Solar energy biogas slurry evaporation and concentration device

An evaporation concentration, solar energy technology, applied in evaporation, cascade evaporator, evaporator accessories and other directions, can solve the problems of high operation requirements, complex system, high cost, and achieve the effect of low operation cost, improved concentration efficiency and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1 (basic embodiment)

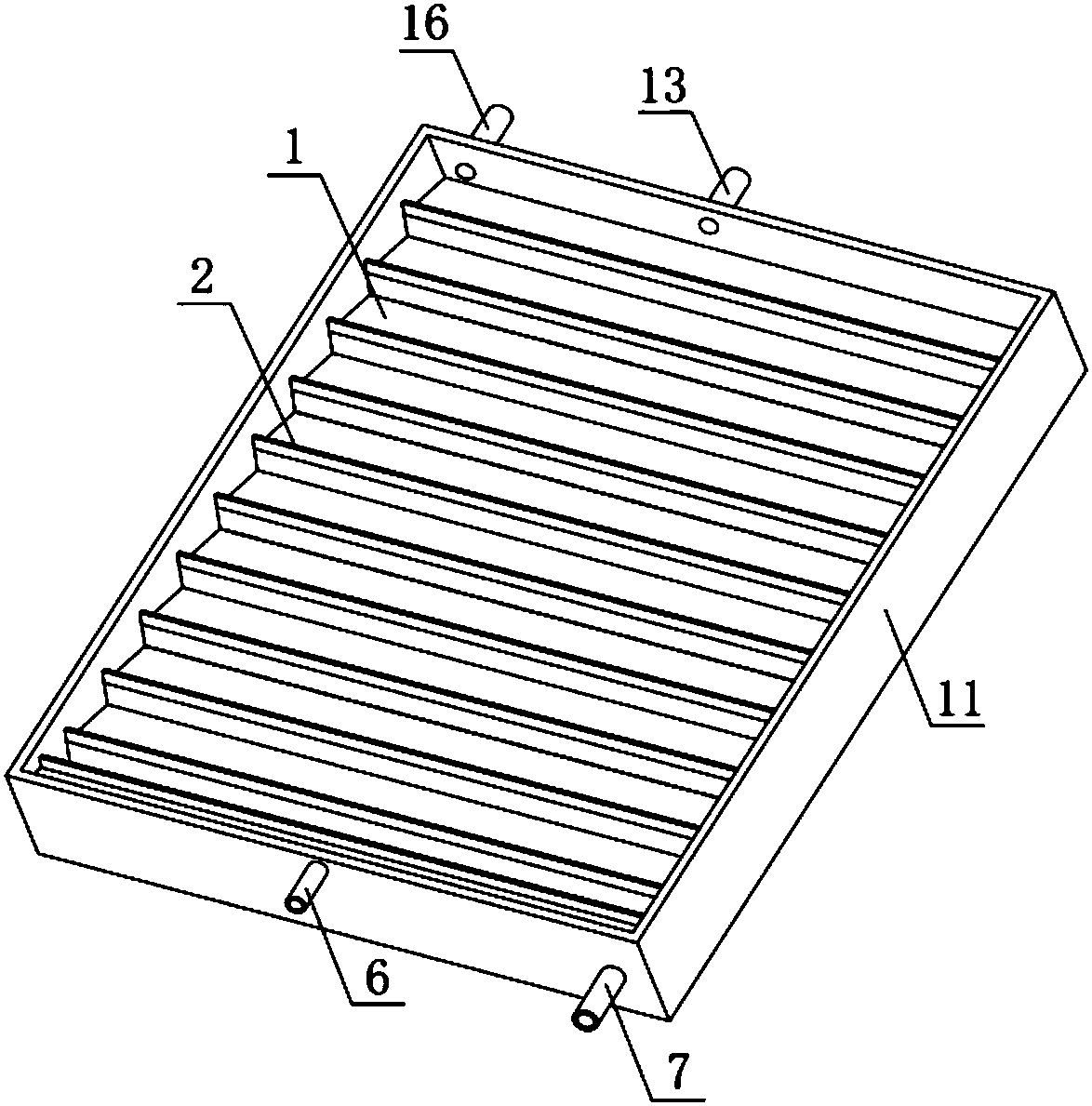

[0028] The invention is a solar biogas slurry evaporation and concentration device, the device includes: a heat collecting plate, a transparent cover plate, a distiller shell, a distillation chamber, a distillate collection tank, a heat storage material, a thermal insulation material layer, and a distillate recovery pool , Concentrate recovery tank, fan and inverted trapezoidal support. The heat collecting plates are placed inside the still shell. Water baffles are placed on the edge of each heat collector plate 1, and the length of the water baffles is equal to the length of the heat collectors so that the biogas slurry flows in a straight line (see Figure 4 ), or the length of the water baffle is less than the length of the collector plate and they are arranged in a staggered manner (see Figure 6 ), so that the biogas slurry is S-flow. The transparent cover plate is placed on the top of the distiller shell, and an airtight distill...

Embodiment 2

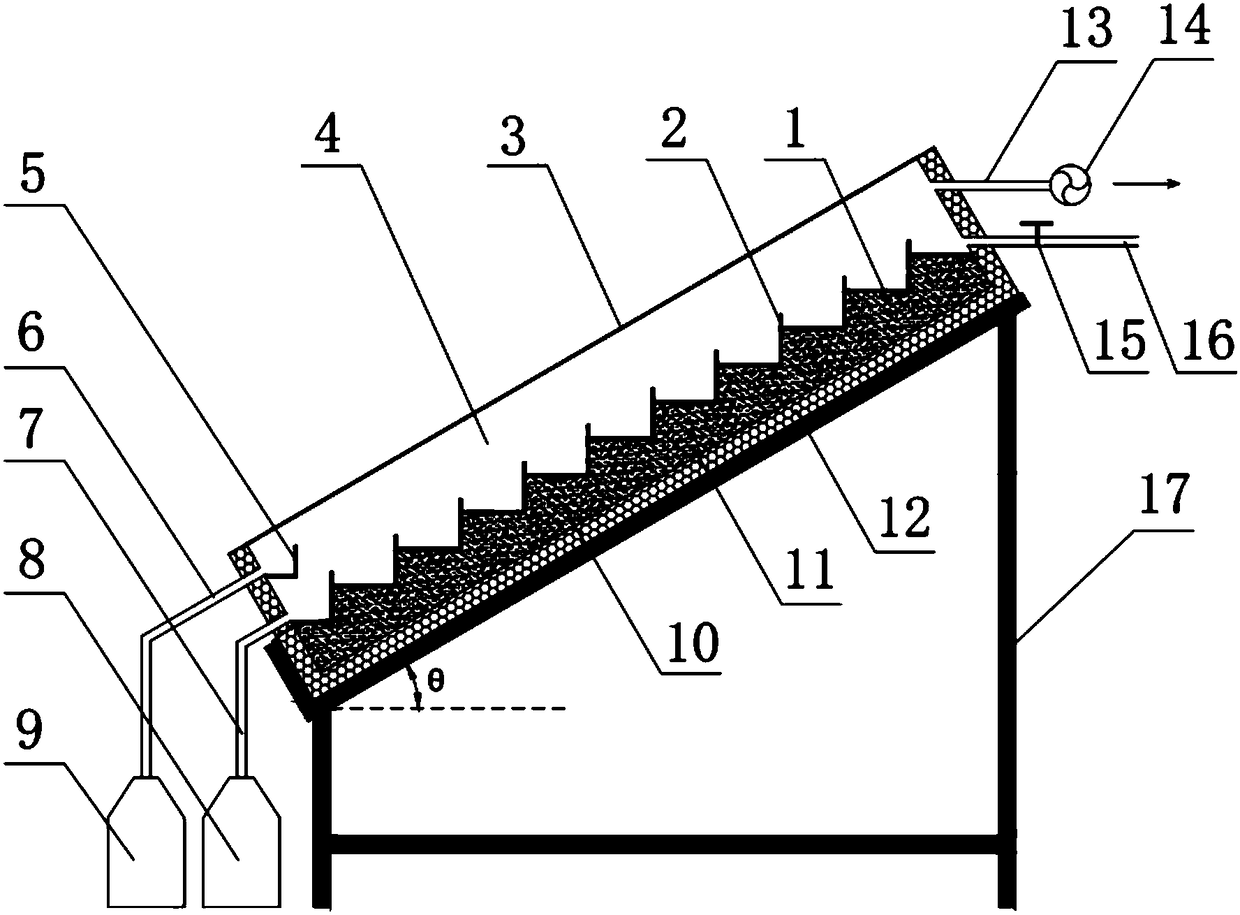

[0039] combine figure 1 and 3 Embodiments of the present invention will be described. This embodiment is a micro-negative pressure solar biogas slurry evaporation and concentration device. Among them, the length of the heat collecting plate can be 1m, the width of the horizontal part is 0.05m, and the width of the vertical part is 0.03m, and there are 20 steps in total. The length of the water retaining plate can be 1m, the height can be 10mm, and the total area of the heat collecting plate and the water retaining plate is 1.8m 2 , The transparent cover plate is 4mm tempered glass (the sunlight transmittance is not less than 90%), and the fan is 40W exhaust fan. The thermal storage material is paraffin wax, and the thermal insulation material is rubber and plastic thermal insulation material. The installation angle (horizontal angle) between the evaporative concentration device and the horizontal plane is 30°. The evaporation and concentration device of the present inv...

Embodiment 3

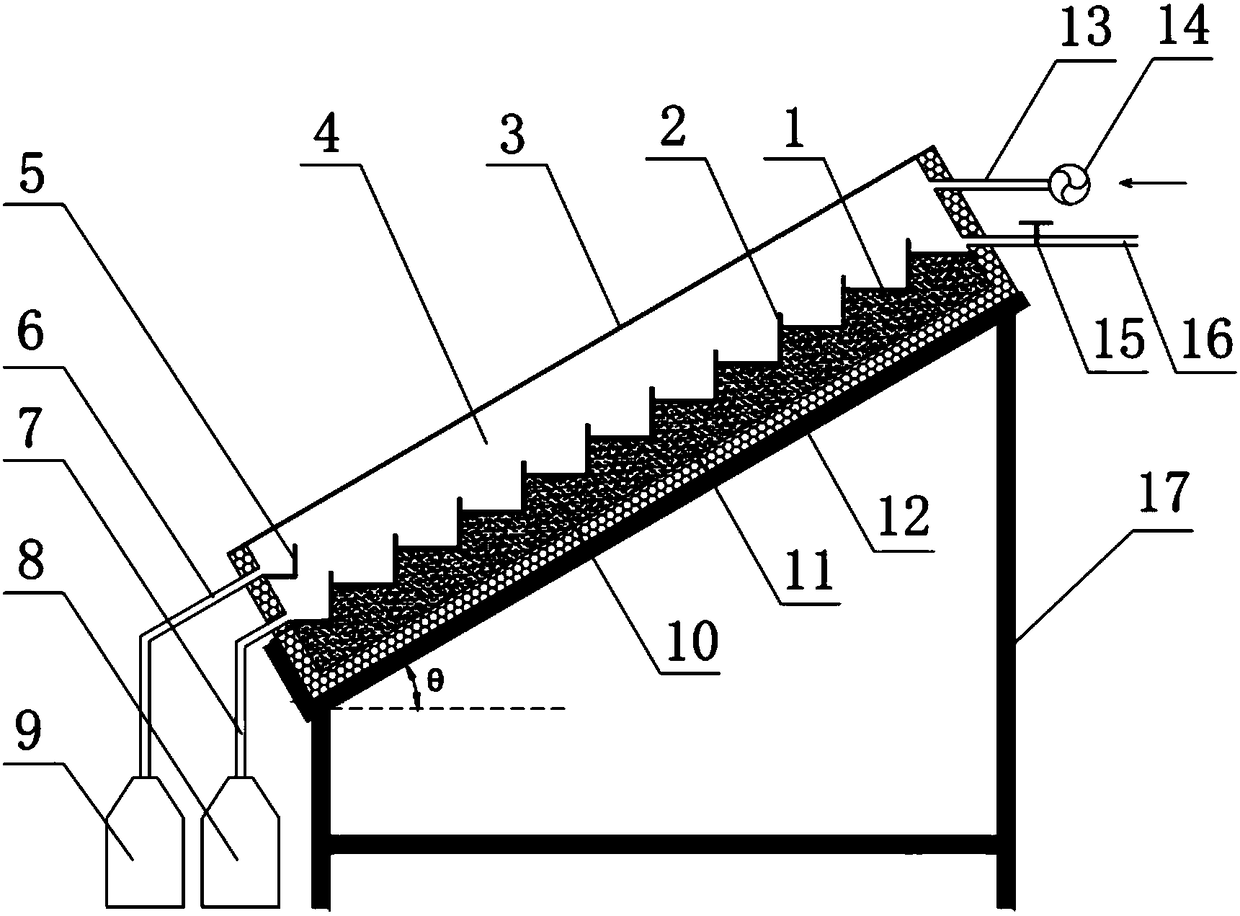

[0041] combine figure 2 and 3 Embodiments of the present invention will be described. This embodiment is a micro positive pressure solar biogas slurry evaporation and concentration device. Compared with the solar biogas slurry evaporation and concentration device described in Embodiment 1, the fan is improved in the evaporation and concentration device of this embodiment. In this embodiment, the length of the heat collecting plate can be 1m, the width of the horizontal part can be 0.05m, and the width of the vertical part can be 0.03m, and there are 20 steps in total. The length of the water retaining plate can be 1m, the height can be 10mm, and the total area of the heat collecting plate and the water retaining plate can be 1.8m 2 , the transparent cover is 4mm tempered glass (sunlight transmittance not less than 90%), the fan is 40W inlet fan, the heat storage material is paraffin wax, and the insulation material is rubber and plastic insulation material. The installa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com