Device and method for treating power plant waste water

A power plant wastewater and treatment device technology, applied in the direction of gaseous effluent wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problem of increasing investment costs and operating costs, short flue lengths, and relatively large impact on unit loads Large and other problems, to achieve the effect of improving the efficiency of wastewater treatment and reducing the amount of steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

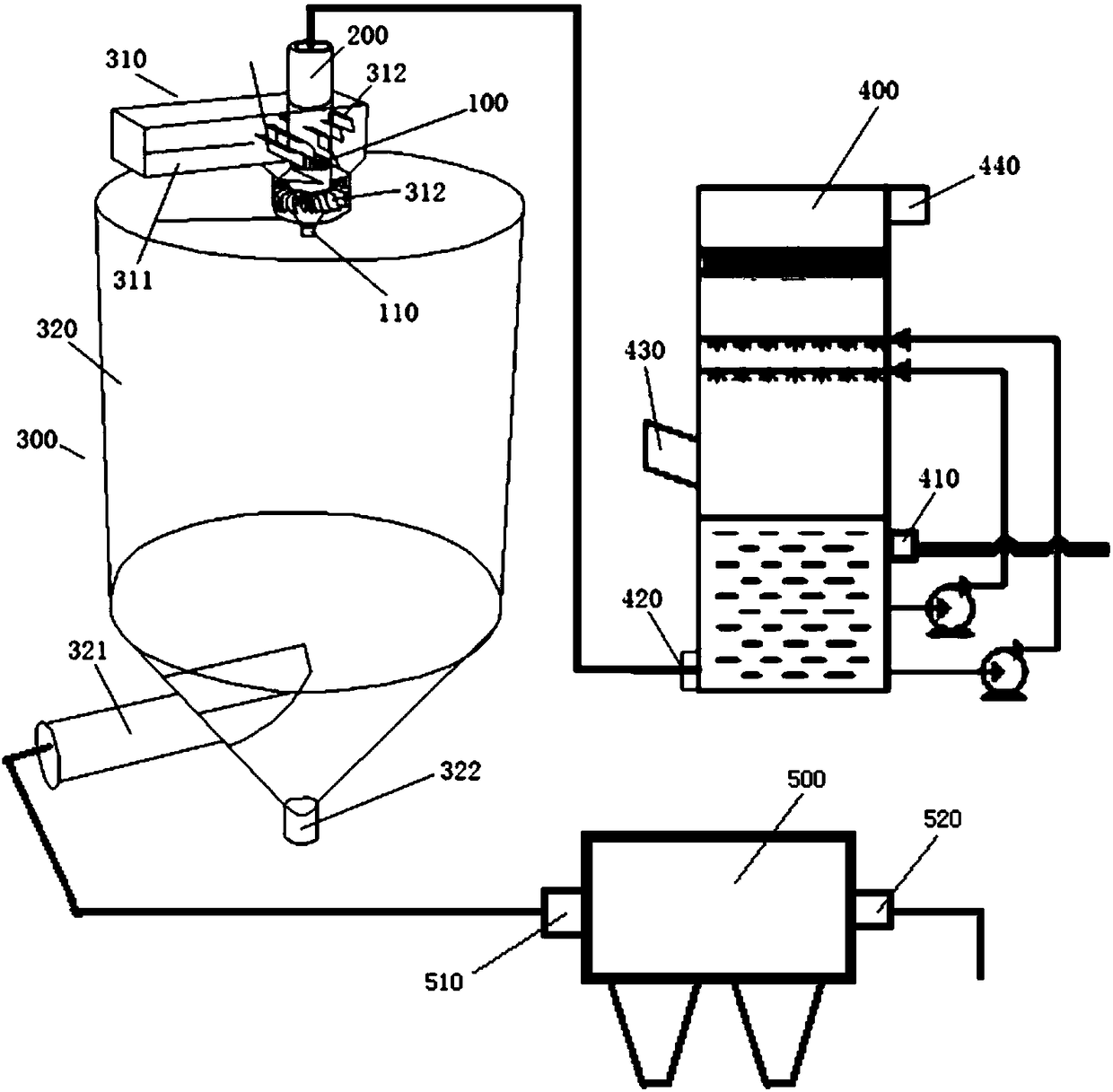

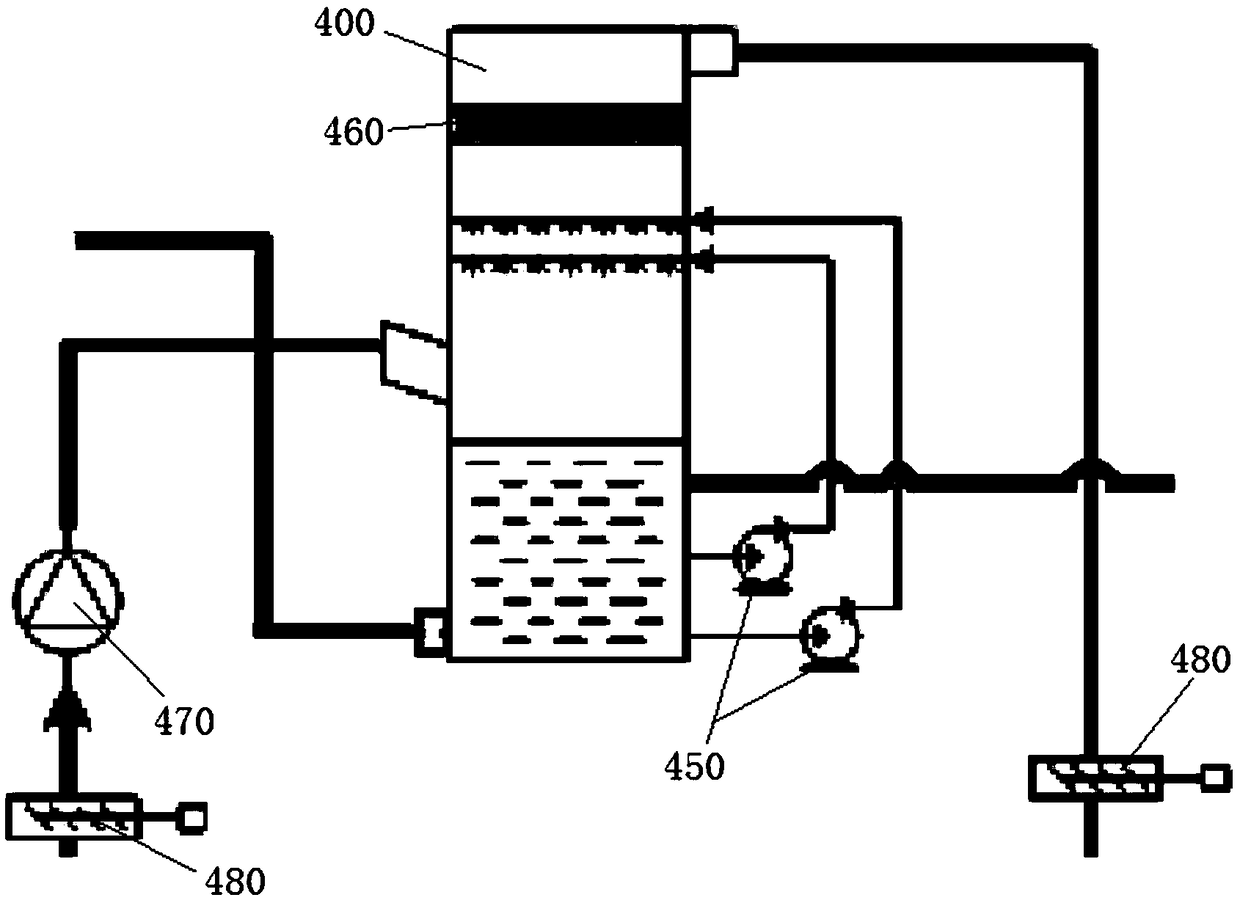

[0046] Such as figure 2 As shown, the present invention provides a plant wastewater treatment device, including: rotary atomizer 100, evaporation tower dust collector 500 and concentration tower 400; also includes: atomization evaporation tower 300; described atomization evaporation tower 300 is provided with heat Air distributor 310 and evaporation tower tank body 320; The bottom of described evaporation tower tank body 320 is provided with air outlet 321 and ash outlet 322; Described hot air distributor 310 is arranged on the top of described evaporation tower tank body 320 or The side wall of the upper end of the evaporation tower tank body 320; the hot air distributor 310 includes an air duct 311 and a hot air deflector 312 arranged in the air duct 311; the outlet of the air duct 311 is connected to the The inner cavity of the evaporation tower tank body 320 is connected; the air duct of the hot air distributor 310 is provided with a rotary atomizer installation sleeve 20...

Embodiment 2

[0056] Such as Figure 5 As shown, this embodiment is based on Embodiment 1, the hot air deflector 312 includes: an air turbulence deflector 3121 and an air swirl deflector 3122; the air turbulence deflector 3121 is Relative to the air flow direction, the air duct is arranged in a leaf mosaic manner; the air swirl deflector 3122 is fixedly arranged on the outer wall of the rotary atomizer installation sleeve 200, arranged in a fan blade structure .

[0057] The setting of the air turbulence deflector is used to block the air velocity and change the flow state of the air in the air duct to a turbulent state, which helps to achieve the uniform filling of the air duct and the formation of a relatively uniform high temperature that meets the conditions of evaporation and vaporization field; the setting of the air swirl deflector helps to transform the turbulent air into a swirl, which in turn helps the high-temperature flue gas to pass through the tube wall of the rotary atomizer...

Embodiment 3

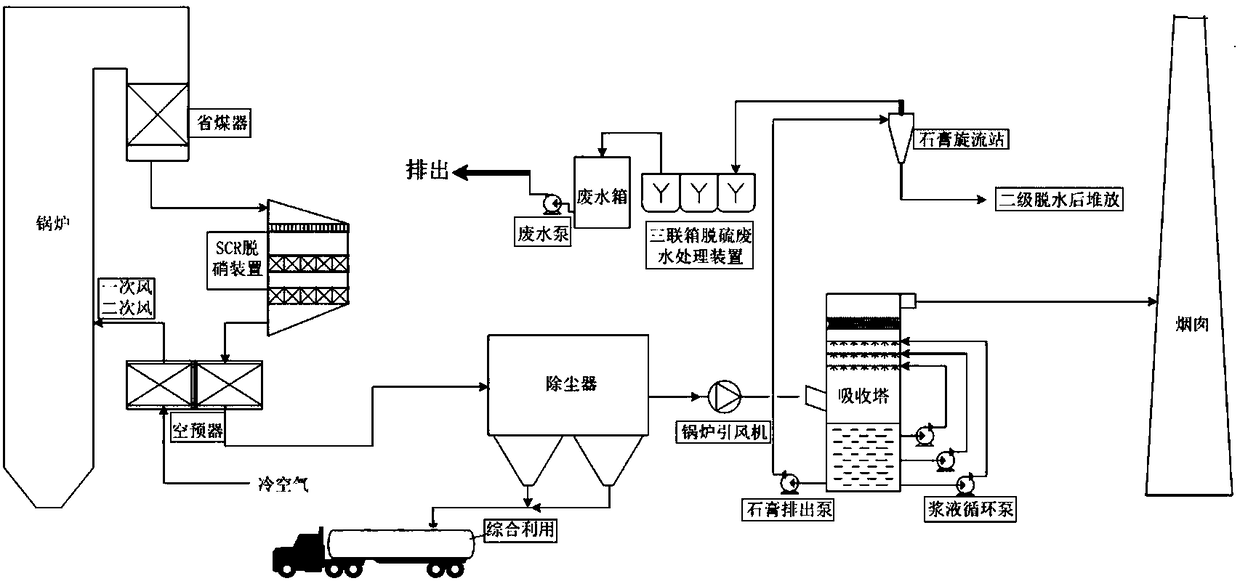

[0063] On the basis of the above embodiments, this embodiment also provides a power plant wastewater treatment method, using the aforementioned power plant wastewater treatment device, the power plant is provided with a denitrification device, a waste water tank, a dust collector, a boiler induced draft fan and an absorption Tower, said method comprises the steps:

[0064] The waste water input interface of described thickening tower is established to be connected with the waste water tank that is provided with in the power plant through the first water delivery pipeline, and the setting of described first water delivery pipeline satisfies that waste water is led to described thickening tower from described waste water tank;

[0065] The rotary atomizer installation sleeve is established to be connected with the concentrated water output interface through the second water delivery pipeline, and the setting of the second water delivery pipeline meets the requirement that the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com