Composite methanol evaporator

A methanol evaporator, compound technology, applied in the direction of evaporator accessories, evaporation, evaporator liquid feeder, etc., can solve the problems of low air utilization rate, increased production cost, low combination effect, etc., to save production time , improve utilization efficiency, uniform density effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

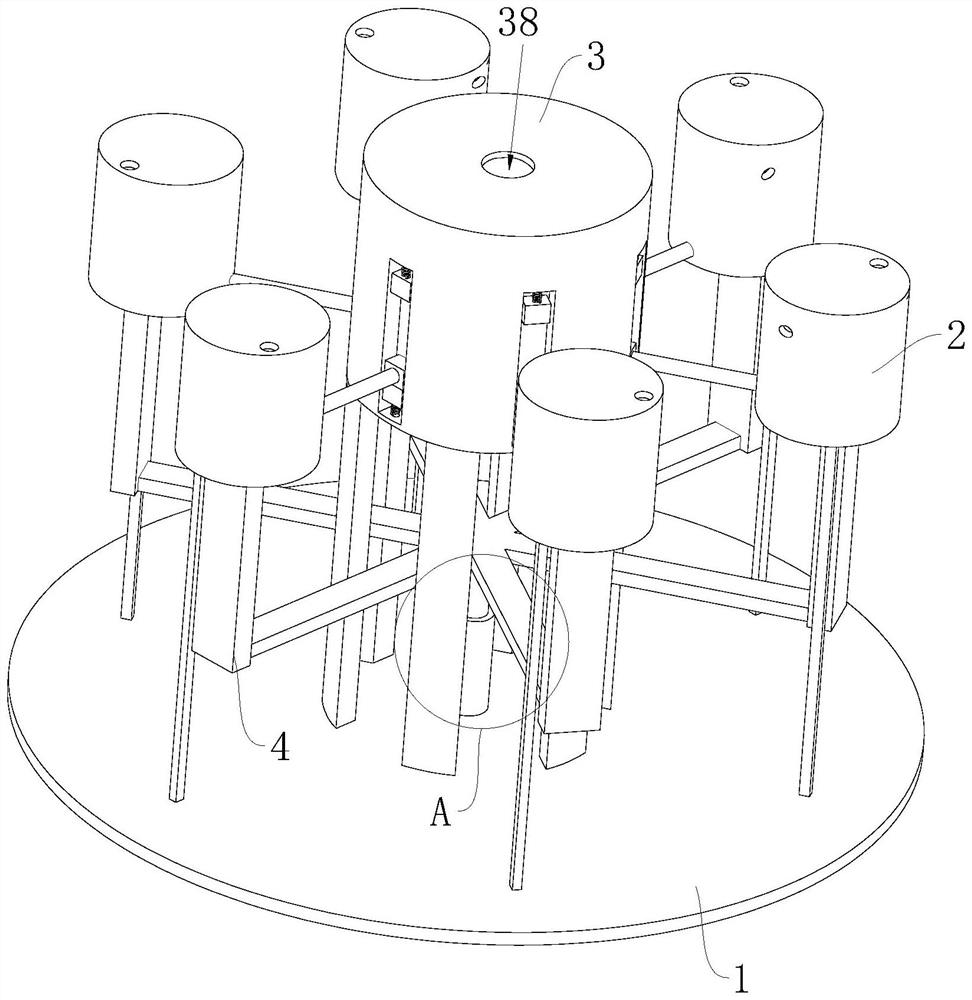

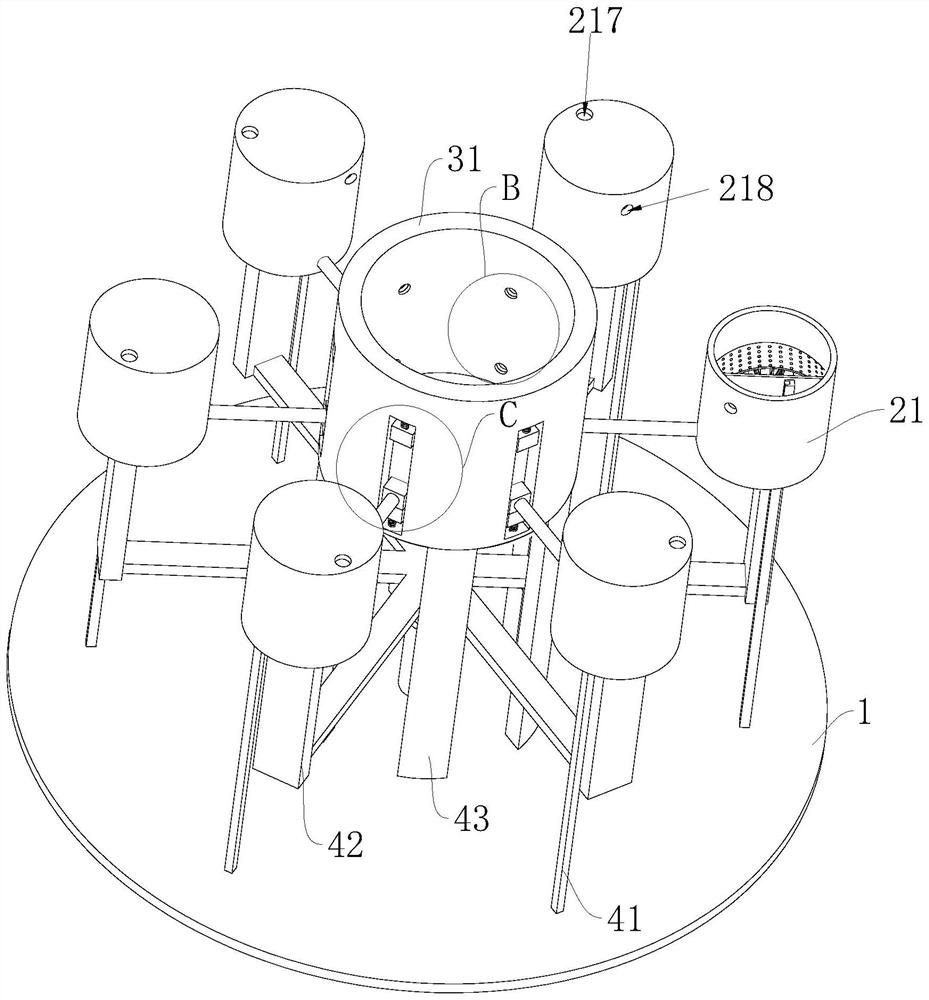

[0029] Such as Figure 1-Figure 10 As shown, a composite methanol evaporator according to the present invention includes a base 1 and a power mechanism 4, a power mechanism 4 is installed on one side of the base 1, a heating mechanism 2 is installed on one side of the power mechanism 4, and a heating mechanism 2 is installed on one side A supply mechanism 3 is installed;

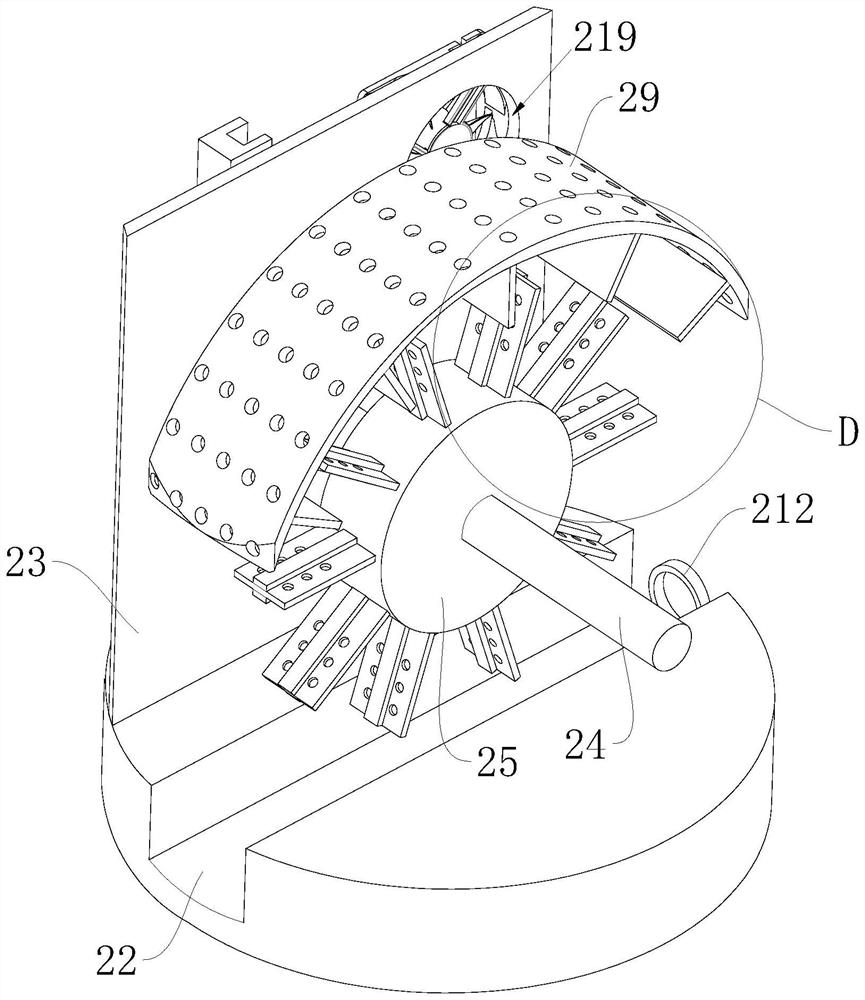

[0030] The heating mechanism 2 includes a heating shell 21, a liquid accumulation tank 22, a partition 23, a rotating shaft 24, a turntable 25, a blade plate 26, a groove 27, a heating plate 28, an arc plate 29, an impact plate 210, a volatilization hole 211, and a pipeline 212, the first sliding block 215 and the first sealing ring 216, the upper part of the base 1 is equipped...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com