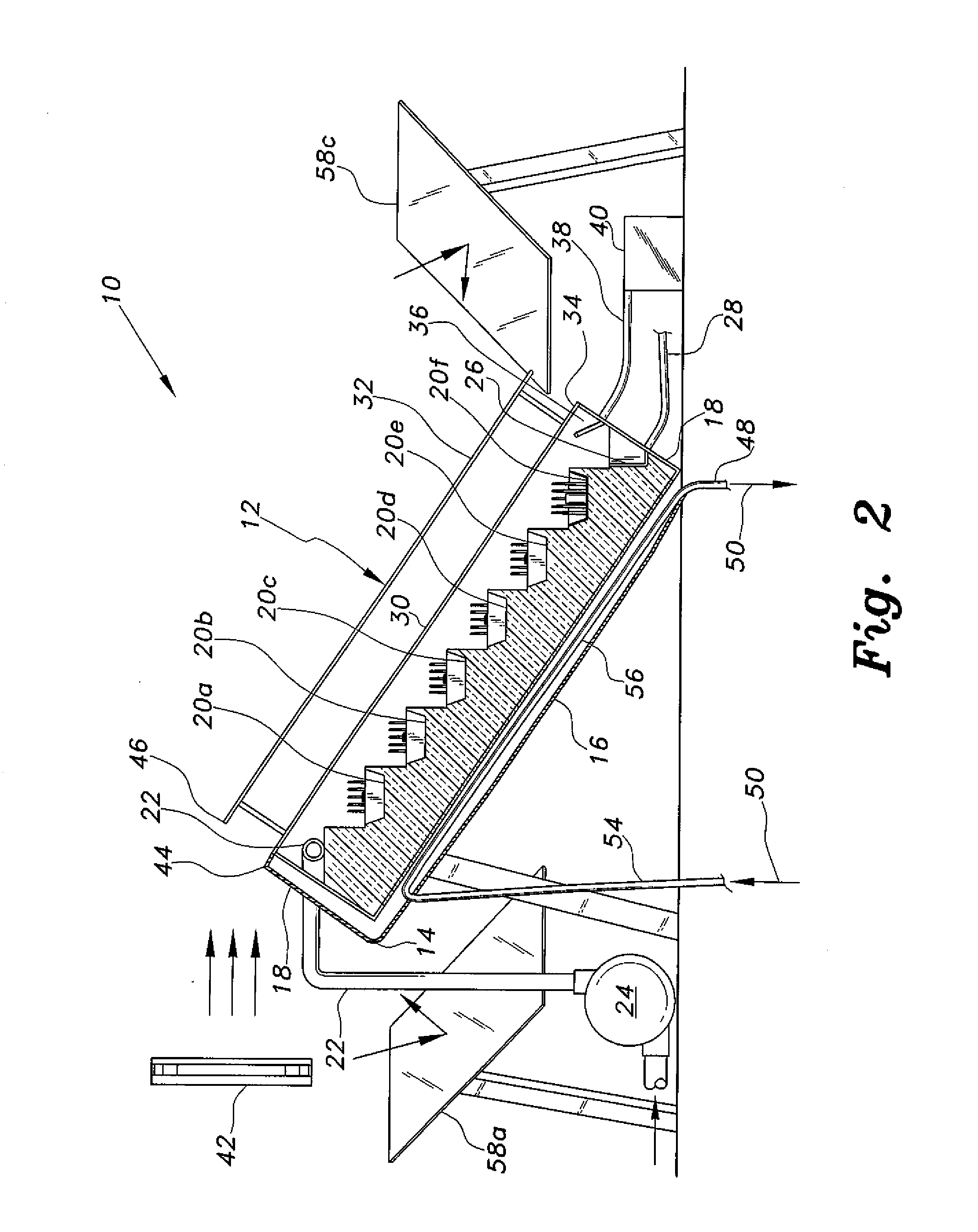

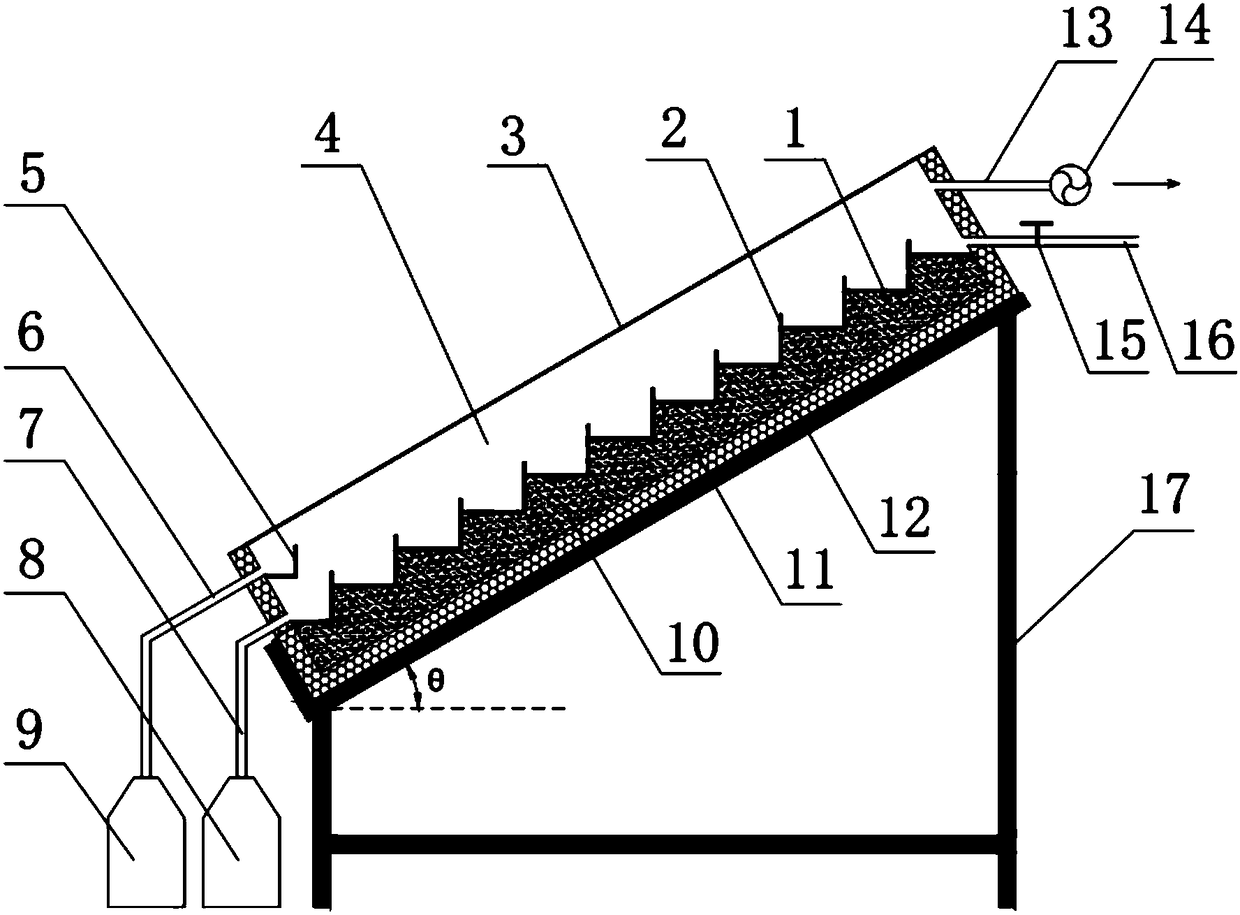

Water desalination system using geothermal energy

ActiveUS20150083575A1Speed up evaporationReduce dissipationGeneral water supply conservationOther heat production devicesWater desalinationGeothermal heating

The water desalination system using geothermal energy includes a plurality of stepped evaporation trays. Salt water flows into the uppermost tray and cascades to each successively lower tray to overflow from the lowermost tray when all trays are full. Two sloped glass panels pass solar energy therethrough to heat the water. Condensation collects on the inner panel and runs down the panel to collect in a trough at the lower edge. The desalinated water then flows to a collection tank. Additional heat energy is provided by a working fluid (e.g., air) that is pumped to subterranean levels where significant geothermal heat is produced. The heated air is then circulated around the evaporation trays to enhance evaporation. The required energy for the operation of the system may be provided by solar cells and wind energy. Mirrors and functionally graded material further increase the efficiency of the desalination system.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Low energy vacuum distillation method and apparatus

InactiveUS20050178648A1Lower initial costMaintenance freeGeneral water supply conservationAuxillariesWater sourceEngineering

A sub-atmospheric pressure desalinating still employs a closed top, open bottom pipe filled with source water to be distilled, such as seawater, having a height greater than the height of a column of seawater that can be supported by the pressure at the bottom of the tank so that a subatmospheric pressure volume is formed at the top. Water from the source is also pumped into the subatmospheric volume and passed through an evaporator which enlarges its surface volume. A small percentage of the water is vaporized and the balance is cooled to provide the heat of vaporization and falls into the top of the seawater column, creating a downward flow. The vapor is drawn from the vacuum and condensed, preferably in a second subatmospheric volume above a column of fresh water.

Owner:SMART VCR PARTNERSHIP

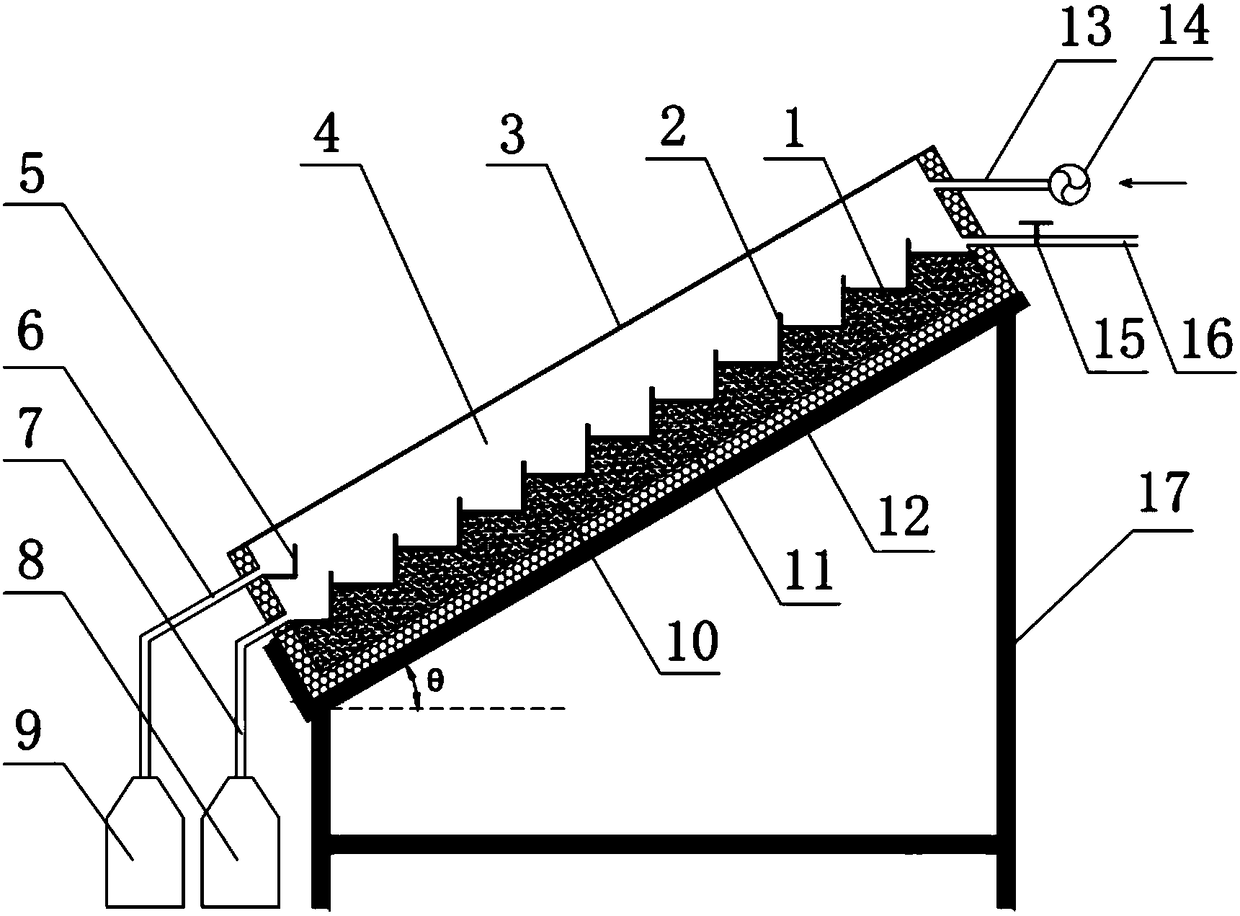

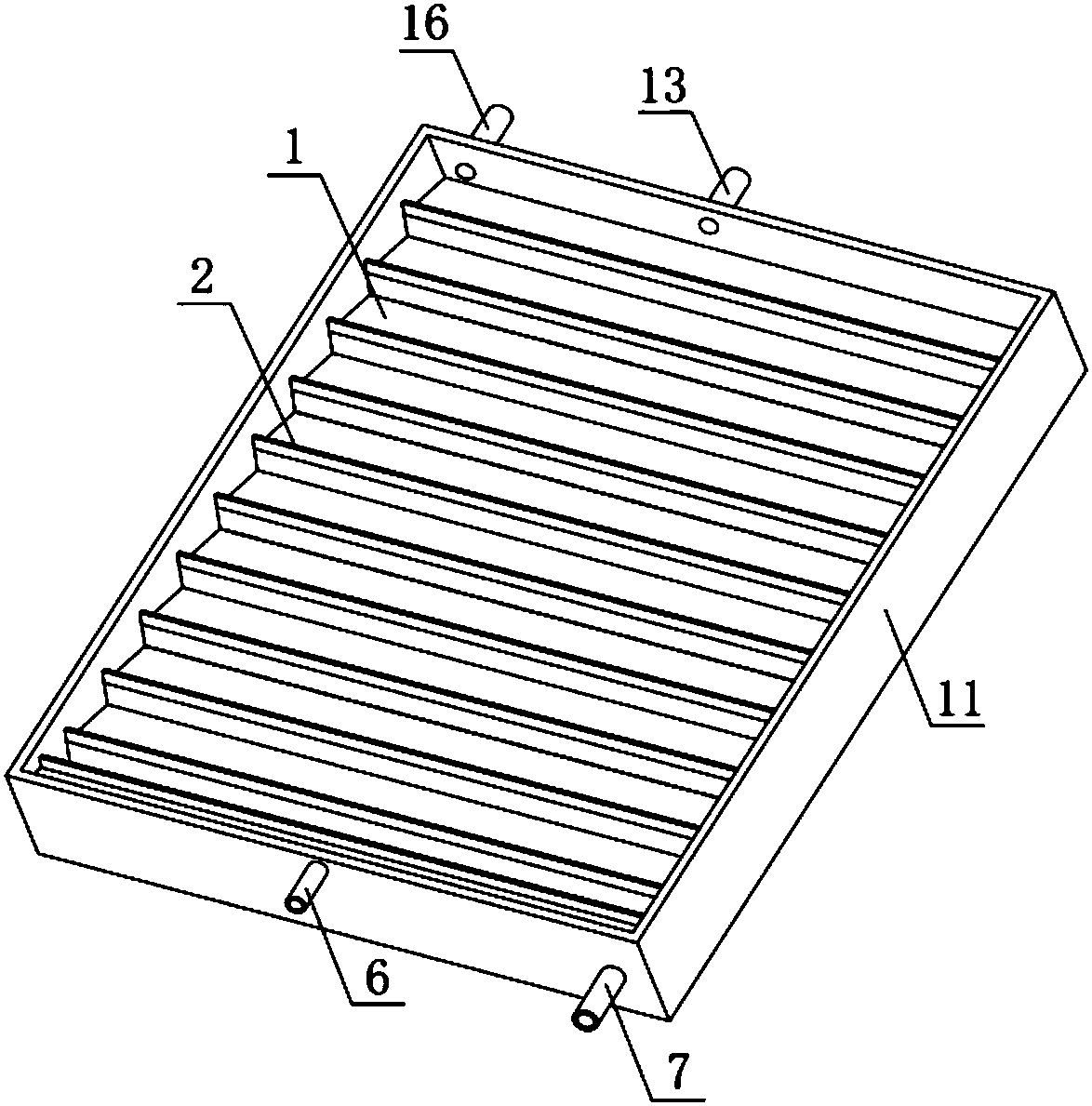

Solar energy biogas slurry evaporation and concentration device

PendingCN108328685AImprove concentration efficiencyIncrease heat absorption areaGeneral water supply conservationEvaporator accessoriesDistillationEvaporation

The invention relates to a solar energy biogas slurry evaporation and concentration device, which comprises a heat collecting plate, a transparent cover plate, a distillation device case, a distillation chamber, a distillation liquid collecting groove, a distillation liquid recovery pool, a concentration liquid recovery pool and the like, wherein the heat collection plate is arranged in the distillation device case; a water baffle plate is arranged at the edge of each layer of heat collection plate; the length of the water baffle plate is identical to the length of the heat collection plate; the biogas slurry flows in a direct flow mode; or the length of the water baffle plate is smaller than the length of the heat collection plate, and the water baffle plates are in staggered arrangement;the biogas slurry flows in an S shape; the transparent cover plate is arranged at the upper part of the distillation device case; the distillation chamber is arranged between the transparent cover plate and the heat collection plate; the upper end of the distillation chamber is connected with a feeding pipe and an air inlet / exhaust pipe; the lower end of the distillation chamber is connected withthe distillation liquid discharge pipe and the concentration liquid discharge pipe; the air inlet / exhaust pipe is connected with a fan; the distillation liquid collection groove is fixedly arranged in the distillation case; the distillation liquid discharge pipe and the distillation liquid recovery pool are connected; the concentration liquid recovery pool is connected with the heat collection plate; paraffin is arranged in the lower part of the heat collection plate; a heat insulation material is arranged at the periphery and the bottom of the distillation device case; the integral device ispositioned on a reverse trapezoidal support frame.

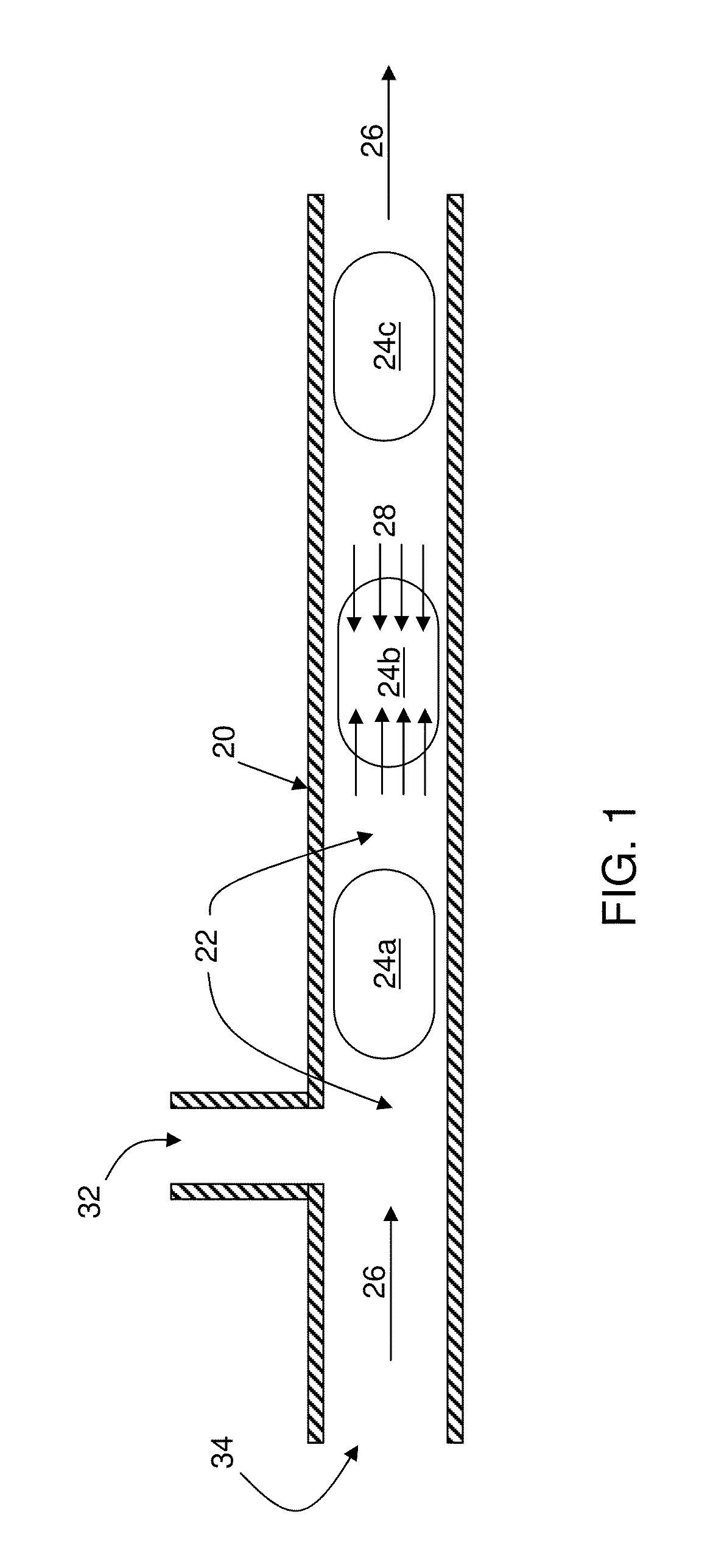

Small-scale method and apparatus for separating mixtures

ActiveUS8435387B2Space heating and ventilationUsing liquid separation agentBoiling pointScale separation

The present invention generally relates to the small-scale separation of a mixture of two or more components with different boiling points into enriched fractions. In some embodiments, a first and second fluid (e.g., a liquid and a gas, a liquid and a liquid, etc.) are passed through a channel. The first fluid may include at least two components, each with a unique boiling point. Upon contacting the first and second fluids within the channel, at least a portion of the most volatile of the components in the first fluid (i.e., the component with the lowest boiling point) may be transferred from the first fluid to the second fluid. In some instances, the transfer of the volatile component(s) from the first fluid to the second fluid may be expedited by heating, in some cases above the boiling point(s) of the component(s) to be transferred from the first fluid to the second fluid. Contact between the first and second fluids may be maintained, for example, via segmented flow, bubbling flow, etc. In some instances, separation between the first and second fluids may be maintained in a channel that is essentially free of interior microchannel surface irregularities.

Owner:MASSACHUSETTS INST OF TECH

Distillation processes, distillation units, and systems therefor

ActiveUS20170340987A1Weaken energyPromote high ratioGeneral water supply conservationVapor condensationDistillation methodContaminated water

Processes and systems suitable for purifying or otherwise treating liquids to remove contaminants therein, including but not limited to contaminated water, to permit reclaiming, recycling, and reuse of the liquids. Such a process and system entails the use of a cascading distillation system that evaporates a liquid from the feedstock and then condenses and collects a more purified form of the liquid. The cascading distillation system can be operated to selectively process the feedstock through any of a series of vessels at which different amounts and / or contaminants may be removed from the feedstock.

Owner:LUTTERBACH RICKEY S

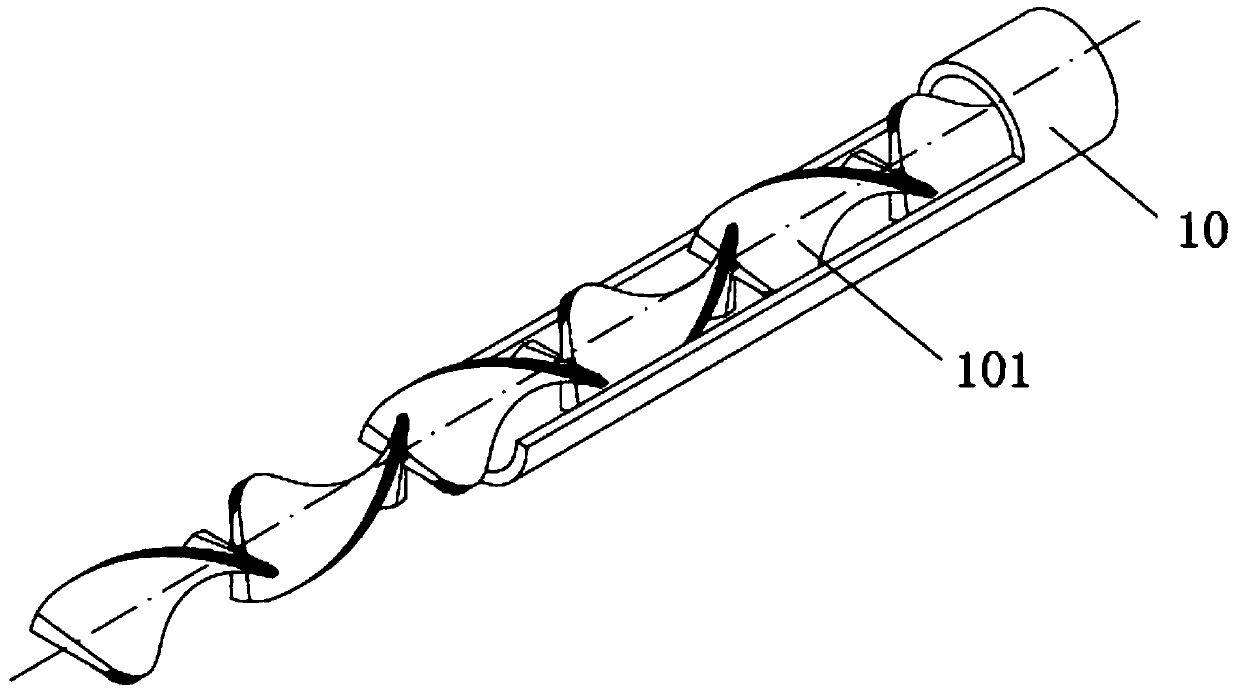

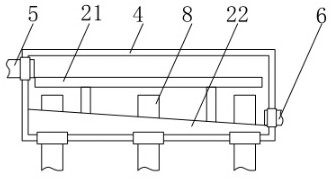

Polymer devolatilization device

PendingCN109646975AShort heating timeAvoid high temperature aging decompositionEvaporator accessoriesCascade evaporatorsShell and tube heat exchangerEngineering

The invention provides a polymer devolatilization device. The devolatilization device is sequentially provided with a feeding distribution area, a heating devolatilization area, a first falling stripdevolatilization area, a first falling film devolatilization area, a second falling strip devolatilization area, a second falling film devolatilization area and a material collection region. The feeding distribution area is provided with a feeding hole, a shell-and-tube heat exchanger is arranged in the heating devolatilization area, and the pipe layer of the shell-and-tube heat exchanger includesseveral heating row tubes, wherein the upper portions of the heating row tubes are used for feeding, and the lower portions of the heating row tubes are used for discharging; a volatile component outlet is formed in the first falling film devolatilization area, a liquid collection falling film distributor is arranged in the first falling film devolatilization area, and the liquid collection falling film distributor is connected with a motor outside the bottom of the devolatilization device through a rotating shaft, the bottom surface of the side face of the material collection region is provided with a discharge hole, and the material collection region is provided with a push device used for pushing polymer to move downwards. According to the technical scheme, the devolatilization deviceis compact in structure and small in size, and the device can be used for static and dynamic multi-stage high efficiency devolatilization of the polymer at the appropriate process temperature.

Owner:上海宥壹化工科技有限公司

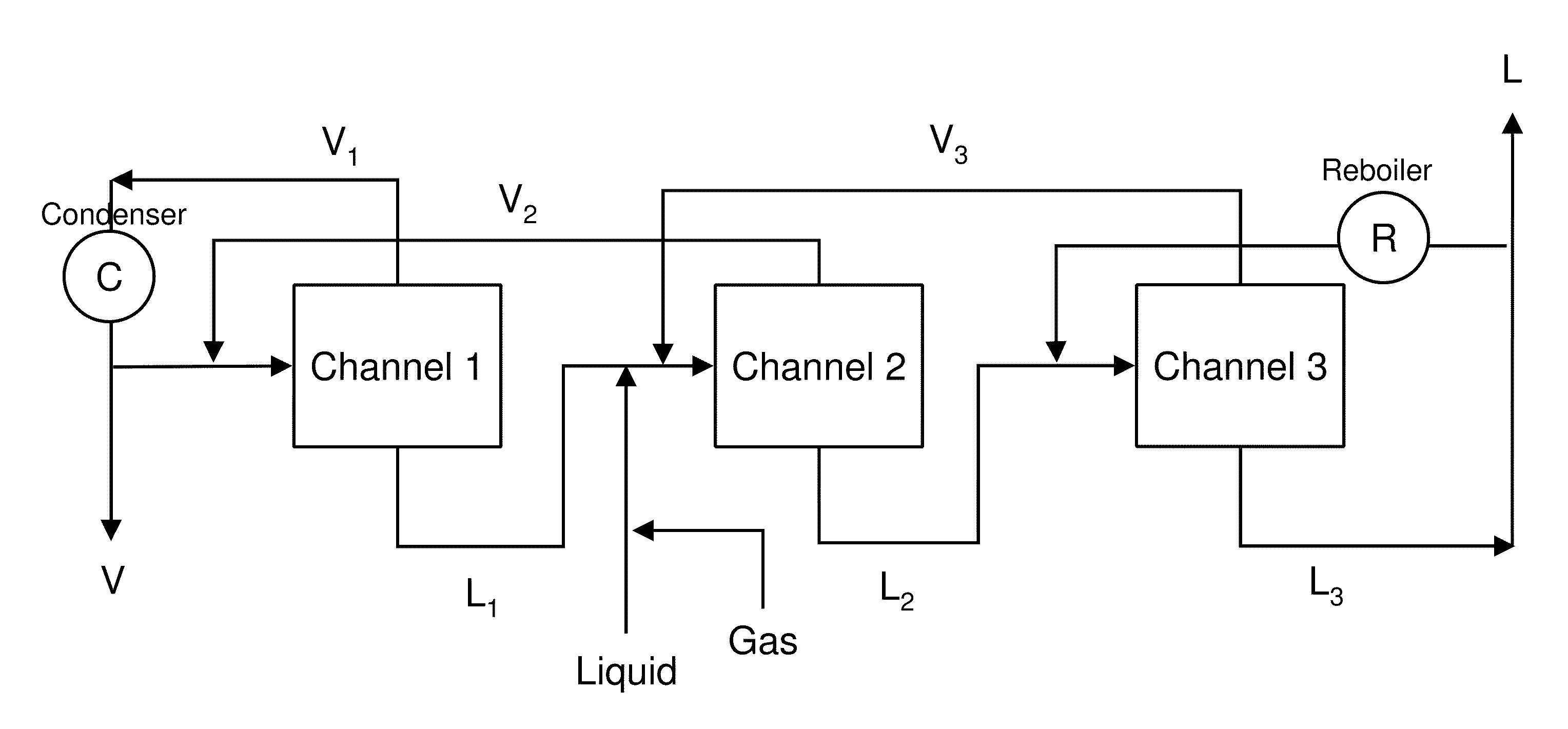

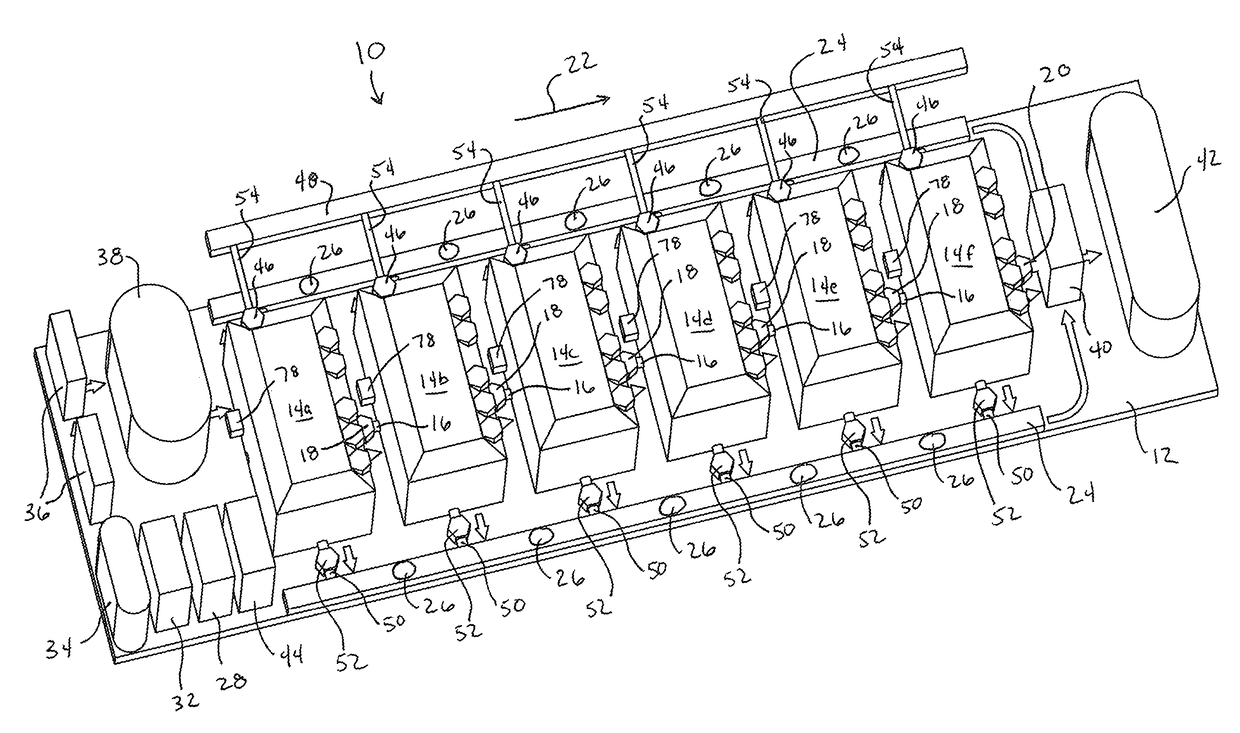

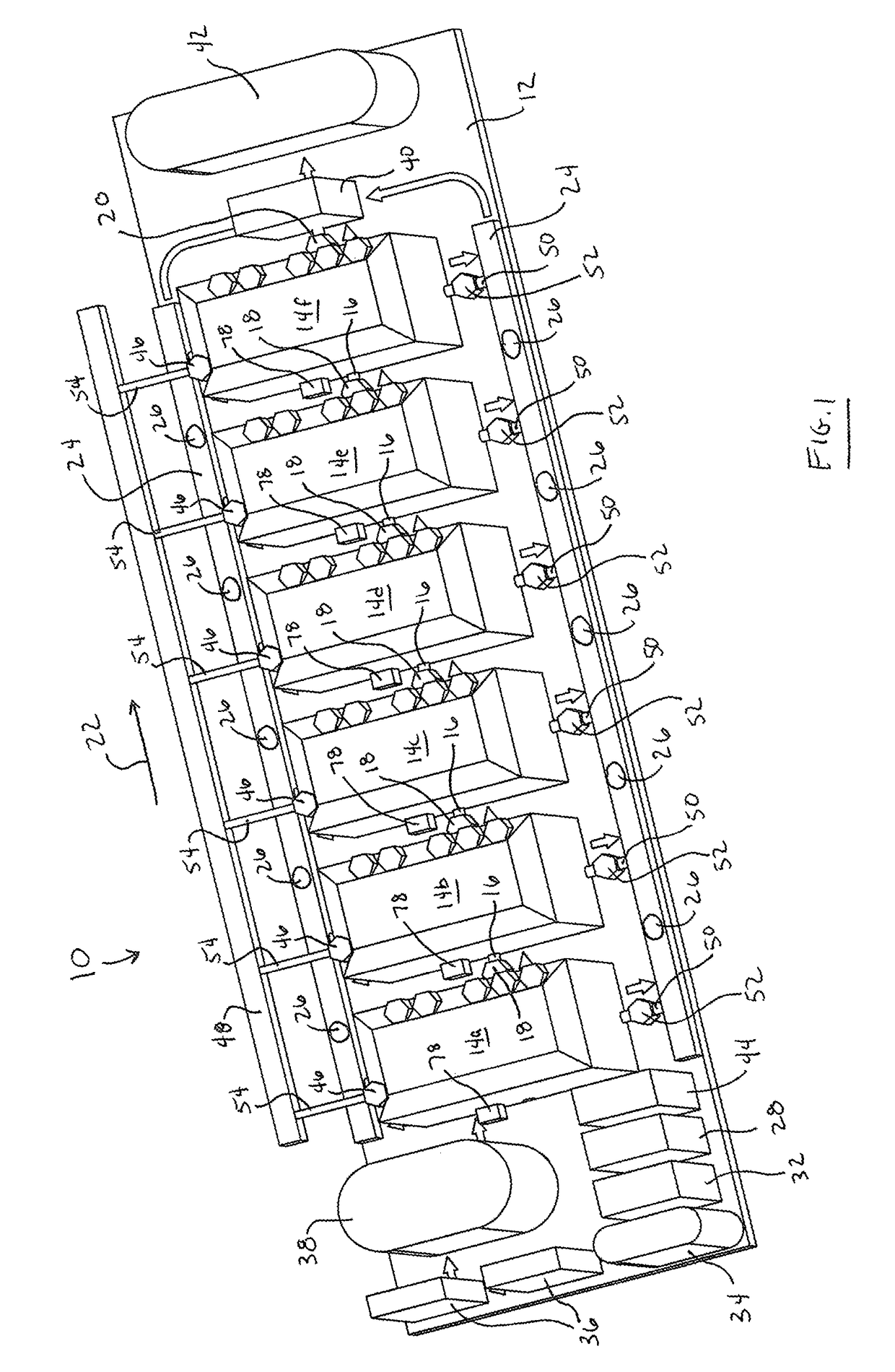

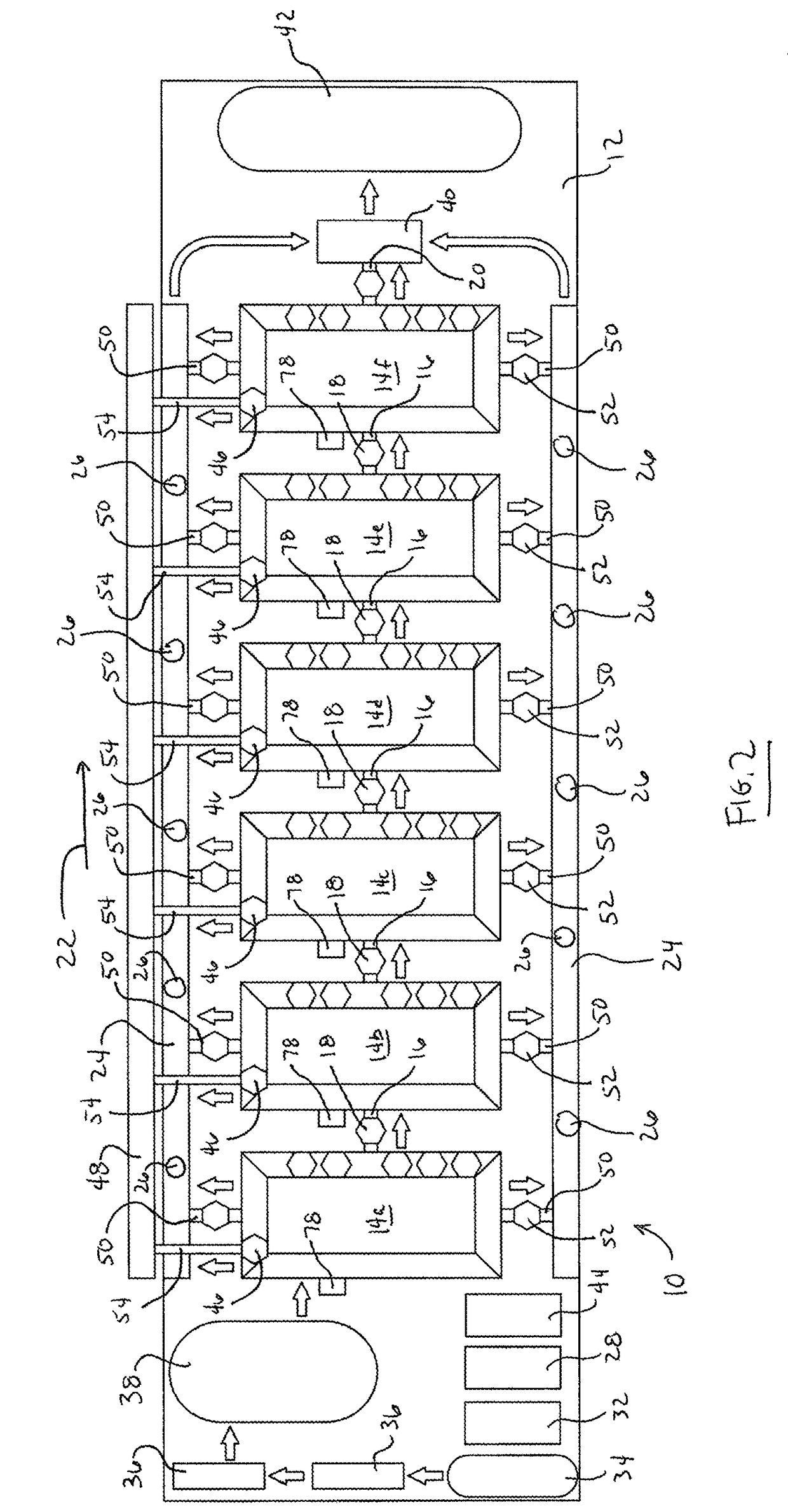

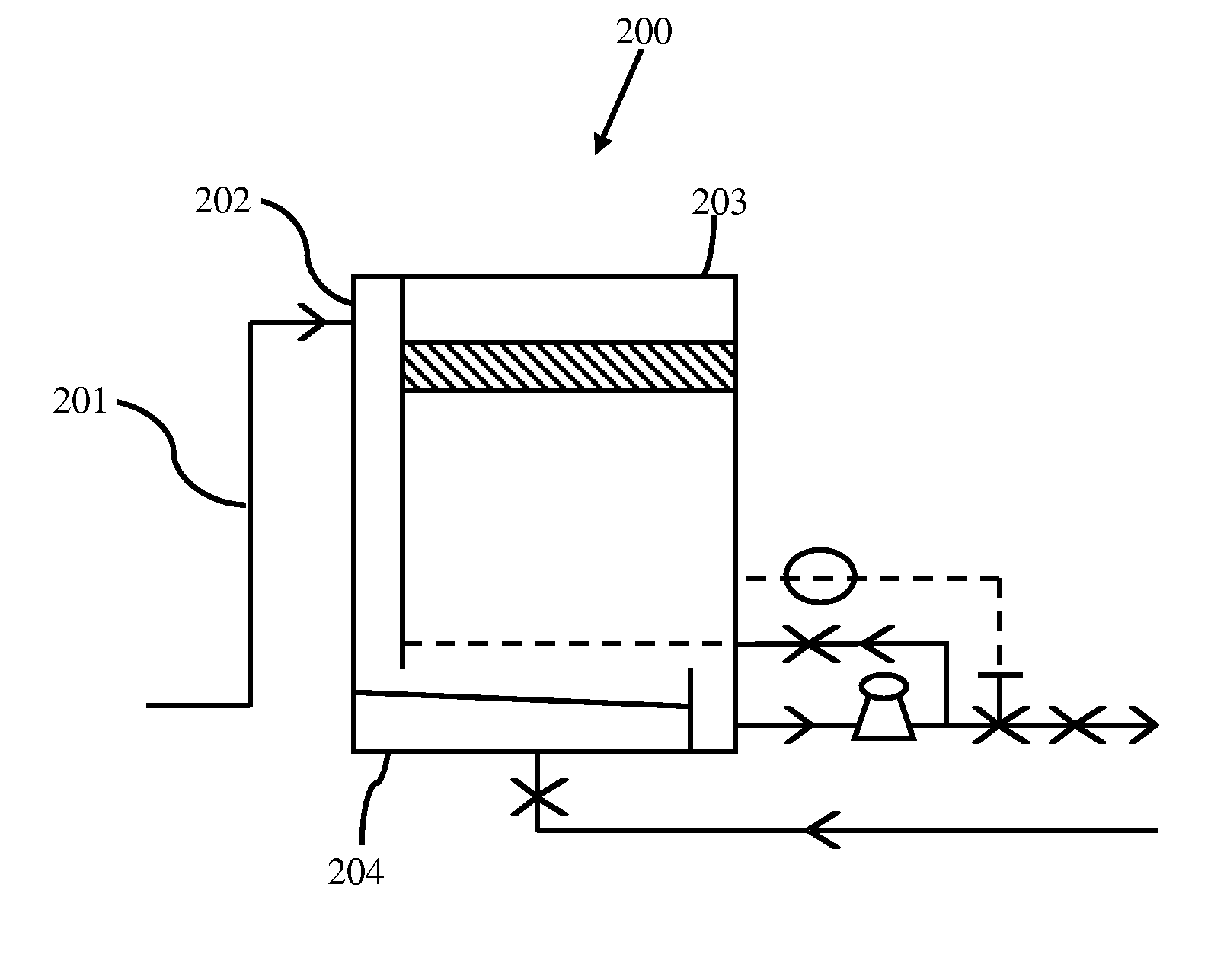

Novel horizontal method for tray distillation and other gas-liquid contact operations

ActiveUS20150001038A1Improve efficiencyImprove operational flexibilityThermal non-catalytic crackingDistillation regulation/controlReboilerEngineering

The present invention discloses a horizontal multi-stage distillation system. The system comprises a feed stream, a distillate stream, a residue stream, a group of vessels, a plurality of vapour non-return valves (NRVs), a plurality of plurality of pumps, a plurality of liquid recycle NRVs, a liquid stream, a vapour stream, a plurality of liquid recycle streams, a plurality of level transmitters, a plurality of flow control valves (FCVs) and a plurality of liquid non-return valves (NRVs). Each vessel is connected to the adjacent vessel. The group of vessels comprises a condenser vessel, a reboiler vessel, a feed vessel, at-least one rectification vessel and at-least one stripping vessel. The present invention provides a horizontal multi-stage distillation system with higher efficiency and operational flexibility compared with equivalent vertical distillation columns. The present invention also avoids the interstage backflow of the liquid and vapours.

Owner:KATYAL AMIT

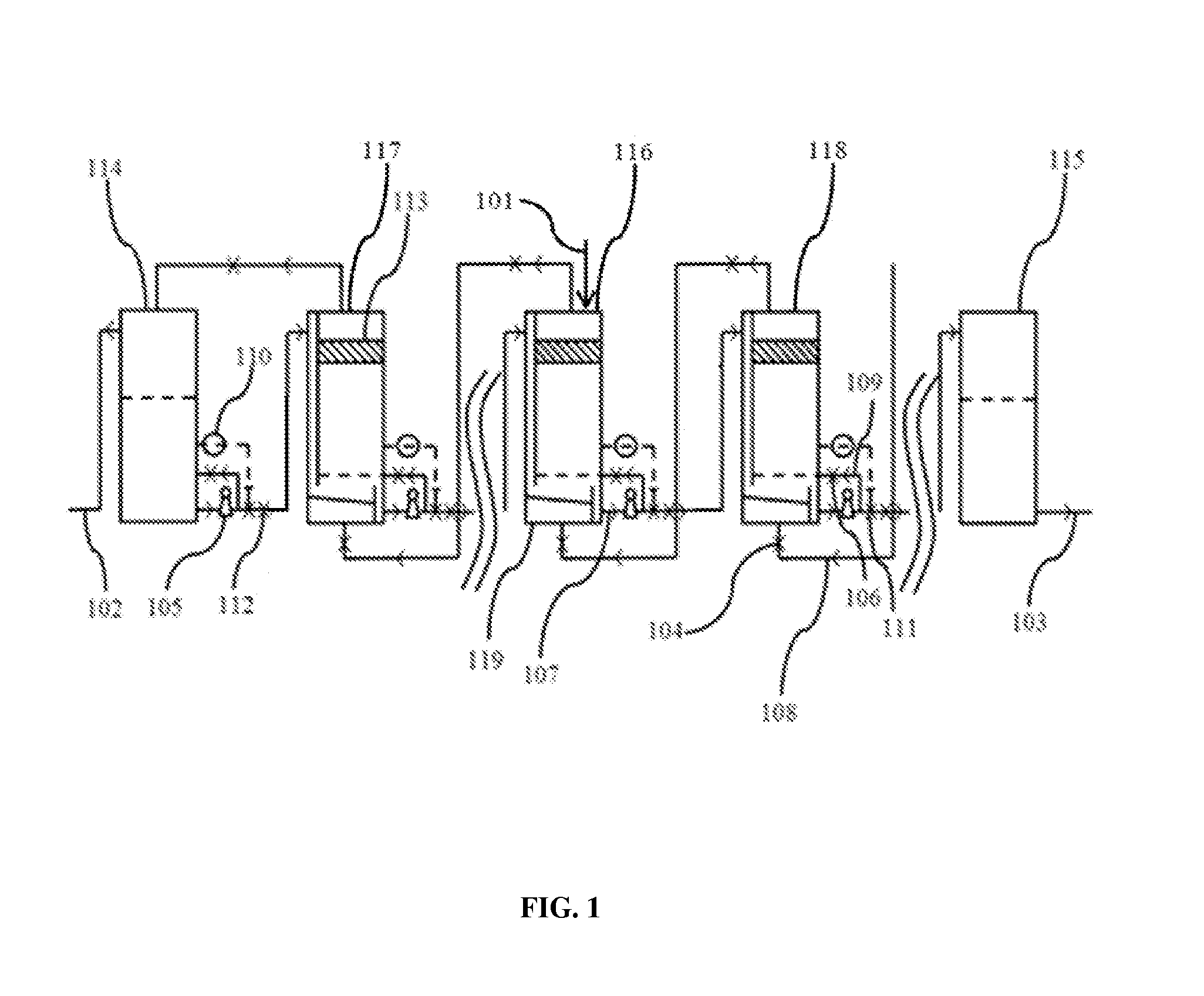

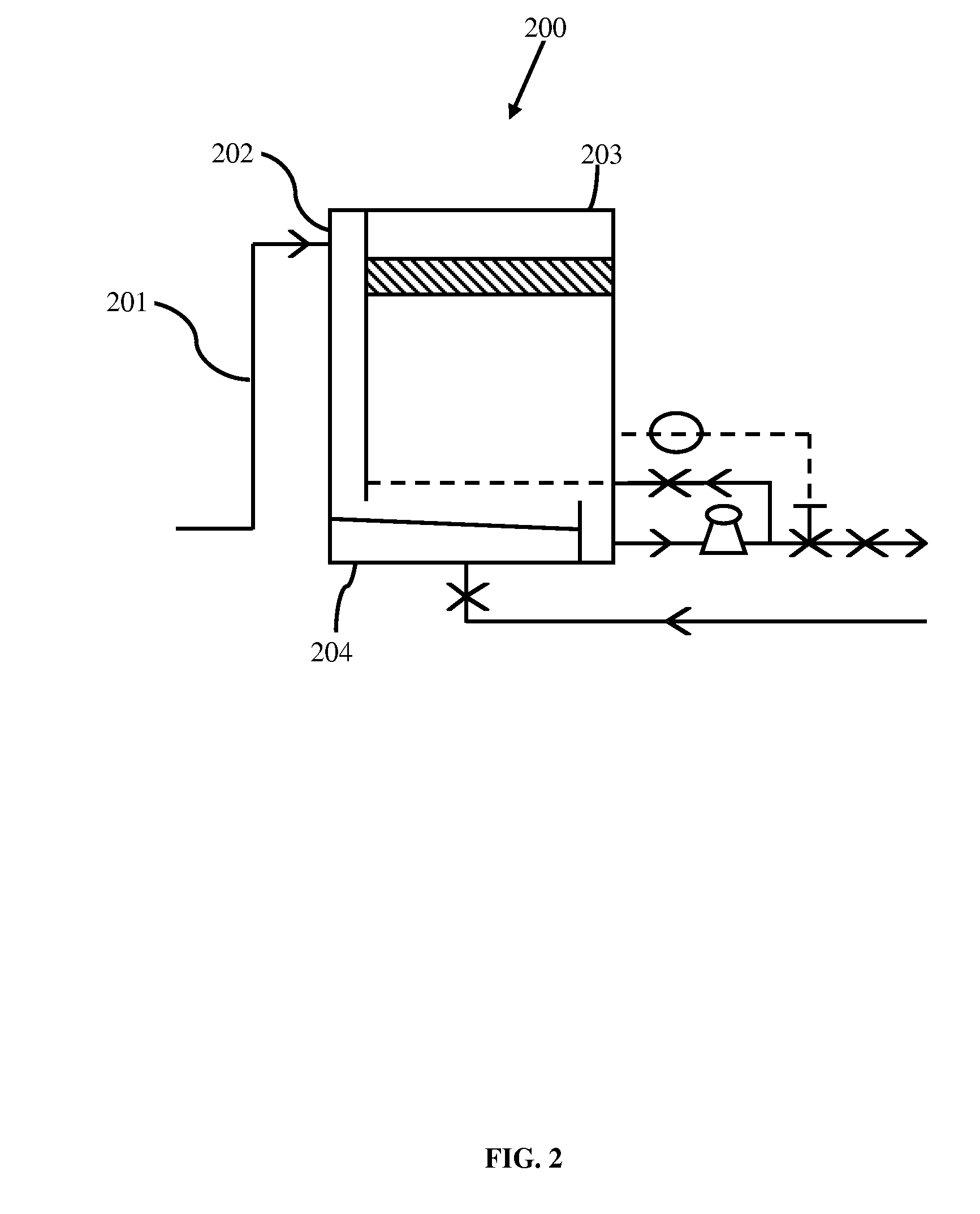

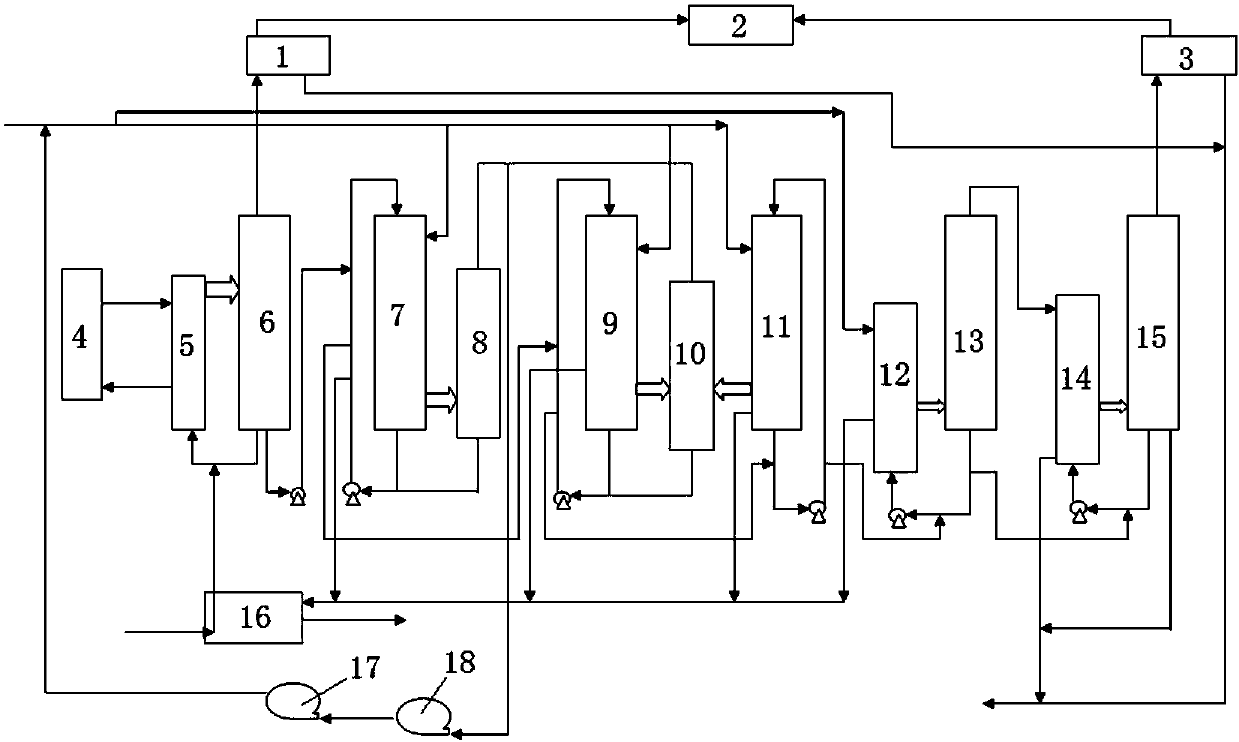

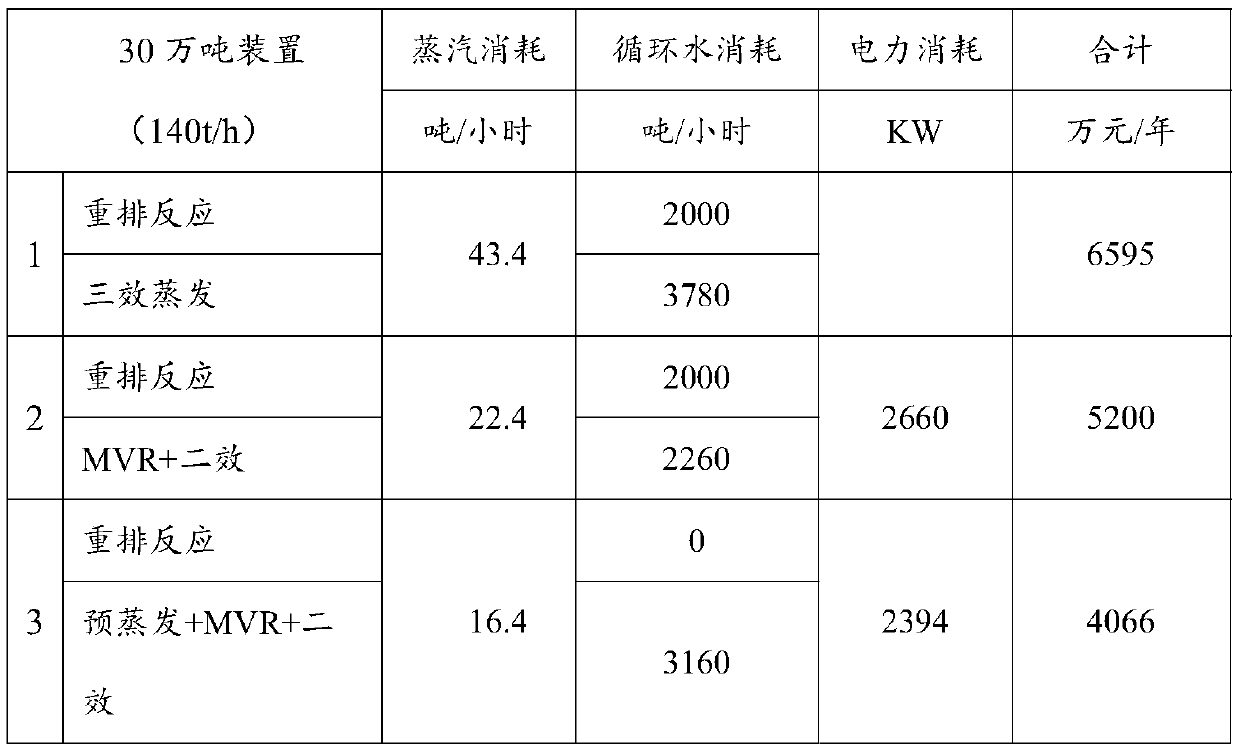

Caprolactam aqueous solution energy-saving evaporation system and method

PendingCN111013170AGreat operating flexibilityImprove energy savingEvaporation with vapour compressionEvaporator accessoriesThermodynamicsReboiler

The invention discloses a caprolactam aqueous solution energy-saving evaporation system and method, wherein the caprolactam aqueous solution energy-saving evaporation system comprises a preheater, a falling film heater, a pre-evaporator, a first first-effect falling film heater, a first first-effect evaporator, a second first-effect falling film heater, a second first-effect evaporator, a third first-effect falling film heater, a second-effect reboiler, a second-effect evaporator, a triple-effect reboiler and a triple-effect evaporator; a material inlet of the falling film heater is connectedwith a material outlet of the preheater, and circulating hot water is circulating hot water from a rearrangement reactor; a material inlet of the pre-evaporator is connected with a material outlet ofthe falling film heater; a material inlet of the first first-effect falling film heater is connected with a material outlet of the pre-evaporator, and a bottom liquid outlet is connected with the topof the first first-effect falling film heater; a material inlet of the first first-effect evaporator is connected with a gas phase outlet of the first first-effect falling film heater; an inlet of thesecond-effect reboiler is connected with a liquid outlet of the third first-effect falling film heater; a material inlet of the second-effect evaporator is connected with a material outlet of the second-effect reboiler; an inlet of the triple-effect reboiler is connected with a liquid outlet of the second-effect evaporator; and a material outlet of the triple-effect evaporator is connected with amaterial outlet of the triple-effect reboiler.

Owner:LIAOCHENG MEISI NEW MATERIAL TECH CO LTD

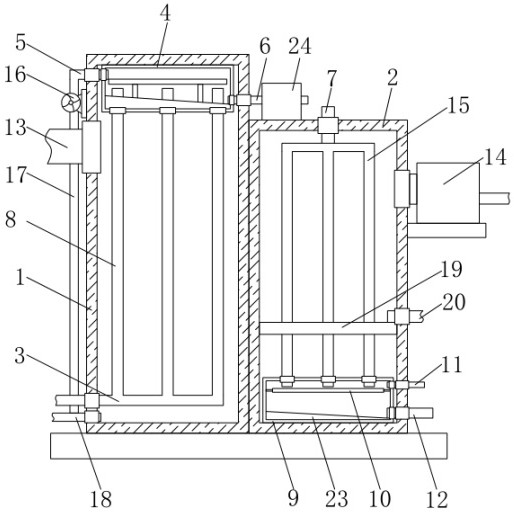

Carrier gas evaporator

ActiveCN105617697ASolve the problem of easy formation of sediment compactionImprove evaporation efficiencyEvaporator accessoriesCascade evaporatorsEvaporationEngineering

The invention discloses a carrier gas evaporator. The carrier gas evaporator comprises a cylinder, wherein a separation column is longitudinally arranged in the cylinder to divide the cylinder into an evaporation area and a liquid return area, at least one heating area is arranged on the inner wall of the lower portion of the evaporation area, a heating pipe filled with a heating medium is arranged on the inner wall of the heating area, a plurality of carrier gas evaporation hollow panels are longitudinally and evenly arranged on the outer wall of the heating area, a plurality of air outlets are evenly formed in each carrier gas evaporation hollow panel, and the carrier gas evaporation hollow panels are communicated with the heating area. By the adoption of the carrier gas evaporator, deposition and hardening of substances in liquid can not be caused in the whole evaporation reaction process, the problem that deposition and hardening are caused easily according to a traditional method that liquid is directly heated by means of a heat exchange pipe is solved, and then evaporation efficiency is improved, evaporation effect is improved and continuous and ordered proceeding of the whole evaporation process is guaranteed.

Owner:WUXI HEZHONG ENVIRONMENTAL PROTECTION TECH CO LTD

High-efficient extracting device special for bone soup powder

InactiveCN109329841AEasy to useControl cooking timeEvaporator accessoriesCascade evaporatorsEngineeringHigh pressure

The invention relates to a high-efficient extracting device special for bone soup powder. The high-efficient extracting device comprises an extraction device body, wherein the extraction device body is sequentially provided with a constant-pressure decocting jar, a high-pressure decocting jar and an extraction separation jar from top to bottom; a separating cylinder is arranged in the extraction separation jar; the lower end of the separating cylinder is in sealing connection with the bottom wall of an extraction separation jar body; a connecting plate which extends to the inner wall of the separating cylinder is arranged at the upper end of the separating cylinder; a fat collecting cylinder which extends to the lower side of the connecting plate is fixed to the connecting plate; and a fatoutlet is formed in the extraction separation jar body. According to the high-efficient extracting device disclosed by the invention, the work done by a plurality of equipment can be completed by oneequipment, and the using is convenient; and a first discharging valve and a second discharging valve can independently control a switch, so that the decocting time can be effectively controlled in time, and the working efficiency is improved.

Owner:山东龙盛食品股份有限公司

Integrated evaporator

InactiveCN111603791AIncrease concentrationImprove evaporation effectCascade evaporatorsEvaporators with vertical tubesHigh concentrationEngineering

The invention discloses an integrated evaporator and belongs to the evaporator technical field. The integrated evaporator comprises a first evaporation box and a second evaporation box which are arranged in parallel; an air inlet is formed in the upper portion of the side wall of the first evaporation box; a water inflow pipe is arranged at the bottom of the first evaporation box in a penetratingmode; a first evaporation pipe communicated with the water inflow pipe at the bottom end is vertically arranged in an inner cavity of the first evaporation box; and a first separation box is arrangedat the top of the inner cavity of the first evaporation box. According to the integrated evaporator, the first evaporation box and the second evaporation box are arranged in parallel; rising film evaporation is carried out on a solution in the first evaporation box, so that primary purification can be carried out; falling film evaporation is carried out on the relatively concentrated solution subjected to primary evaporation in the second evaporation box, so that high-concentration purification can be carried out on the solution; since the advantages of the two modes are reasonably combined and utilized, the solution is subjected to two-step evaporation, the defects of the two evaporators are avoided, an evaporation effect is improved, the low-concentration solution can be subjected to high-concentration purification, and an expected evaporation effect can be achieved.

Owner:安徽春辉环保工程科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com