Flat-iron and steam generating device thereof

A steam generating device and steam technology, applied in steam generation, steam generation methods, hand irons, etc., can solve the problem that the boiler cannot generate a large amount of steam, and achieve the effects of improving efficiency, increasing vaporization efficiency, and increasing the conduction area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

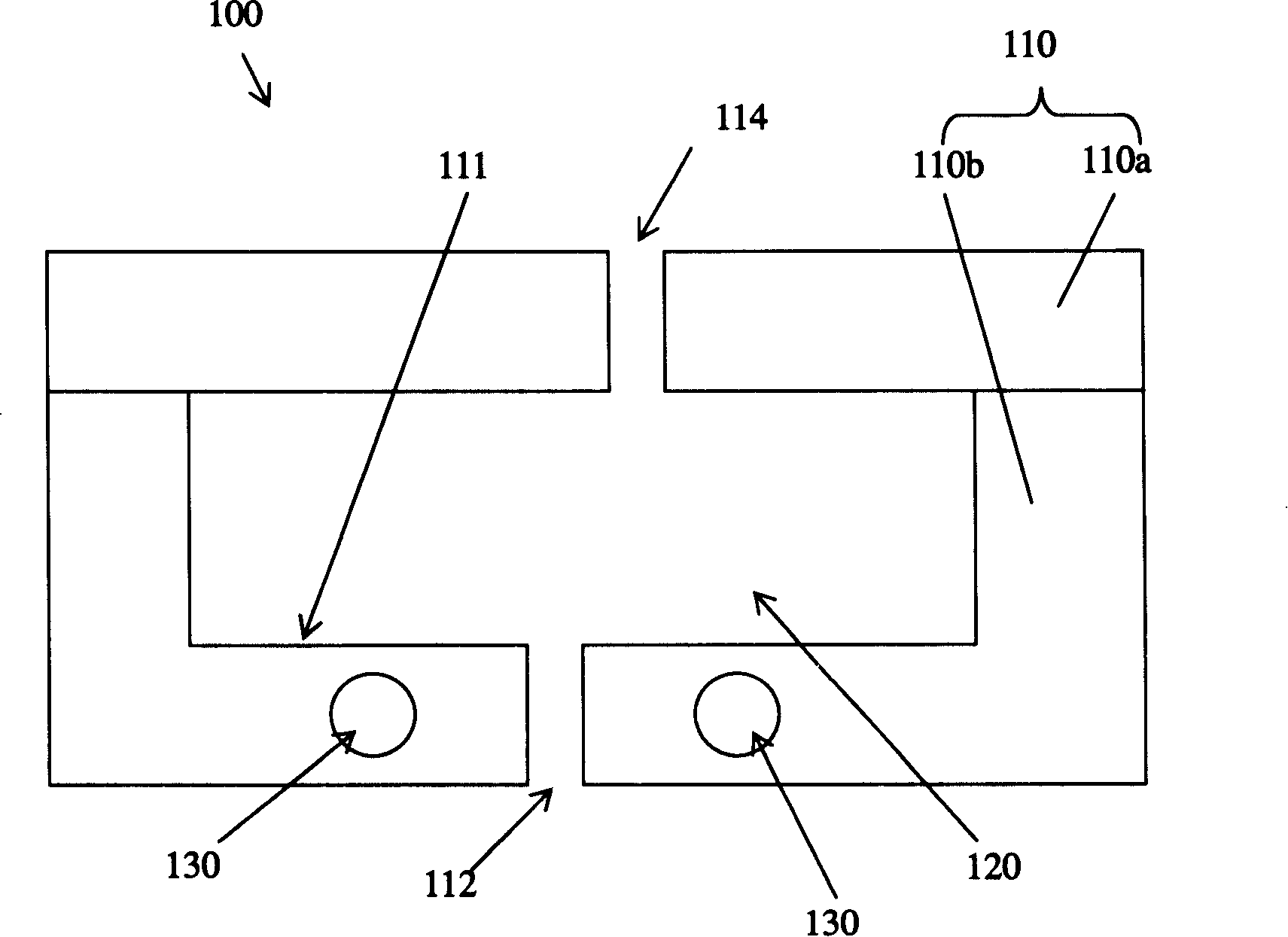

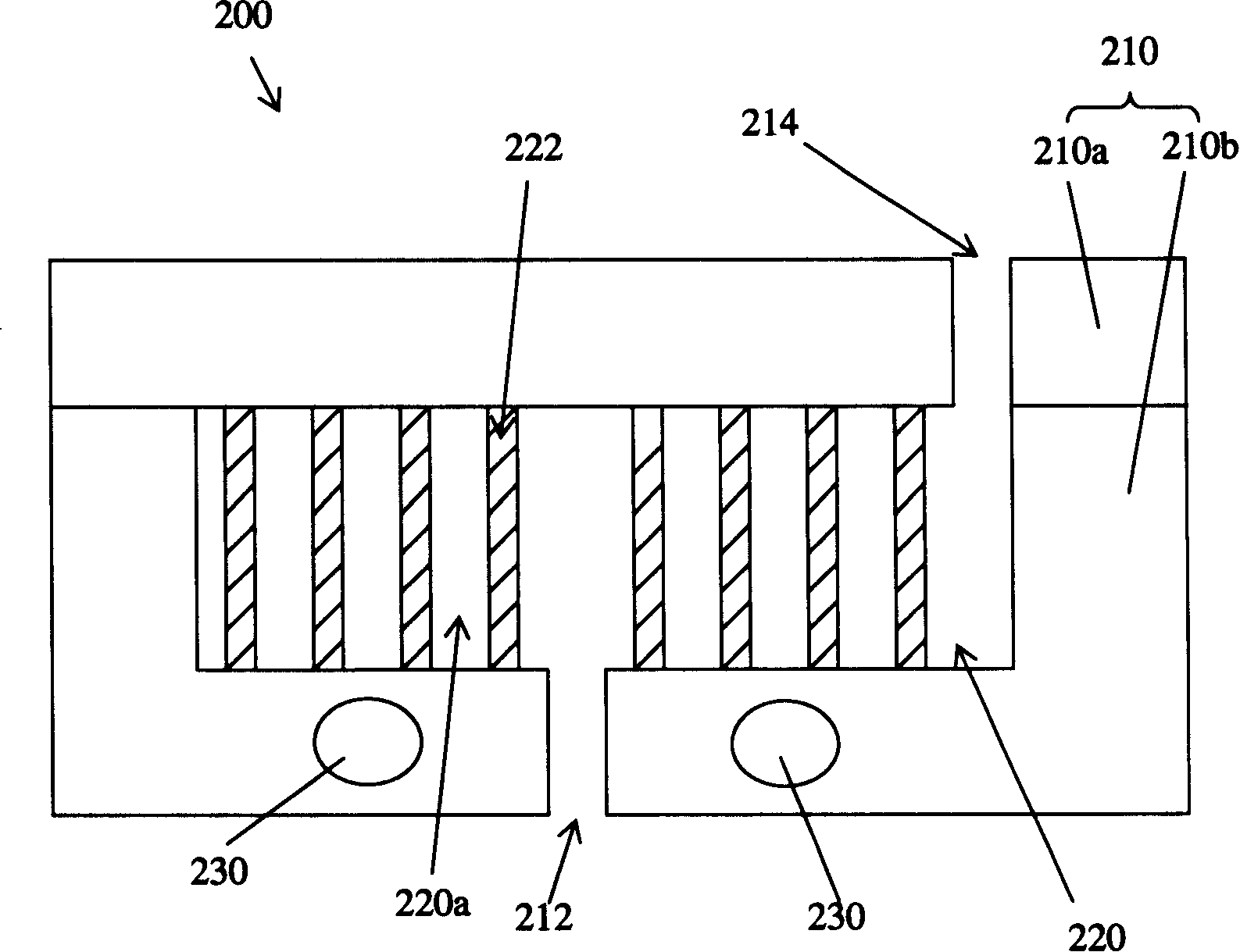

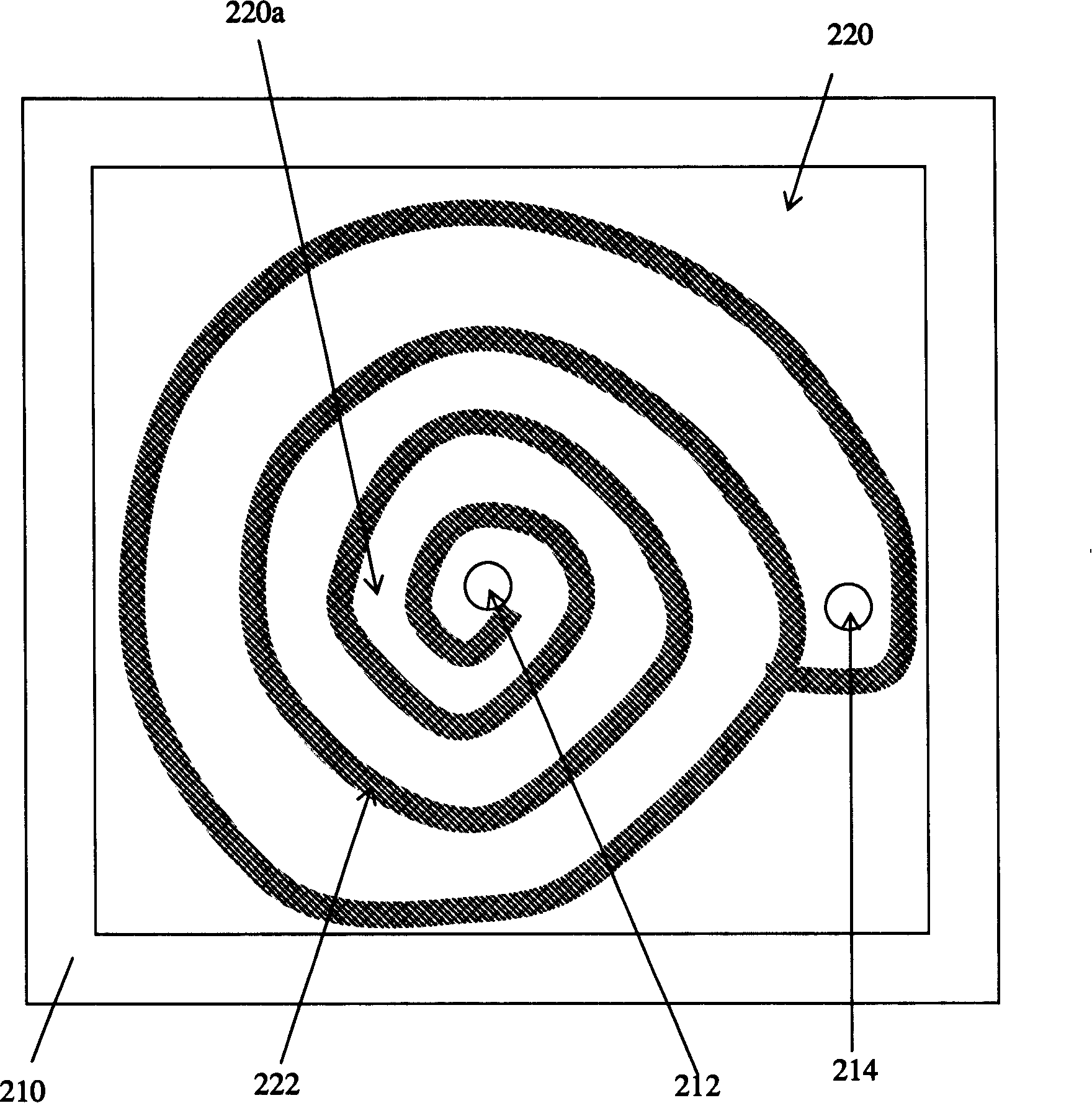

[0034] According to the heat conduction equation, Q=μ×A×ΔT, where Q is the amount of heat conduction, μ is the conduction coefficient of the object, A is the conduction area, and ΔT is the temperature difference, so the heat conduction is mainly related to the conduction coefficient of the object, the size of the conduction area and related to the temperature difference. The present invention mainly provides a steam generating device between the water tank and the electric heating plate, and uses the steam generating device to provide sufficient thermal energy conduction to the water, so that the water can be transformed into superheated and greater than normal pressure before being sent to the electric heating plate. steam. In the present invention, the steam generating device is a pipeline with a heating function, or a boiler with a flow channel structure, that is, the steam generating device of the present invention utilizes the size of the increased conduction area and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com