A vacuum system capable of using heat generated by concentrated tail gas

A vacuum concentration and tail gas technology, which is applied in the direction of evaporator accessories, evaporation, chemical instruments and methods, etc., can solve the problems of energy waste and high tail gas temperature, and achieve the effects of increased concentration output, easy operation, and intuitive control methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to enable those skilled in the art to better understand the technical solution of the present invention, its specific implementation will be described in detail below in conjunction with the accompanying drawings:

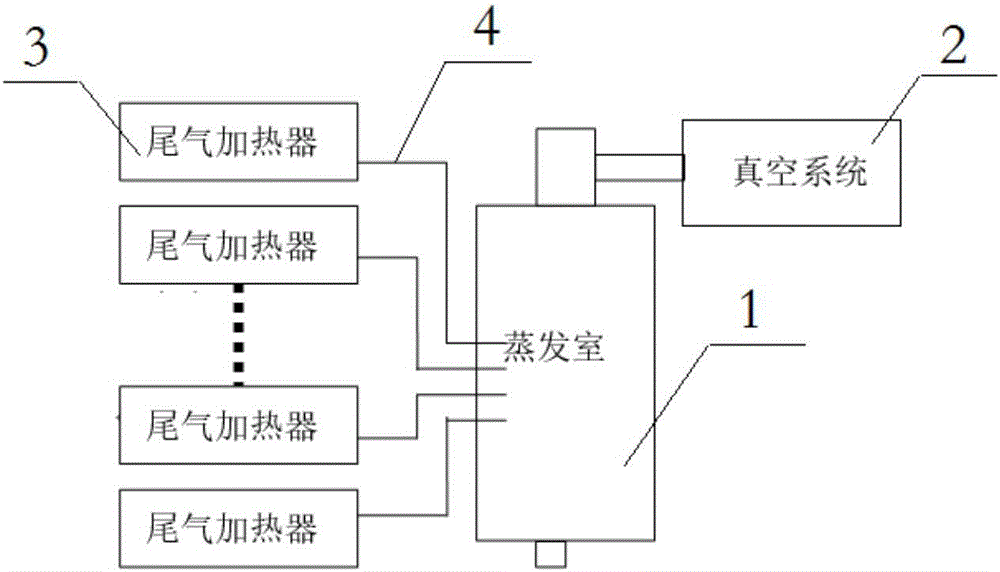

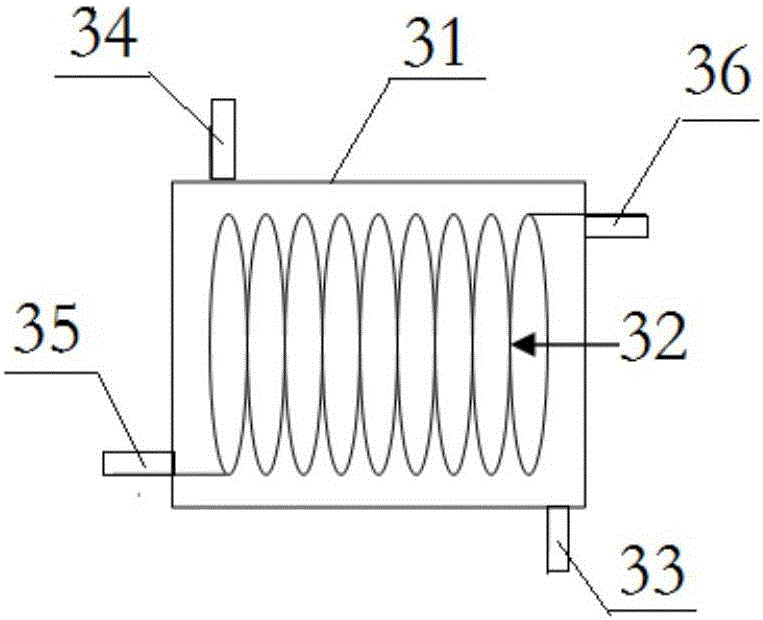

[0018] see figure 1 , figure 2 with image 3 , the best embodiment of the present invention, a vacuum concentrated tail gas thermal energy utilization system, including an evaporation chamber 1, a vacuum device 2, a number of exhaust heaters 3 and a number of feed pipes 4.

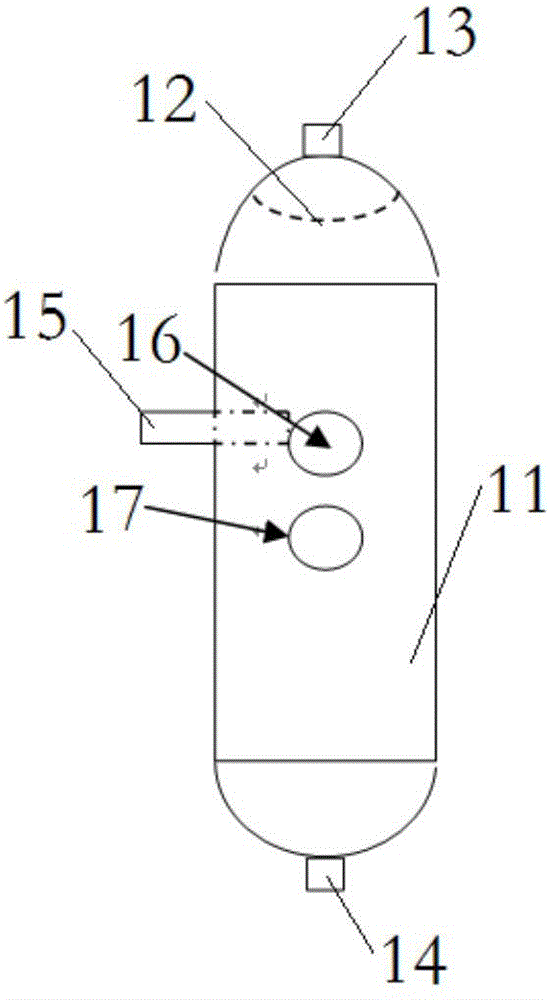

[0019] see Figure 4 , the evaporation chamber 1 includes a tank body 11 and a spherical anti-shock baffle 12, the top of the tank body 11 is provided with an air suction port 13, the spherical anti-shock baffle 12 is arranged in the tank body 11 and is located directly below the air suction port 13, the tank body The bottom end of 11 is provided with discharge port 14, and the wall surface of tank body 11 is provided with feed port 15, feed observation hole 16 and liquid le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com