Patents

Literature

41results about "Evaporator liquid feeder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

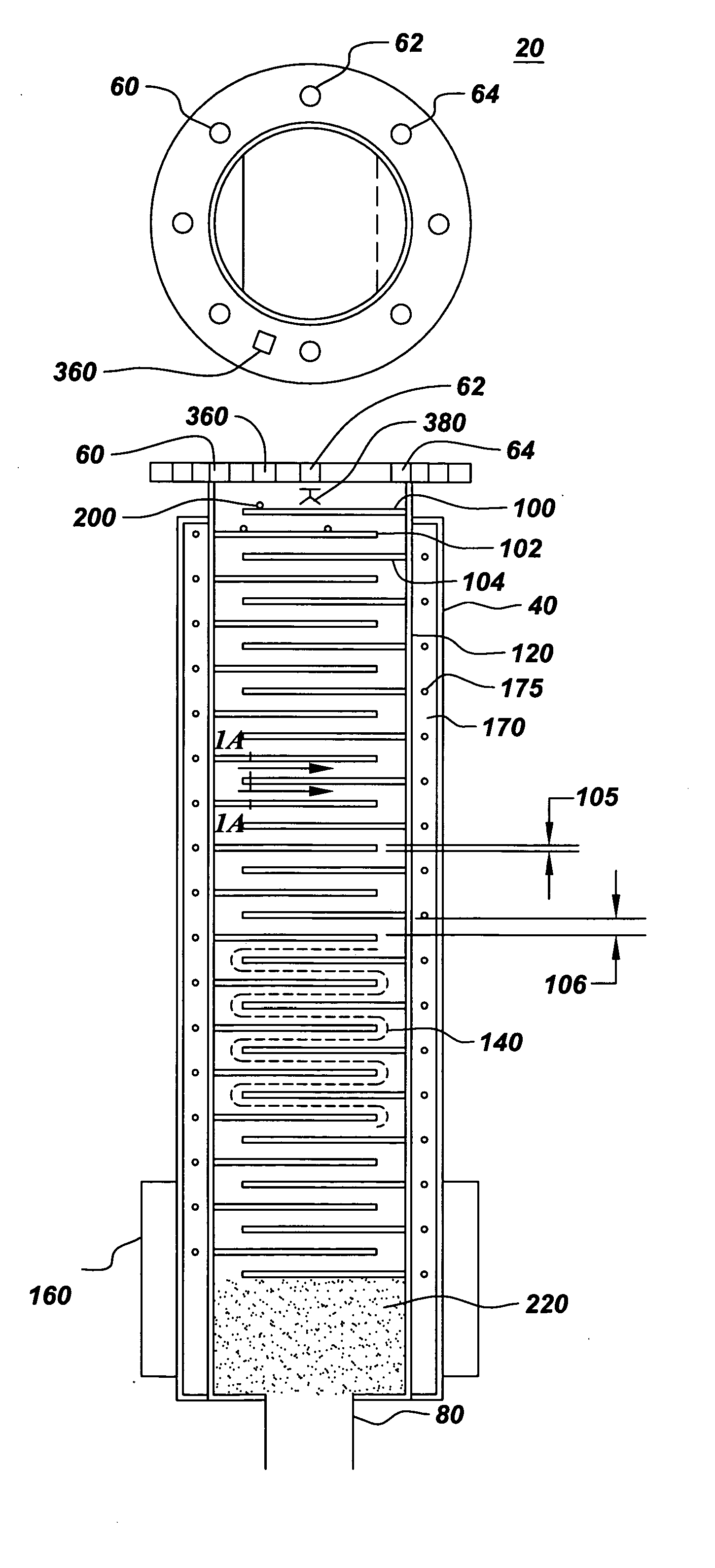

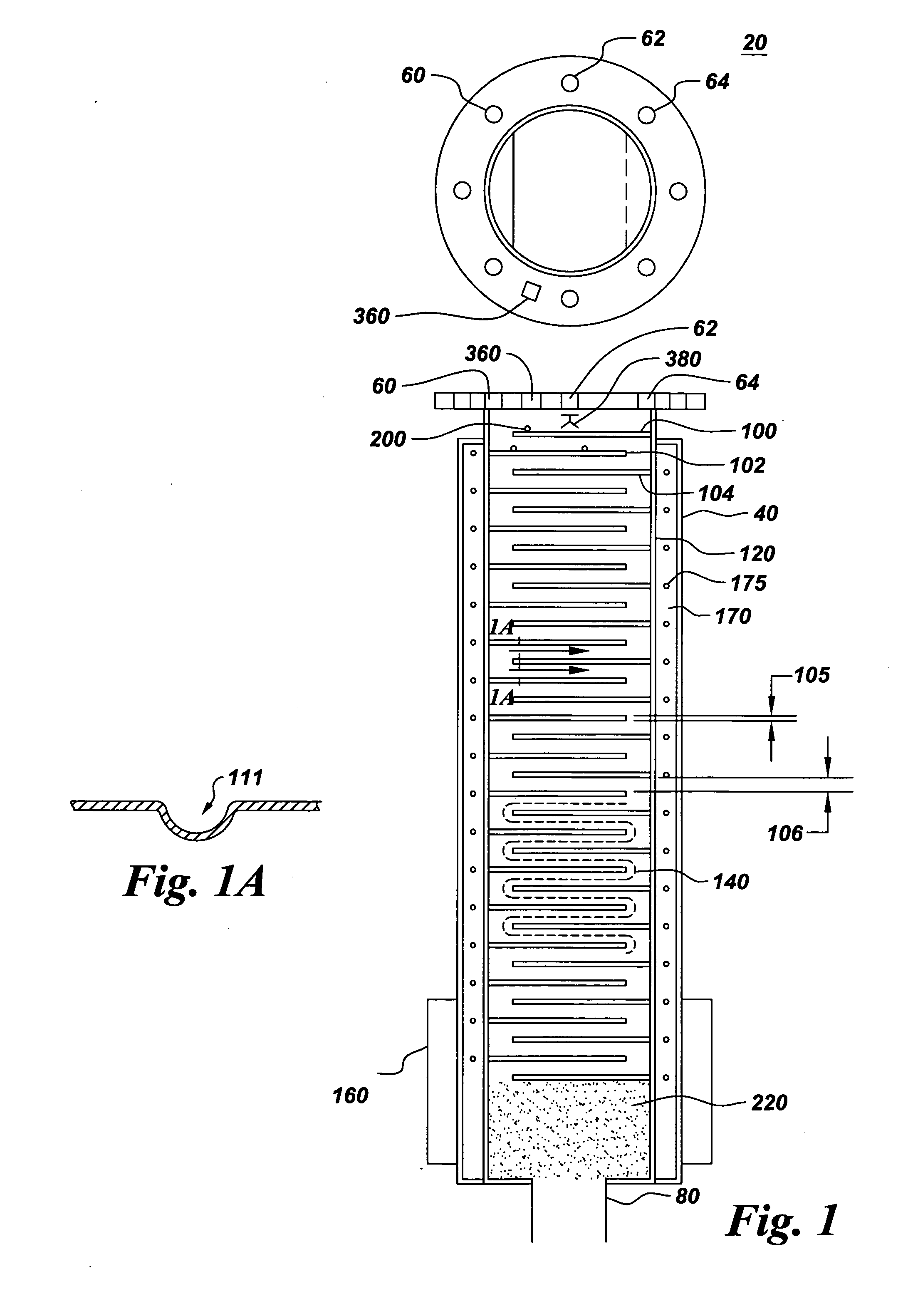

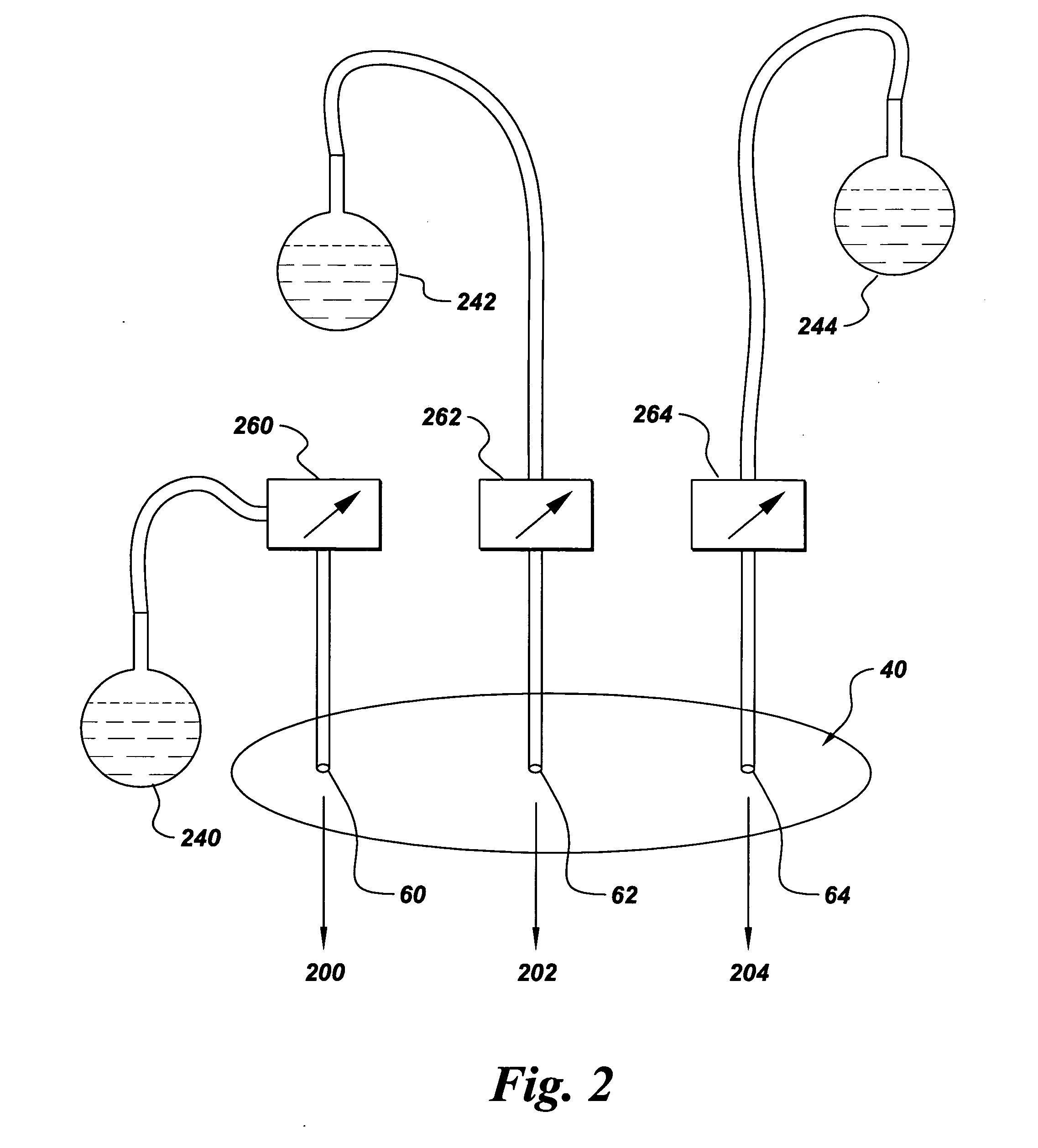

Apparatus for the evaporation of aqueous organic liquids and the production of powder pre-forms in flame hydrolysis processes

InactiveUS20050205215A1Drying using combination processesEvaporator liquid feederOrganic liquidsEvaporation

An organic liquid evaporation system is disclosed. The organic liquid evaporation system comprises a housing having at least one inlet and at least one outlet. At least a first evaporator plate radially extending from a sidewall of the housing, and at least a second evaporator plate radially extending from a sidewall of the housing define a serpentine flow path within the housing. A heating source is in thermal communication with the first evaporator plate and the second evaporator plate, wherein the heating source provides heat to the first and second evaporator plates to evaporate organic liquid introduced within the inlet to produce a vapor through the outlet. A method for preparing powder pre-forms and oxide soot using the organic liquid evaporation system is also disclosed.

Owner:GENERAL ELECTRIC CO

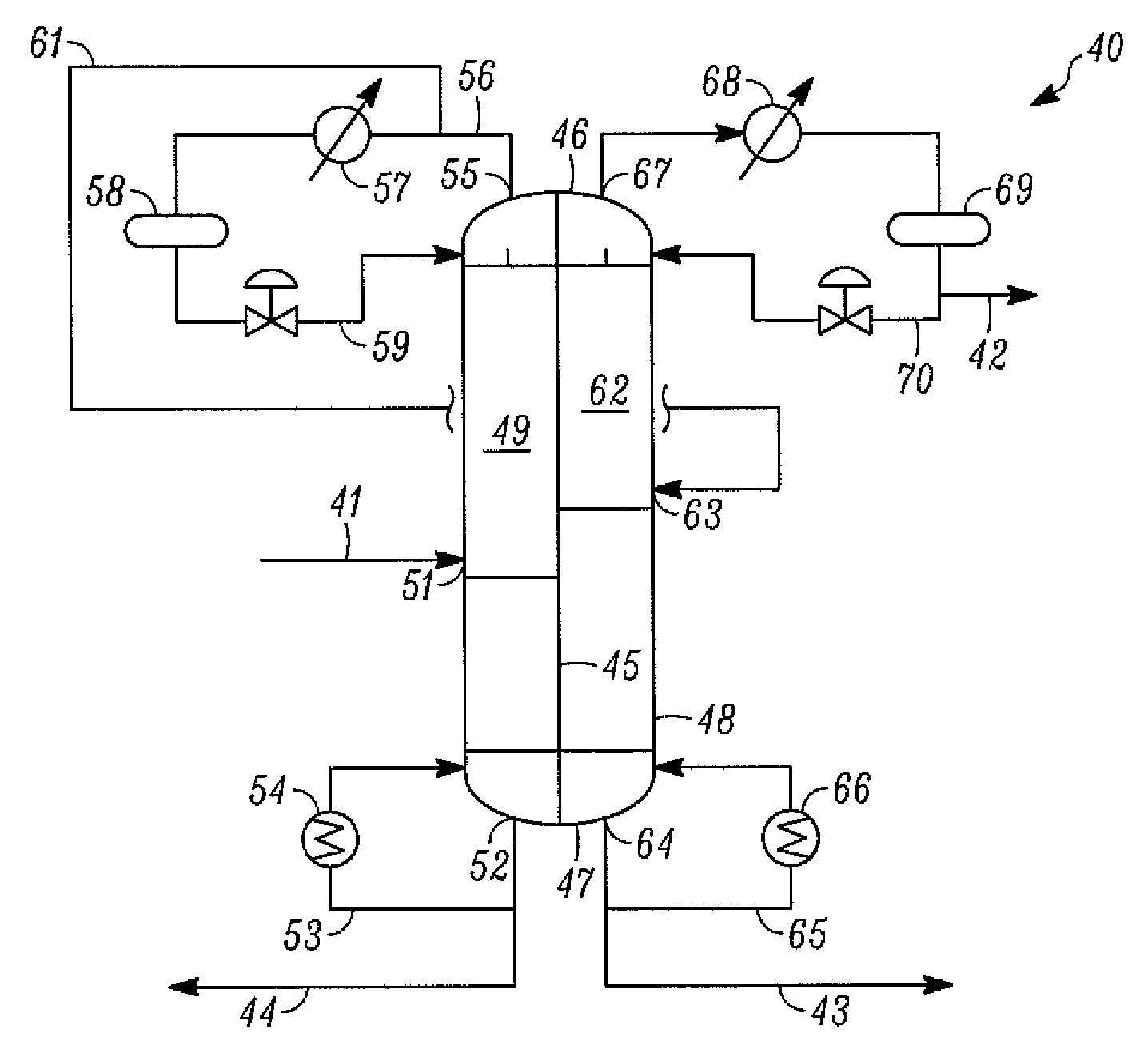

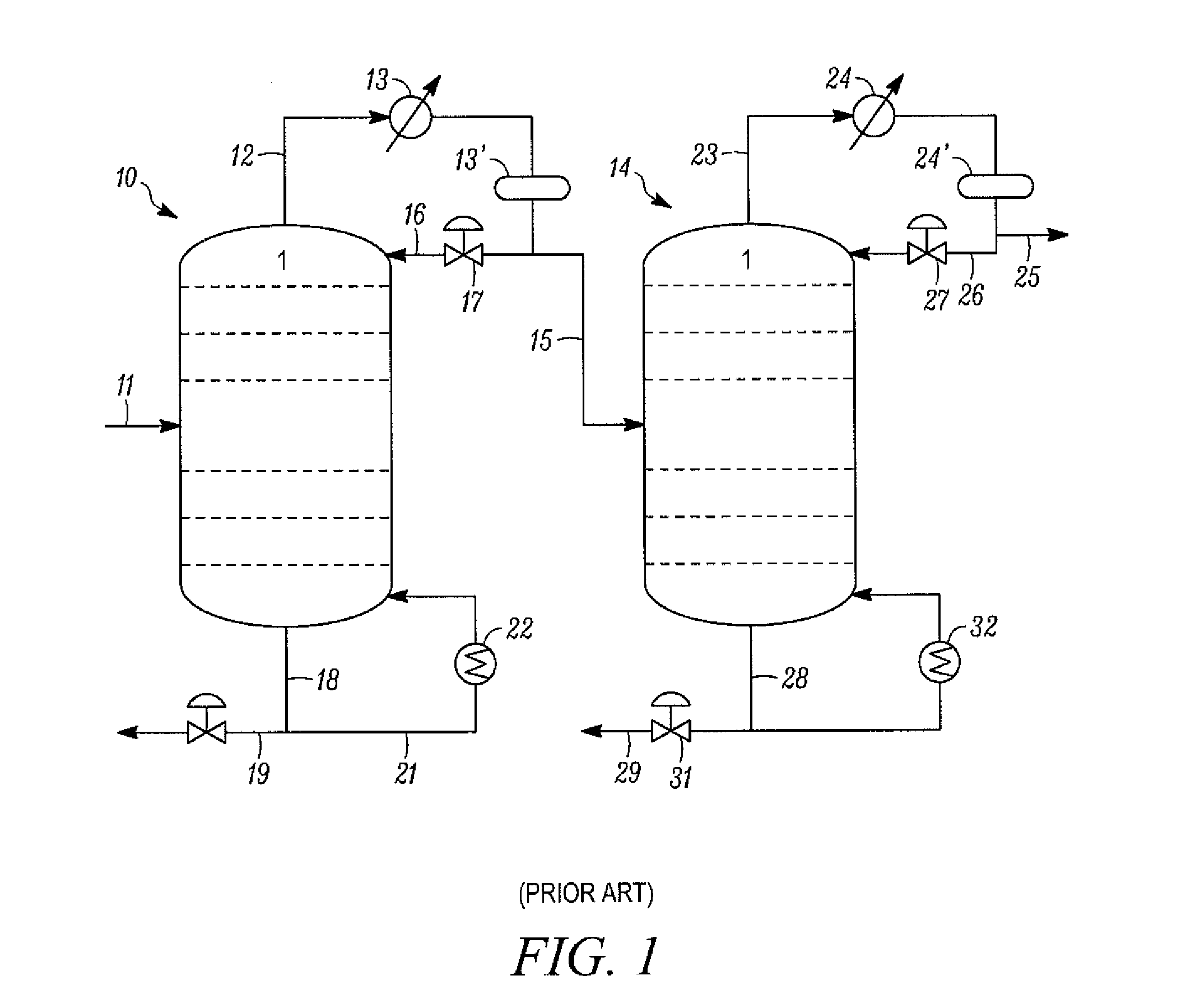

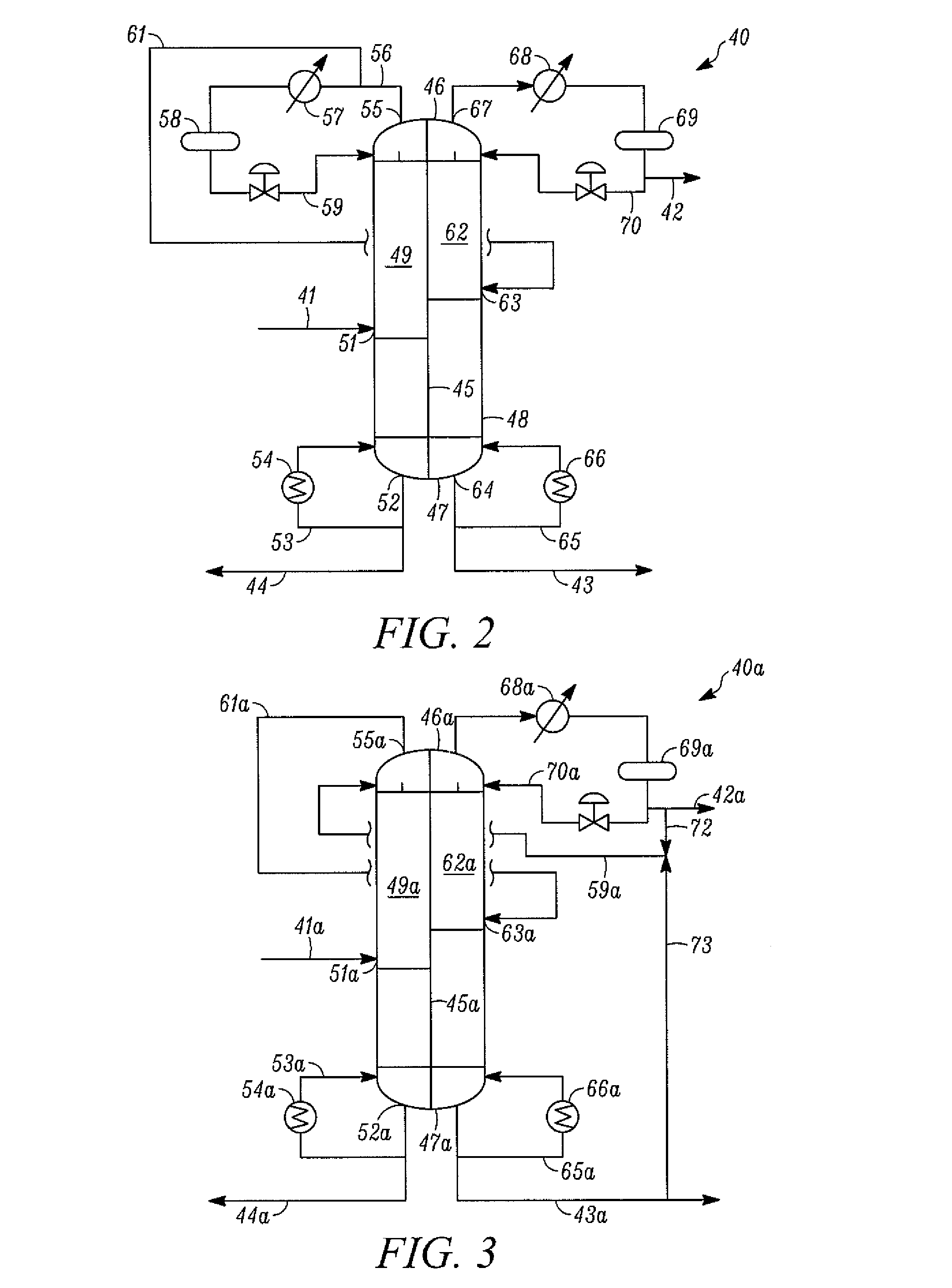

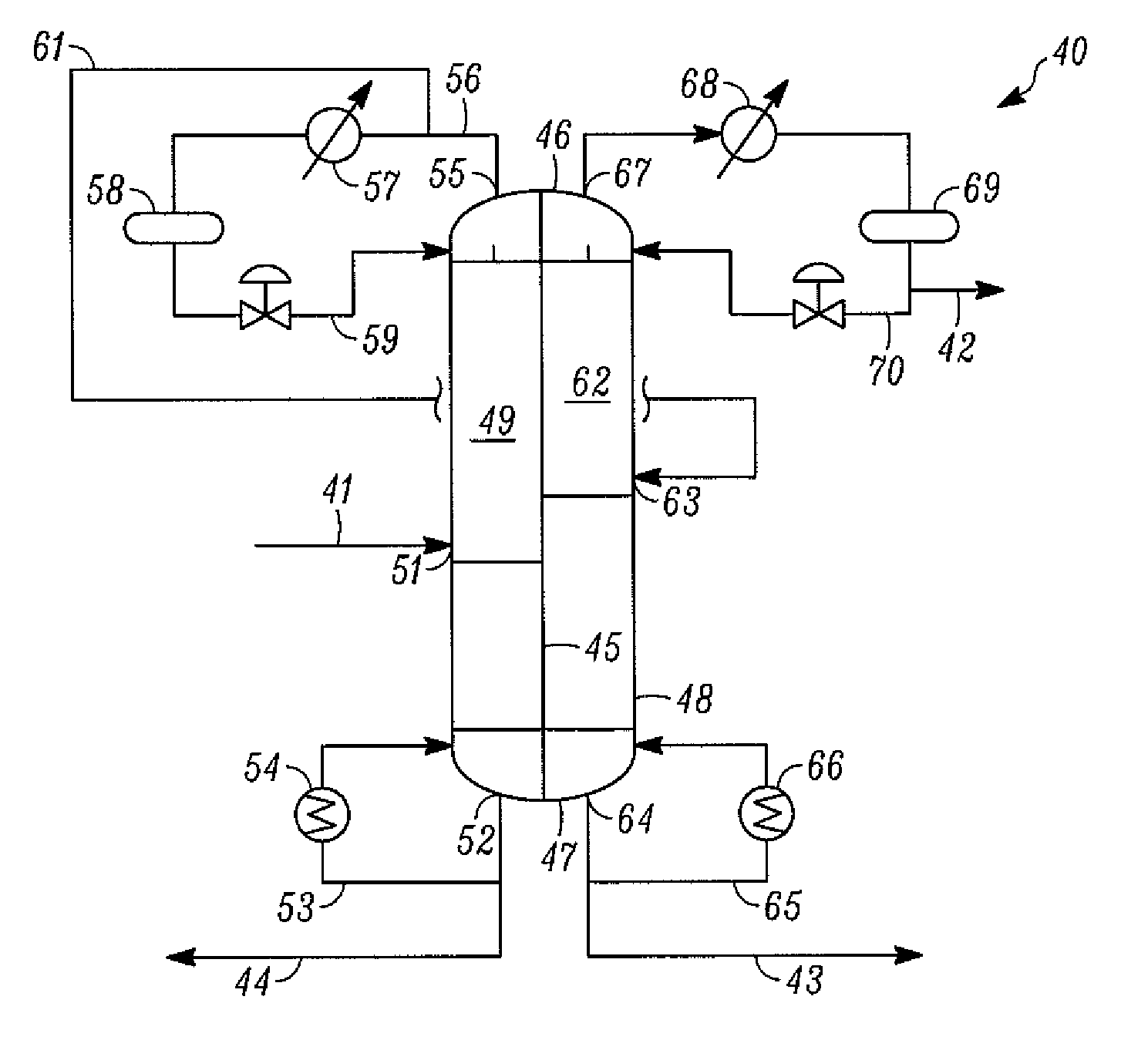

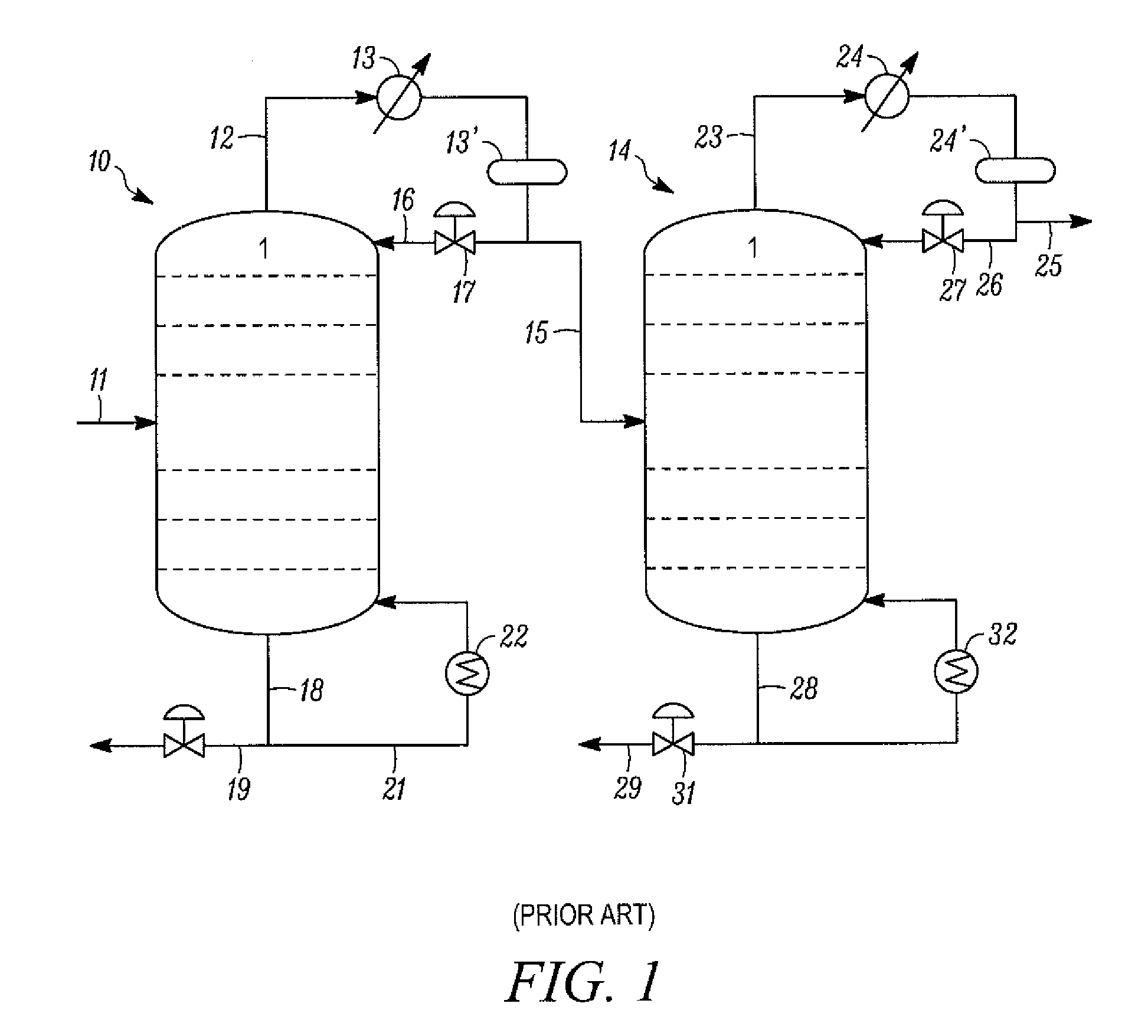

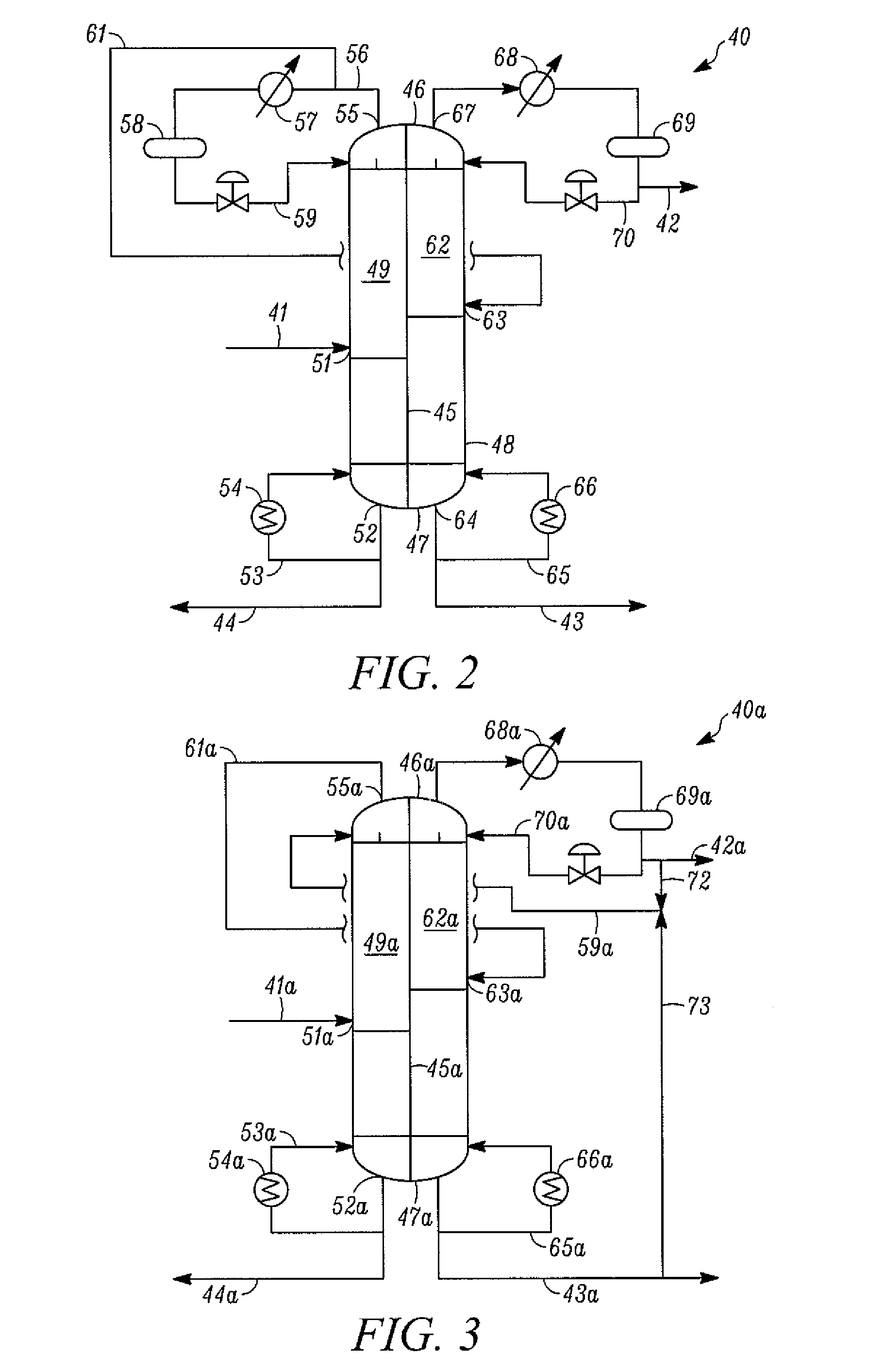

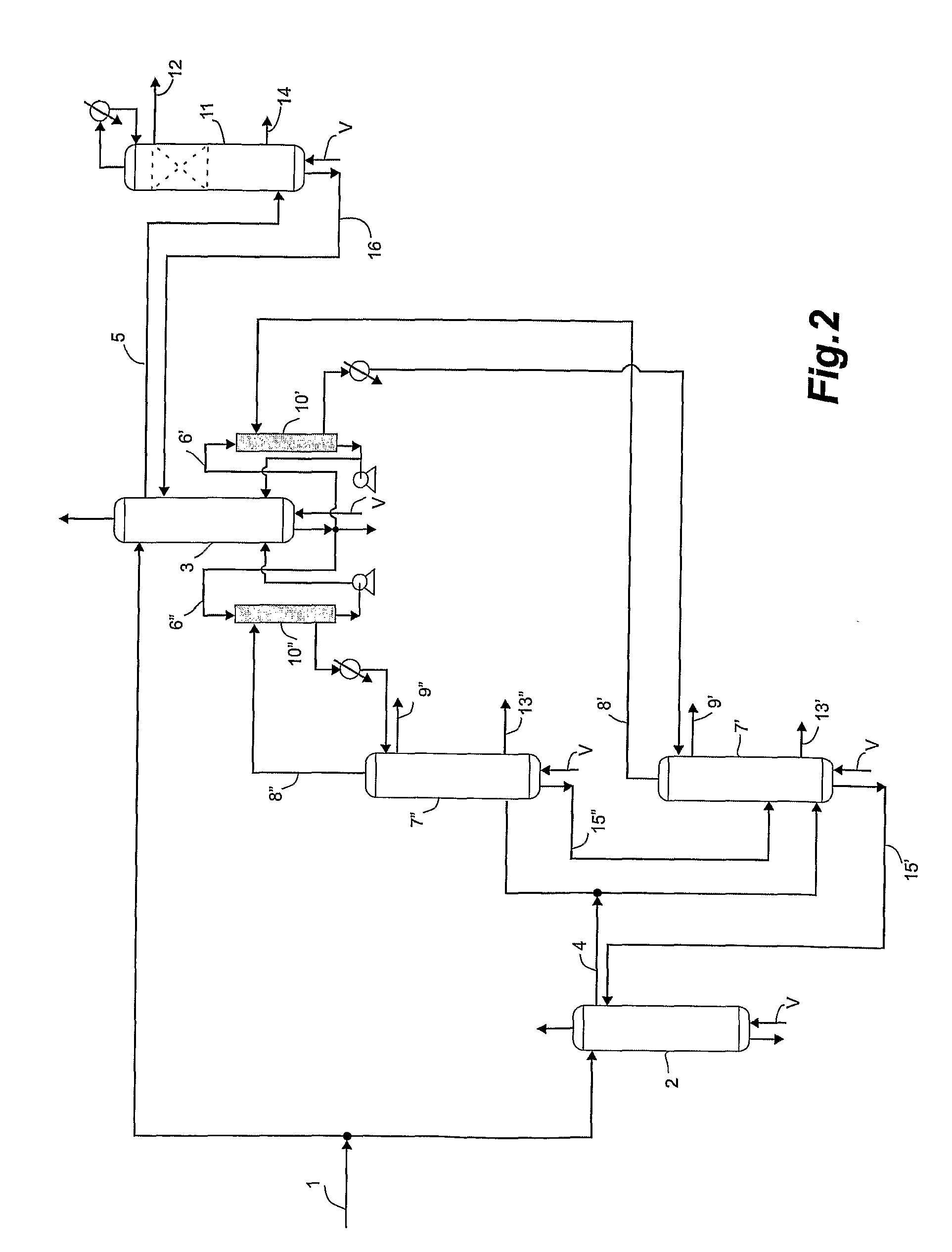

Apparatus and Methods for Separating Butene-1 from a Mixed C4 Feed

ActiveUS20080161618A1Reduce constructionLow costSolvent extractionDistillation in boilers/stillsButeneFractionating column

A process is disclosed for recovering 1-butene from a feed steam comprising n-butane, isobutane and butene isomers using a single, divided wall distillation column. The disclosed process includes introducing the feed steam into an inlet of a first side of a distillation column, wherein the distillation column comprises a top, a bottom and a center dividing wall extending between the bottom and the top of the column and dividing the column into the first side and a second side. The process includes taking off an isobutane stream from the top of the second side of column, taking off a 1-butene stream as a bottoms stream from the second side of the column, and taking off a combination 2-butene and n-butane stream as a bottom stream from the first side of column.

Owner:UOP LLC

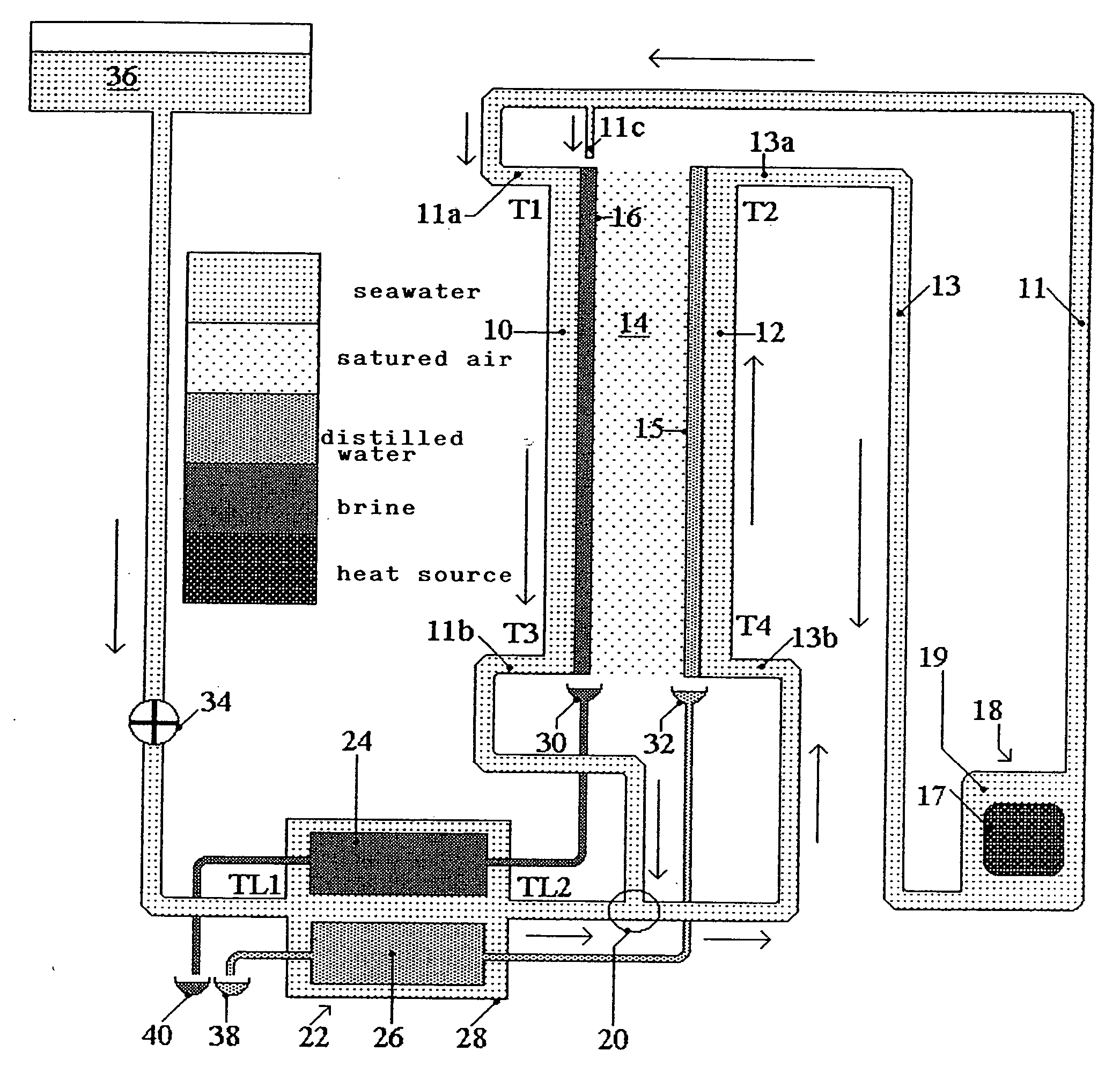

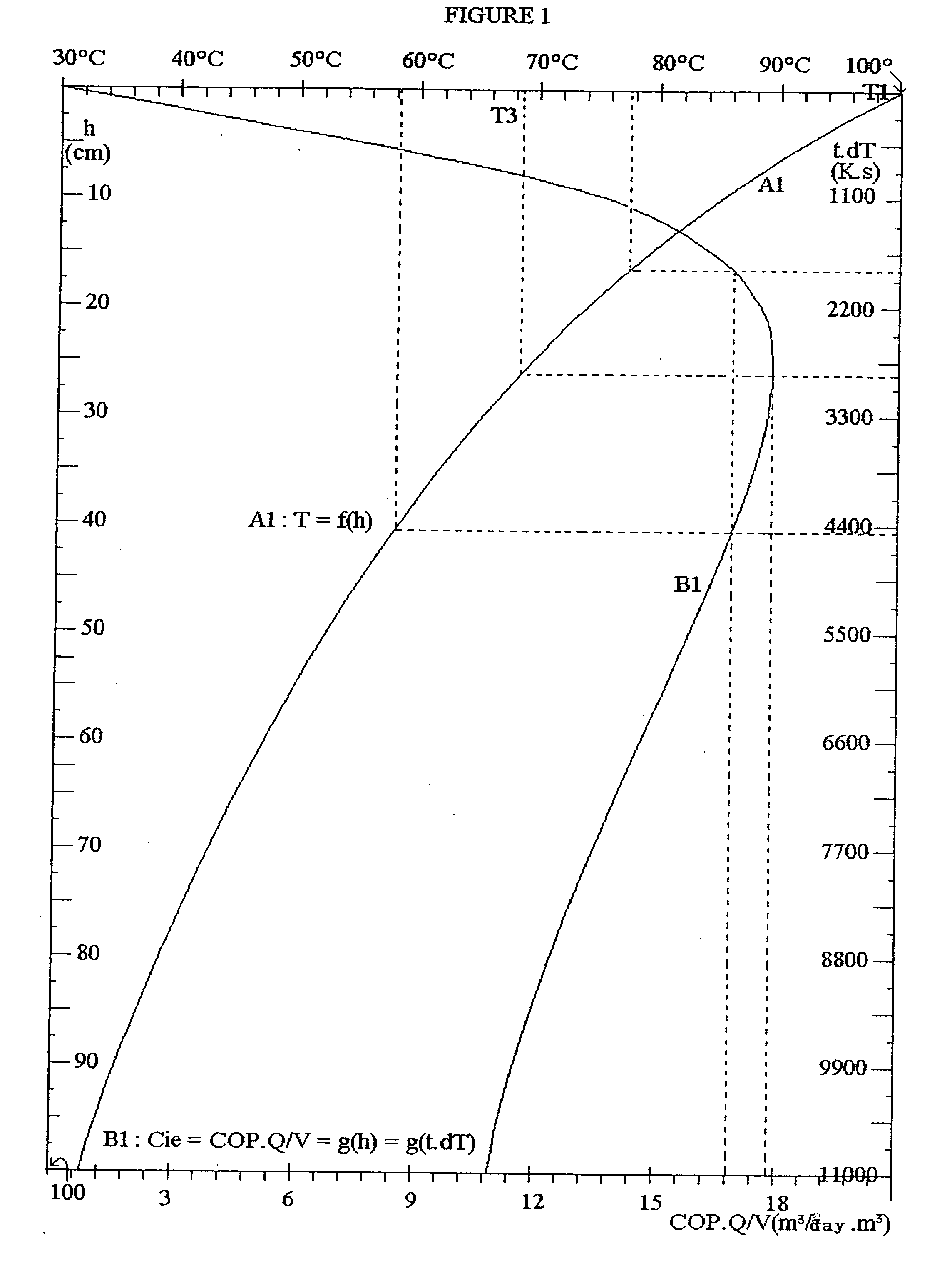

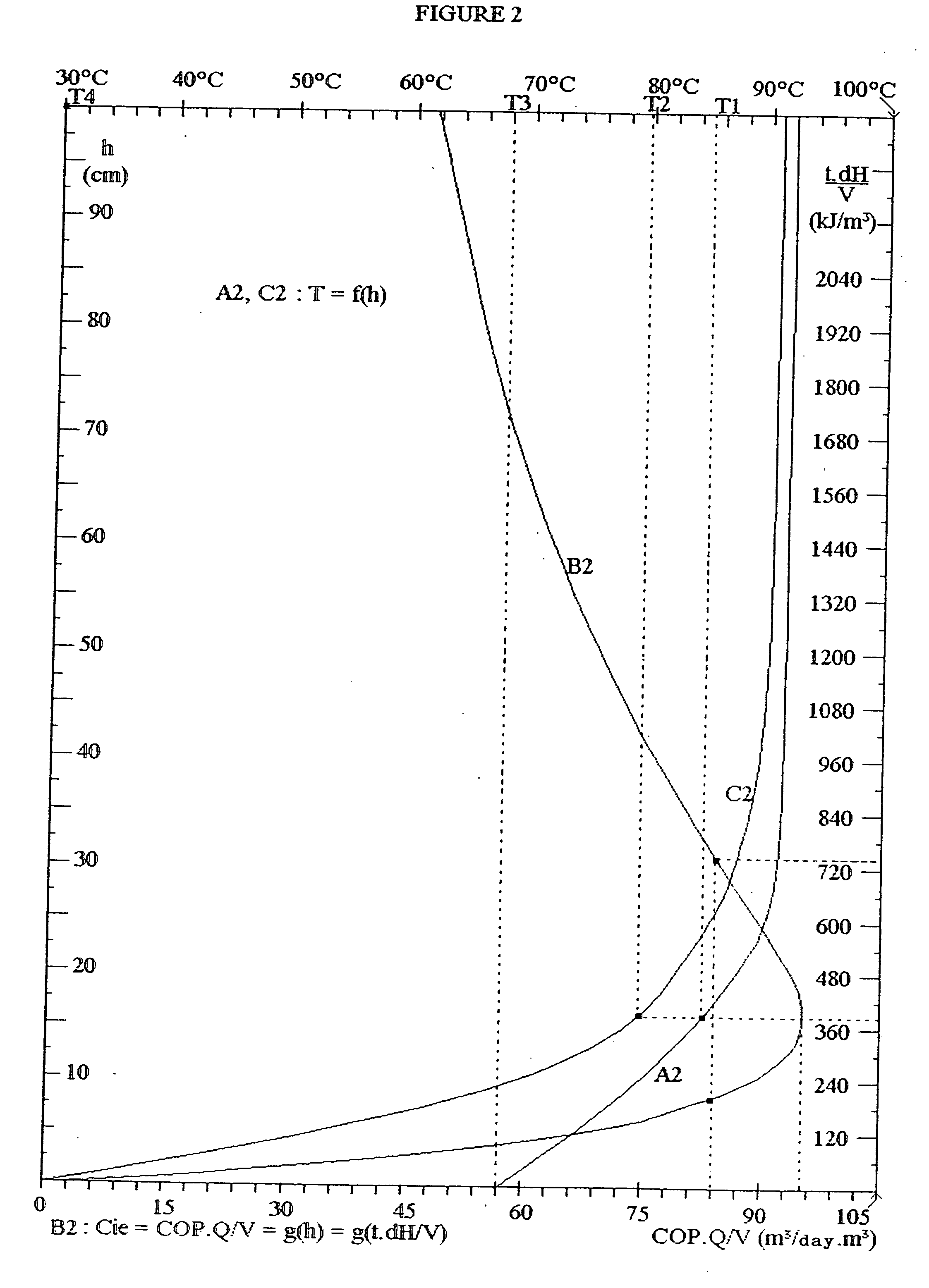

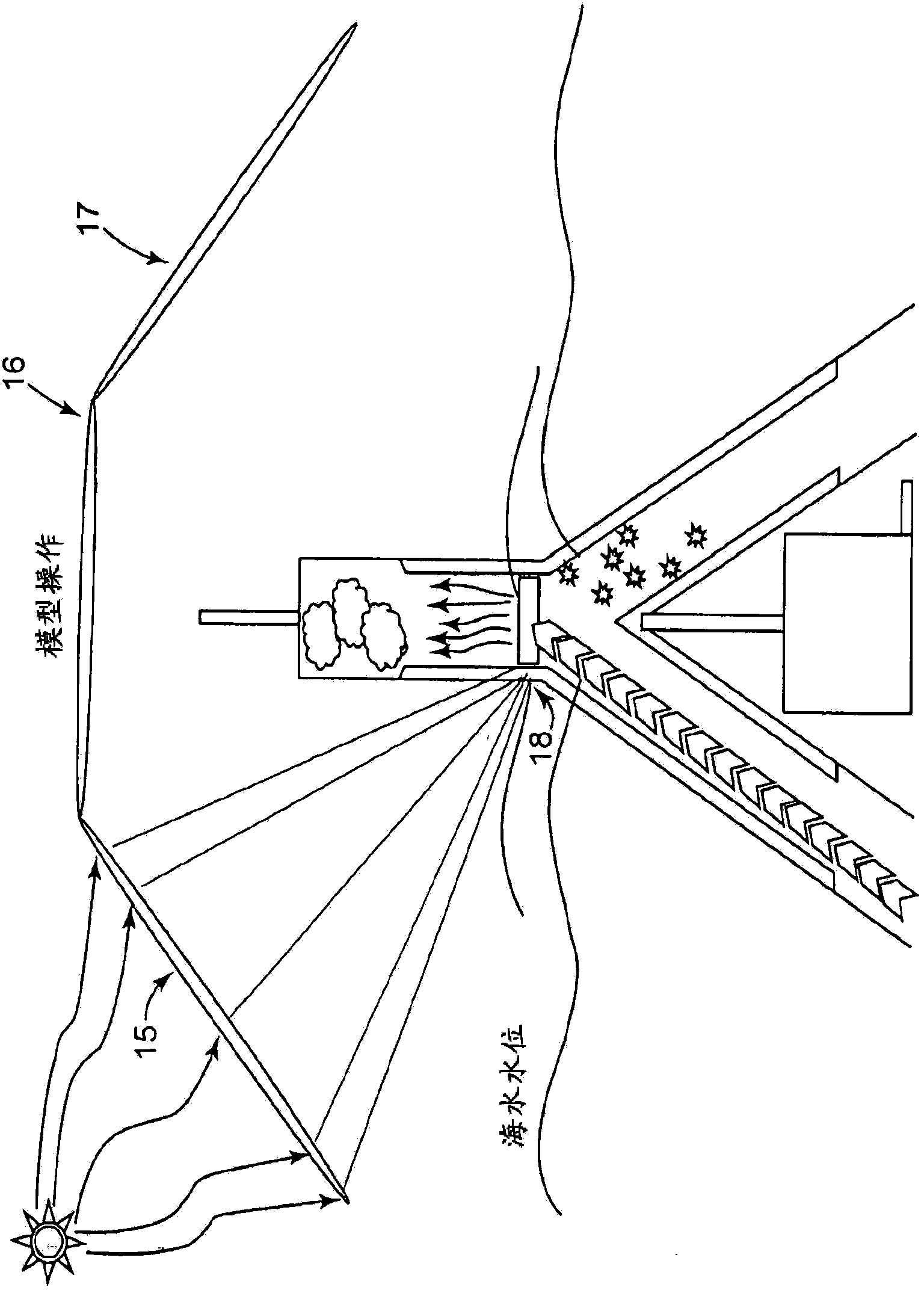

Distillation methods and devices in particular for producing potable water

InactiveUS20060272933A1Improve efficiencyHigh densityGeneral water supply conservationAuxillariesEngineeringSeawater

The inventive device is embodied in the form of a chamber-oven for diffusing vapour and saturated hot air which circulate in a closed circuit by natural convection. Said device is embodied in the form of a domestic-use solar energy collecting device provided with a greenhouse whose surface is equal to 1 m2 and produces from 50 to 100 litres / day of distilled water. The device comprises a distillation unit arranged between two furnaces (59′, 79′) in a temperature-controlled container (48′). Said distillation unit comprises 100 flat thin hollow plates having a surface of 20 dm2 by face and an active volume of 200 dm3. The fine and tensioned walls (54) of said plates are provided with a hydrophilic coating (60′) and internal (56′) and inter-plate (58′) spaces. The lower chimney (59′) comprises a greenhouse (118′, 119′) whose bottom is embodied in the form of an impermeable black layer provided with a thin hydrophilic carpet on the rear part thereof. Saturated hot air at a temperature of 80° C. enters inside (56′) hollow plates from bellow and exits from the top at a temperature of 50° C. A high chimney (79′) is provided with a monoblock heat exchanger (84′) which is transversed by a non-potable water to be distilled which, afterwards is spread warm (40° C.) over the hydrophilic coating (60′). During passage through the heat exchanger (84) the air is cooled to 30° C. and moved down by gravity to the inter-plate spaces (58′) and exits therefrom at a temperature of 78° C. The distilled water condensed in the plates and by the heat exchanger is collected and removed. Brine is received in the bottom of the inter-plate space and distributed along the thin hydrophilic carpet of the bottom (122′) of the greenhouse. An air current passes along said hot carpet is heated and saturated and enters the plates. The brine liquor finally flows in an air-preheating tank (63′) which is emptied each morning. The greenhouse can be substituted by a heating tube transversed by a heating fluid or associated with another steam-jet tube. The more powerful chamber-ovens can produce at least 200 m3 / day of distilled water for collective consumption. Said invention can be used for salt removal from seawater, co-generating electricity and potable water and for producing food concentrates.

Owner:THE THIRD MILLENIUM WATER

Apparatuses and methods for separating butene-1 from a mixed C4 feed

ActiveUS7528290B2Reduce constructionLow costSolvent extractionDistillation in boilers/stillsButeneDistillation

A process is disclosed for recovering 1-butene from a feed steam comprising n-butane, isobutane and butene isomers using a single, divided wall distillation column. The disclosed process includes introducing the feed steam into an inlet of a first side of a distillation column, wherein the distillation column comprises a top, a bottom and a center dividing wall extending between the bottom and the top of the column and dividing the column into the first side and a second side. The process includes taking off an isobutane stream from the top of the second side of column, taking off a 1-butene stream as a bottoms stream from the second side of the column, and taking off a combination 2-butene and n-butane stream as a bottom stream from the first side of column.

Owner:UOP LLC

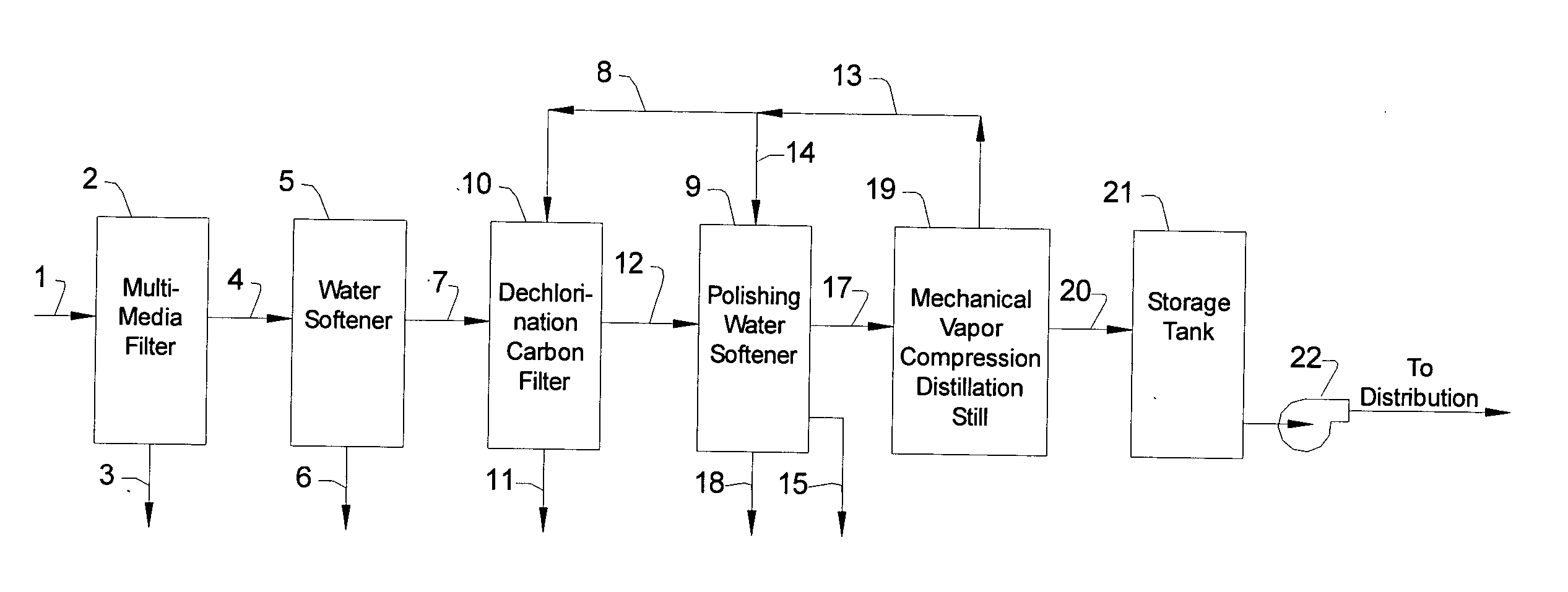

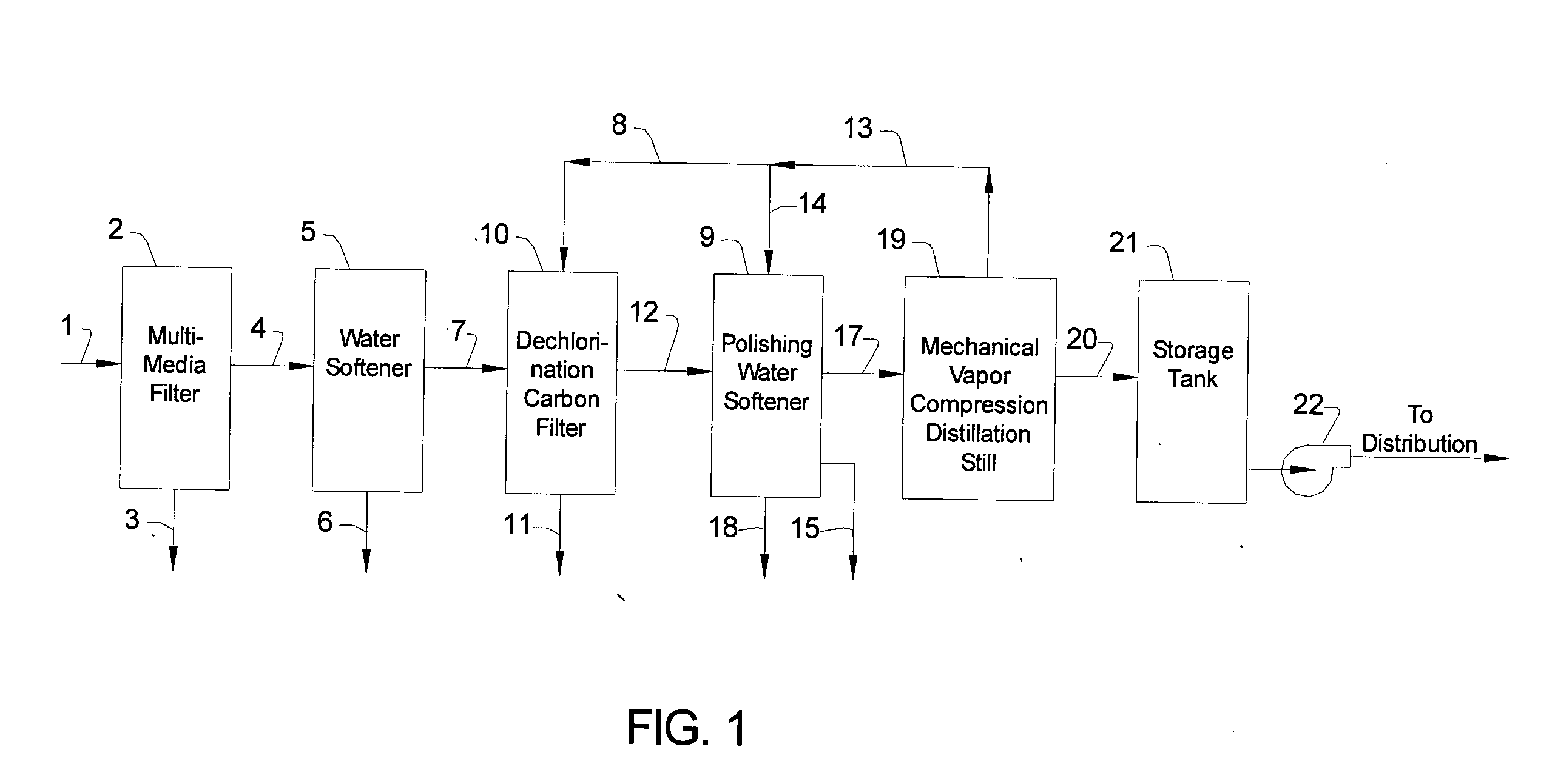

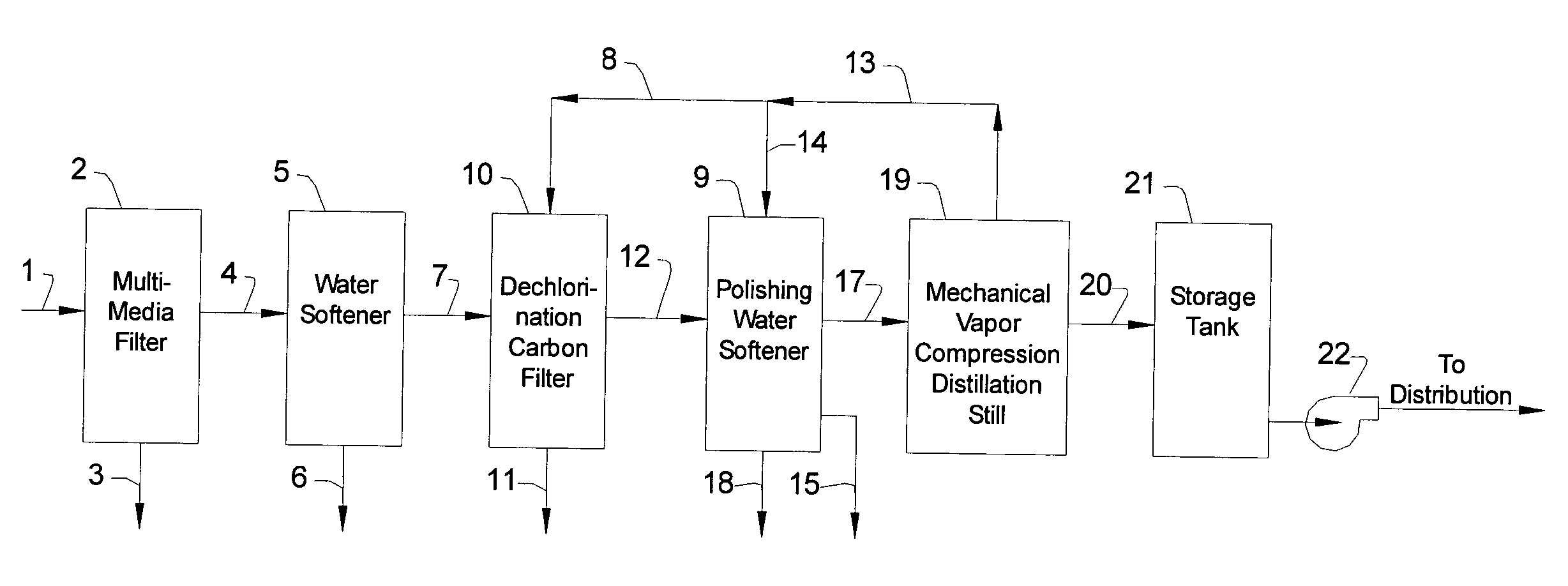

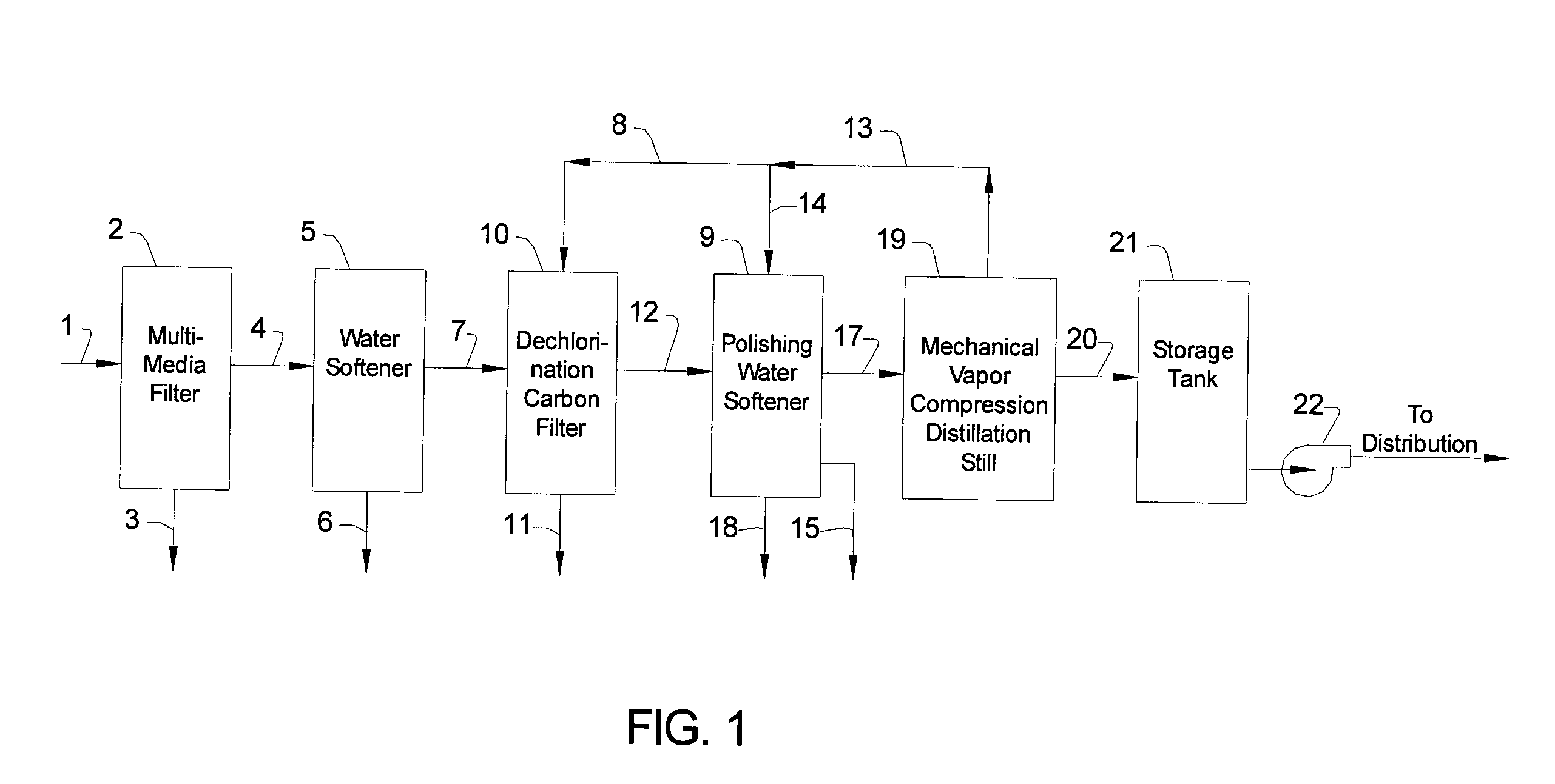

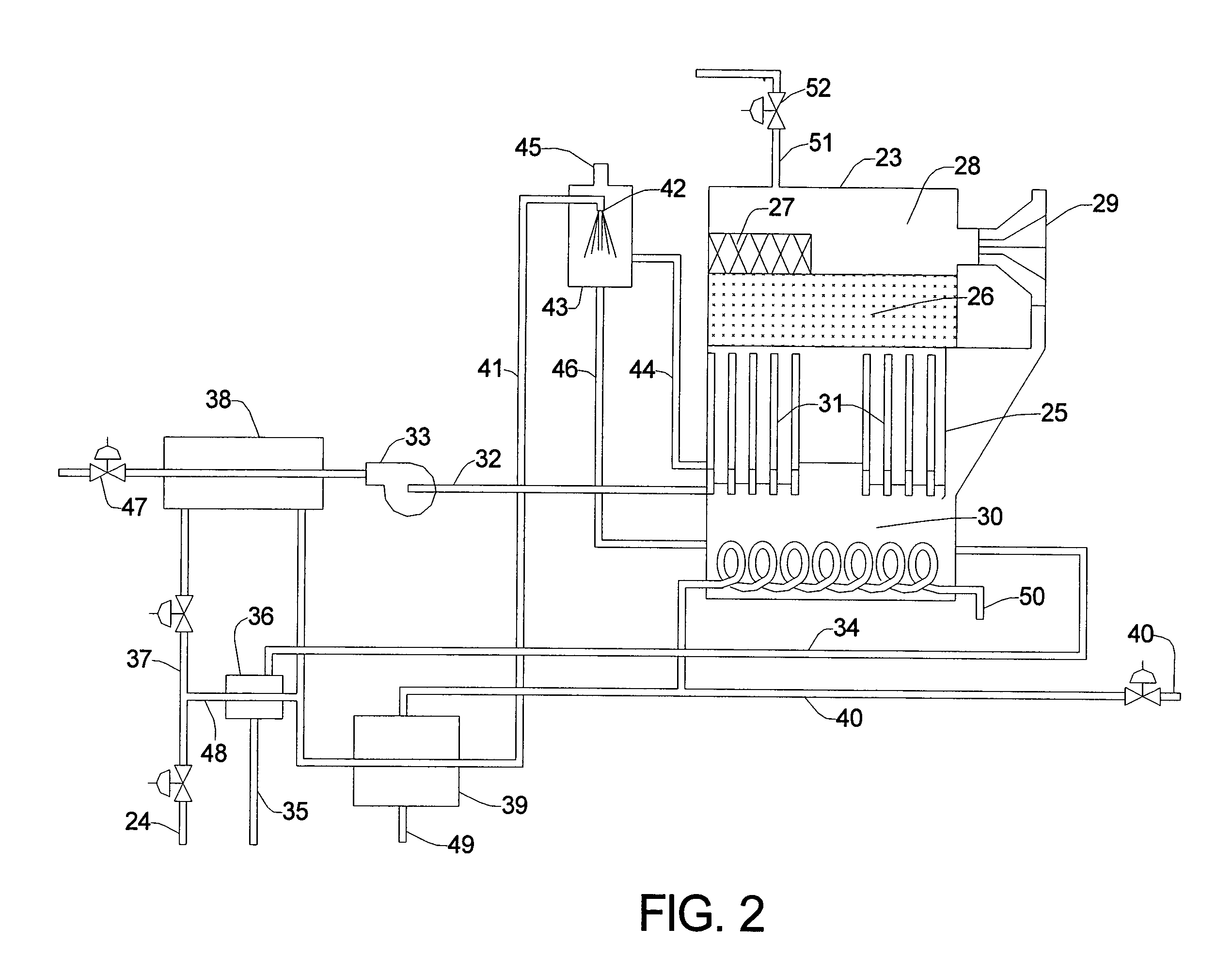

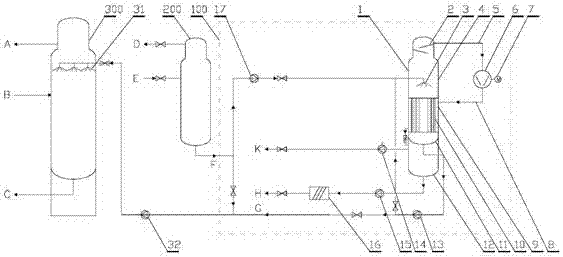

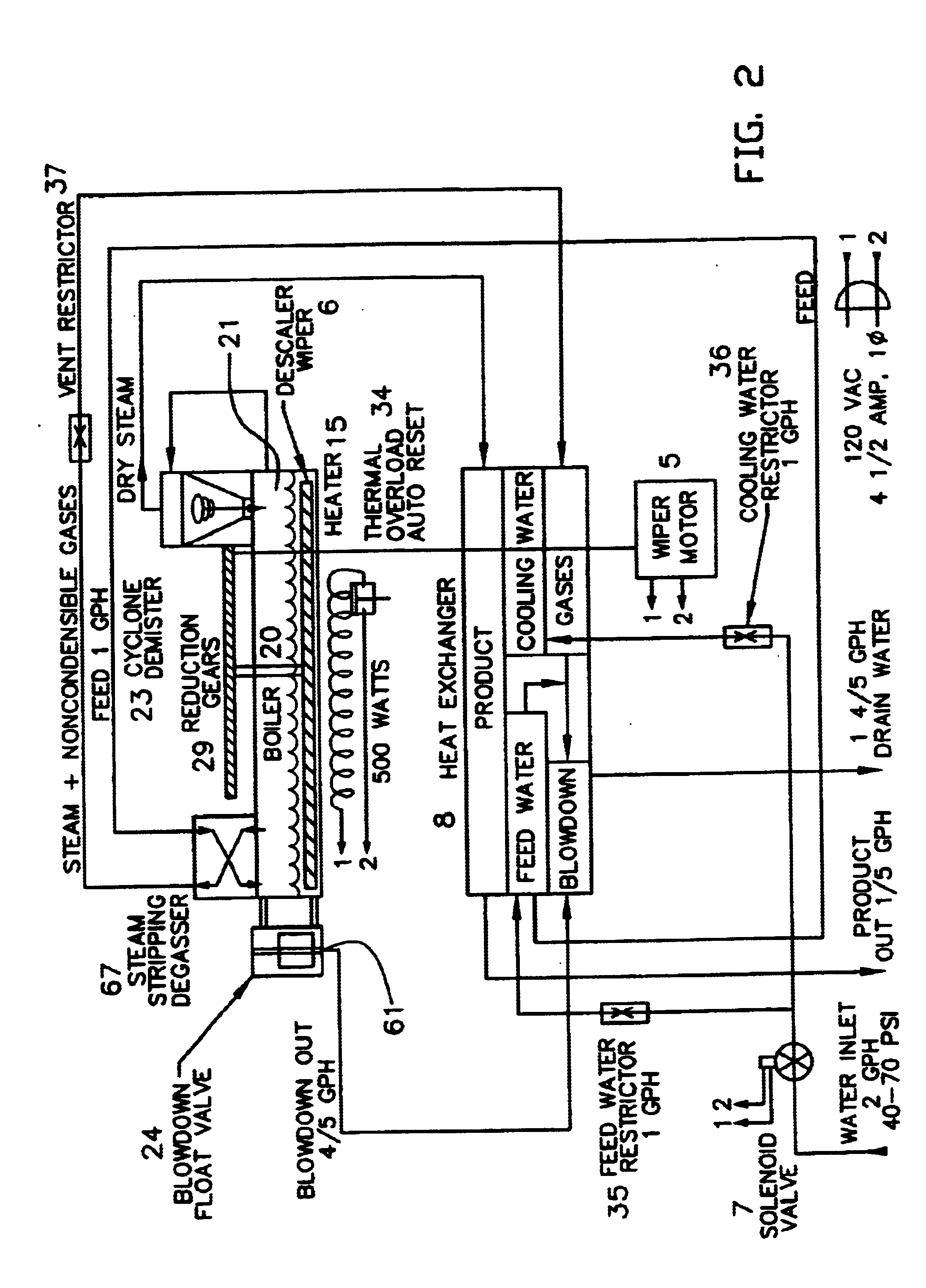

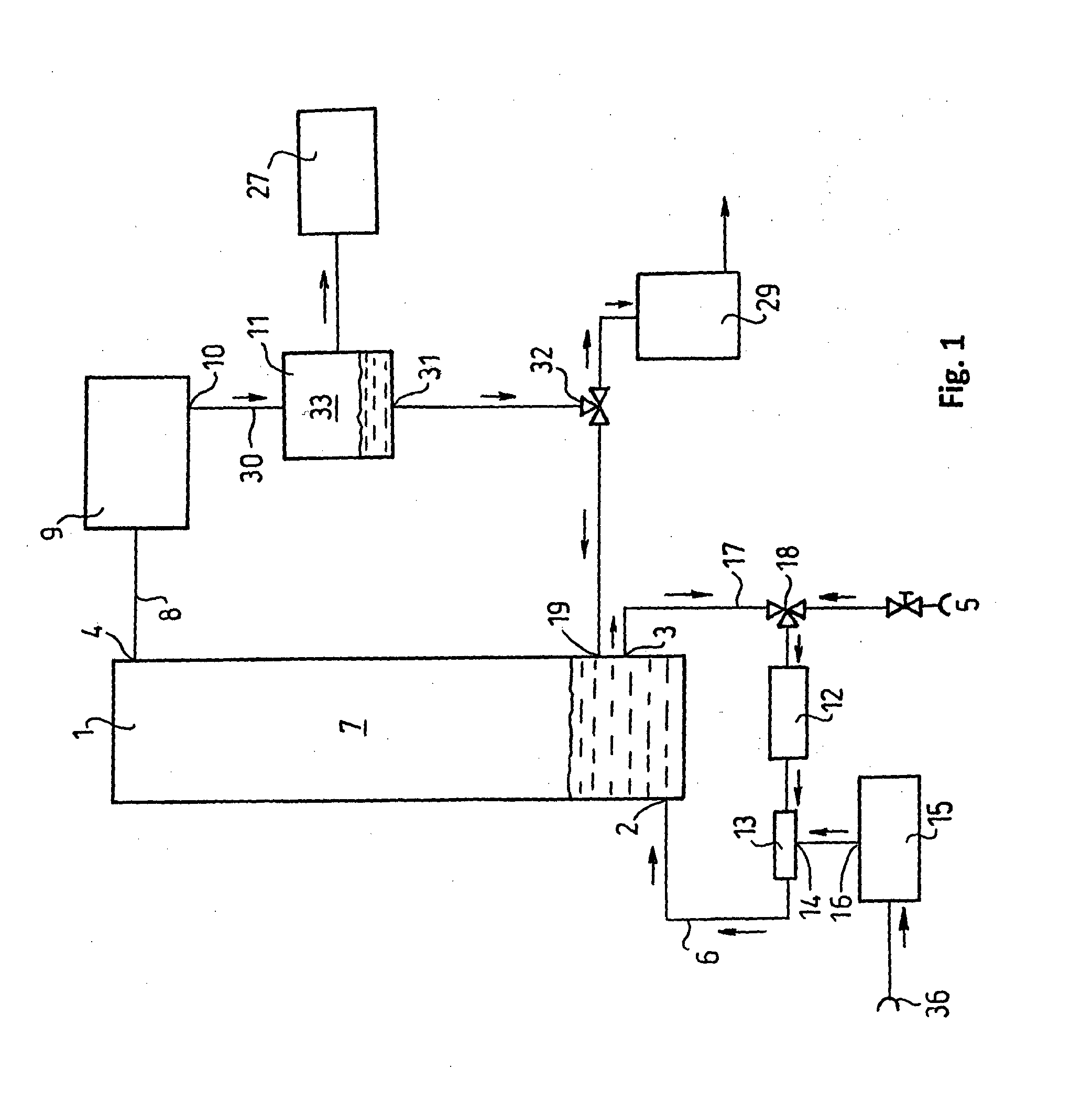

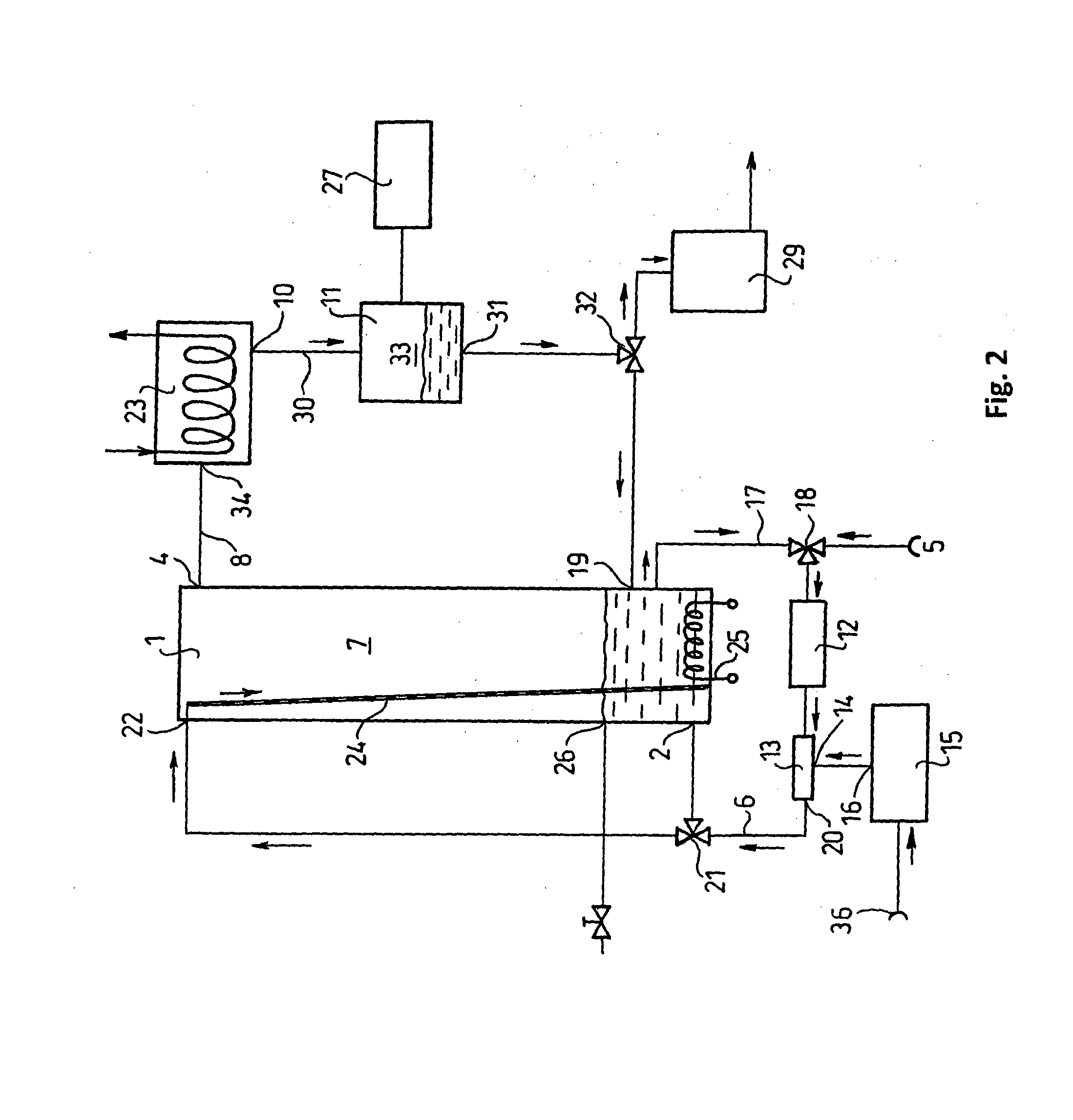

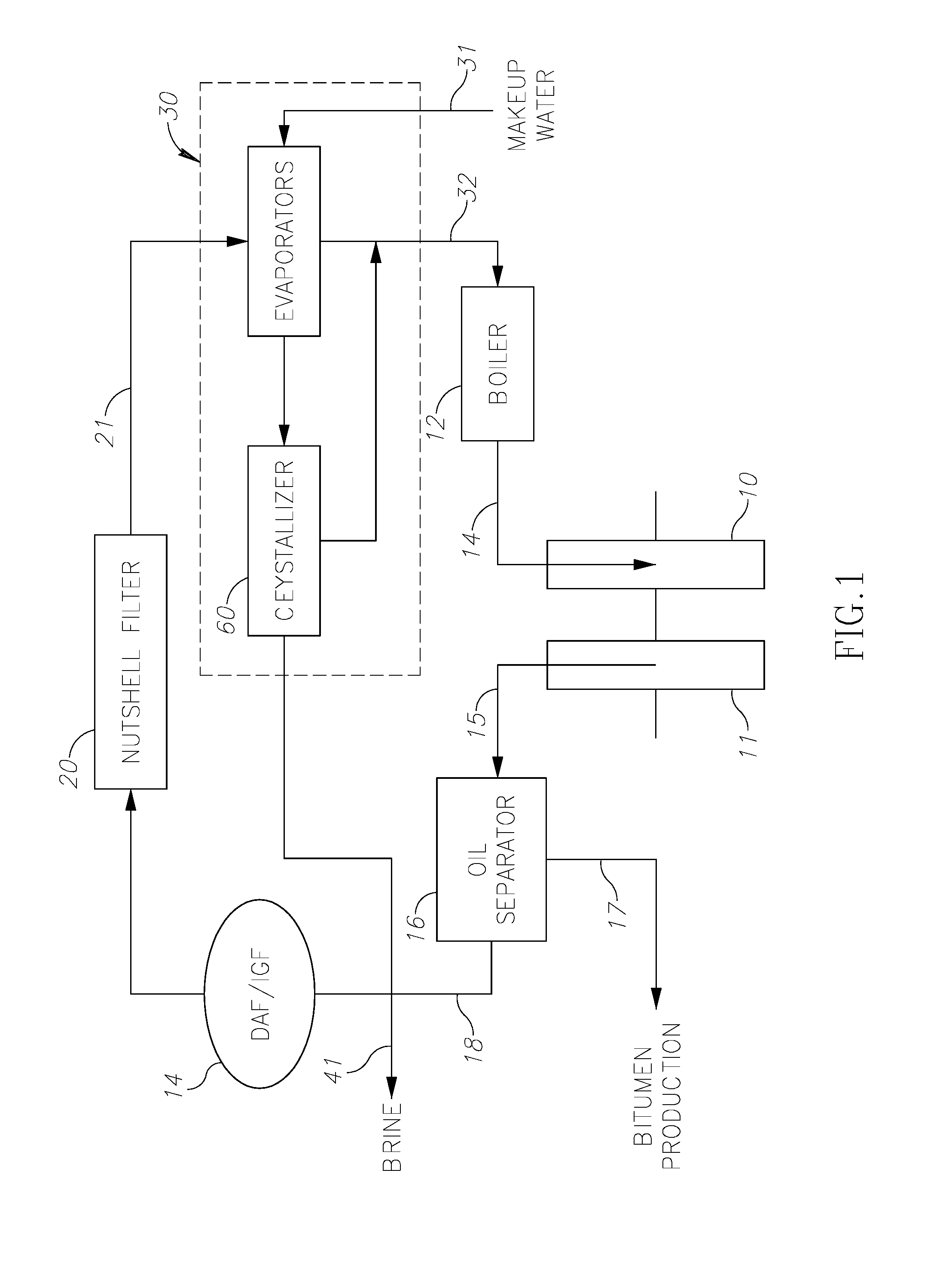

Method and system for the manufacture of pharmaceutical water

InactiveUS20050056594A1Eliminate processingRemoving hardnessLiquid degasification with auxillary substancesAuxillariesDistillationWater quality

A method is provided for manufacturing pharmaceutical water by means of distillation and sanitizing the equipment used in said manufacturing. The method comprises the removal of suspended solids from chlorine-containing water by means of a multimedia filter, followed by a water-softening step and a dechlorination step. Ammonia is then removed from the dechlorinated water before subjecting the water to distillation in a mechanical vapor compression distillation unit. A portion of the generated low-pressure-steam is used to sanitize the manufacturing equipment at certain prescribed locations, and the distilled water, exhibiting United States Pharmacopoeia purified water quality, is withdrawn from the still and stored as pharmaceutical water product. No reverse osmosis operation is required. A system for carrying out the process is also provided. Sanitization is carried out while the system is in a standby mode.

Owner:MECHANICAL EQUIP

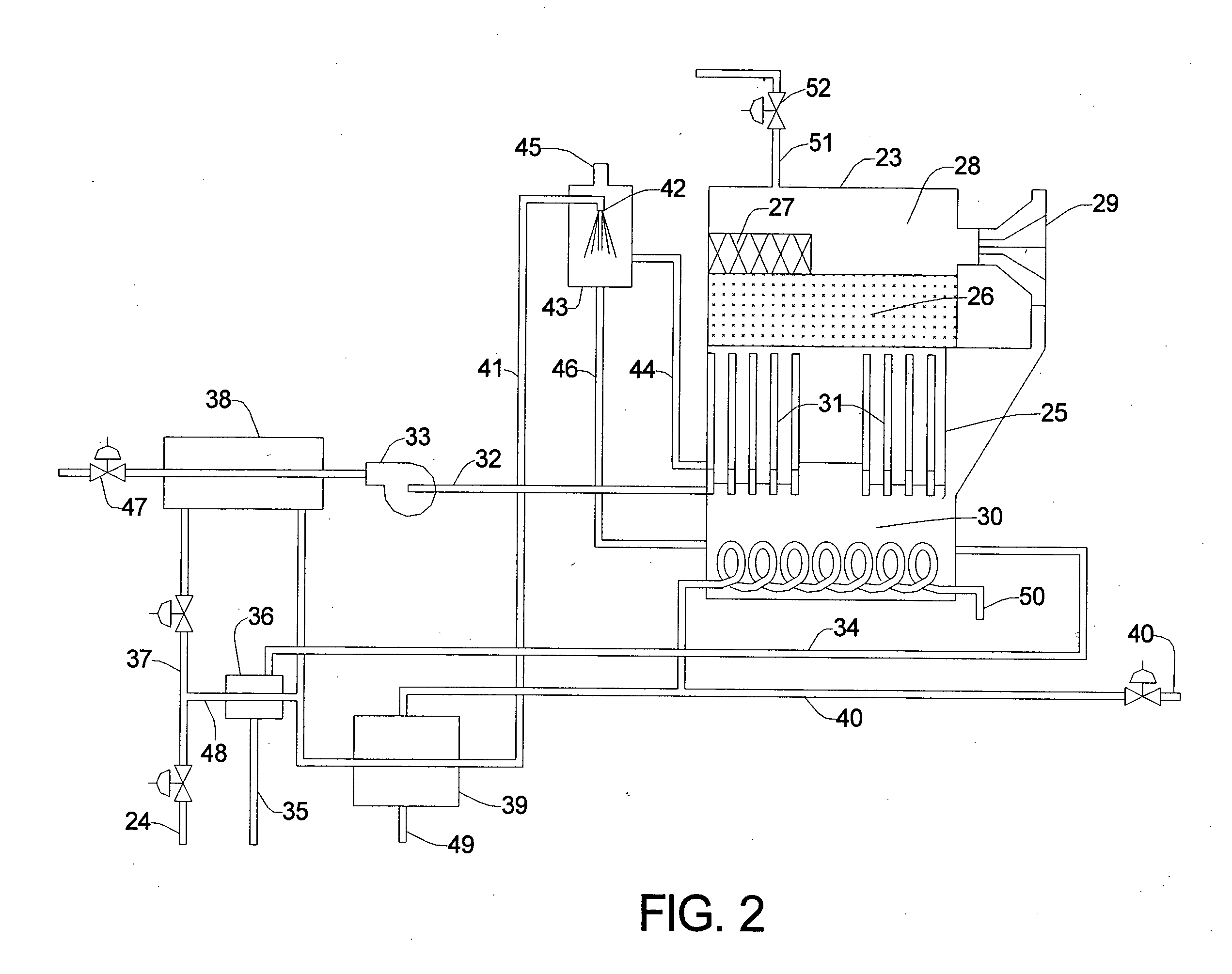

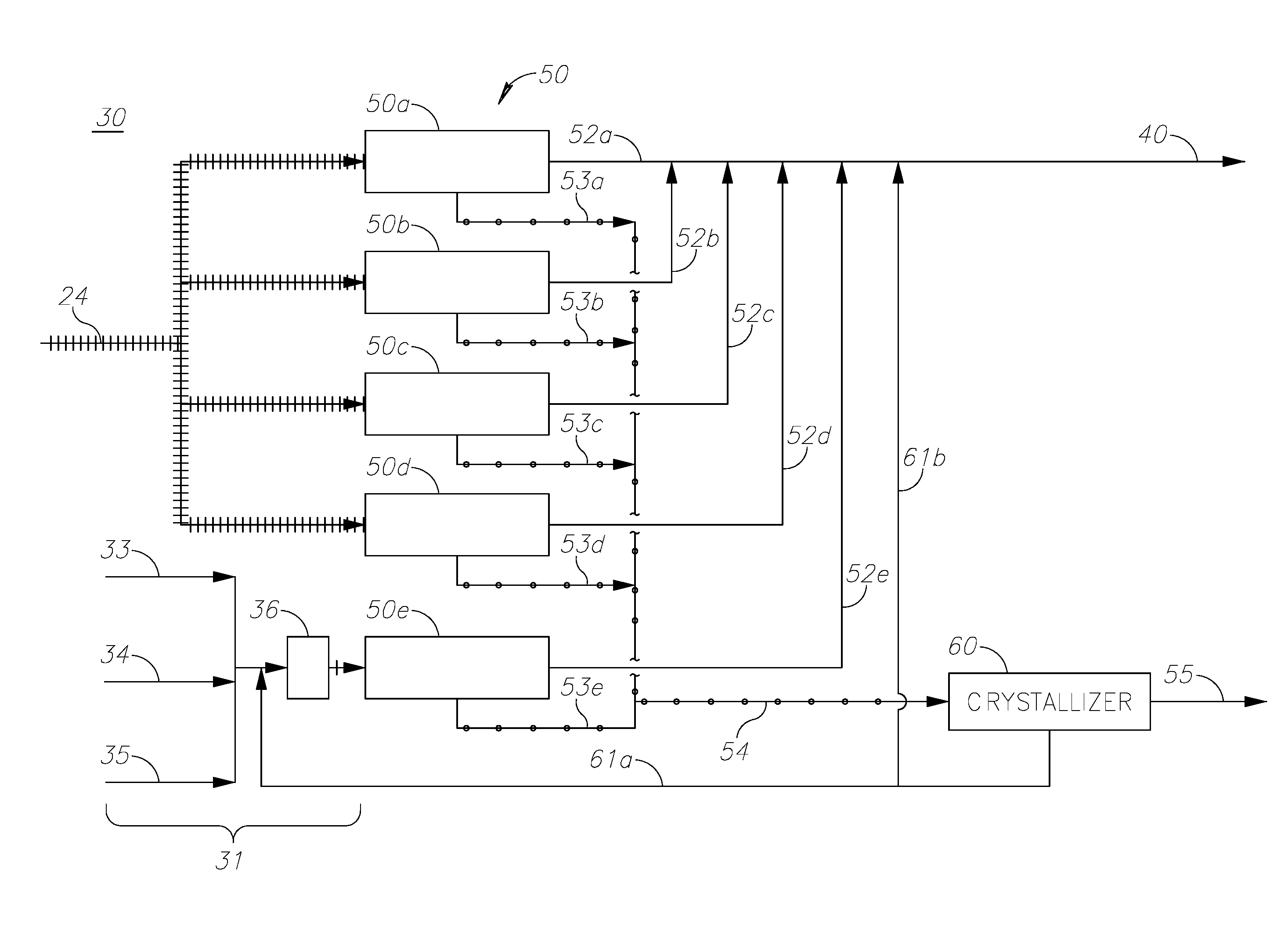

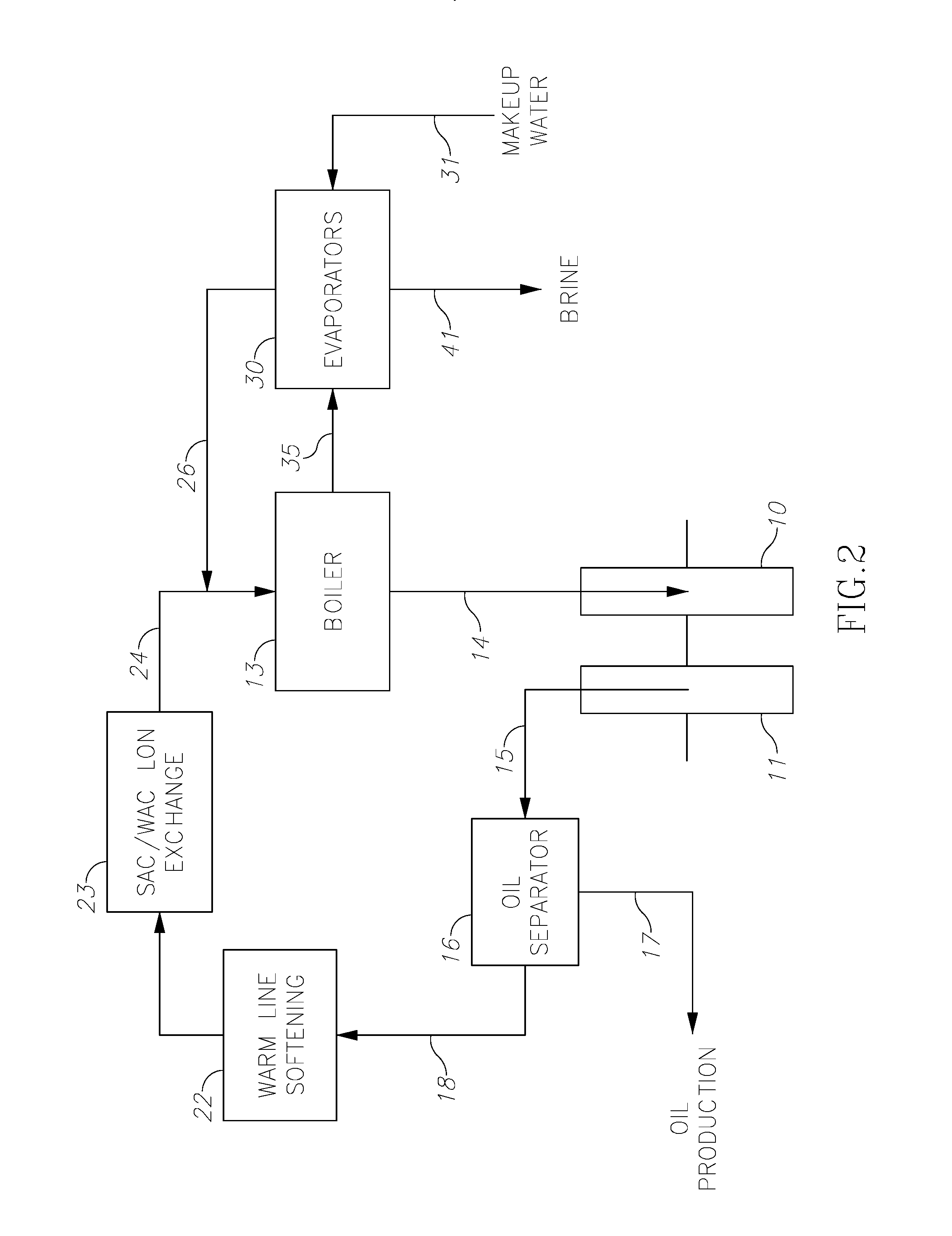

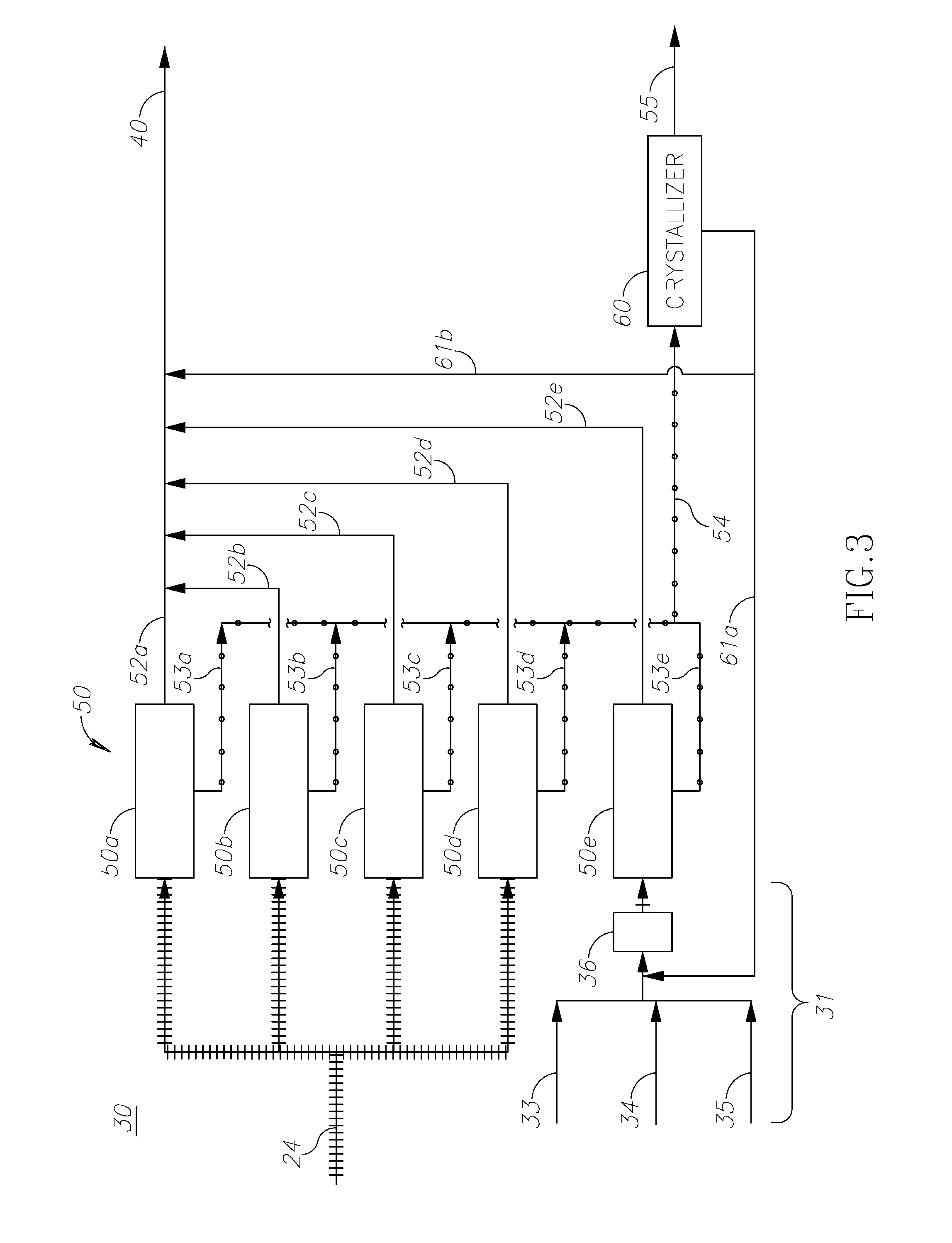

Evaporator array for a water treatment system

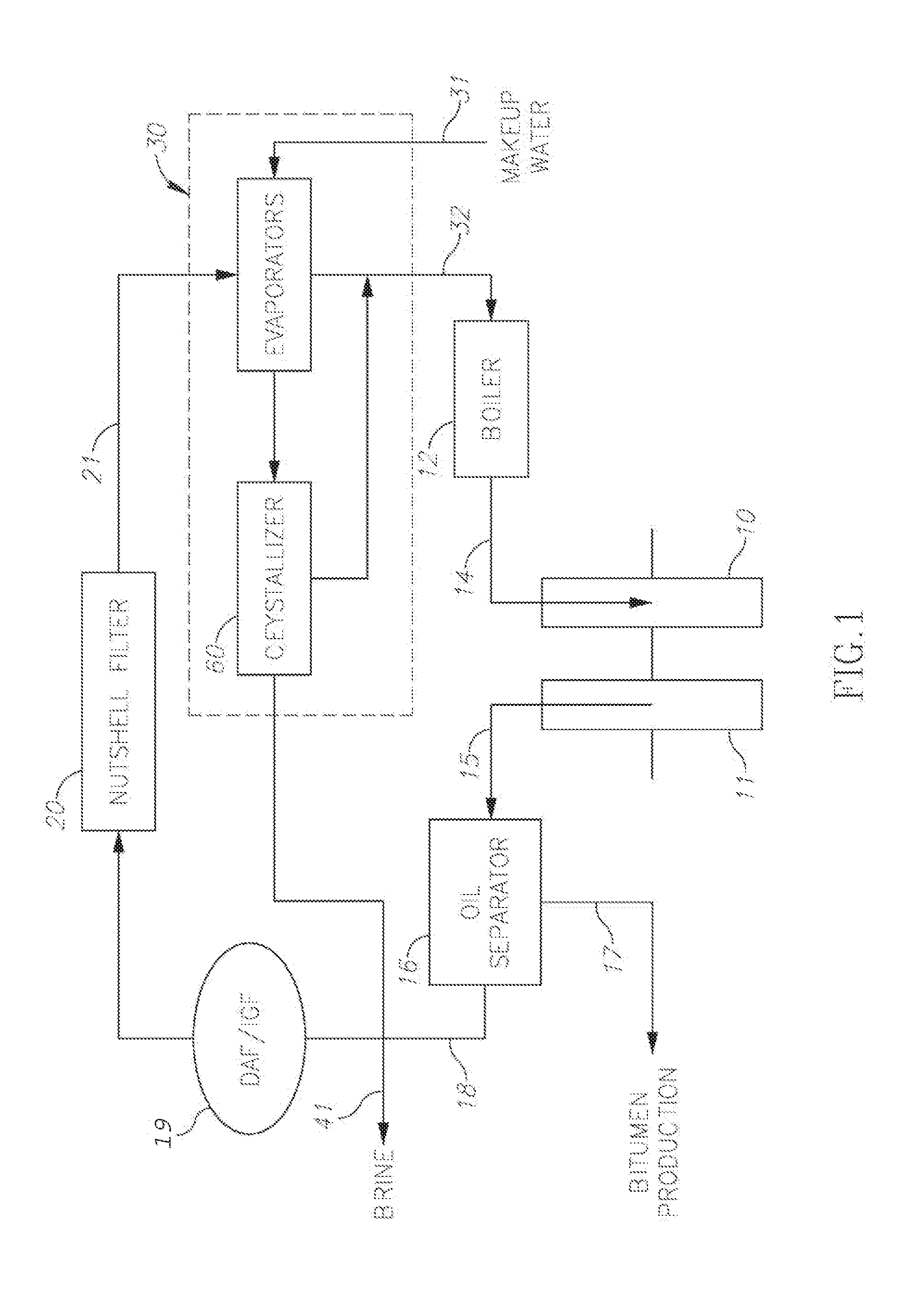

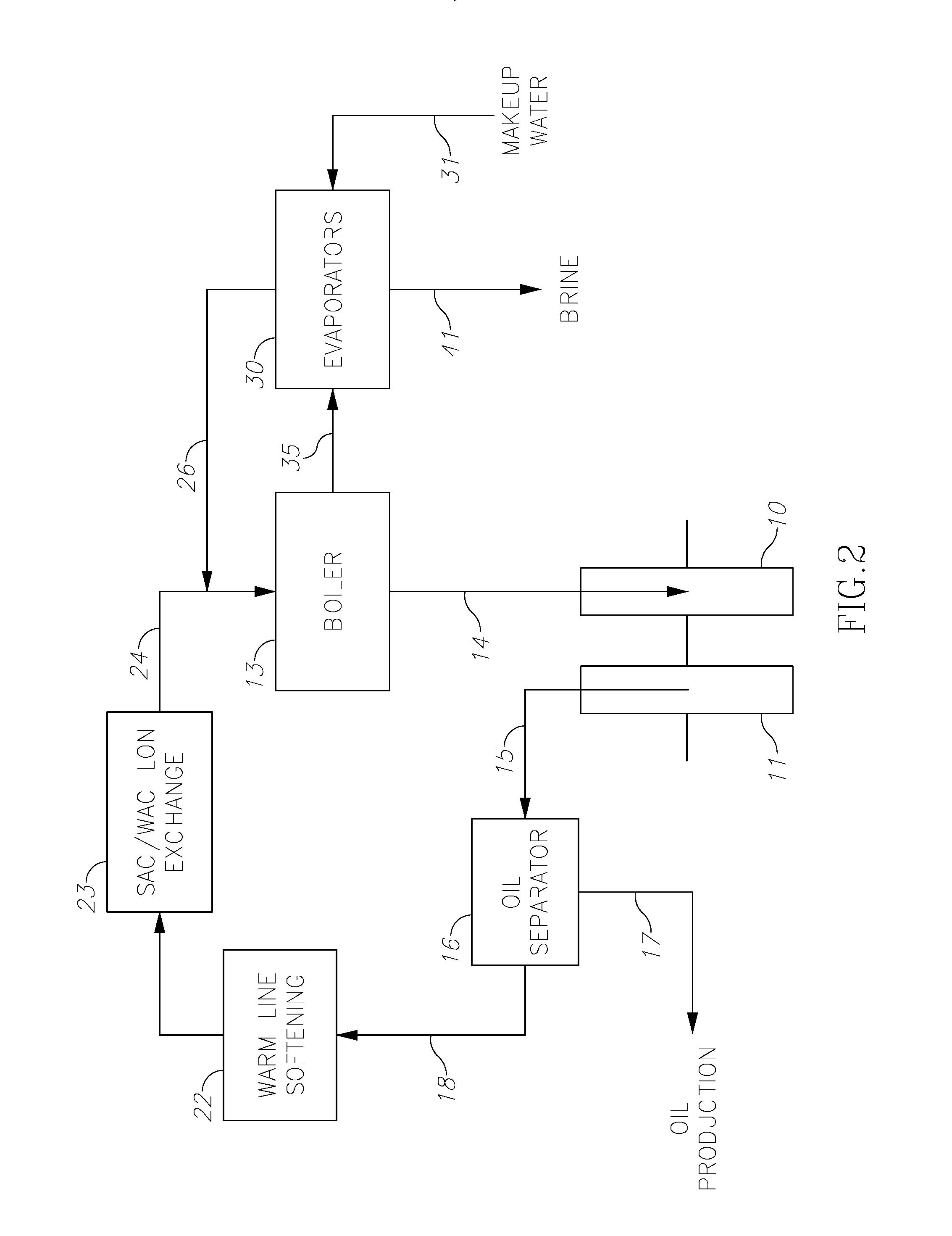

ActiveUS9499413B2Waste water treatment from quariesWater treatment parameter controlWater treatment systemEngineering

An evaporator array for a water treatment system, the evaporator array comprising a produced water feed and a first evaporator to receive produced water from the produced water feed, a makeup water feed and a second evaporator to receive makeup water from the makeup water feed, an output feed to receive distillate from the first evaporator and the second evaporator, and a blowdown feed to receive blowdown from the first evaporator and the second evaporator, wherein the first evaporator and the second evaporator each have a working pH, the working pH of the first evaporator being higher than that of the second evaporator.

Owner:I D E PROJECTS LTD

Method and system for the manufacture of pharmaceutical water

InactiveUS6977047B2Removing hardnessEliminate processingLiquid degasification with auxillary substancesAuxillariesDistillationWater quality

A method is provided for manufacturing pharmaceutical water by means of distillation and sanitizing the equipment used in said manufacturing. The method comprises the removal of suspended solids from chlorine-containing water by means of a multimedia filter, followed by a water-softening step and a dechlorination step. Ammonia is then removed from the dechlorinated water before subjecting the water to distillation in a mechanical vapor compression distillation unit. A portion of the generated low-pressure-steam is used to sanitize the manufacturing equipment at certain prescribed locations, and the distilled water, exhibiting United States Pharmacopoeia purified water quality, is withdrawn from the still and stored as pharmaceutical water product. No reverse osmosis operation is required. A system for carrying out the process is also provided. Sanitization is carried out while the system is in a standby mode.

Owner:MECHANICAL EQUIP

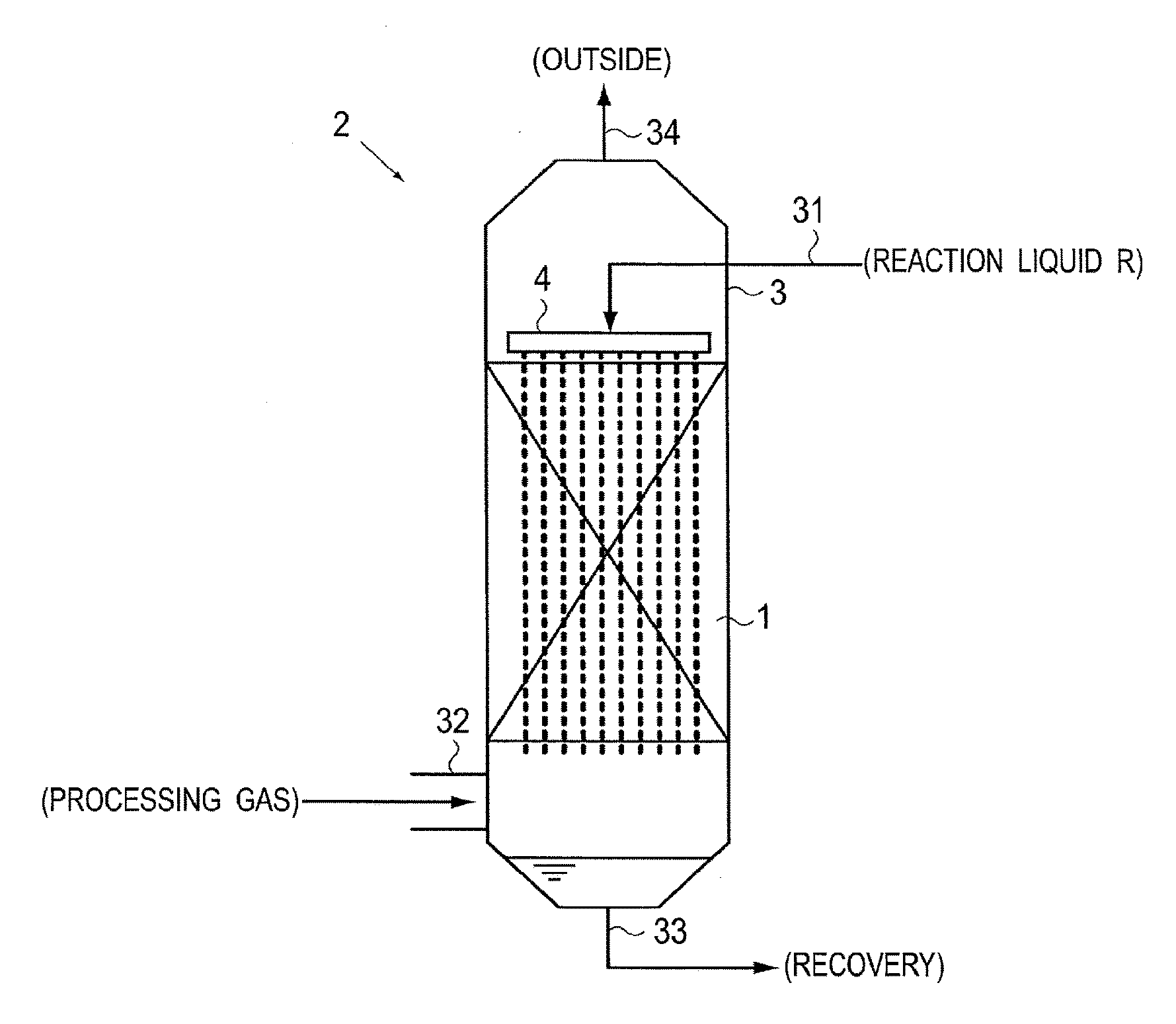

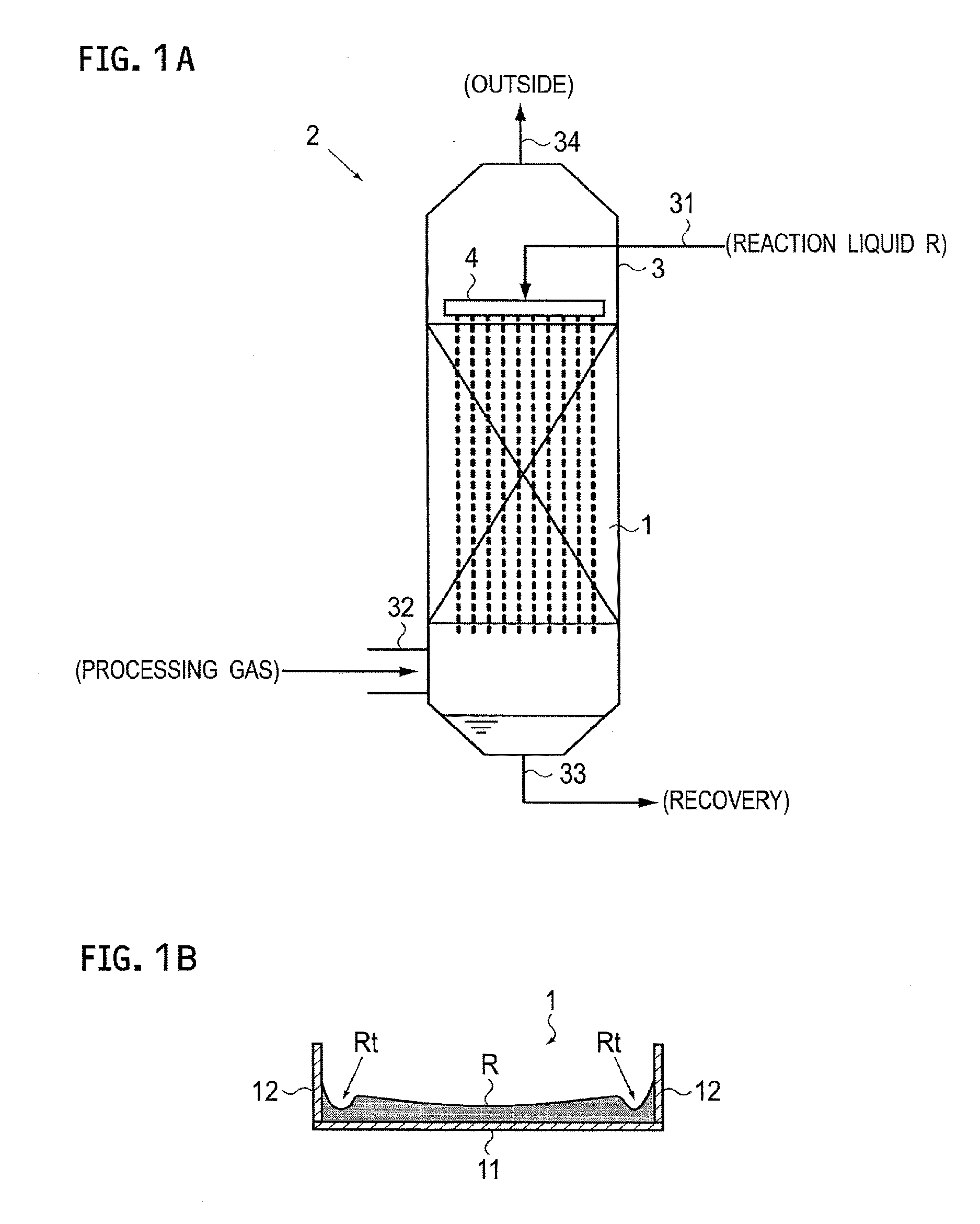

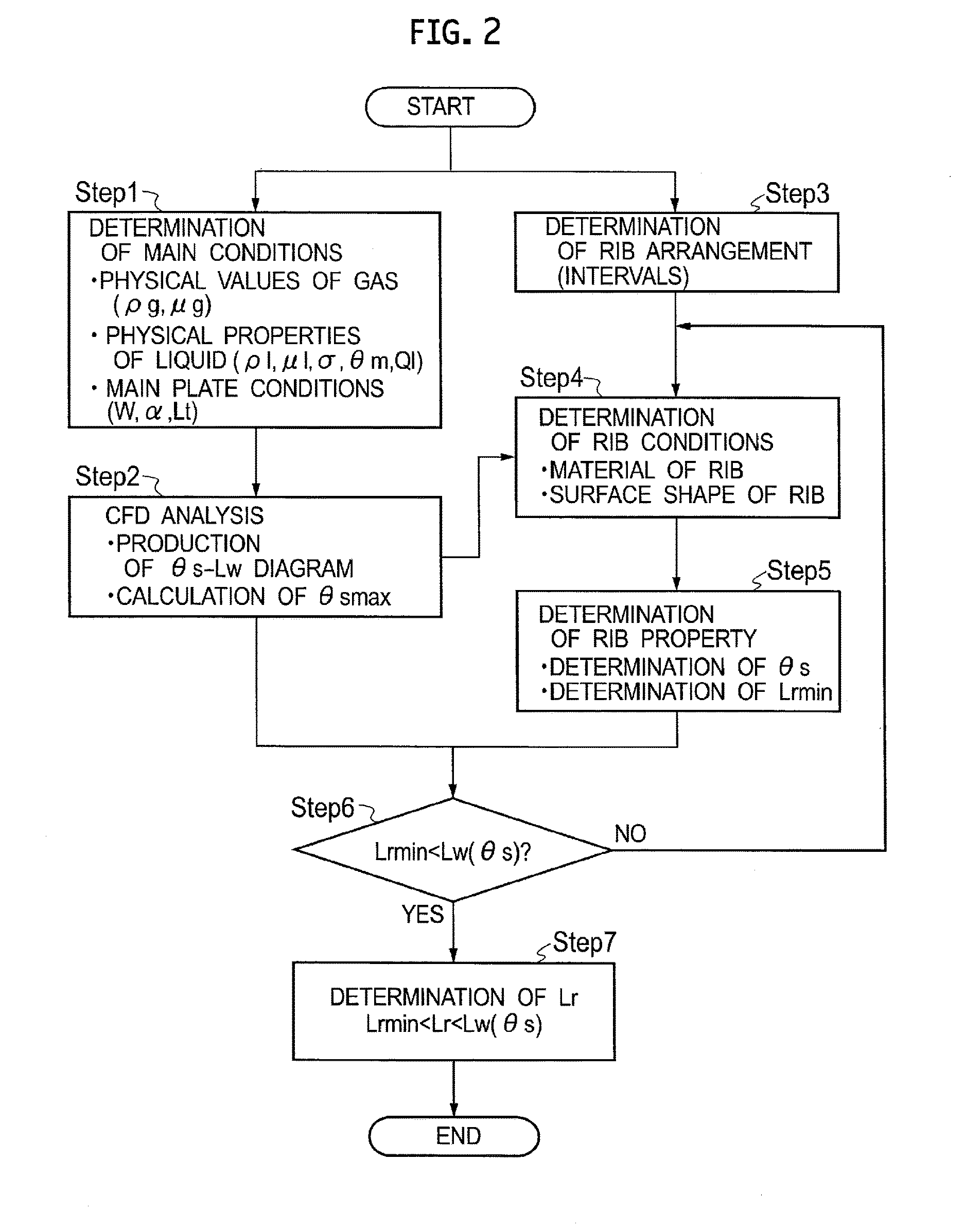

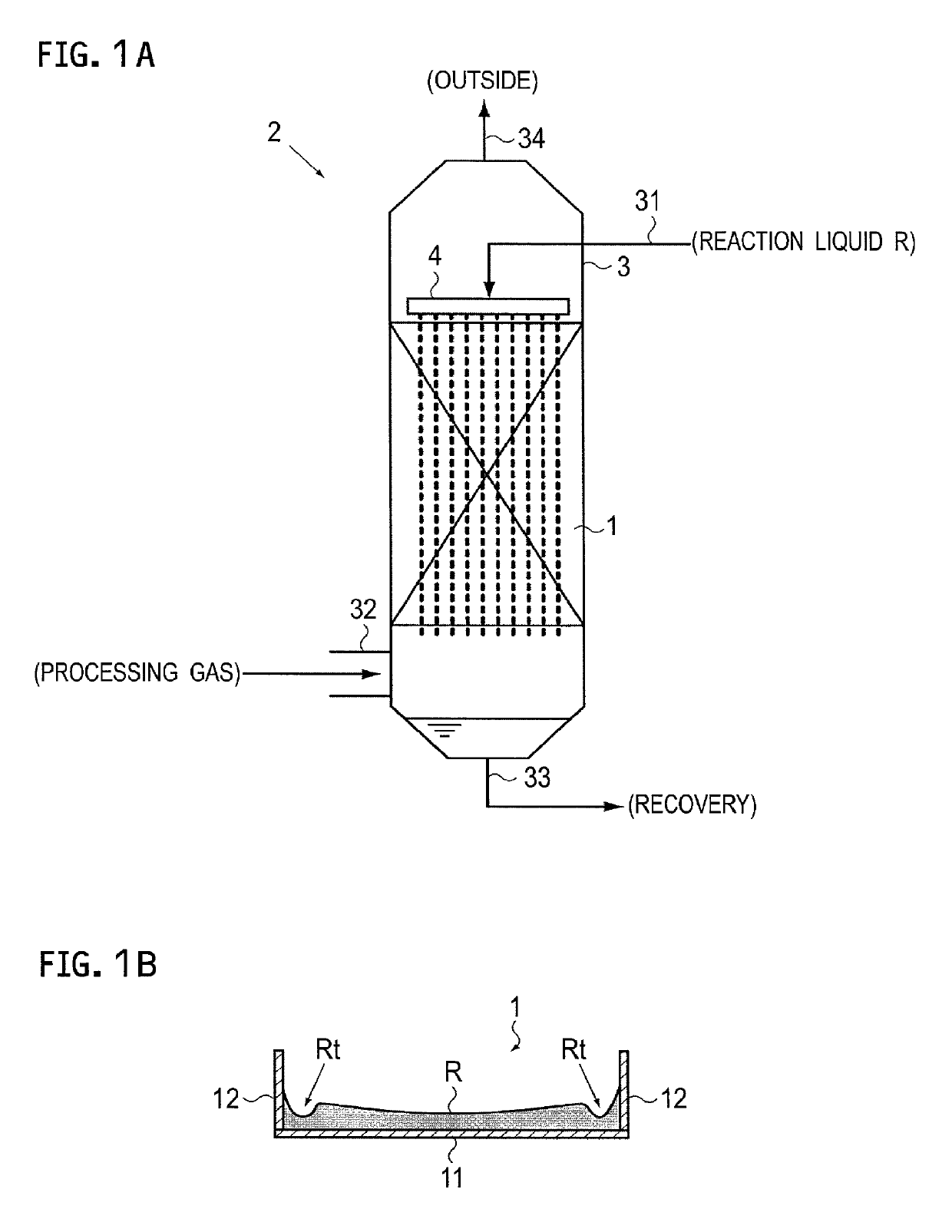

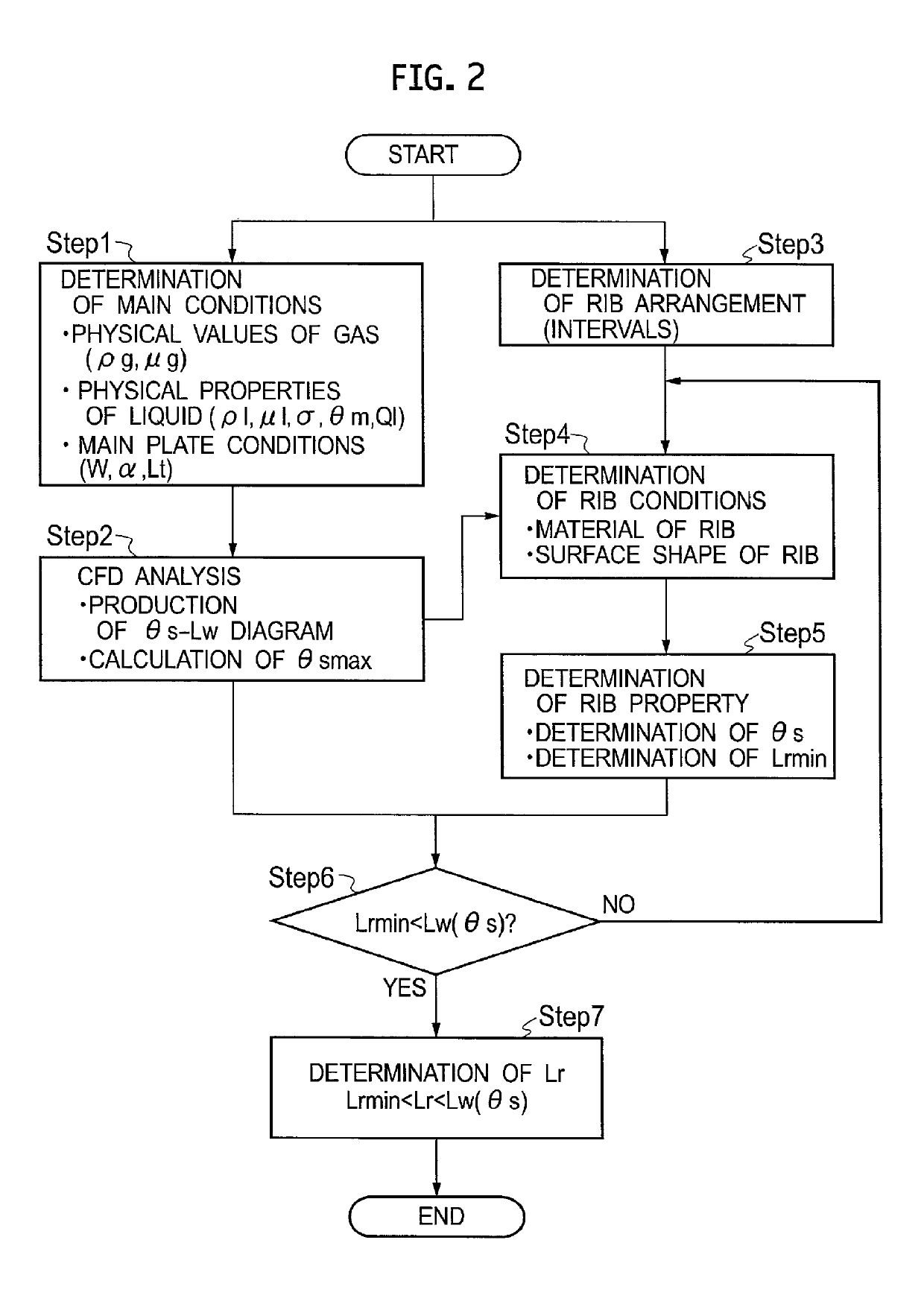

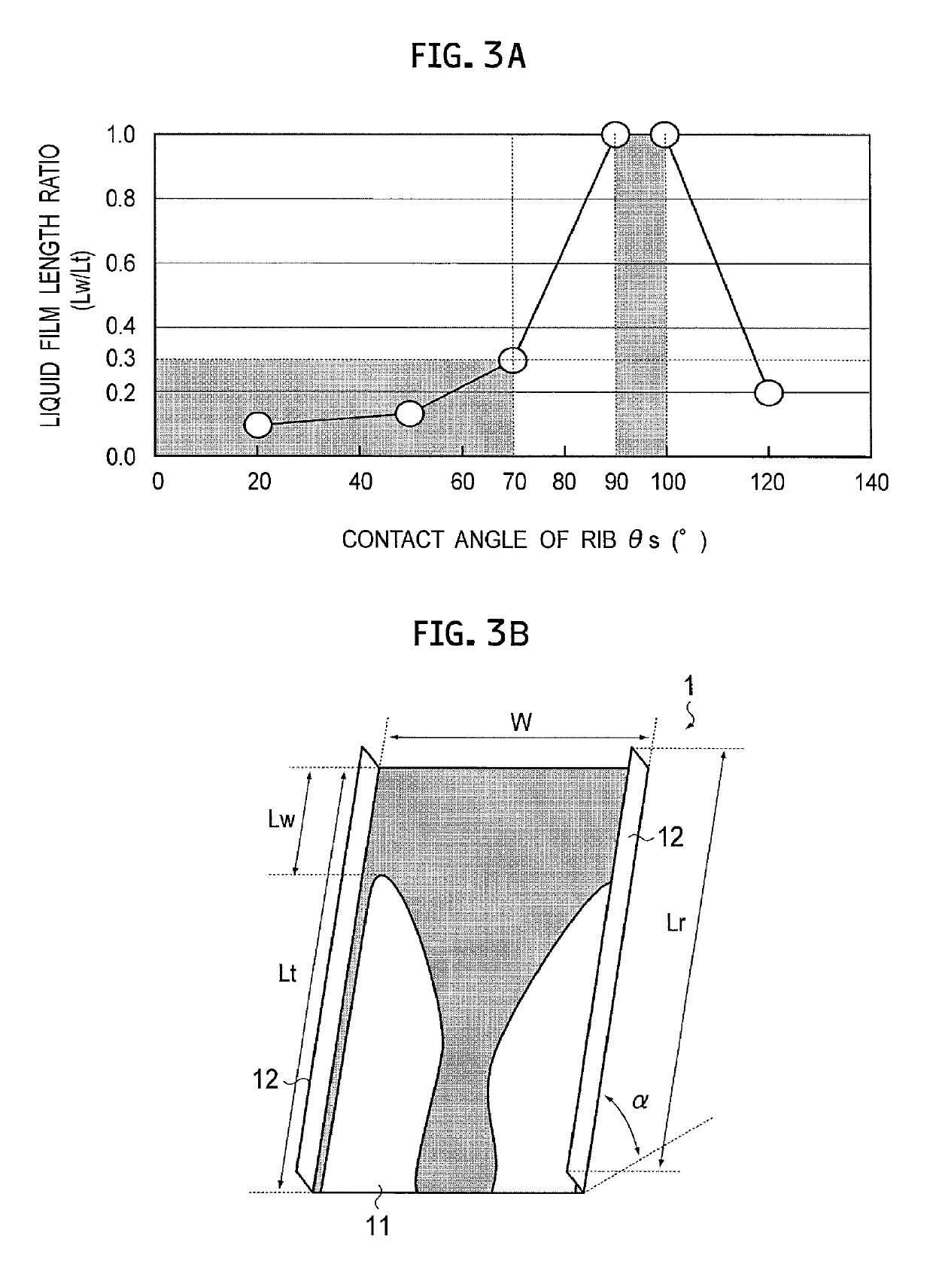

Method of manufacturing packing and packing

ActiveUS20170014797A1Reduce weightWeight increaseGas treatmentDispersed particle separationEngineeringProduct gas

A method of manufacturing packing includes: determining types of a gas and a liquid which are brought into gas-liquid contact and a main plate to be used; calculating a relationship between a contact angle and a liquid film length ratio; determining the arrangement (intervals) of a rib; determining rib conditions; calculating the minimum value of the flow direction length of the rib satisfying the contact angle and a strength requirement; confirming whether or not a liquid film length is greater than the minimum value; and determining the flow direction length of the rib within a range from the minimum value to the liquid film length.

Owner:IHI CORP

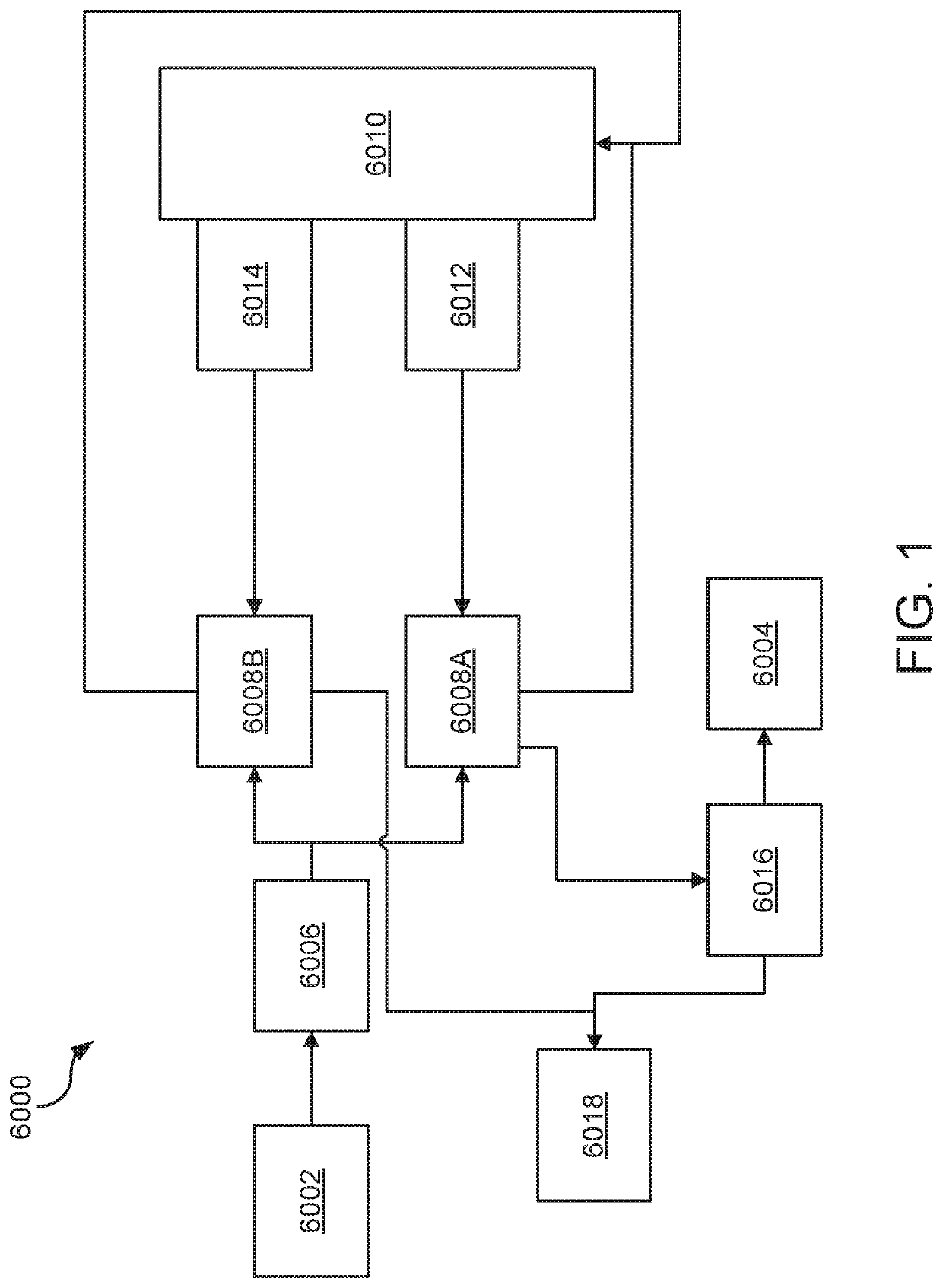

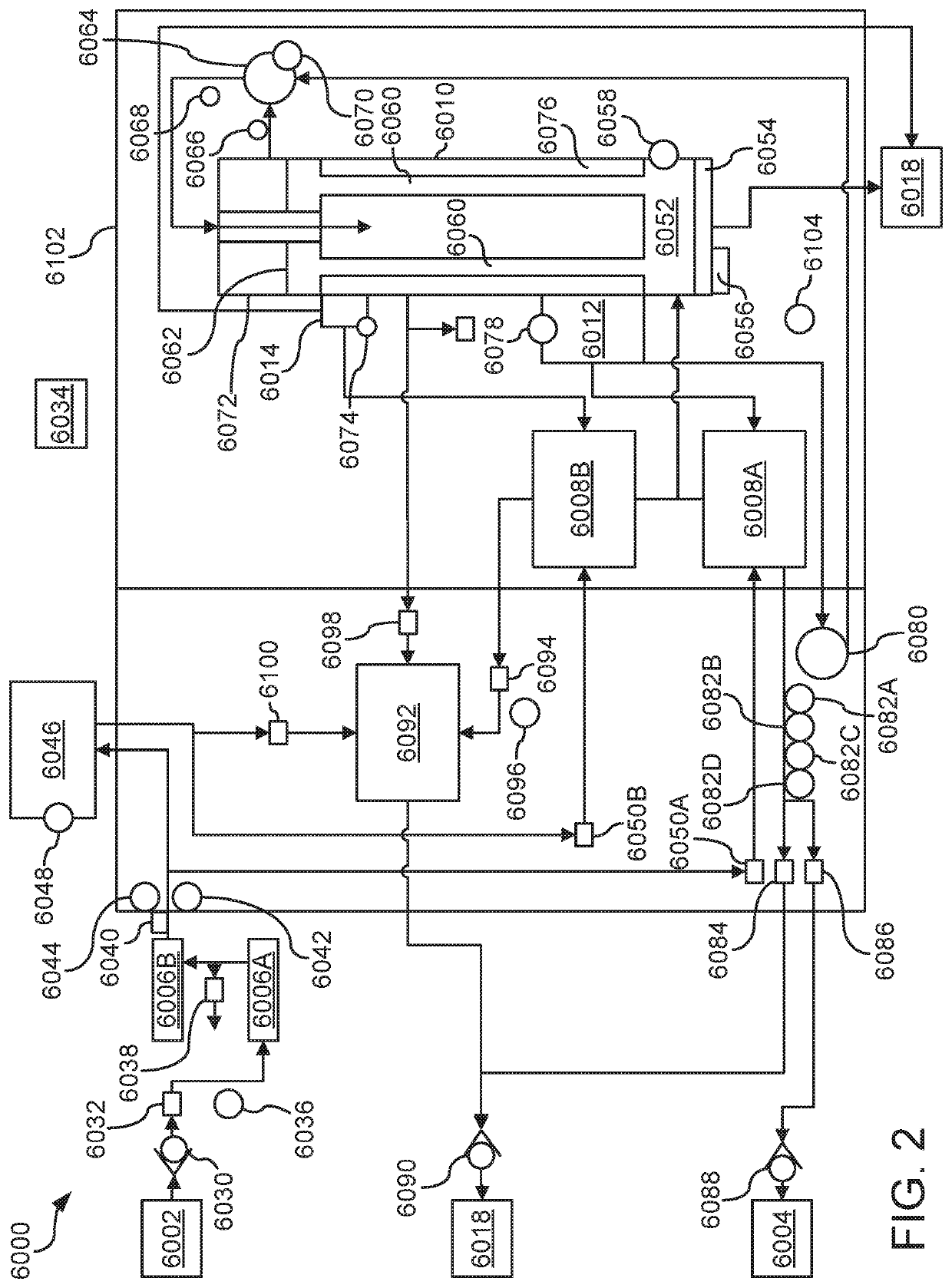

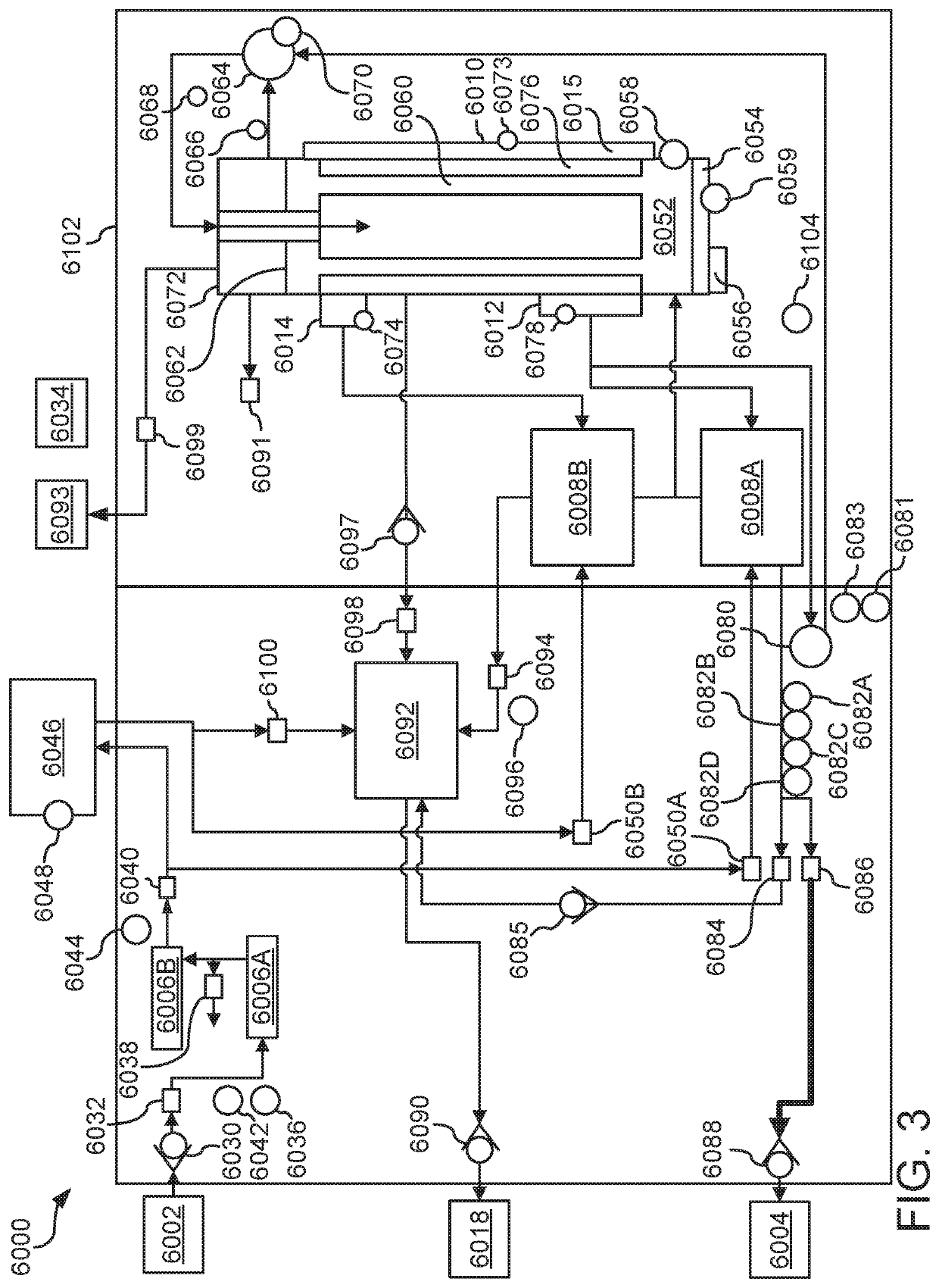

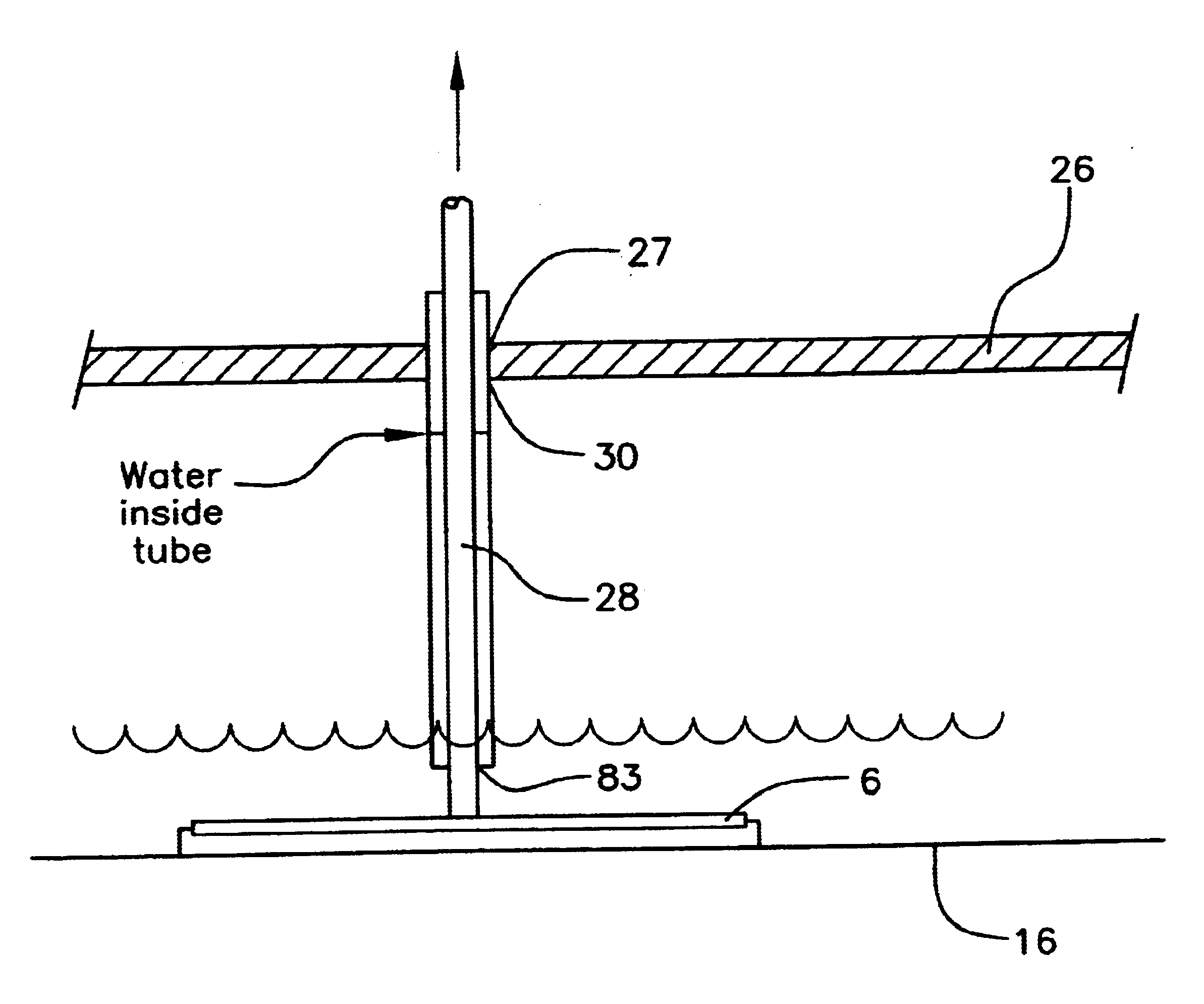

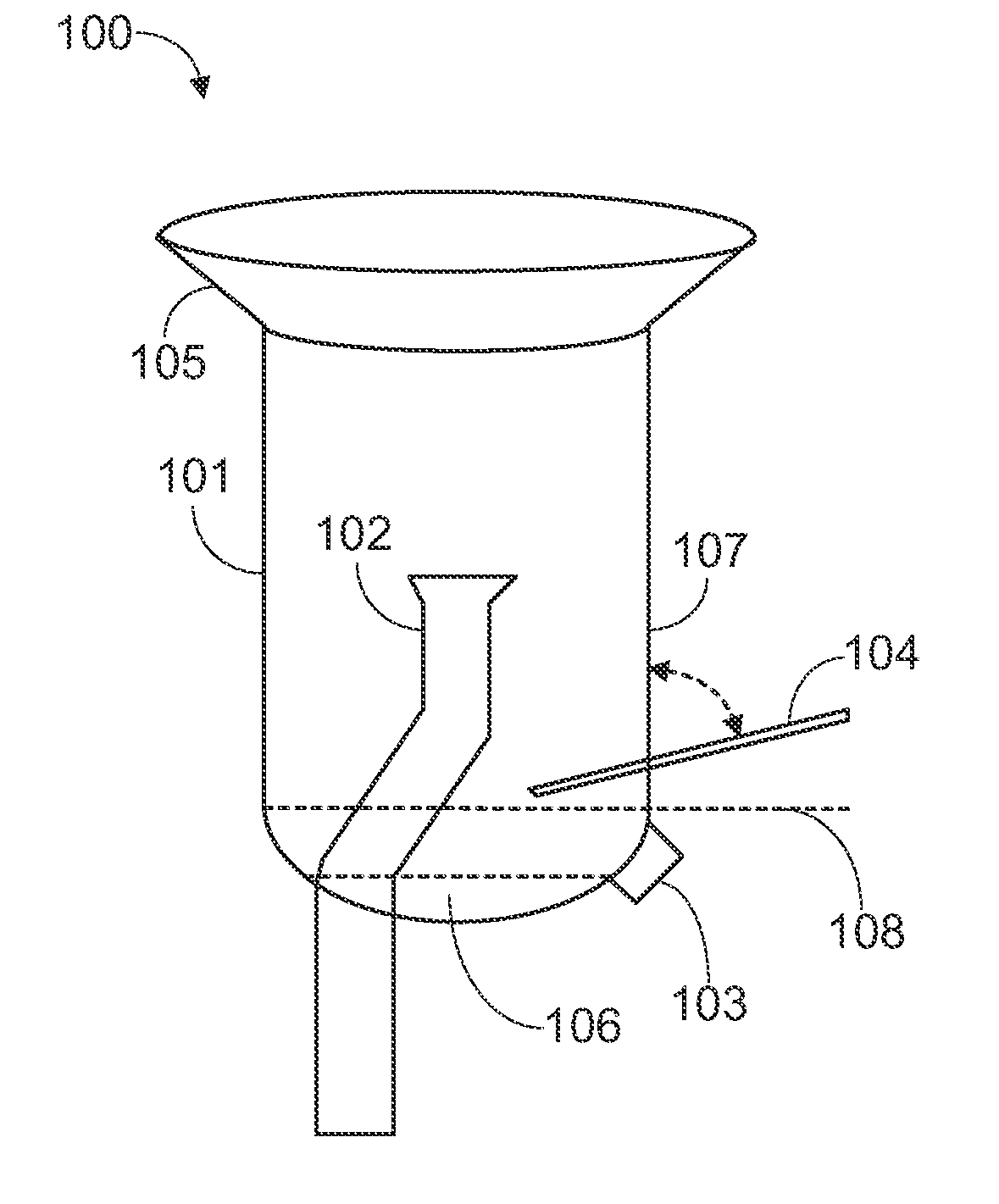

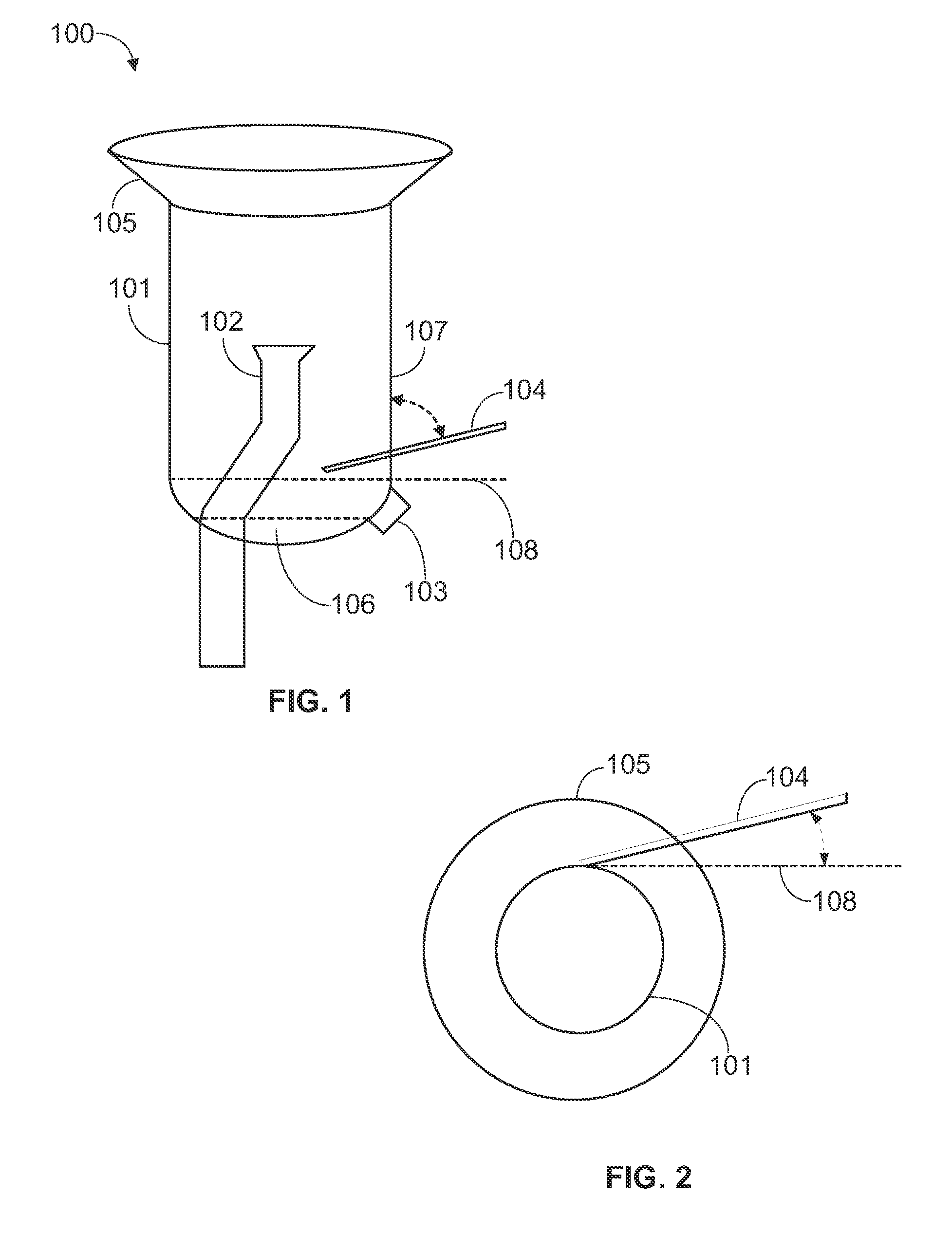

Water Distillation Apparatus, Method and System

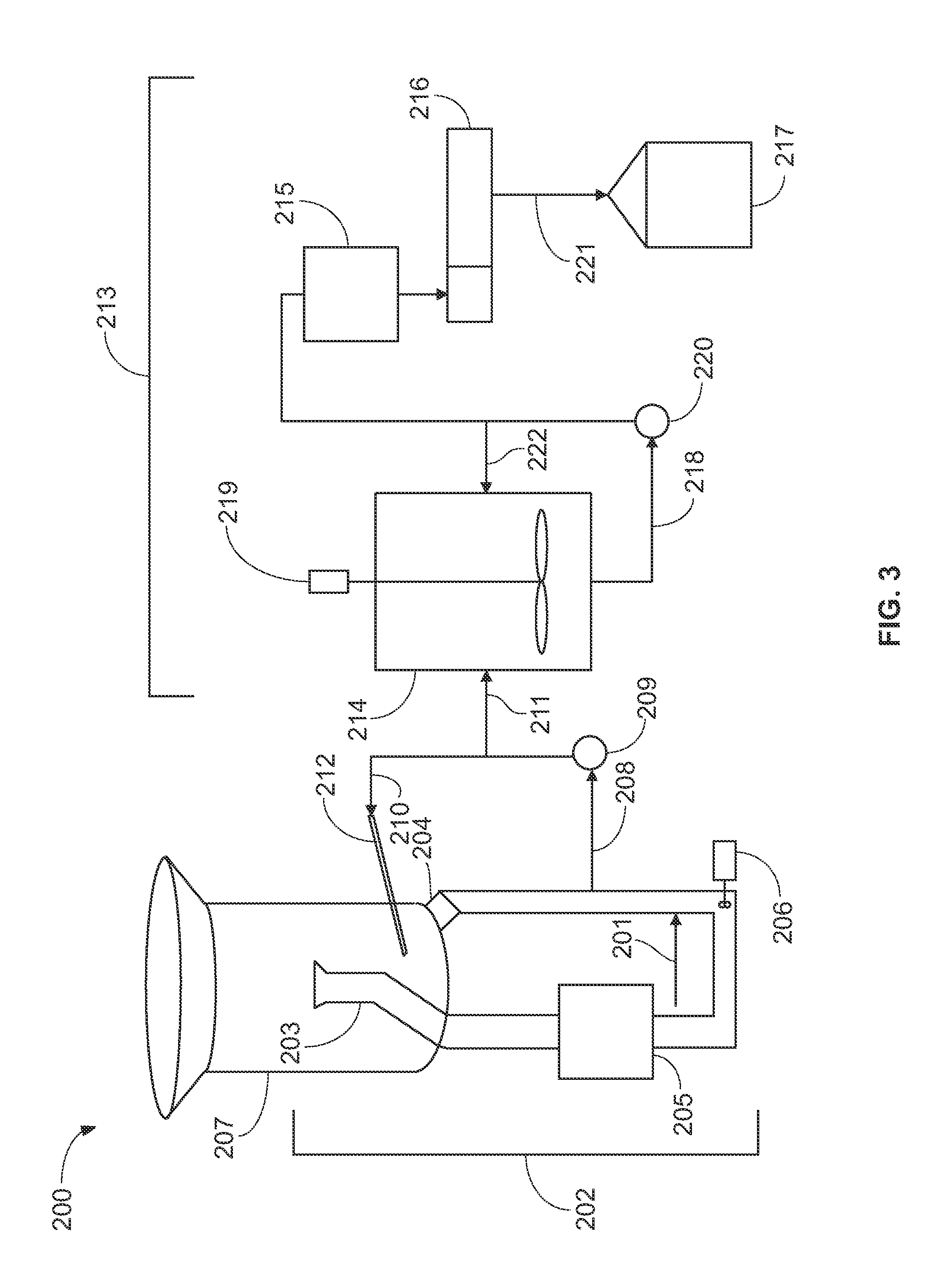

ActiveUS20200115254A1Water treatment parameter controlEvaporator liquid feederWater vaporProcess engineering

A water vapor distillation system. The system includes a water vapor distillation device configured to receive a volume of source water from a fluid source and produce distillate, the device comprising: a concentrate flow path comprising a concentrate output; a distillate flow path comprising a distillate output; at least one source proportioning valve; a first heat exchanger comprising at least a portion of the distillate flow path; a second heat exchanger including at least a portion of the concentrate flow path, wherein the first heat exchanger and the second heat exchanger in fluid flow communication with the fluid source; a distillate sensor assembly in communication with the distillate flow path and located downstream the first heat exchanger, the distillate sensor assembly configured to generate a distillate temperature measurement; and a controller configured to control the source proportioning valves, the controller configured to: receive the distillate temperature measurement; determine the difference between a first target temperature and the distillate temperature measurement; and split the source water from the fluid source between the first heat exchanger and the second heat exchanger based on the difference between the first target temperature and the distillate temperature measurement.

Owner:DEKA PROD LLP

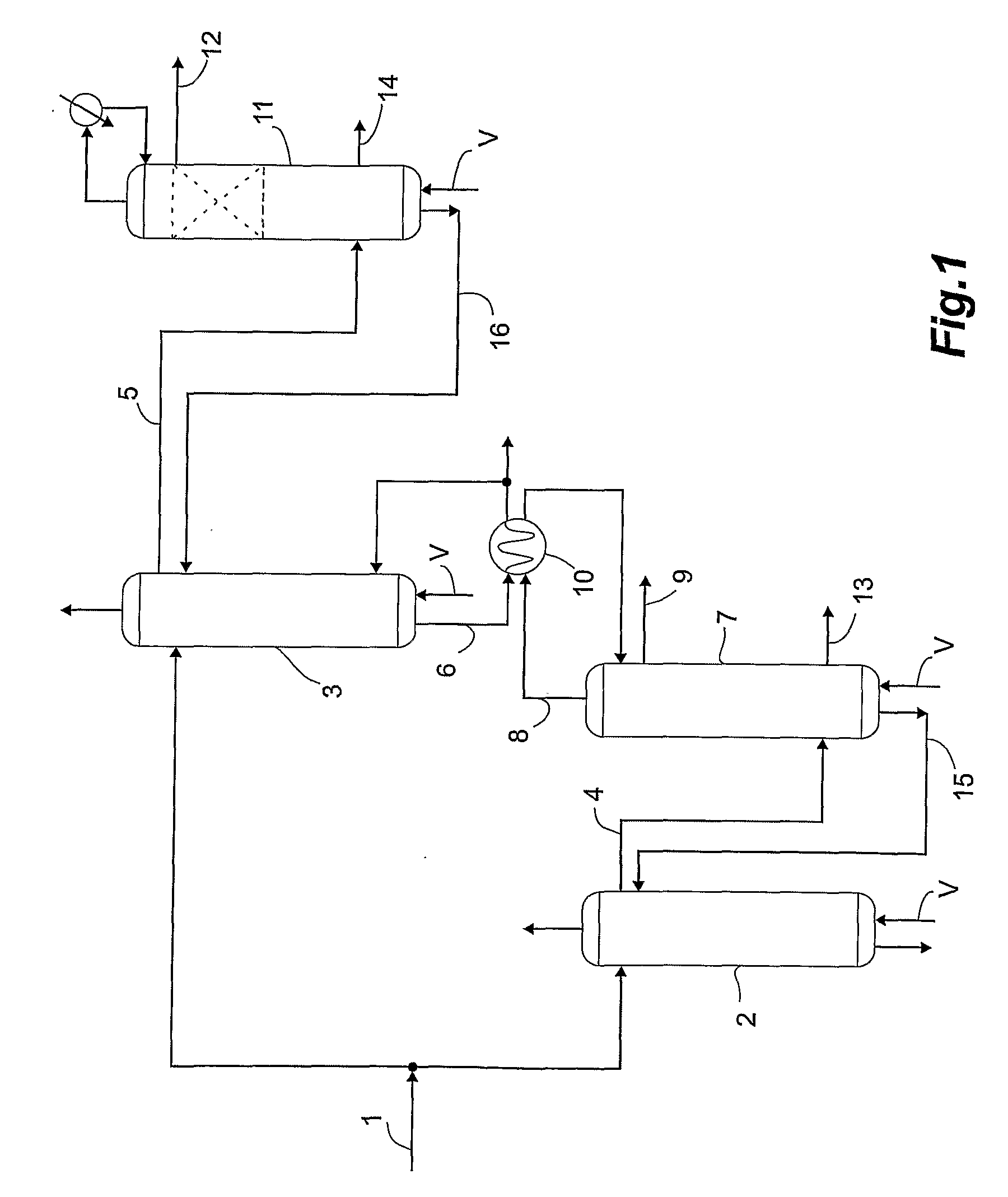

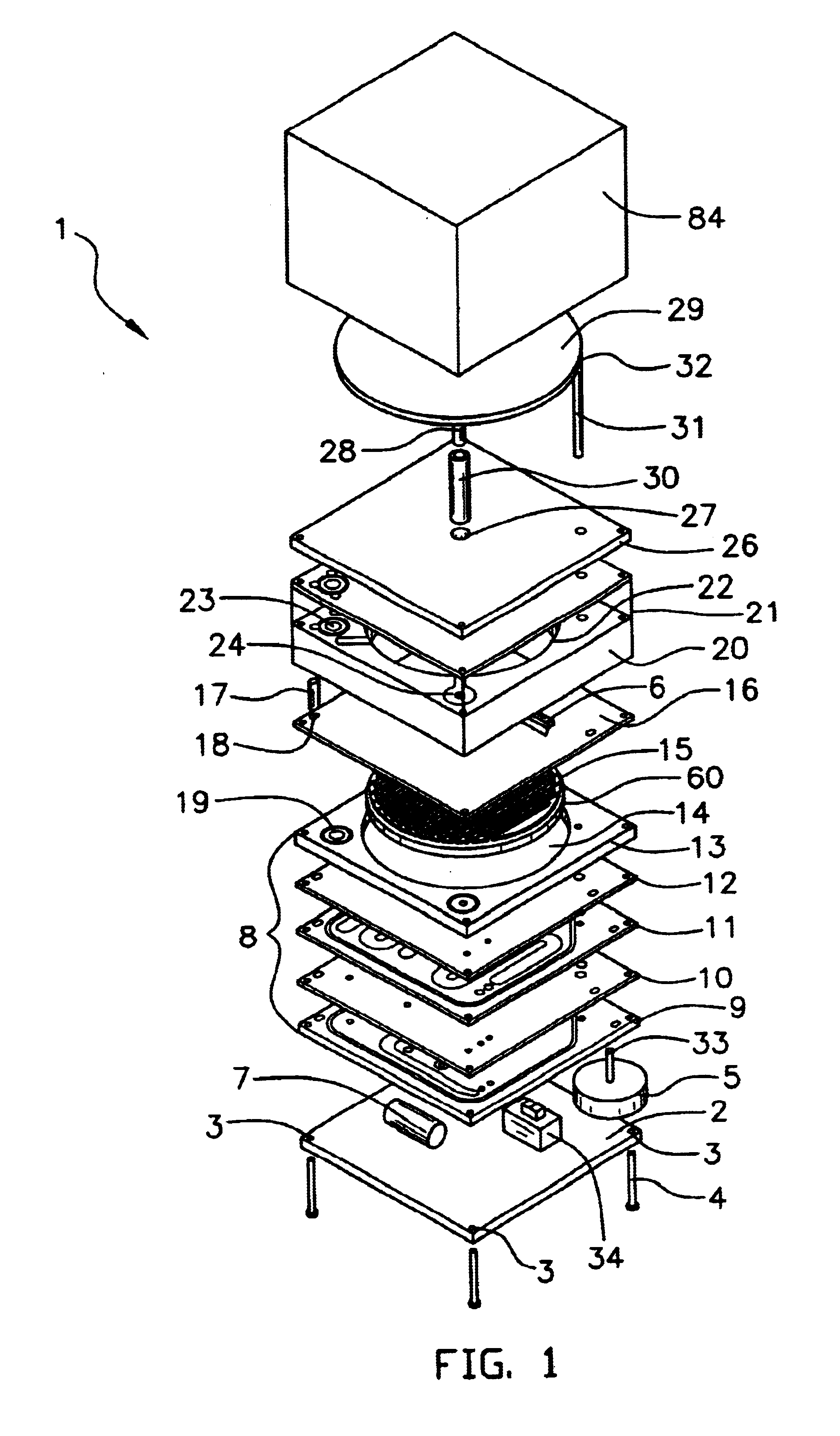

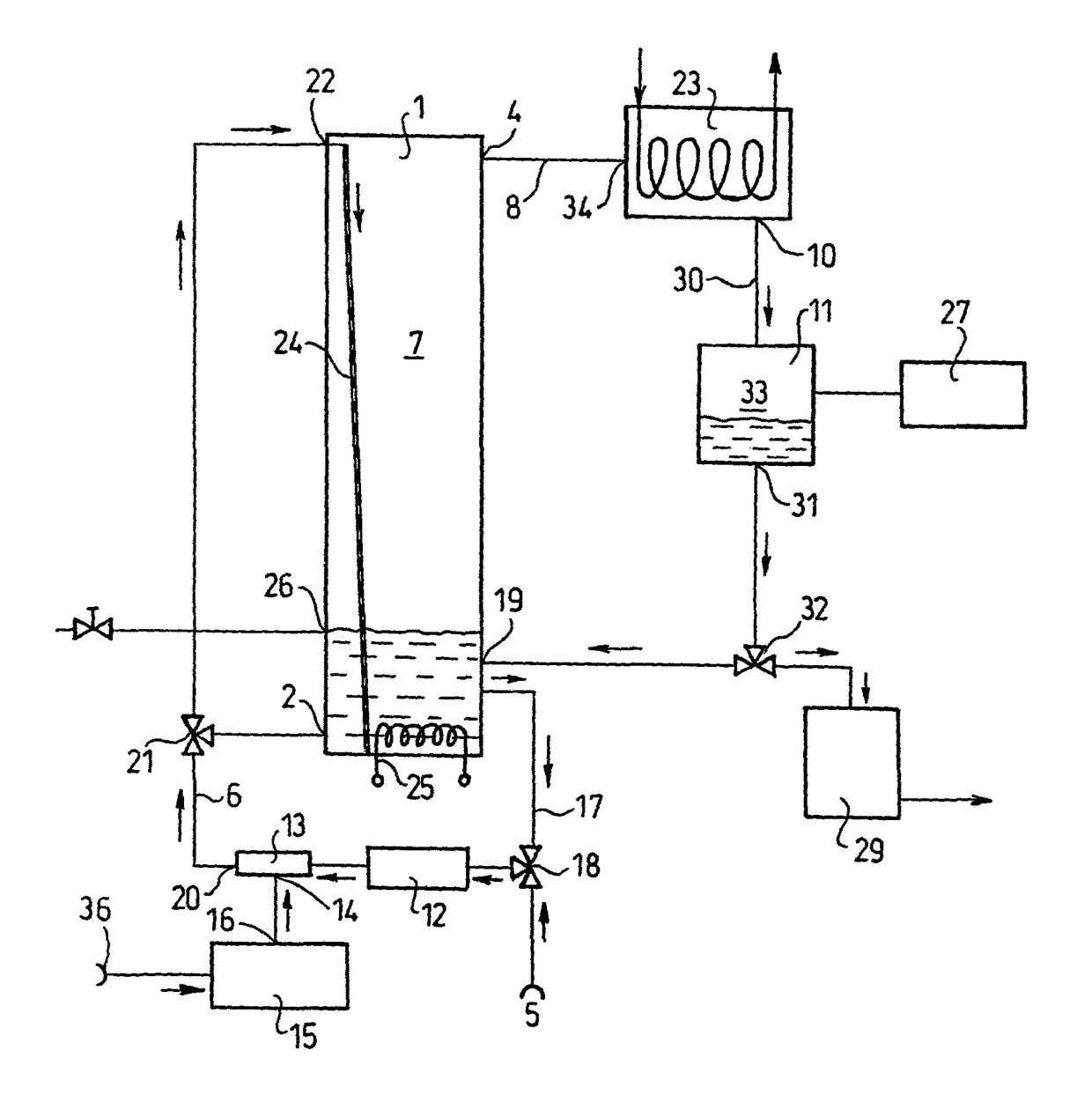

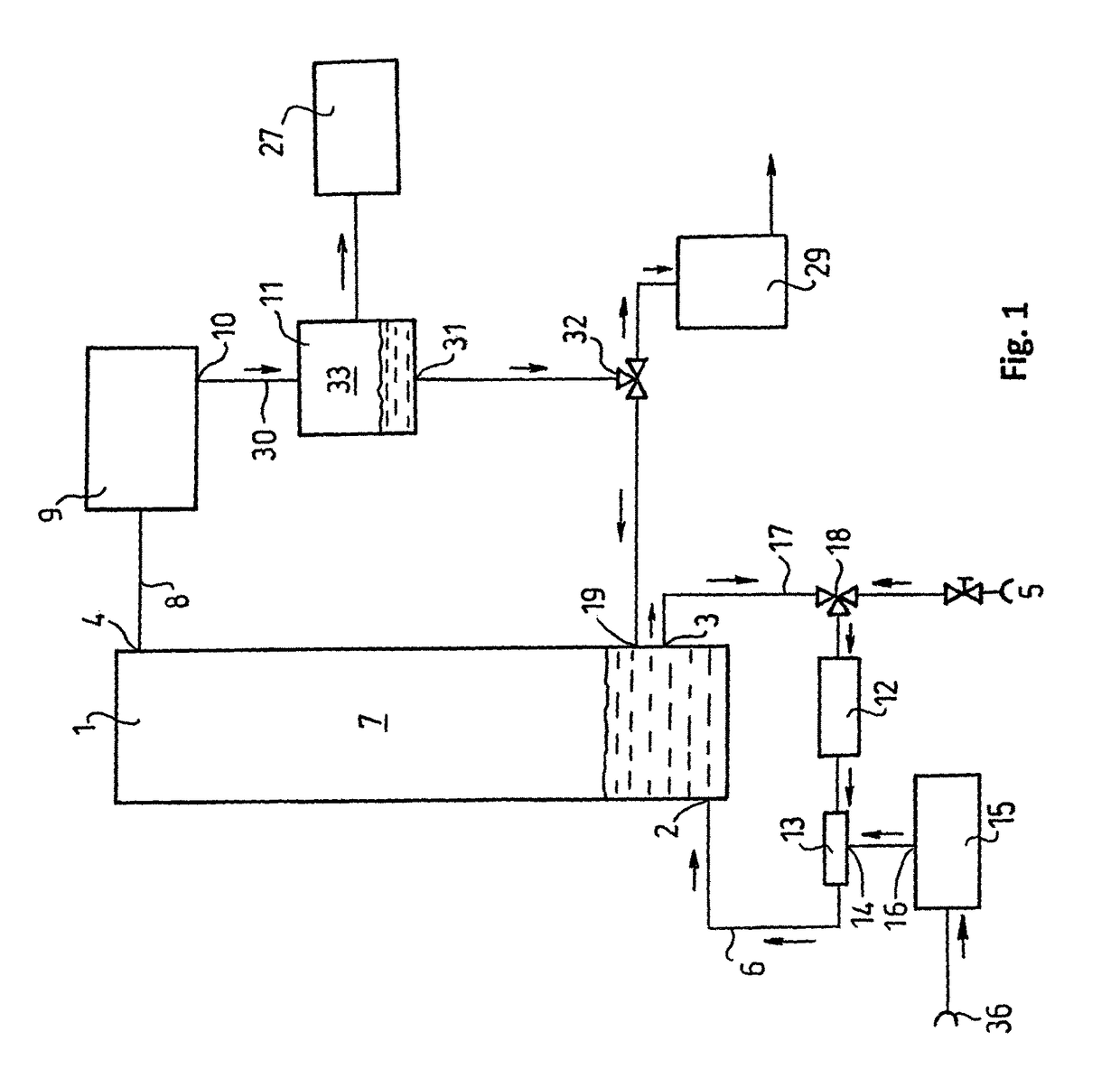

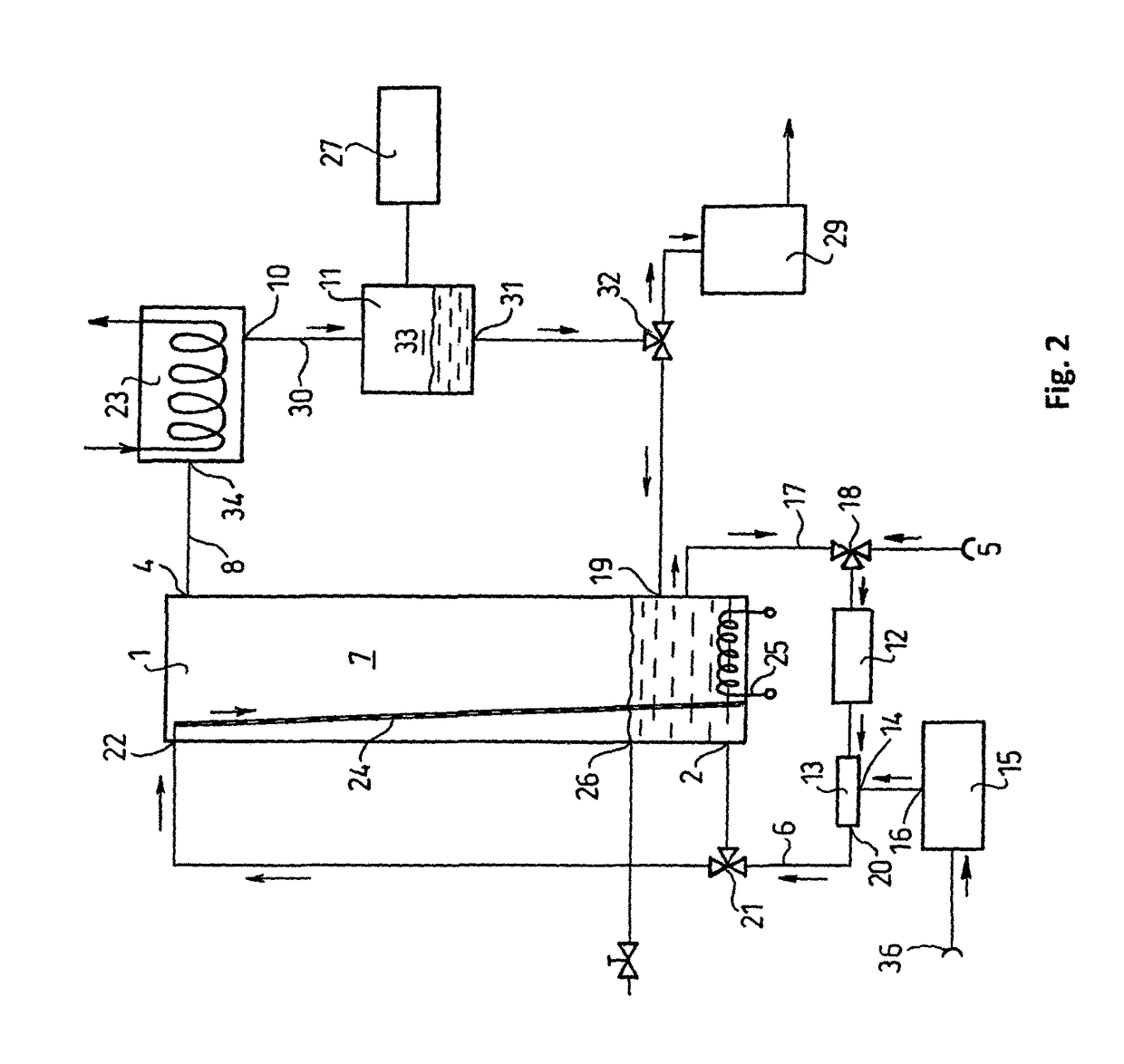

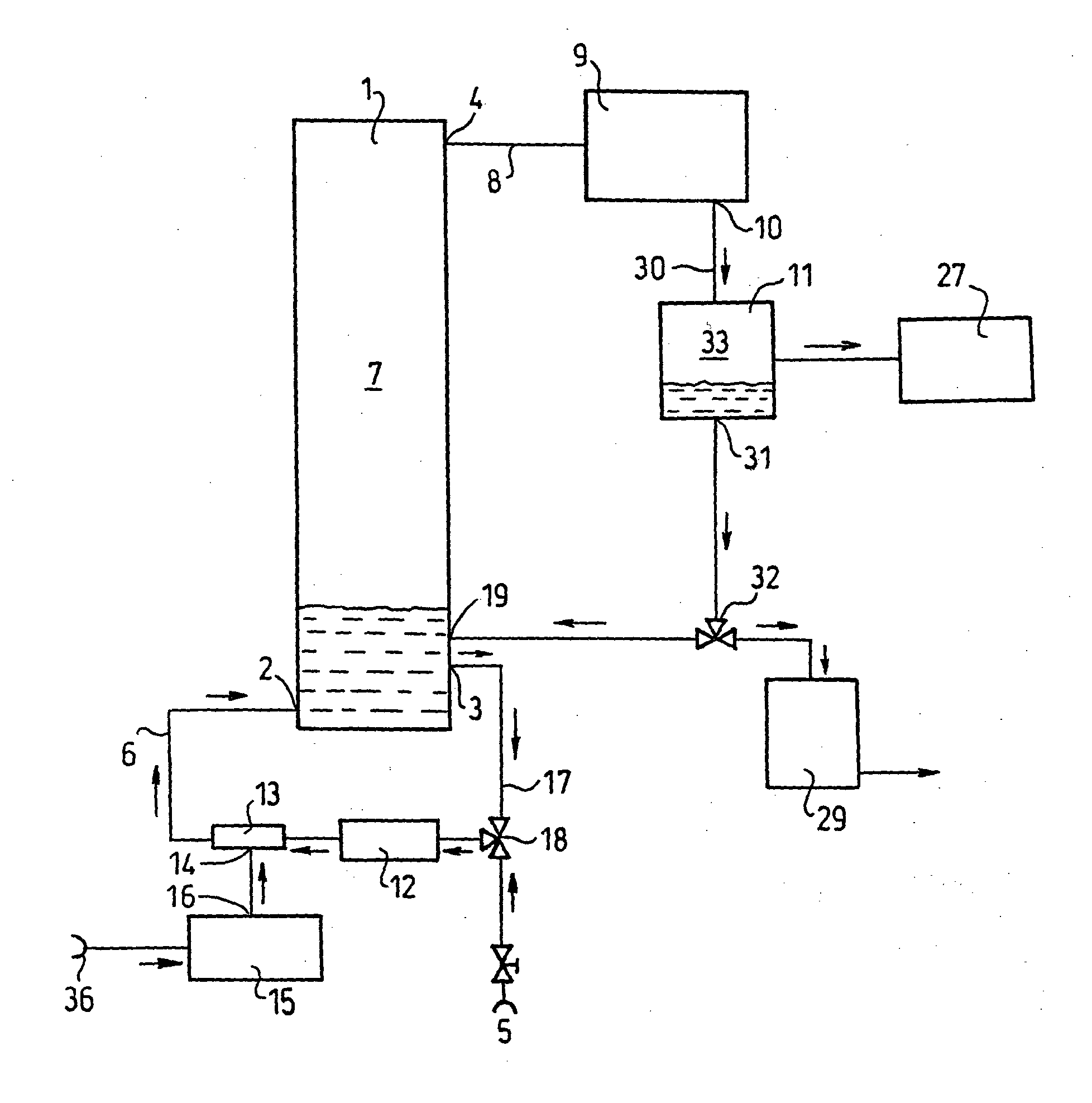

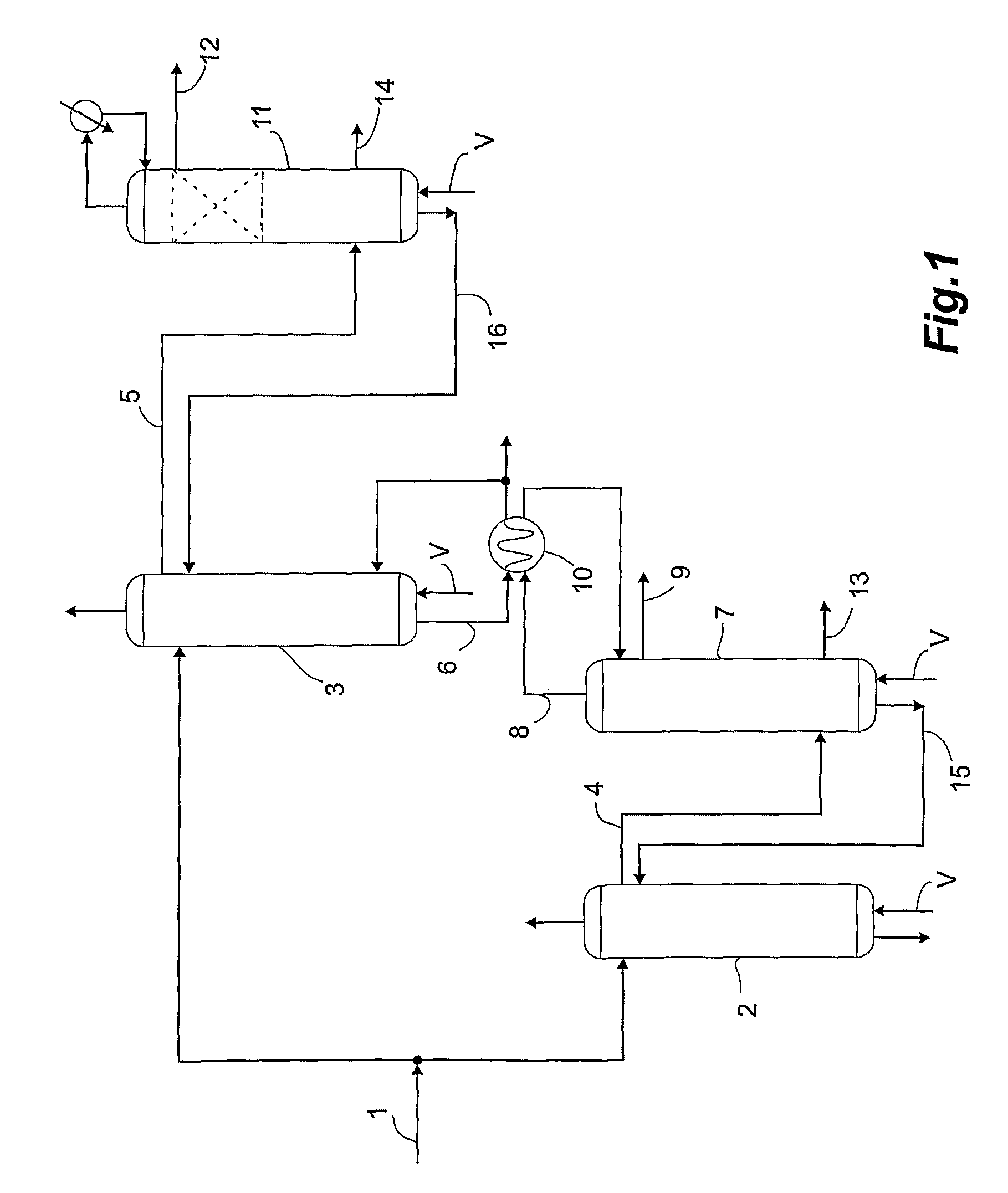

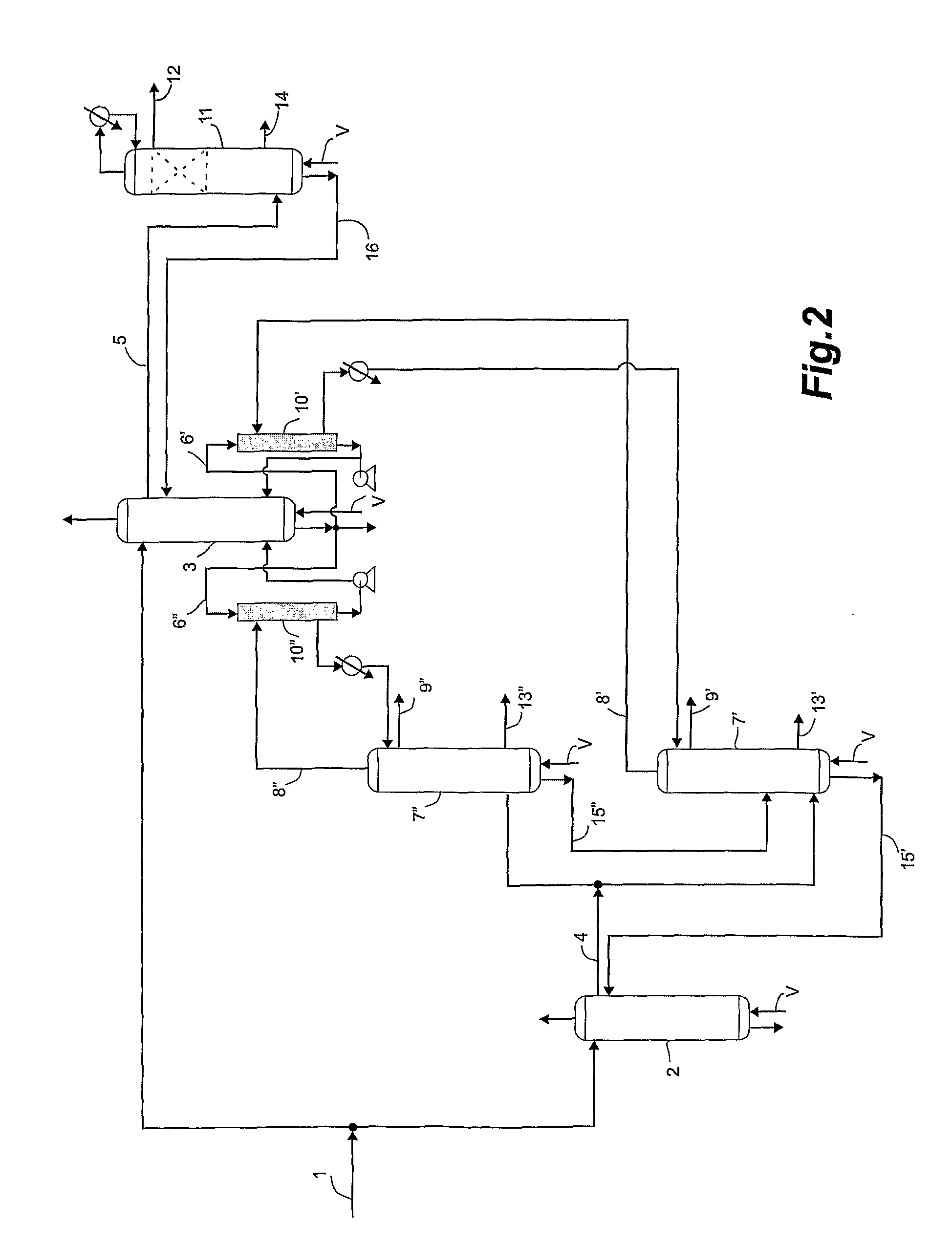

Process and System for Producing Alcohol by Split-Feed Distillation

InactiveUS20090324796A1Reduce stressSpeed up the restore processFermented solutions distillation/rectificationBiofuelsAlcoholDistillation

The present invention relates to a process and a system for producing alcohol by distillation with energy optimization using split-feed technology. The process of the present invention comprises the steps of: a) splitting a stream of wine (1) to feed two depuration columns (2, 3), the depuration column (2) generating a stream of phlegma (4) and the depuration column (3) generating a stream of phlegma (5) and a stream of vinasse (6); b) feeding the stream of phlegma (4) into at least one rectification column (7) generating a top flow (8) and a stream of hydrated alcohol (9); c) effecting the heat exchange between the top flow (8) from at least one rectification column (7) and the stream of vinasse (6) from the depuration column (3) in at least one heat exchanger (10); and d) feeding the stream of phlegma (5) into a rectification column (11) generating a stream of hydrated alcohol (12). The present invention further relates to hydrated alcohol produced by the process described above and to a process for producing anhydrous alcohol.

Owner:SIEMENS LTDA +1

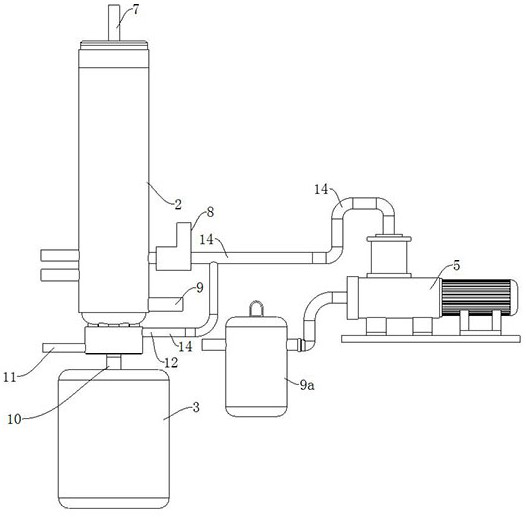

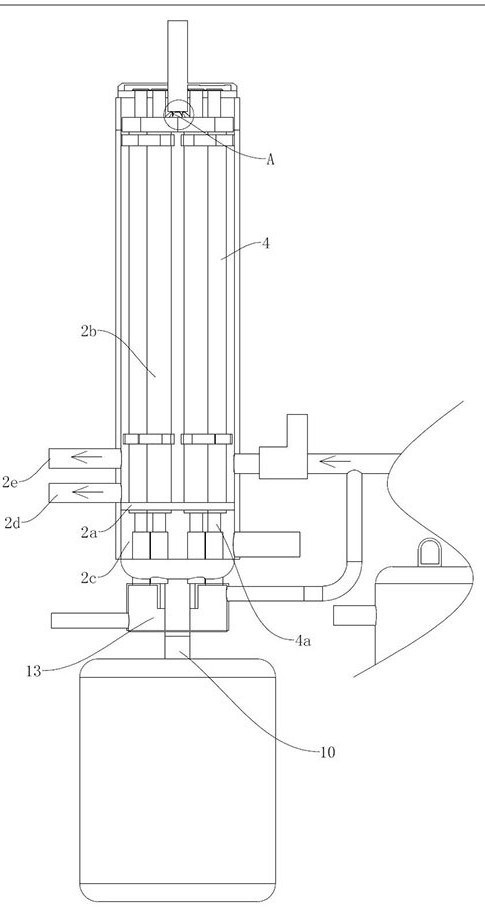

Heat pump type concentration control method of vegetable protein extraction and sterilization technology feed liquid

InactiveCN107126721ASolve the problem of concentration controlIncrease production capacityHeat recovery systemsEvaporation with vapour compressionDistillationHigh pressure

A heat pump type concentration control method of a vegetable protein extraction and sterilization technology feed liquid belongs to the technical field of vegetable protein production technologies and industrial energy saving. When the concentration of the feed liquid discharged from a flash evaporation tank is low due to the affection of the kind and the quality of protein powder in the extraction and sterilization technology of vegetable protein production, a heat pump type liquid feed concentration technology link is set to properly increase the concentration of the spray-dried feed liquid sent to downstream in order to increase the technologic productivity. The heat pump type liquid feed concentration technology link is characterized in that the feed liquid discharged from the flash evaporation tank is sent into a heat pump type negative pressure distillation device, a part of water is separated, and the concentrated feed liquid is sent into the high pressure nozzle of a drying tower, and undergoes spray drying, so the spray drying productivity is increased by 20-40%; and the separated water passes through a post-positioned treatment module, and is sent to a protein production extraction technology segment to realize recycling.

Owner:北京清大天工能源技术研究所有限公司

Water processing device with liquid seal

InactiveUS6858150B2Valve arrangementsLiquid degasification with auxillary substancesDegasserEnvironmental engineering

A water processing device for removing contaminants from water for consumption, consisting of: 1) a heat exchanger; 2) a heater; 3) a boiler chamber; 4) a liquid level control device; 5) a demister; 6) a degasser; and, 7) a self-cleaning component. A water seal to prevent steam from leaking from the device with liquid seal is also provided.

Owner:STEPHAN B SEARS

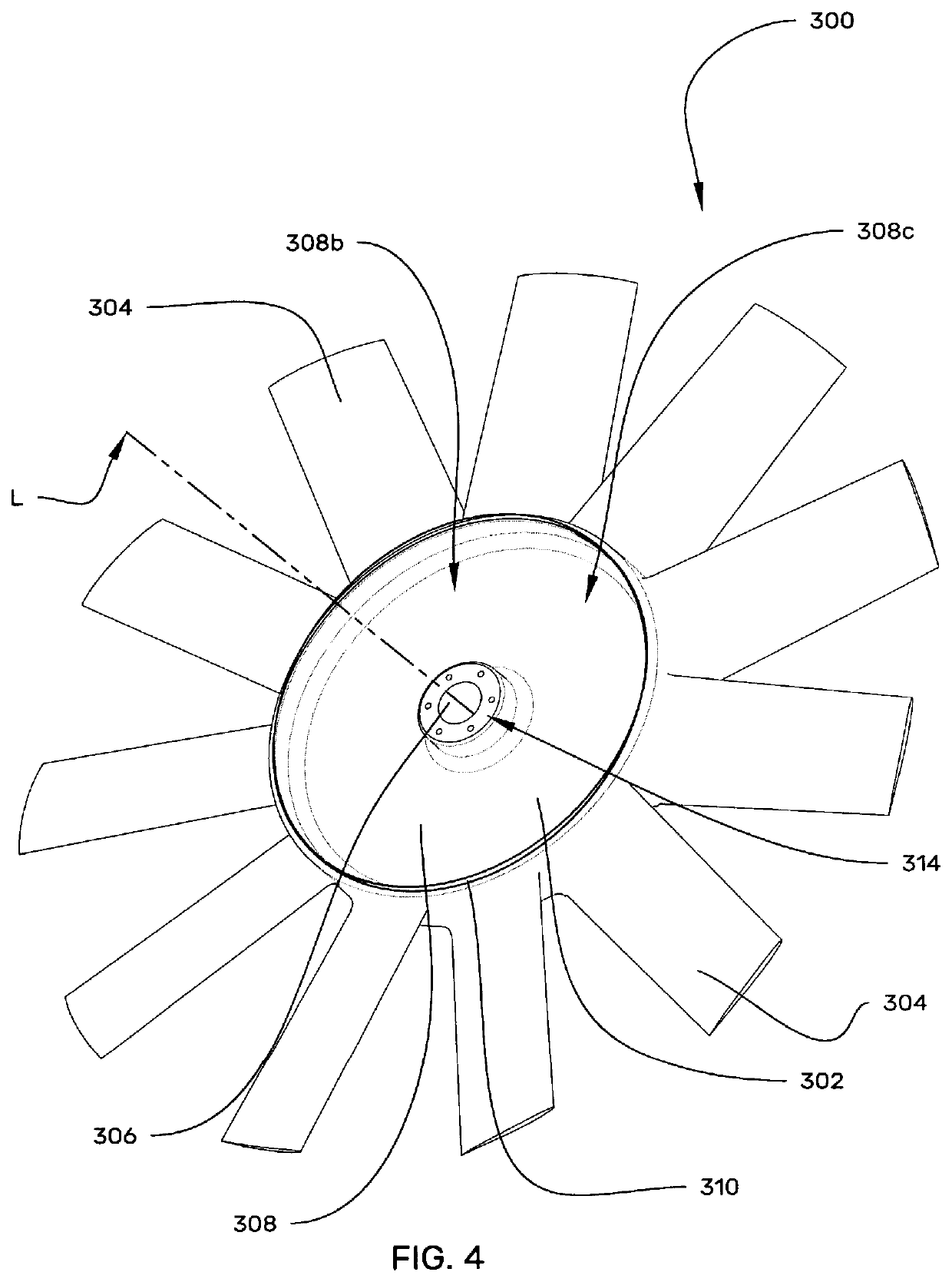

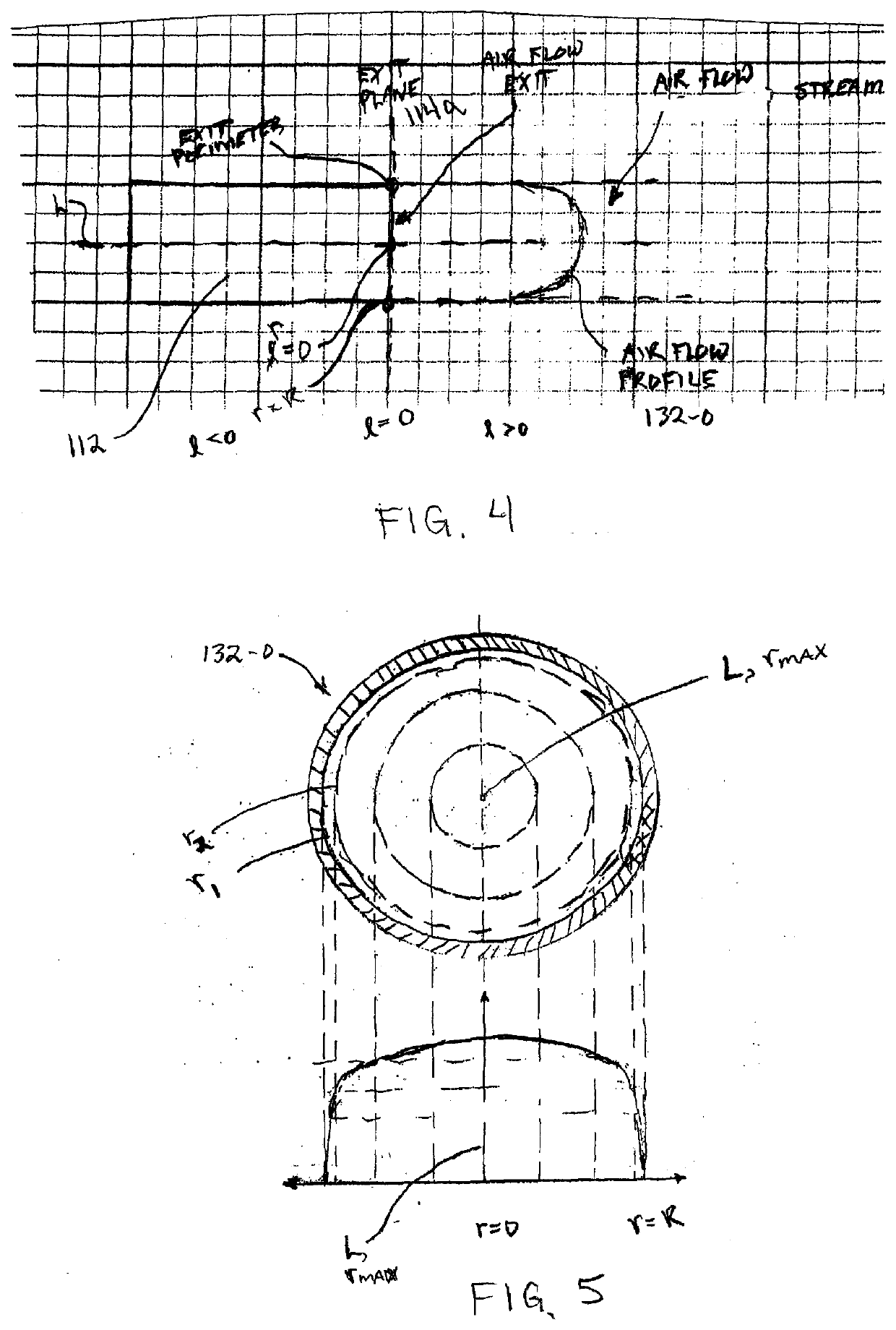

Impeller for ambient water evaporators, and related system and method

An impeller design is provided for use in evaporating water from an ambient water body. The impeller includes a hub and a plurality of impeller blades. The blades have one or more profiles that correspond to certain profiles characterized by the National Advisory Committed for Aeronautics parameters known as NACA 4 parameters. One or more blade angles also may more specifically identify the blade profiles. The impeller blades also may be identified by a plurality of profiles on a given blade, preferably including a base profile and a tip profile. The impeller optionally but preferably is made of a fiberglass material. In preferred embodiments it constitutes an integrated unit, such as a unitary molded or cast unit. It may be coated by a suitable corrosion-resistant coating, for example, such as a clear coat or gel coat. Various features of the impeller hub also are disclosed. An impeller system also is disclosed. The system includes an impeller as described above and means for mitigating non-longitudinal flow in the air flow channel in which the impeller caused air movement. The means for mitigating non-longitudinal flow preferably includes a plurality of guide vanes disposed downstream of the impeller.

Owner:RESOURCE WEST

Process and apparatus for the separation of the components of a liquid mixture

ActiveUS9675903B2More separatedEfficient separationLiquid degasification with auxillary substancesEvaporator liquid feederBoiling pointLiquid phase

Process and apparatus for the separation of the components having different boiling points of a liquid mixture, characterized in that forming bubbles by a carrier gas in the liquid mixture where the one or more volatile component is getting enriched in the bubbles, then after said bubbles leave the liquid phase the released vapor content of them is collected and condensed and the obtained liquid being enriched in the more volatile component(s) is separated from the carrier gas.

Owner:HYD RAKKUTATO & GYOGYSZERFEJLESZTO

Process and apparatus for the separation of the components of a liquid mixture

ActiveUS20140158520A1Easy to separateIncrease interface areaLiquid degasification with auxillary substancesDistillation in boilers/stillsFluid phasePhysical chemistry

Process and apparatus for the separation of the components having different boiling points of a liquid mixture, characterized in that forming bubbles by a carrier gas in the liquid mixture where the one or more volatile component is getting enriched in the bubbles, then after said bubbles leave the liquid phase the released vapor content of them is collected and condensed and the obtained liquid being enriched in the more volatile component(s) is separated from the carrier gas.

Owner:HYD RAKKUTATO & GYOGYSZERFEJLESZTO

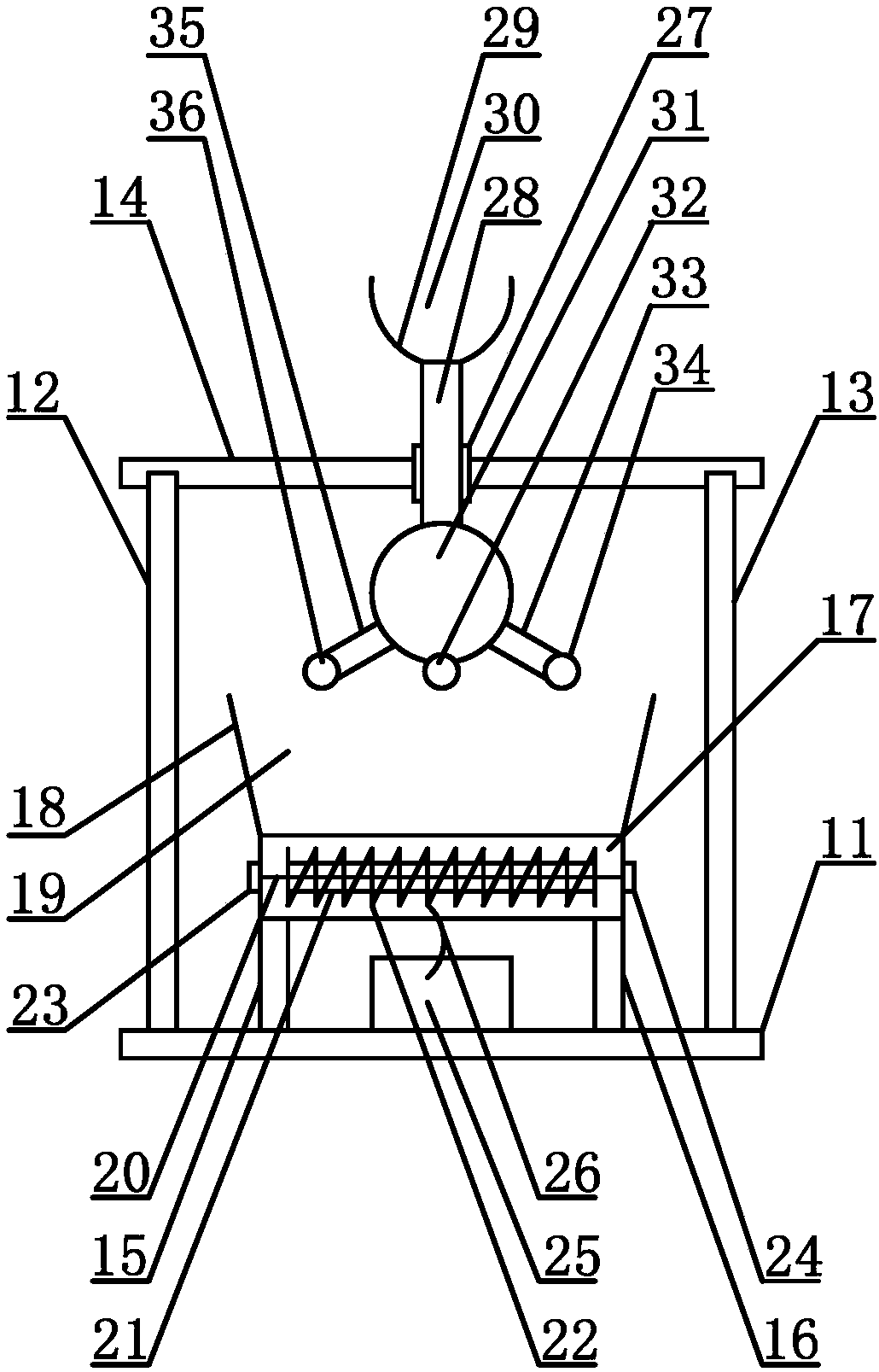

Electric heating evaporator for chemical experiments

PendingCN108211388AIncrease heating areaIncrease the heating areaEvaporator liquid feederEvaporating dishOpen structure

The invention discloses an electric heating evaporator for chemical experiments. The electric heating evaporator comprises a bottom plate, wherein each side of the bottom plate is provided with a sideframe; a top frame is arranged between the tops of the side frames; the bottom plate is provided with side plates; a glass shell is arranged between the tops of the side plates; a glass evaporating dish is arranged at the top of the glass shell; an evaporating cavity is formed inside the glass evaporating dish; the top of the glass evaporating dish is of an open structure; a mounting shaft is arranged inside the glass shell; the peripheral surface of the mounting shaft is sleeved with an electric heating pipe; the peripheral surface of the electric heating pipe is wound with an electric heating wire; and a temperature controller is arranged on the bottom plate, is mounted below the glass shell and is connected with the electric heating wire through a cable. By using the electric heating evaporator disclosed by the invention, the chemical liquid to be evaporated can be poured into a liquid inlet groove of a liquid inlet shell, the liquid inlet shell can deliver the chemical liquid intoa liquid outlet shell through a cyclophon, and the liquid outlet shell can deliver the chemical liquid into the evaporating cavity of the glass evaporating dish through a liquid outlet ball, so thatthe chemical liquid in the evaporating cavity can be conveniently evaporated.

Owner:张天一

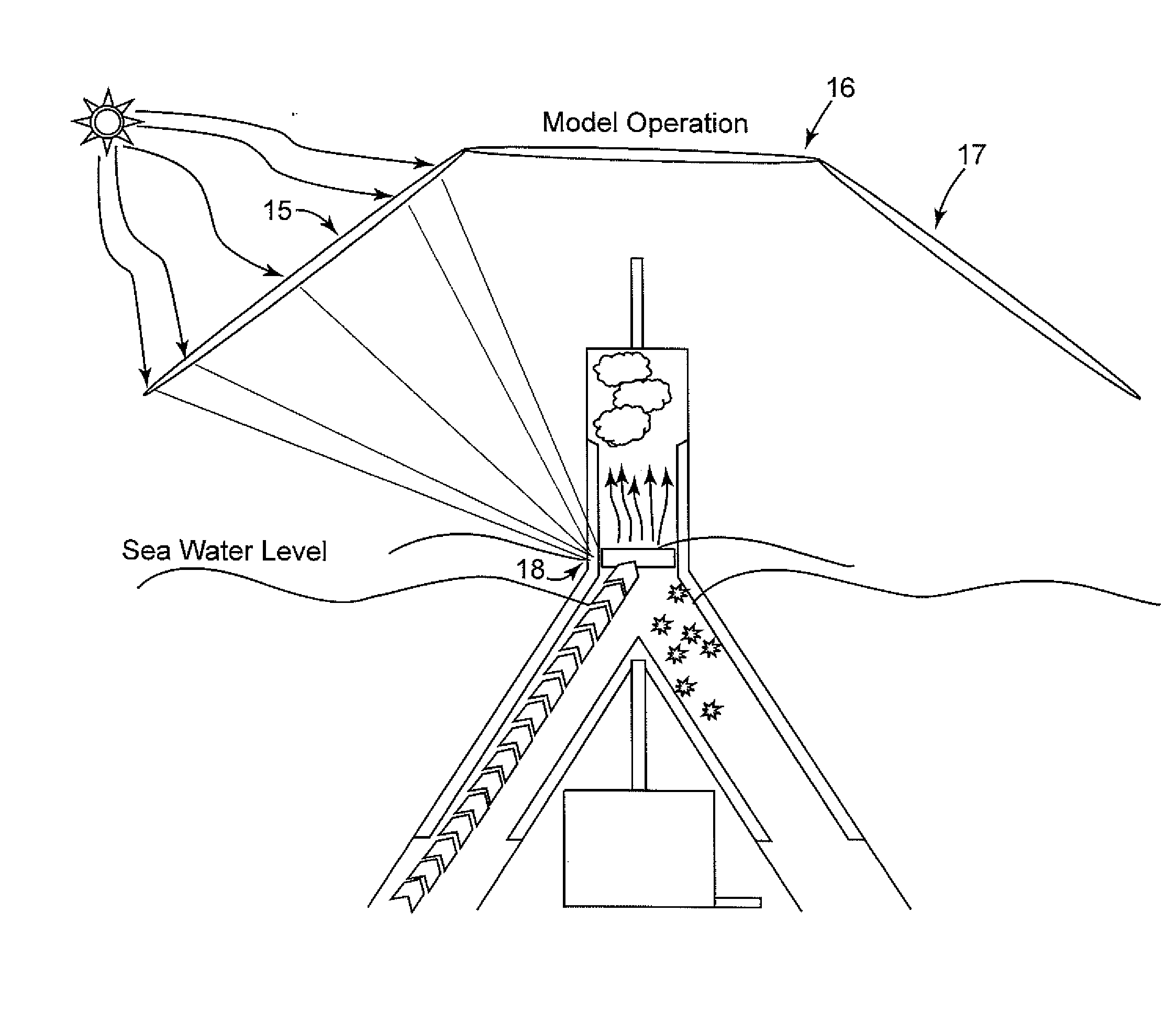

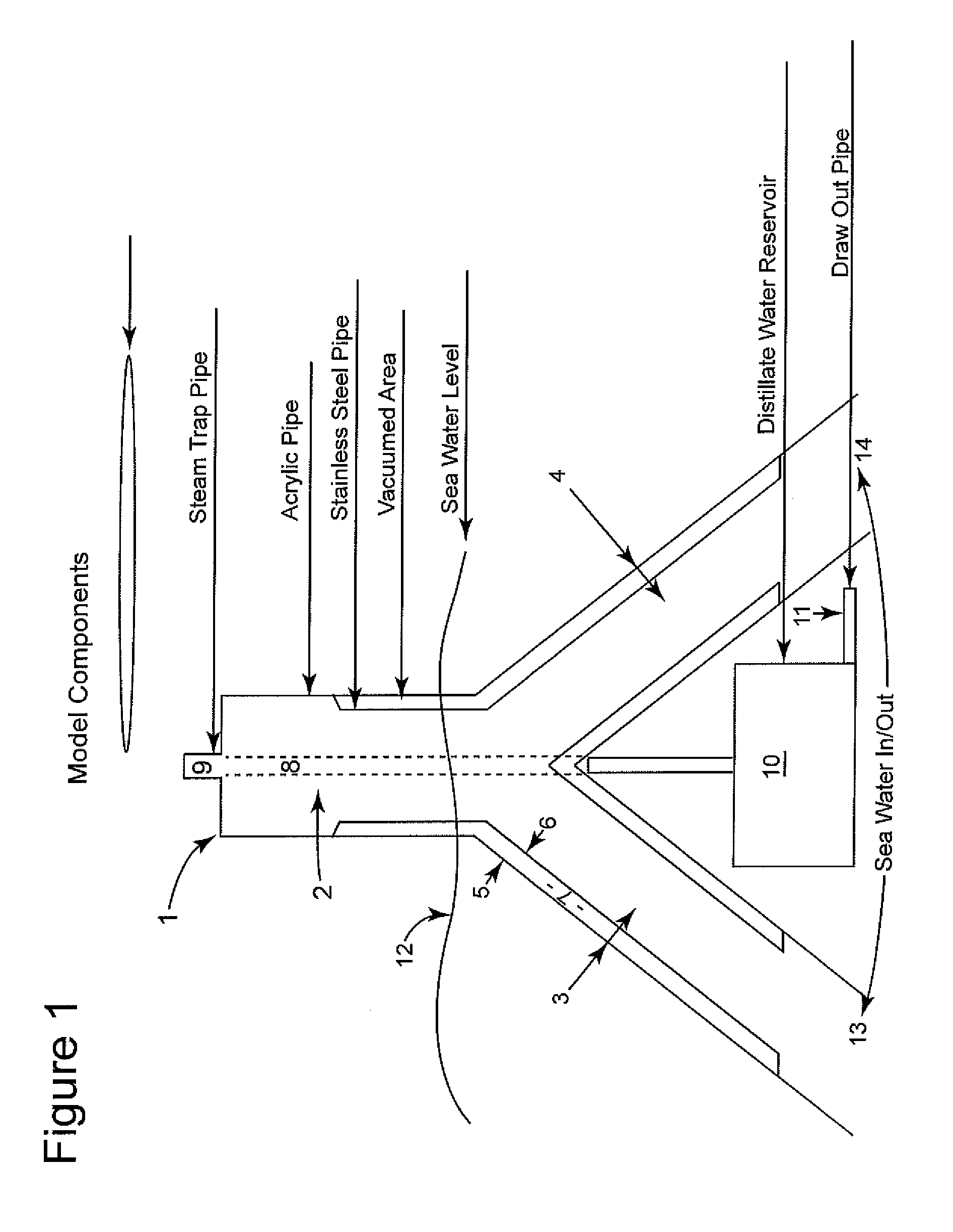

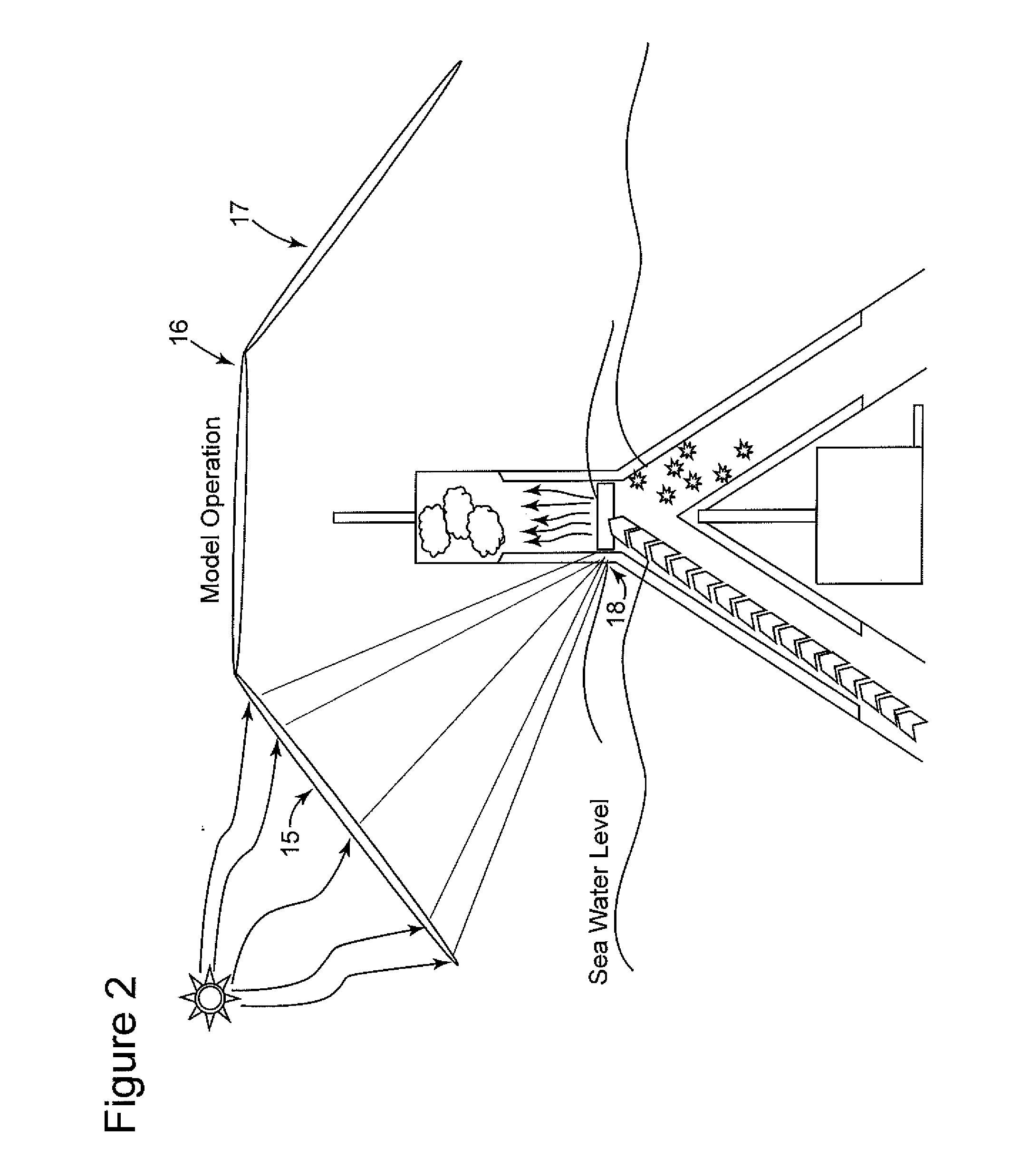

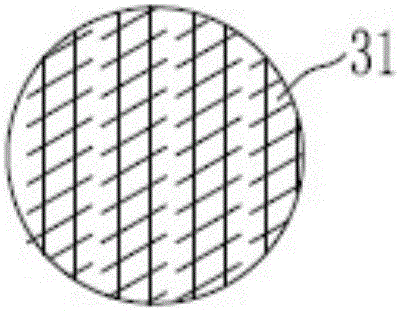

Apparatus for distillation of water and methods for using same

The invention relates to an apparatus and method for distilling fresh water from sea, and brackish water. In essence, an invented, Y-shaped structure is configured such that each leg of the figure contains two, concentric pipe means. One pipe means institutes the exterior of the leg, and is translucent. The smaller pipe means is positioned inside the first, and a vacuum exists between the two. Water is permitted to enter the pipe means, via a further pipe means in communication with the source of the water. When the water rises in the legs of the apparatus, concentrated heat provided via, e.g., Fresnel lenses, acts to evaporate the water, resulting in separation of salt and impurities therefrom. Pure water condenses in the device and accumulates in a reservoir provided for this purpose.

Owner:SAUDI ARABIAN OIL CO

Desalinization Device and Method of Using the Same

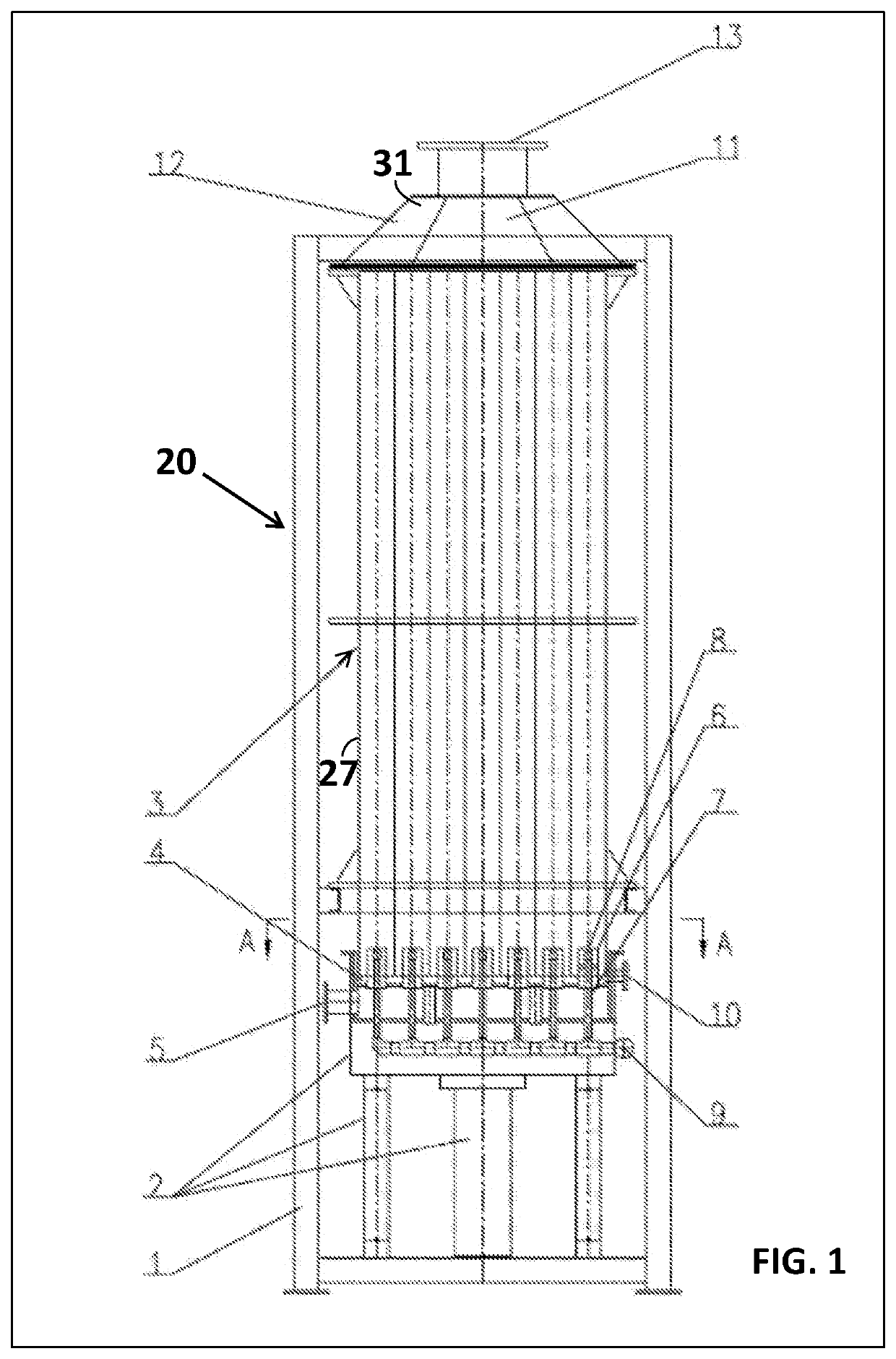

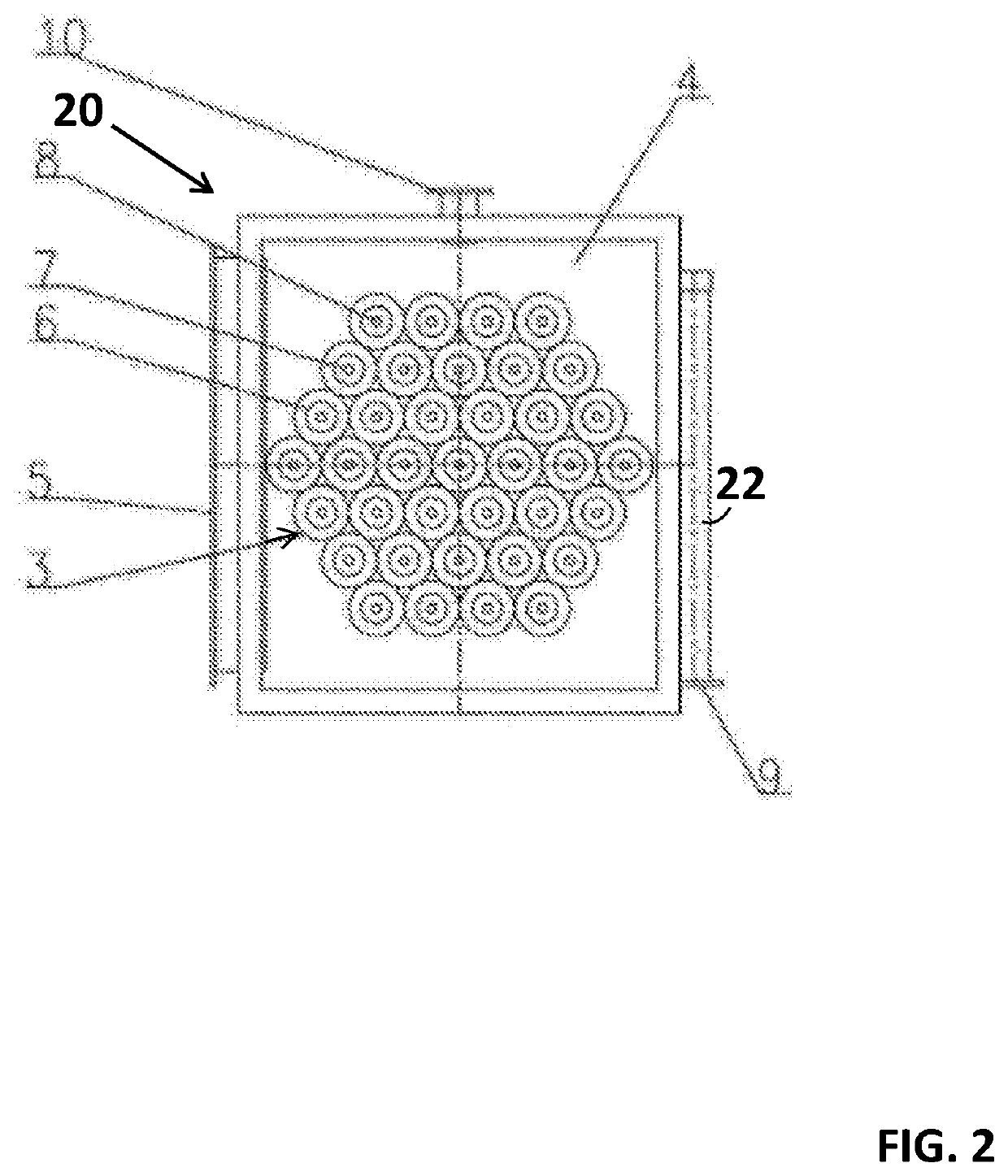

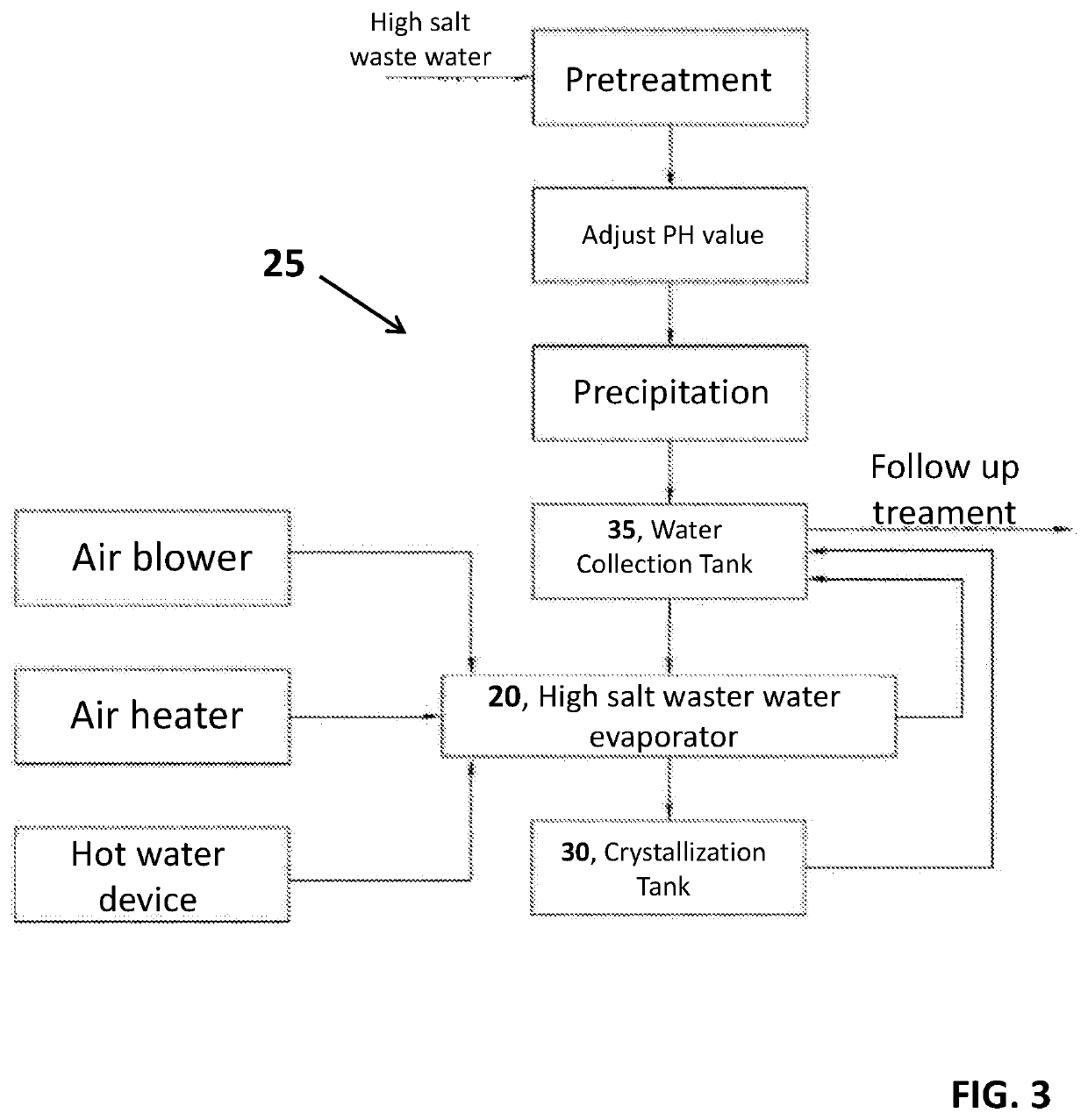

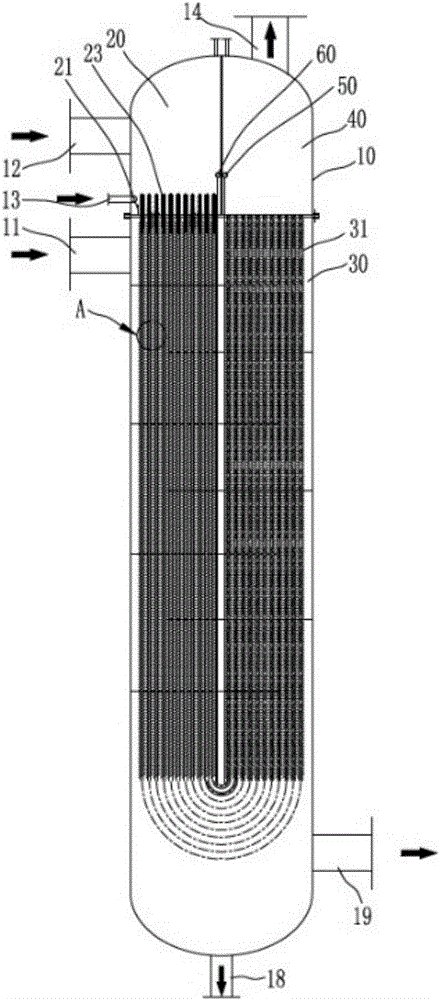

ActiveUS20200087167A1Improve processing efficiencySimple structureGeneral water supply conservationPaint waste treatmentDesalinationWastewater

The invention is a high-salt waste water air powered low temperature evaporating device and method of use. A tray is mounted on a lifting platform; an air inlet and a water inlet are on the tray. Air distributing pipes are arranged at the center of the nested column tubes (33). A groove (4) is installed at the top of the tray, and mounting points are accompanied by multiple nested column tubes (33). The nested column tubes (33) are connected with the air inlet. An atomizer is arranged inside the air distributing pipes; and the atomizer is connected with the water distributing pipes. Using air power evaporates concentrated waste water multiple times so that the salt in the wastewater reaches saturated concentration, and therefore, the wastewater temperature is reduced, salt is crystallized and separated out, liquid is continuously evaporated, and the wastewater can be completely treated.

Owner:LIU DEPEI

Falling-film evaporation efficient gas and liquid mixer

InactiveCN106823424AImprove gasification efficiencyWell mixedTransportation and packagingEvaporator accessoriesEvaporationEngineering

The invention belongs to the field of gas and liquid mixing technologies, and particularly relates to a falling-film evaporation efficient gas and liquid mixer. The falling-film evaporation efficient gas and liquid mixer has the advantages that falling-film evaporation principles are adopted, films are formed on the inner wall of an outer fin heat exchange tube by to-be-mixed liquid, to-be-mixed gas flows in the tube to promote film forming effects, pressures rarely drop after the gas is circulated in the heat exchange tube and the liquid is gasified, heating media are arranged on shell pass, the liquid is evaporated to obtain gas to be mixed with the gas, the falling-film evaporation efficient gas and liquid mixer is high in heat exchange efficiency and liquid gasification efficiency, and the gas and the liquid can be uniformly mixed with each other; the falling-film evaporation efficient gas and liquid mixer is particularly applicable to atomization and gasification heating places such as reaction, heating, remixing and diffusion places with requirements on high gas and liquid mixing and gasification and heat exchange efficiency and requirements on low gas pressure drop.

Owner:JIANGSU DUBLE ENG

Apparatus for distillation of water and methods for using same

The invention relates to an apparatus and a method for distilling fresh water from sea, and brackish water. In essence, an invented, Y-shaped structure is configured such that each leg of the figure contains two, concentric pipe means. One pipe means institutes the exterior of the leg, and is translucent. The smaller pipe means is positioned inside the first, and a vacuum exists between the two. Water is permitted to enter the pipe means, via a further pipe means in communication with the source of the water. When the water rises in the legs of the apparatus, concentrated heat provided via, e.g., Fresnel lenses, acts to evaporate the water, resulting in separation of salt and impurities therefrom. Pure water condenses in the device and accumulates in a reservoir provided for this purpose.

Owner:SAUDI ARABIAN OIL CO

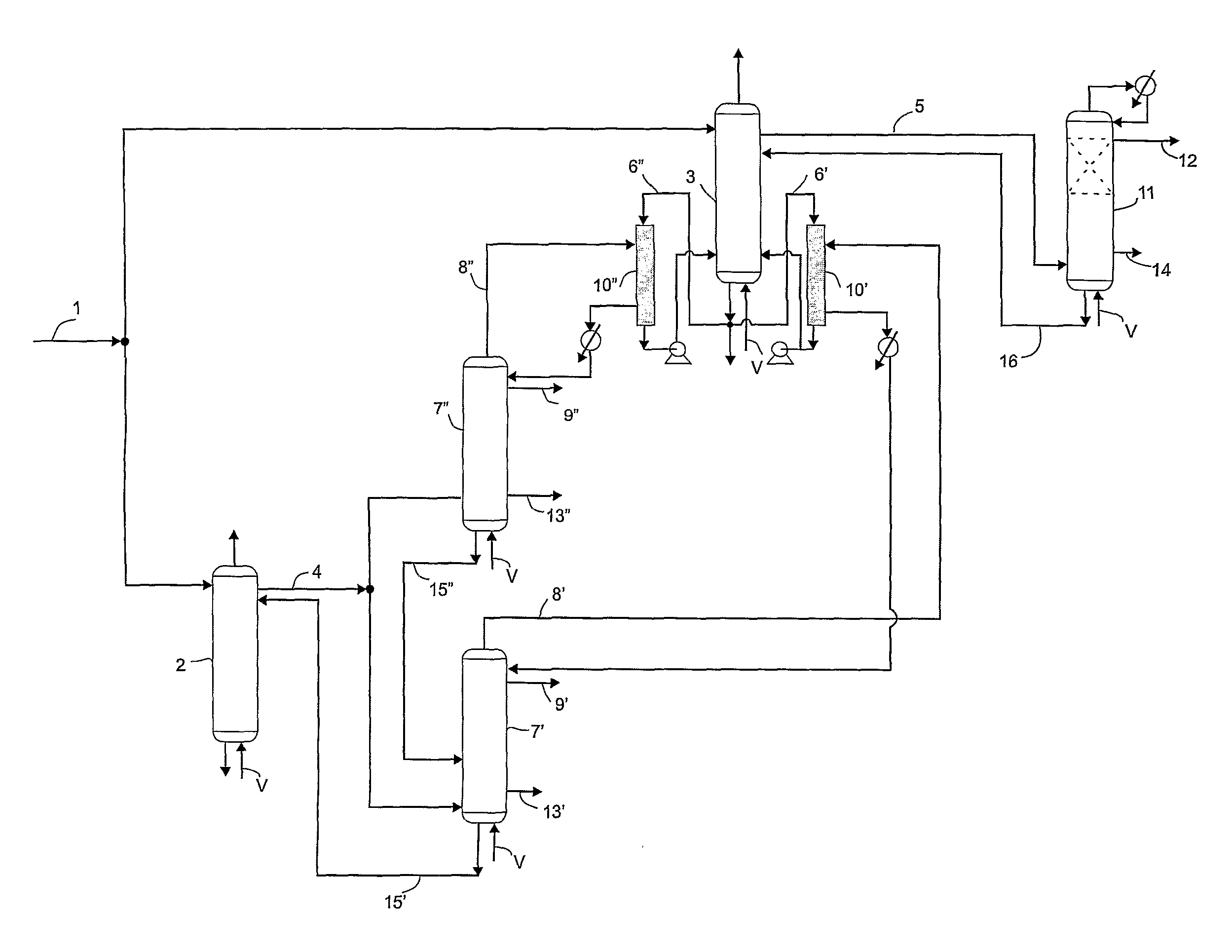

Process and system for producing alcohol by split-feed distillation

InactiveUS8287698B2Easy to operateSufficient thermal loadFermented solutions distillation/rectificationBiofuelsAlcoholDistillation

The present invention relates to a process and a system for producing alcohol by distillation with energy optimization using split-feed technology. The process of the present invention comprises the steps of: a) splitting a stream of wine to feed two depuration columns , the depuration column generating a stream of phlegma and the depuration column generating a stream of phlegma and a stream of vinasse; b) feeding the stream of phlegma into at least one rectification column generating a top flow and a stream of hydrated alcohol; c) effecting the heat exchange between the top flow from at least one rectification column and the stream of vinasse from the depuration column in at least one heat exchanger; and d) feeding the stream of phlegma into a rectification column generating a stream of hydrated alcohol. The present invention further relates to hydrated alcohol produced by the process described above and to a process for producing anhydrous alcohol.

Owner:SIEMENS LTD +1

Method of manufacturing packing and packing

ActiveUS10265676B2Weight increaseIncrease in sizeGas treatmentDispersed particle separationEngineeringUltimate tensile strength

A method of manufacturing packing includes: determining types of a gas and a liquid which are brought into gas-liquid contact and a main plate to be used; calculating a relationship between a contact angle and a liquid film length ratio; determining the arrangement (intervals) of a rib; determining rib conditions; calculating the minimum value of the flow direction length of the rib satisfying the contact angle and a strength requirement; confirming whether or not a liquid film length is greater than the minimum value; and determining the flow direction length of the rib within a range from the minimum value to the liquid film length.

Owner:IHI CORP

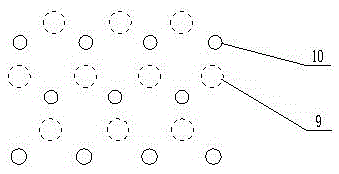

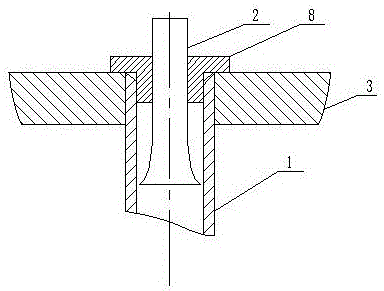

Liquid distributor for falling-film evaporator

InactiveCN106730947AEvenly distributedStable film formationEvaporator liquid feederEvaporators with vertical tubesEngineeringDrainage tubes

The invention provides a liquid distributor for a falling-film evaporator. The liquid distributor comprises heating tubes, a tube plate, a distribution disc, a dispersion disc, a seal head and a feed inlet pipe, wherein drainage tubes are inserted into the upper parts of the heating tubes; the lower parts of the drainage tubes are trumpet-shaped; the drainage tubes and the heating tubes are coaxial; gaps are formed between the outer walls of the drainage tubes and the inner walls of the heating tubes; the heating tubes on the tube plate are distributed in the form of a regular triangle; distribution disc holes in the distribution disc have diameters of 3 to 6 mm; and gaps are formed between the supporting plates for the drainage tube and the tube plate. Material liquid flows from distribution disc holes to tube plate and then enters the drainage tubes after overflowing; due to the buffering action of stored liquid among the drainage tubes, liquid distribution is allowed to be uniform, films formed by the material liquid on the walls of the heating tubes are uniform; and since the design of the distribution disc holes has smaller influence on material liquid distribution compared with common liquid distributor, the liquid distributor provided by the invention is simple.

Owner:HENGYANG YISHUN CHEM CO LTD

Process and apparatus for forced circulation evaporative crystallization with large deposit inventory

ActiveUS20140338843A1Drying using combination processesEvaporator liquid feederUnit operationForced circulation

Disclosed are processes and apparatuses for producing a crystalline product. The processes and apparatuses may extend the operational time of an evaporative crystallizer by providing an internal volume or large deposit inventory for fouling deposits to reside without impacting the unit operation.

Owner:DOW GLOBAL TECH LLC

Evaporator array for a water treatment system

ActiveUS20150360969A1Waste water treatment from quariesGeneral water supply conservationWater treatment systemEngineering

An evaporator array for a water treatment system, the evaporator array comprising a produced water feed and a first evaporator to receive produced water from the produced water feed, a makeup water feed and a second evaporator to receive makeup water from the makeup water feed, an output feed to receive distillate from the first evaporator and the second evaporator, and a blowdown feed to receive blowdown from the first evaporator and the second evaporator, wherein the first evaporator and the second evaporator each have a working pH, the working pH of the first evaporator being higher than that of the second evaporator.

Owner:I D E PROJECTS LTD

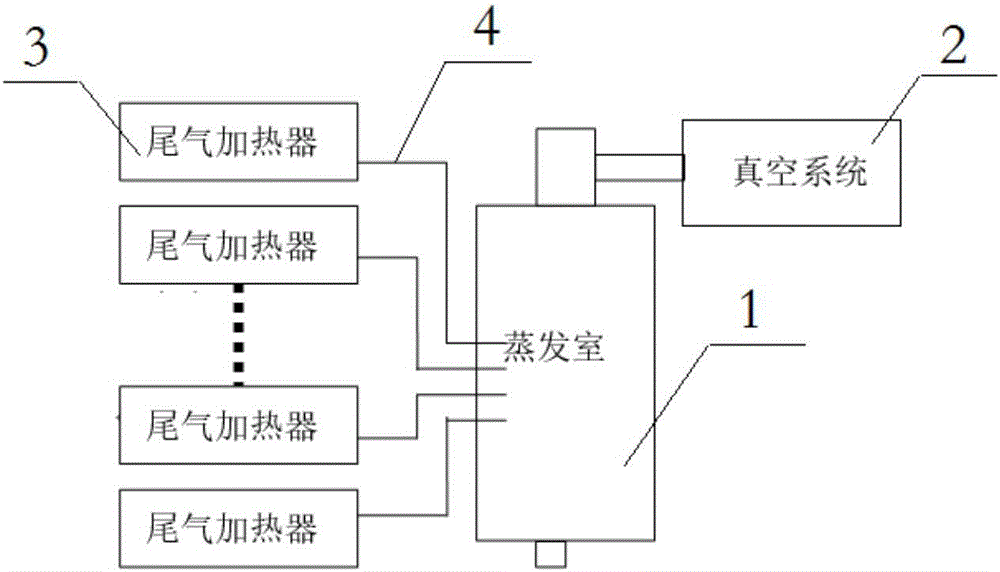

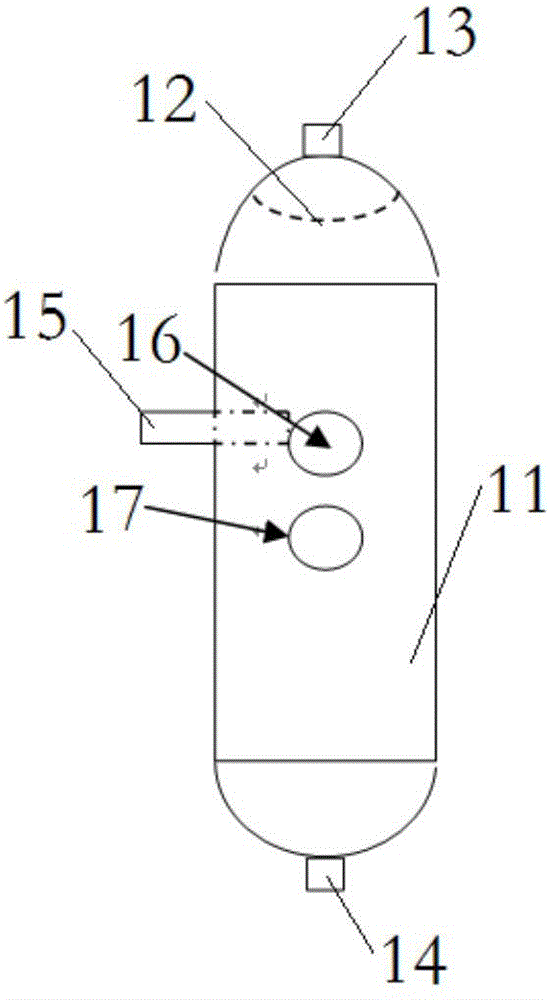

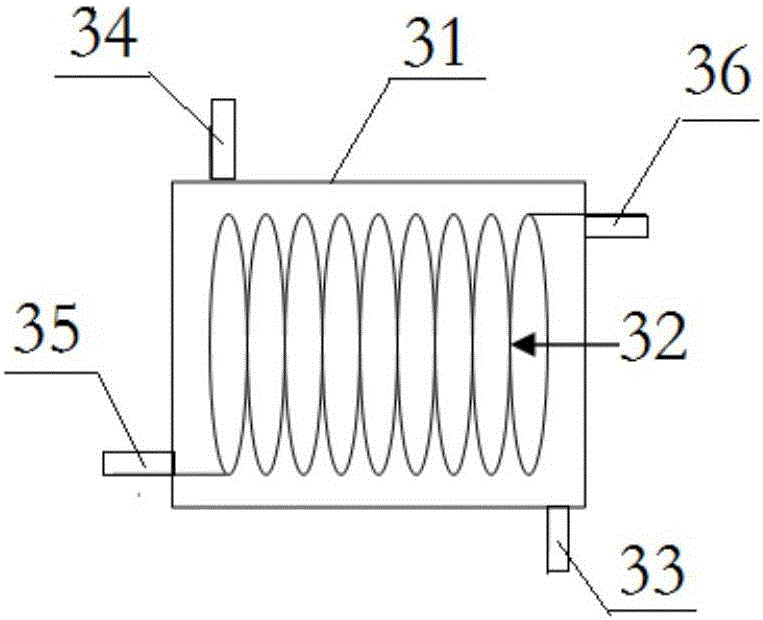

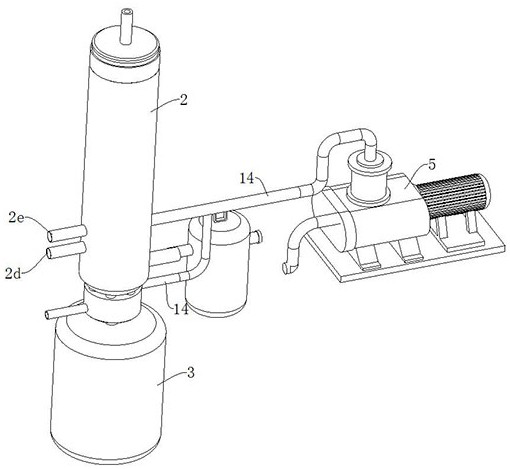

A vacuum system capable of using heat generated by concentrated tail gas

InactiveCN106422379AEfficient use ofIncrease Concentrate YieldEvaporator accessoriesEvaporator liquid feederThermal energyGas heater

The invention discloses a vacuum system capable of using heat generated by concentrated tail gas. The system comprises an evaporation chamber, a vacuum device, several tail gas heaters and several material inlet pipes. The evaporation chamber comprises a tank body and a spherical baffle plate. The top end of tank body is provided with an air extraction hole. The spherical baffle plate is located in the tank body and is placed squarely below the air extraction hole. The bottom of the tank body is provided with material outlets. The lateral side of the tank body is provided with material inlets, an inlet material observation hole and a fluid level observation hole. Viewing glass is placed at both the inlet material observation hole and the fluid level observation hole. The vacuum device is communicated with the air extraction hole of the evaporation chamber. The material outlets of several tail gas heaters pass through several material inlet pipes to communicate with the material inlets of the evaporation chamber. Each of the material inlet pipes is provided with a material inlet valve. The system can effectively utilize the heat generated by the tail gas. On the premises of increasing the concentrated output of tail gas, the system has the advantage of having no new additional energy consumption, being simple in operation and having a straightforward control manner.

Owner:浙江惠光生化有限公司

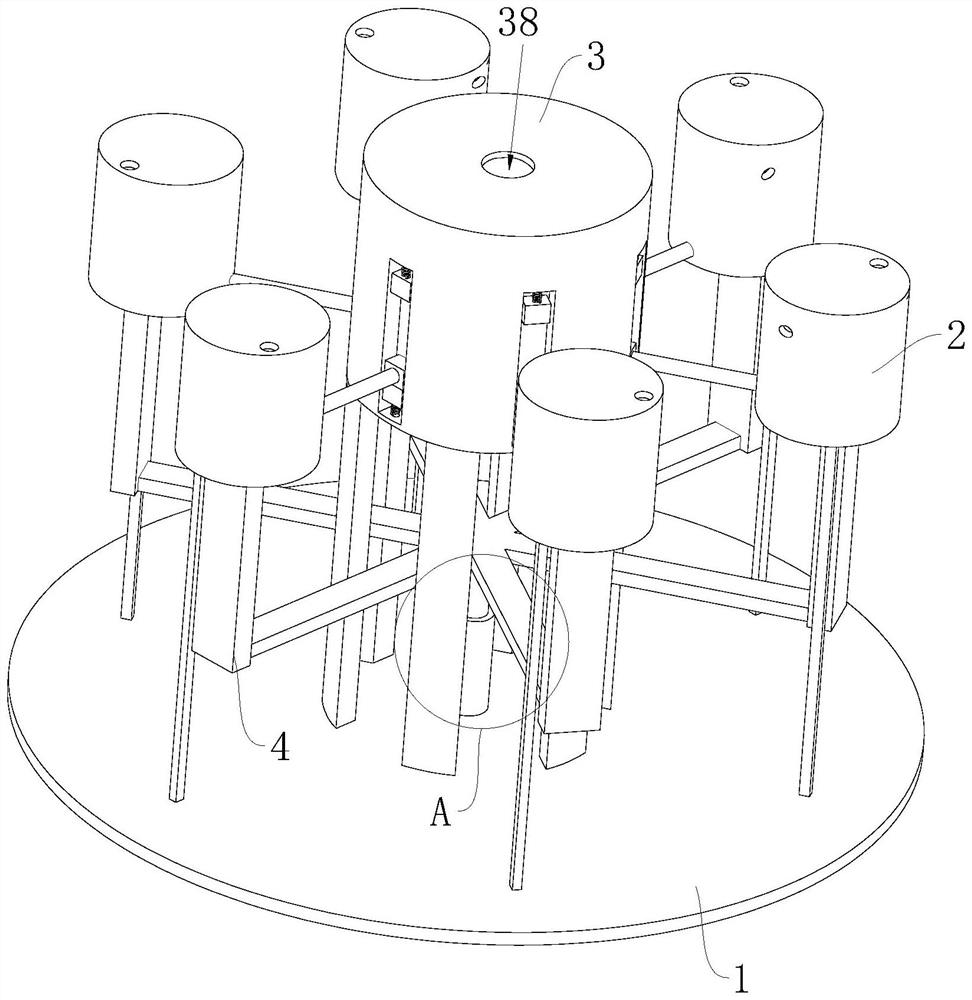

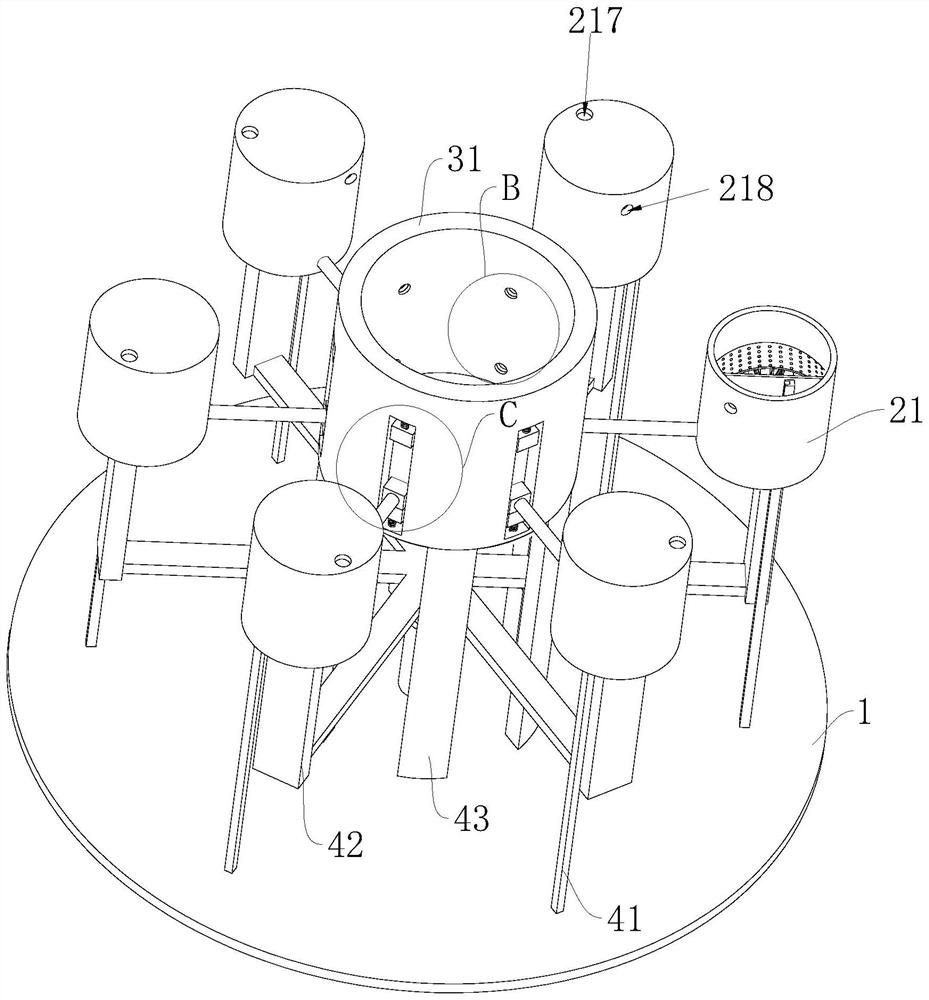

MVR evaporative crystallization system

PendingCN112221169AIncrease the descending strokeShorten the lengthEvaporation with vapour compressionEvaporator liquid feederEngineeringMechanical engineering

The invention relates to the field of MVR evaporative crystallization equipment, in particular to an MVR evaporative crystallization system. The system comprises an evaporation tank, a crystallizer, aplurality of falling-film pipeline sets, a steam compressor and a water distribution device, wherein the plurality of falling-film pipeline sets are distributed in the evaporation tank along the circumference of the evaporation tank at equal angles; each falling-film pipeline set comprises a heat conduction sleeve and an inner heat conduction pipe arranged in the heat conduction sleeve, a liquidfeeding cavity is formed between the heat conduction sleeve and the inner heat conduction pipe, a thickening layer is arranged at the middle section area of the inner heat conduction pipe, and a spiral groove channel is formed in the thickening layer; the water distribution device is arranged at the top end of the evaporation tank and communicates with all the liquid feeding cavities; the crystallizer is arranged at the bottom of the evaporation tank and communicates with the evaporation tank; the bottom of the evaporation tank is provided with a steam distribution disc communicating with allthe inner heat conduction pipes; and the output end of the steam compressor communicates with the evaporation tank and the steam distribution disc through a steam circulation pipeline of a Y-shaped structure. According to the invention, the length of falling-film pipelines can be reduced, and meanwhile, a water film can be effectively heated and evaporated.

Owner:BEIJING HORIZON ENVIRONMENTAL TECH

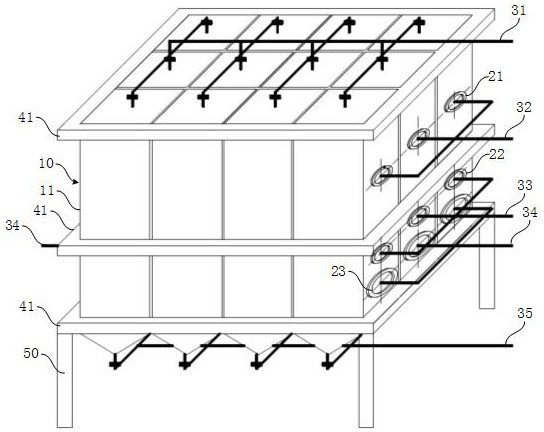

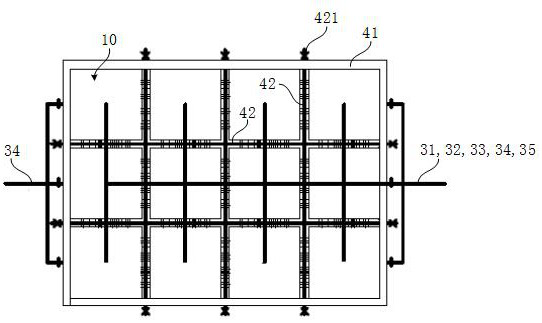

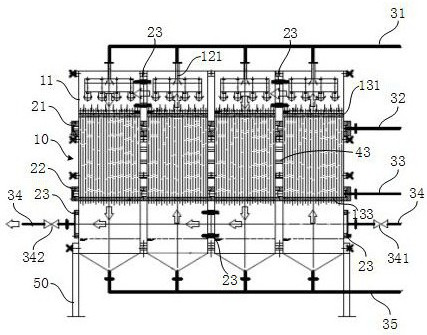

Vertical pipe falling film evaporator

ActiveCN112704888ARealize large-scaleIncrease throughputEvaporator accessoriesEvaporator liquid feederCondensed waterSteam condensation

The invention discloses a vertical pipe falling film evaporator, which comprises a plurality of evaporation units which are detachably connected with one another to form a rectangular array, a shell of each evaporation unit comprises a cylinder body, an upper sealing head and a lower sealing head, the upper sealing head and the lower sealing head are arranged at the two ends of the cylinder body, the cylinder body is cuboid, and each evaporation unit comprises a film distribution section, a heating section and a separation section from top to bottom; a first connecting assembly is used for communicating the heating steam of each row of evaporation units; a second connecting assembly is used for communicating the condensed water of each row of evaporation units; and a third connecting assemblies communicate the secondary steam of each row of evaporation units, and the third connecting assemblies are arranged in each row of evaporation units in an up-down staggered mode, so that the secondary steam reversely flows in the adjacent evaporation units. According to the vertical pipe falling film evaporator, the modular evaporation units are detachably connected into the rectangular array, the heating steam, the condensate water and the secondary steam in the rectangular array form a specific path to be communicated, large-scale production of the vertical pipe falling film evaporator is achieved, and the handling capacity of the evaporator is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

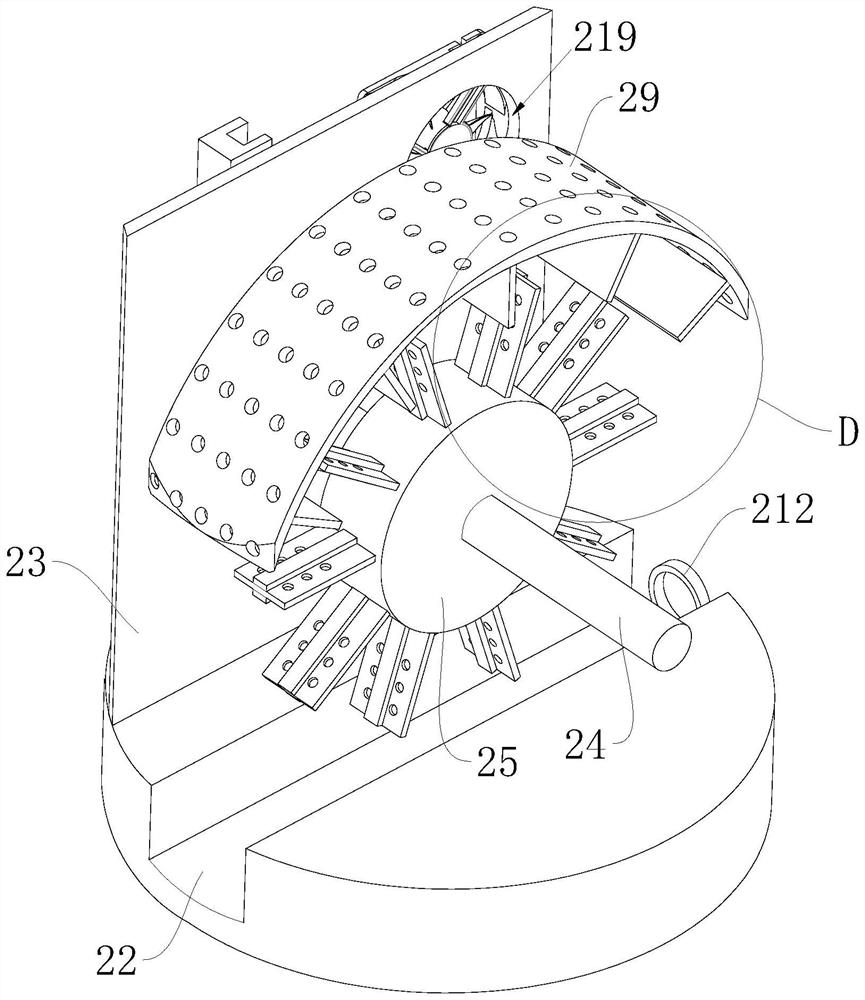

Composite methanol evaporator

PendingCN114100162AImprove vaporization efficiencyShorten production timeEvaporator accessoriesEvaporator liquid feederFan bladeCentrifugal force

The invention relates to the technical field of methanol production, in particular to a composite methanol evaporator which comprises a base and a power mechanism, the power mechanism is mounted on one side of the base, a heating mechanism is mounted on one side of the power mechanism, and a supply mechanism is mounted on one side of the heating mechanism; the heating mechanism comprises a heating shell, a liquid accumulation groove, a partition plate, a rotating shaft, a rotating disc, a fan blade plate, a groove, a heating plate, an arc-shaped plate, an impact plate, a volatilization hole, a pipeline, a first sliding block and a first sealing ring, the heating shell is installed on the upper portion of the base, the liquid accumulation groove is formed in the bottom of the inner side of the heating shell, and the partition plate is fixedly installed at the bottom of the inner side of the heating shell. According to the invention, the heating mechanism is adopted, the groove takes away methanol through the liquid accumulation tank, the methanol in the liquid accumulation tank impacts the impact plate to form atomized methanol due to the action of centrifugal force, the atomized methanol is vaporized by the heat of the heating plate, the methanol liquid is vaporized after being vaporized, the methanol vaporization efficiency is improved, and the production time is saved.

Owner:葛聪聪

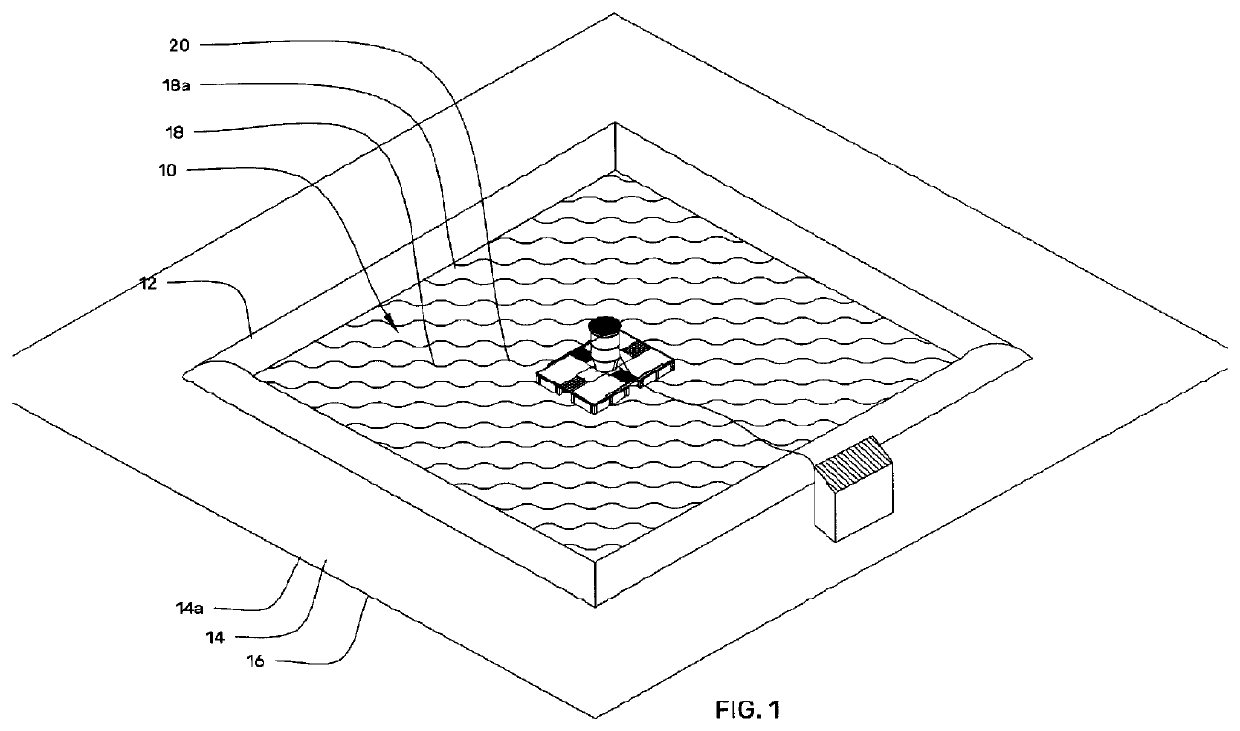

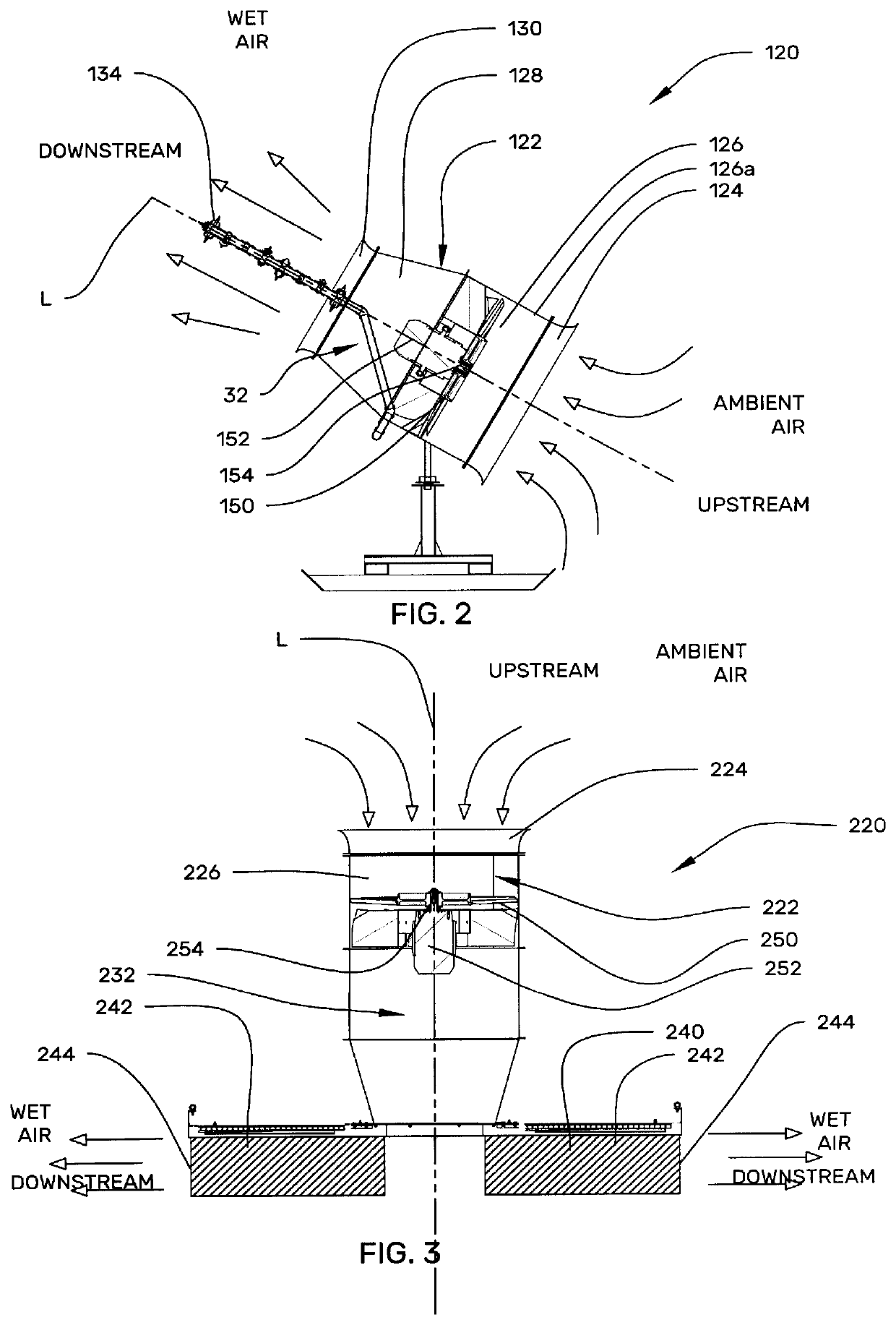

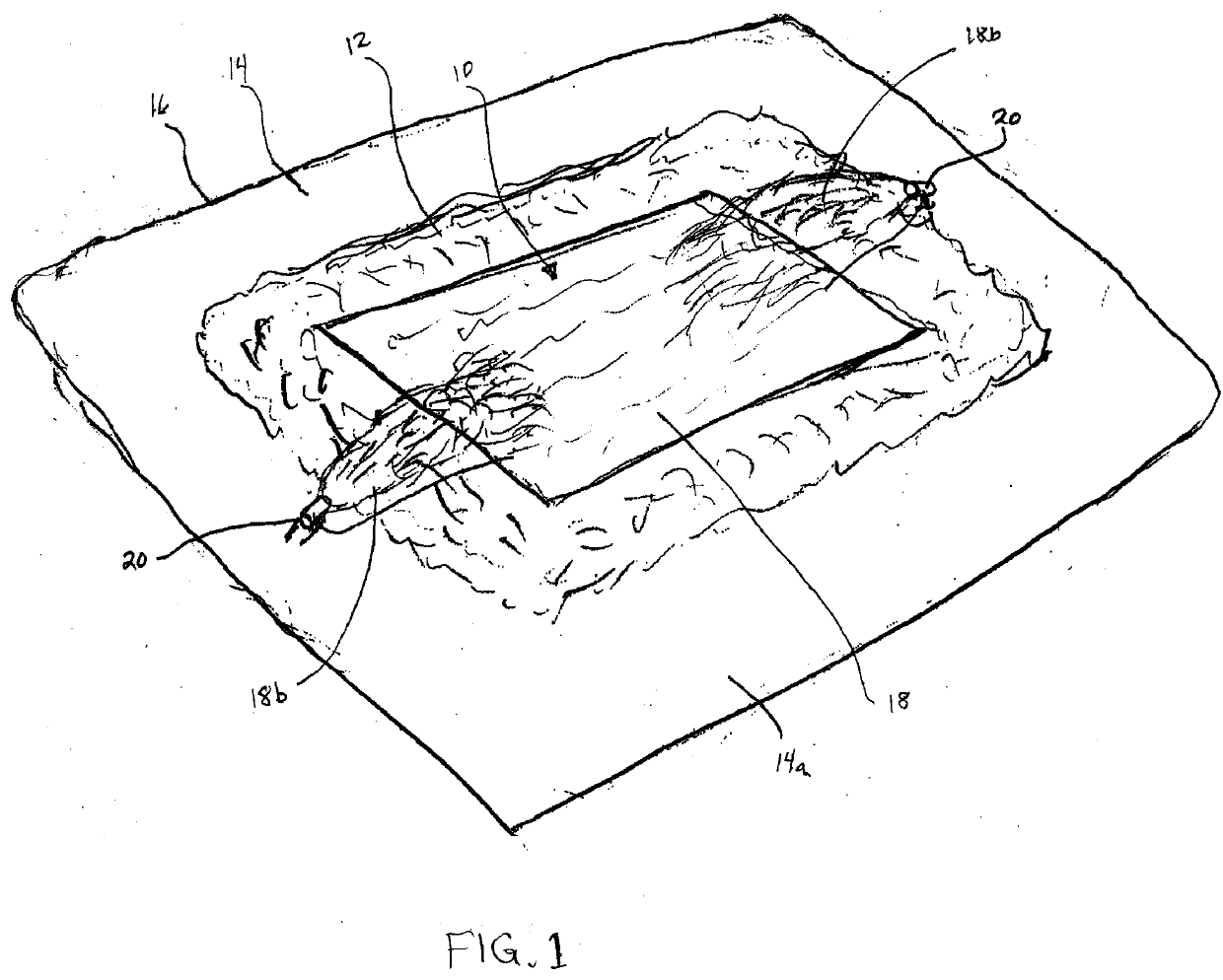

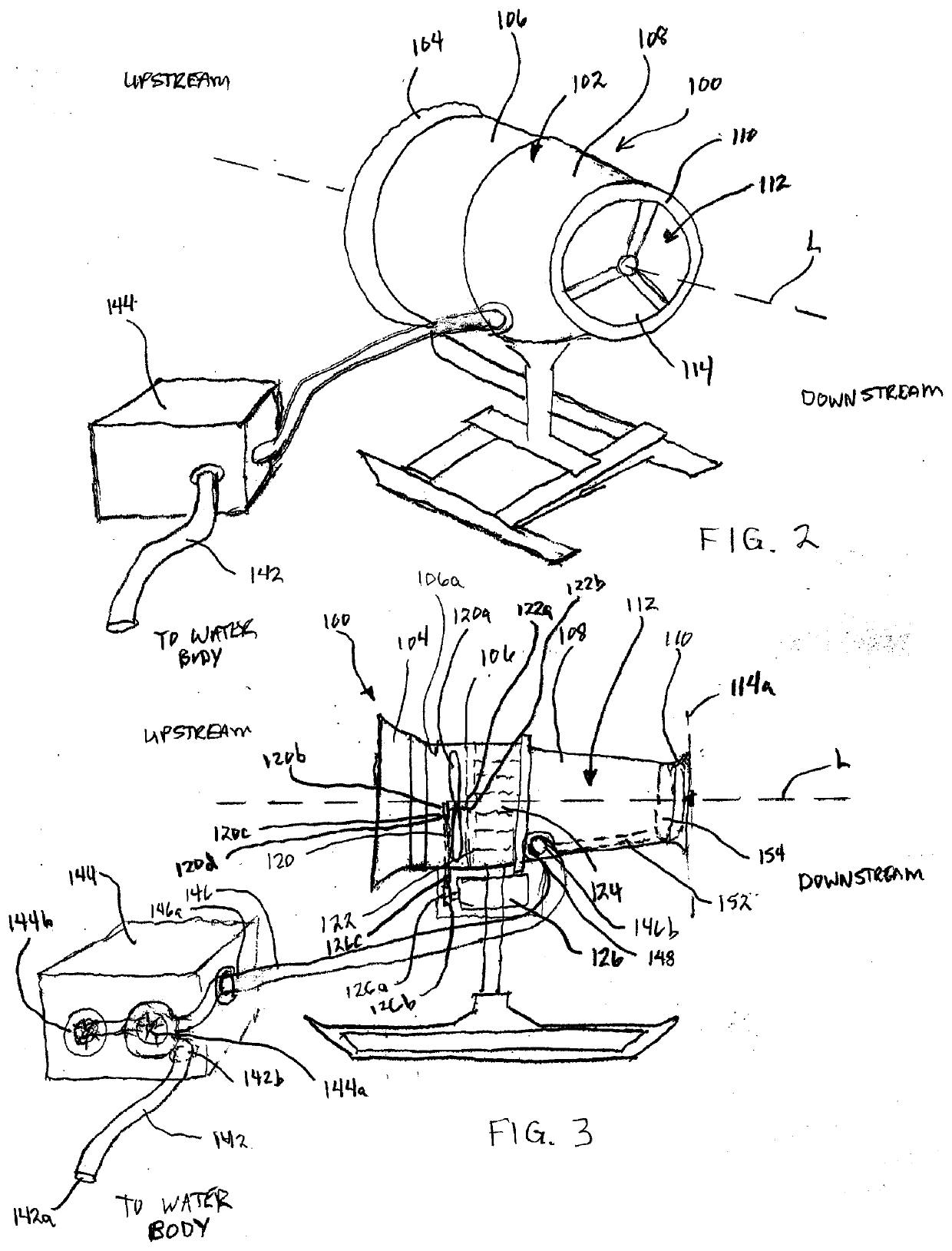

Evaporator for ambient water bodies, and related system and method

InactiveUS20210046397A1Prevent dragging effectWaste water treatment from quariesPump componentsAmbient waterImpeller

An evaporator is provided for evaporating water from an ambient water body. The evaporator includes a housing that in turn includes an air flow channel and an air flow exit. The evaporator also includes an air flow induction device, such as a fan or impeller, that facilitates the directing of an air flow stream through the air flow channel and out the air flow exit. A water injection device is in fluid communication with the air flow channel and is disposed to inject the water from the water body into the air flow stream at a water injection location within the air flow stream and proximate to the air flow exit. A water injection system for injecting water from an ambient water body into an air flow stream directed by an air flow channel of an evaporator also is disclosed, wherein the air flow channel is disposed about a longitudinal axis. The water injection system includes an elongated tubular member disposed parallel with respect to the longitudinal axis, a plurality of water injection nodes disposed at the tubular member and spaced from one another longitudinally, and a support for positioning the elongated tubular member within or proximate to the air flow channel so that the plurality of water injection nodes are positioned within the air flow stream.

Owner:RESOURCE WEST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com