Caprolactam aqueous solution energy-saving evaporation system and method

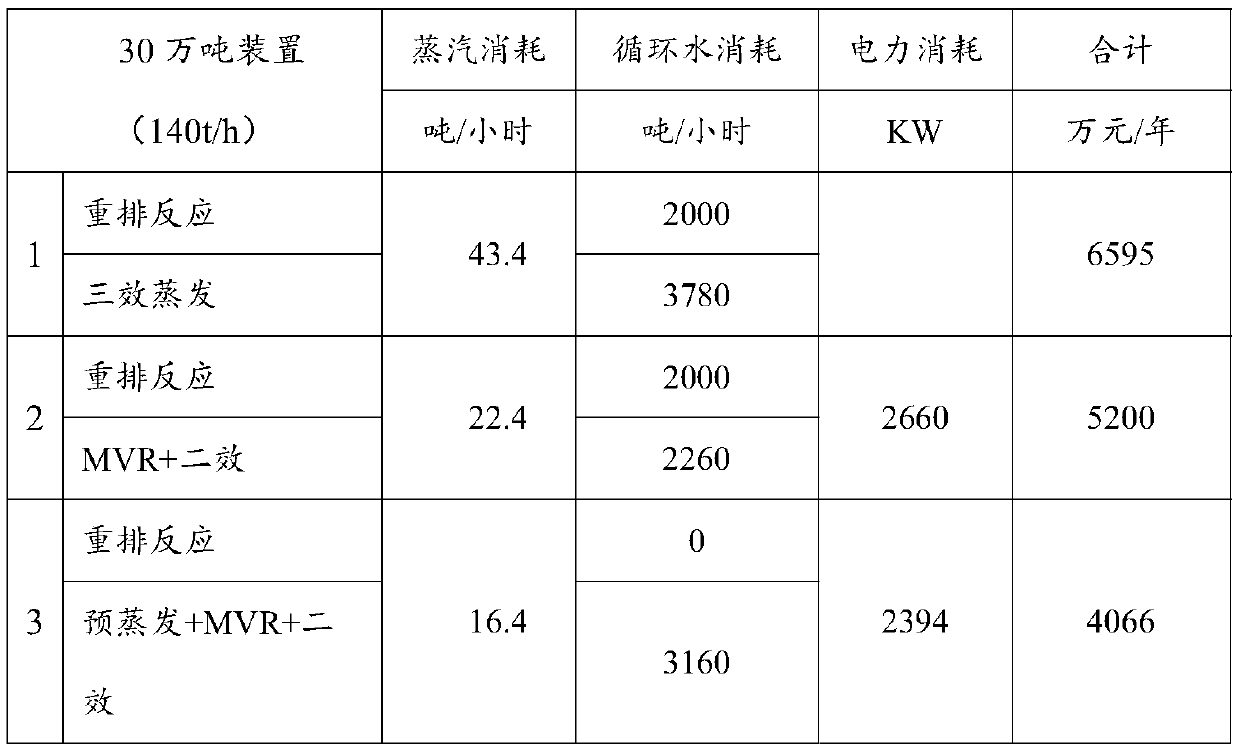

The technology of caprolactam and evaporation system is applied in the field of energy-saving evaporation system of caprolactam aqueous solution, which can solve the problems of large steam consumption, and achieve the effects of reducing usage, remarkable energy-saving effect and large operation flexibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

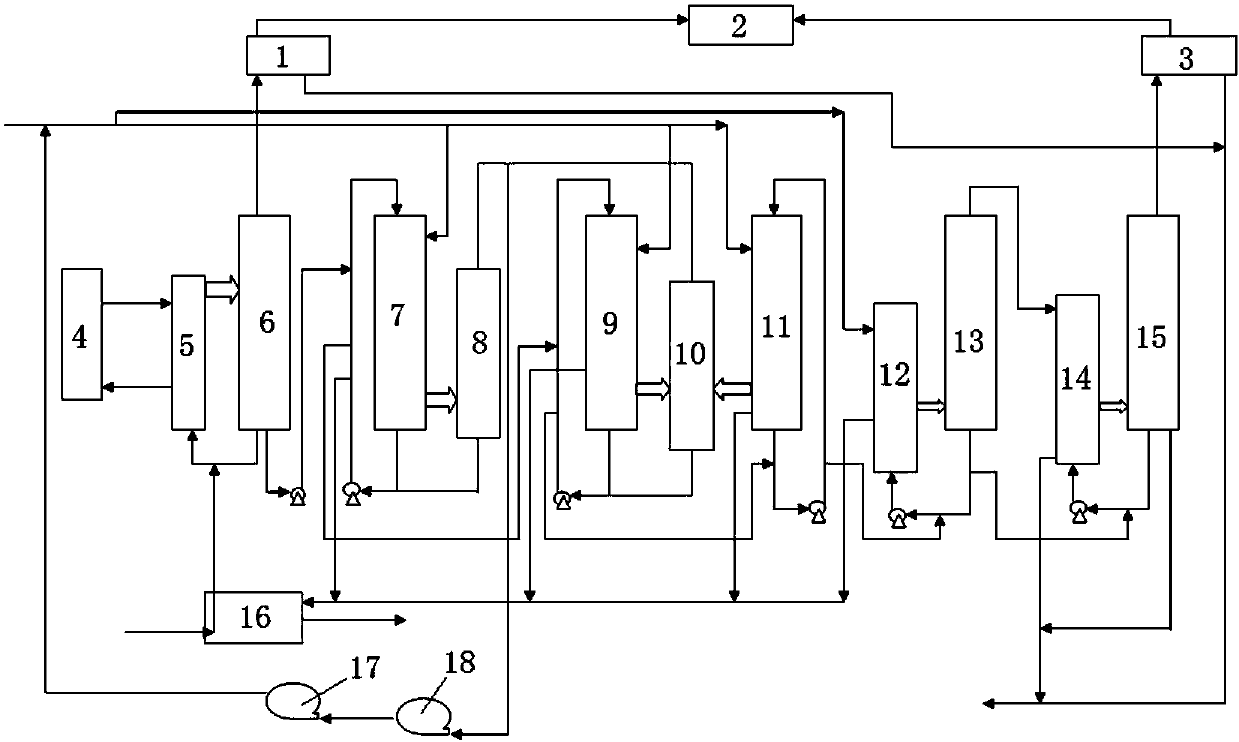

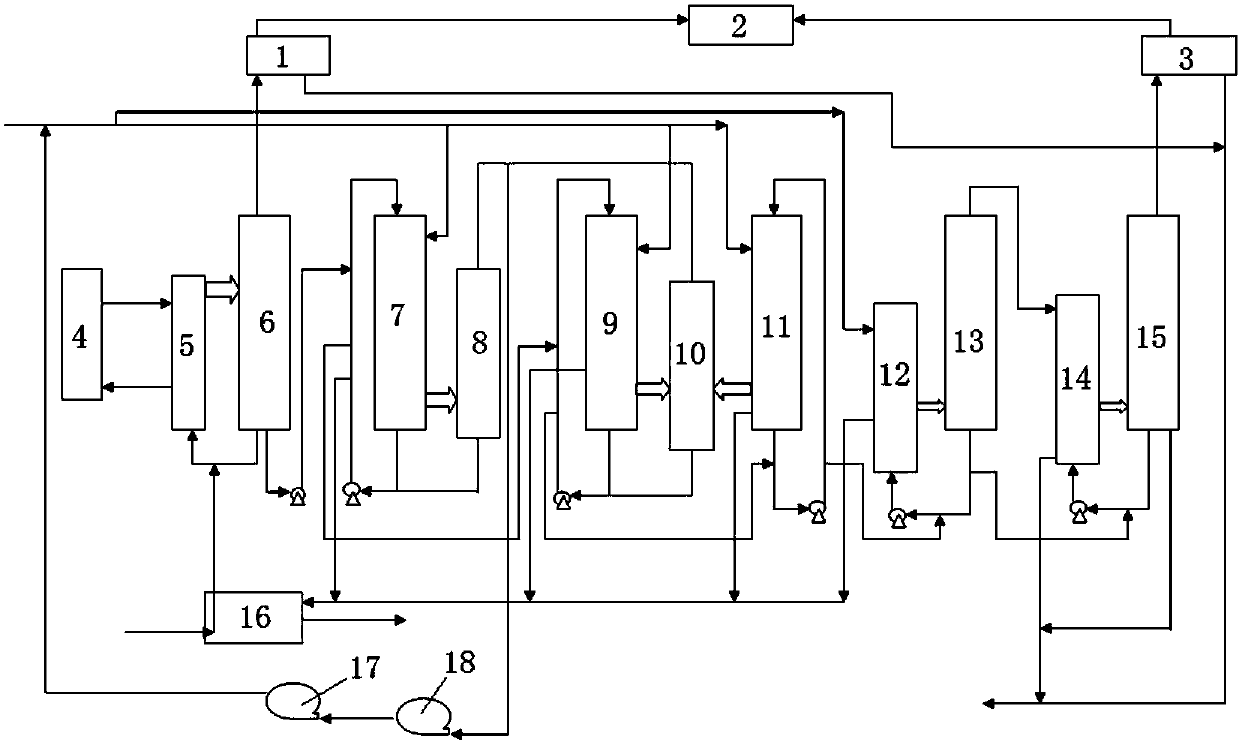

[0058] Such as figure 1 Shown, a kind of caprolactam aqueous solution energy-saving evaporation system comprises:

[0059] Preheater 16, for preheating caprolactam aqueous solution;

[0060] Falling film heater 5, its material inlet is connected with the material outlet of preheater 16, and its circulating hot water is the circulating hot water from rearrangement reactor 4;

[0061] Pre-evaporator 6, its material inlet is connected with the material outlet of falling film heater 5;

[0062] The first one-effect falling film heater 7, its material inlet is connected with the material outlet of pre-evaporator 6, and its bottom liquid outlet is connected with its top;

[0063] The first one effect evaporator 8, its material inlet is connected with the gas phase outlet of the first one effect falling film heater 7;

[0064] The second one-effect falling film heater 9, its material inlet is connected with the first one-effect falling film heater 7 liquid outlets, and its bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com