Patents

Literature

54 results about "Secondary air injection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Secondary air injection (commonly known as air injection) is a vehicle emissions control strategy introduced in 1966, wherein fresh air is injected into the exhaust stream to allow for a fuller secondary combustion of exhaust gases.

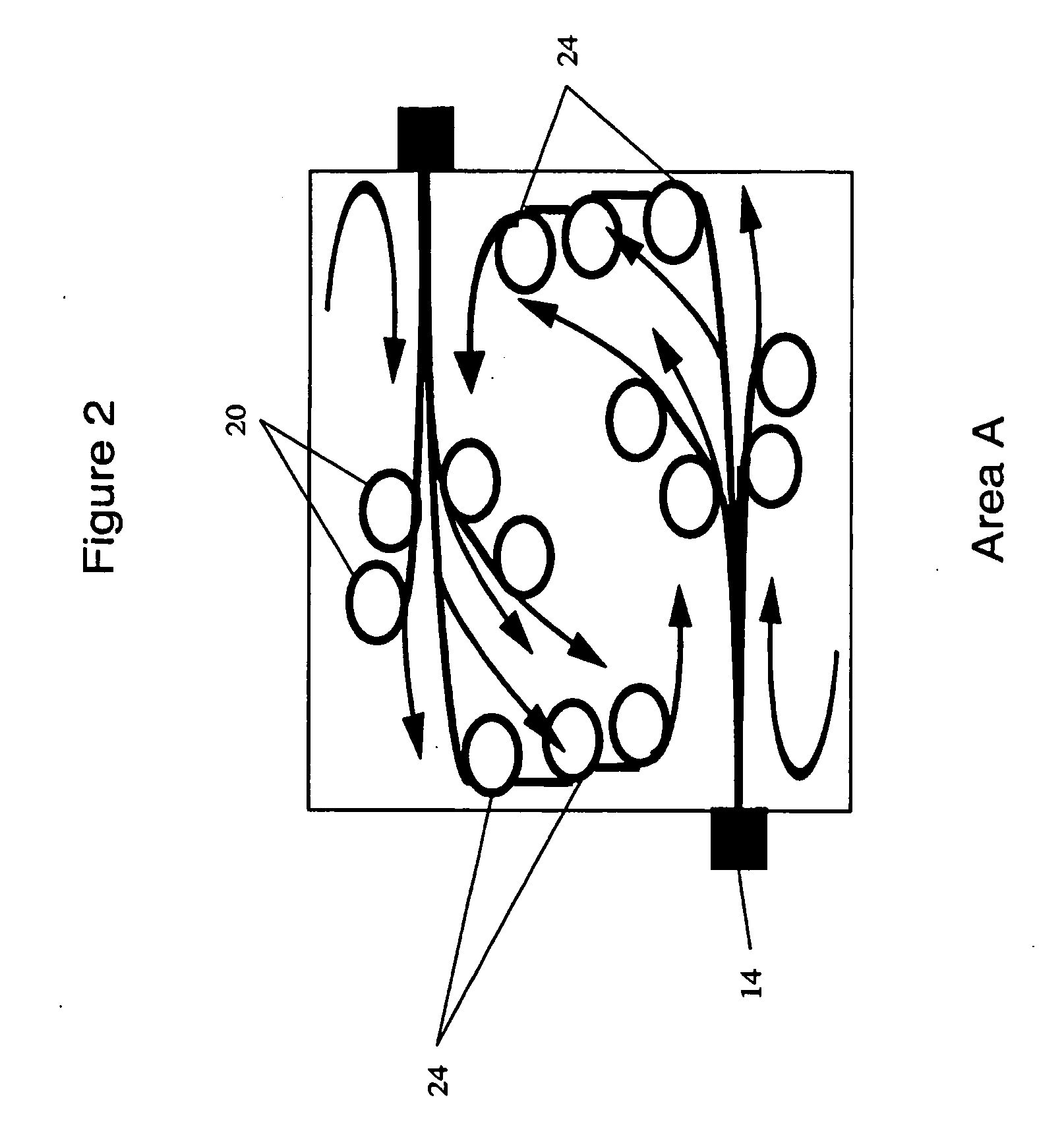

Air staged low-NOx burner

InactiveUS7175423B1Reduce the production of nitrogen oxidesReduce nitrogen oxide emissionsCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustorEngineering

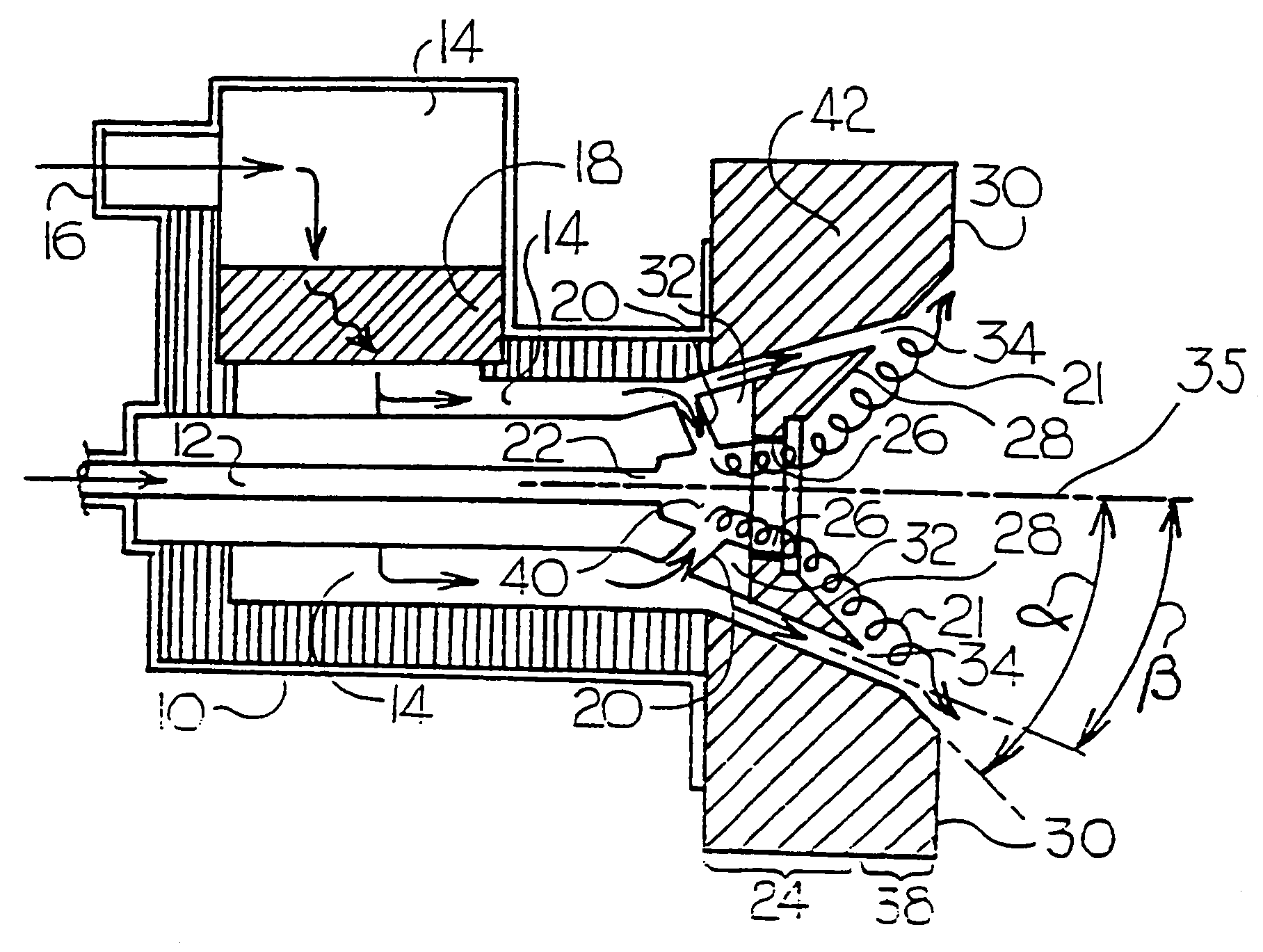

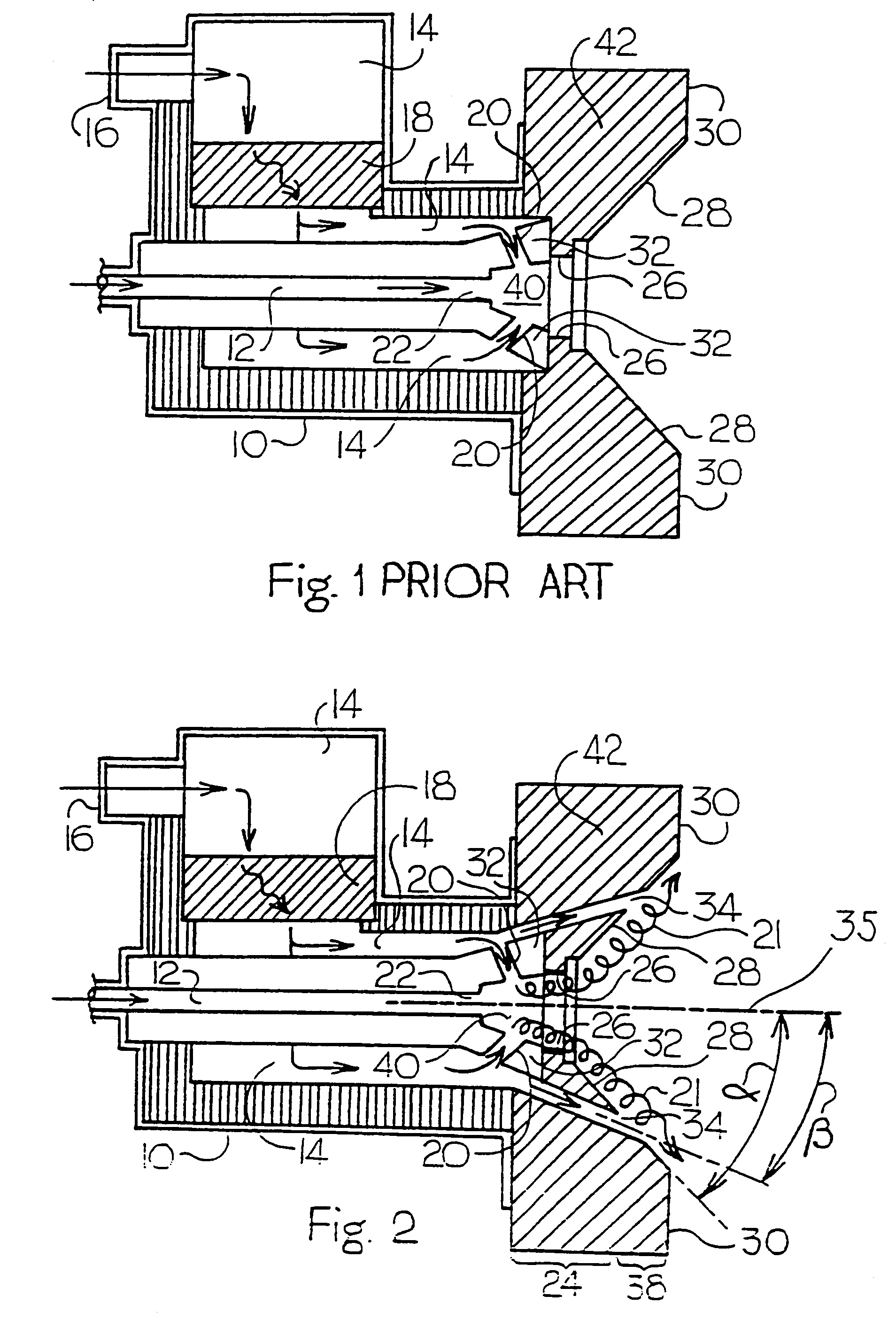

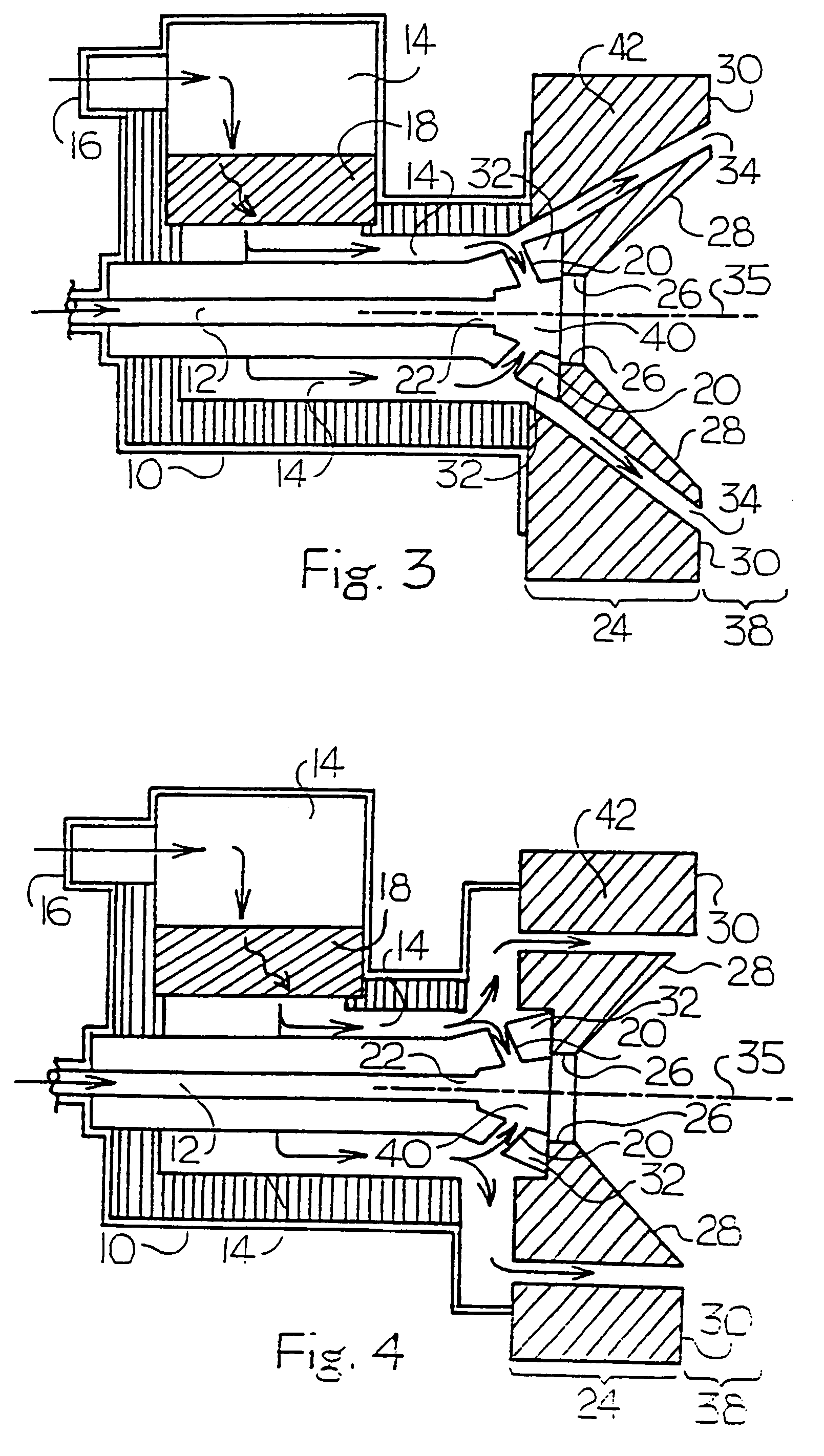

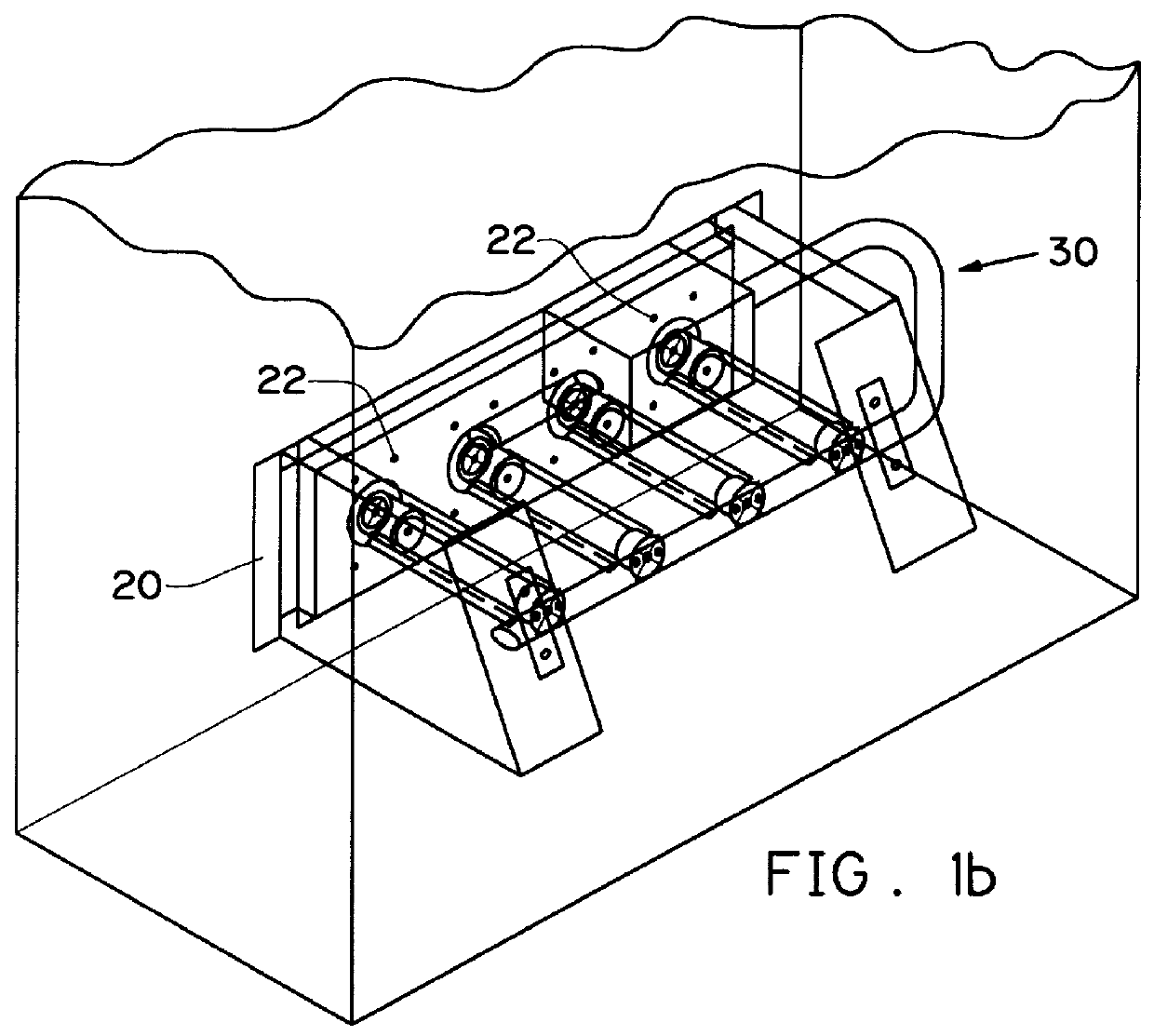

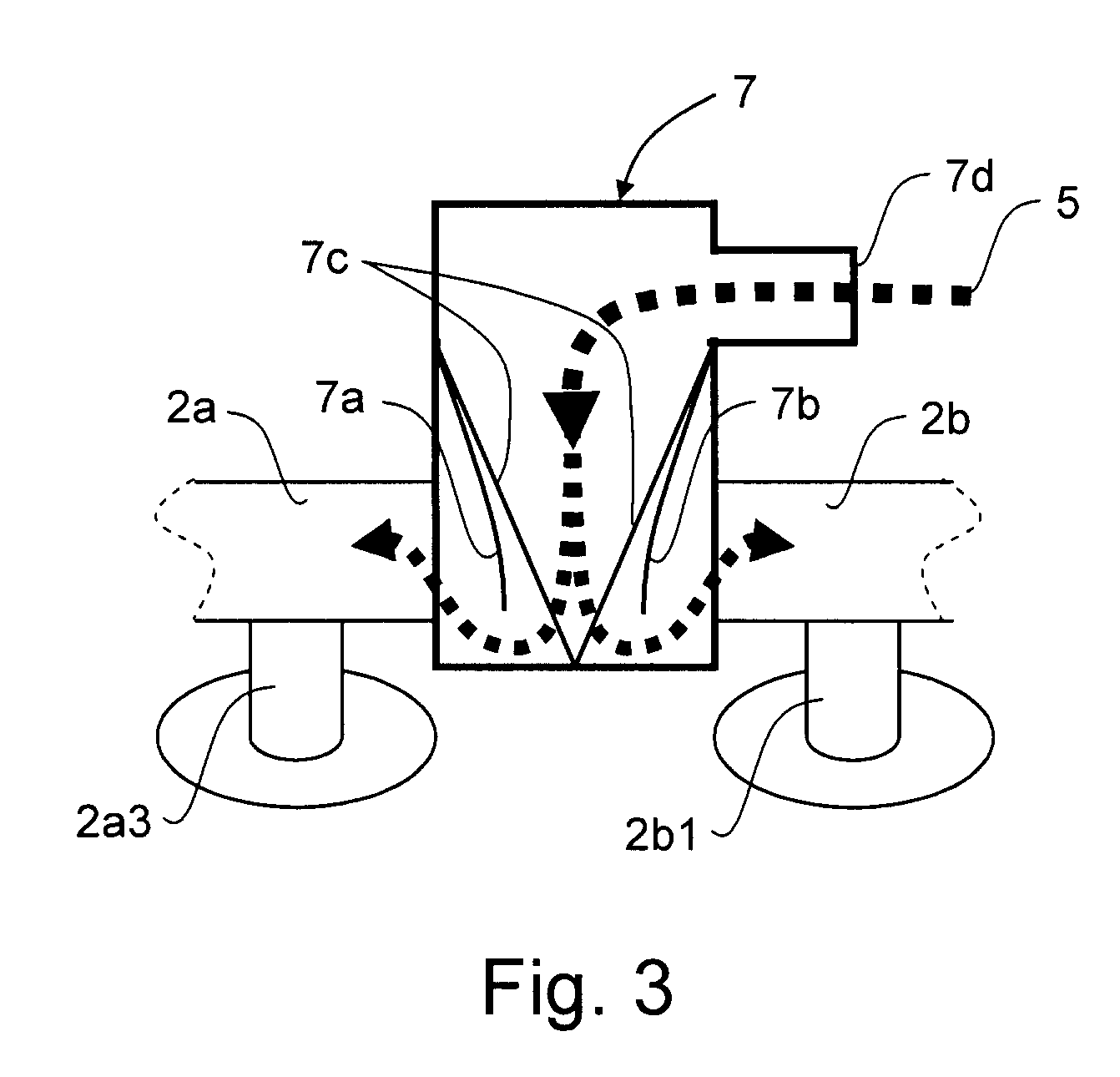

An apparatus and method for using staged air combustion. The apparatus includes a burner body (10) secured to a port block (42), and a fuel passageway (12) extending through the burner body (10), terminating in a fuel nozzle (22), which injects fuel into the burner throat (40). Primary air jets (20) are configured to inject primary air into a primary combustion region (24), which is normally in the burner throat (40). A dish with a dish surface (28) is connected to the burner throat (40); the dish surface (28) extending in a divergent angle with respect to a burner centerline (35). Secondary air jets (34) are connected to the air passageway (14) and extend through the port block (42). The secondary air jets (34) inject secondary air into a secondary combustion region (38), which may be at the dish surface (28) or the hot face (30) of the burner.

Owner:BLOOM ENG

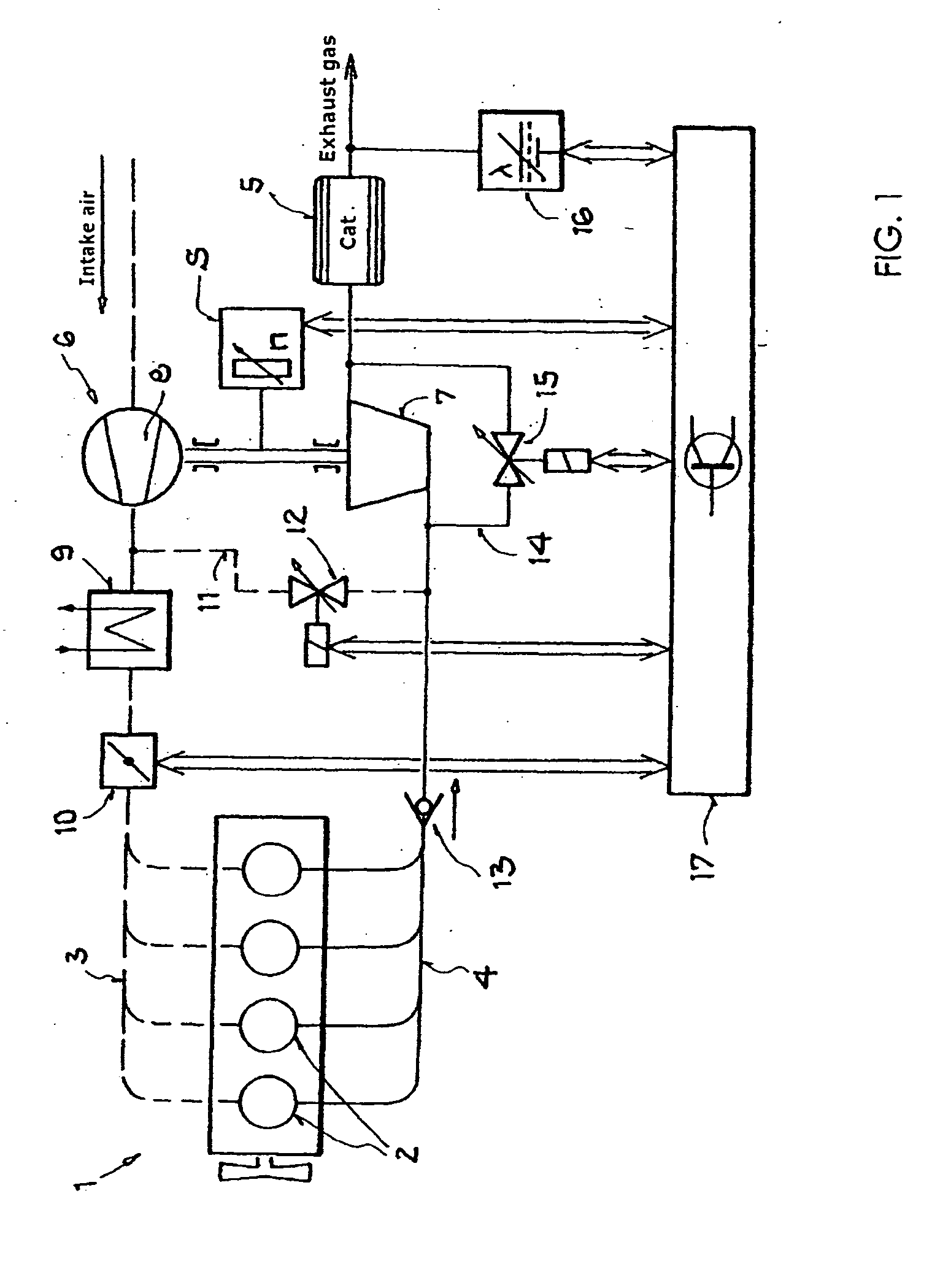

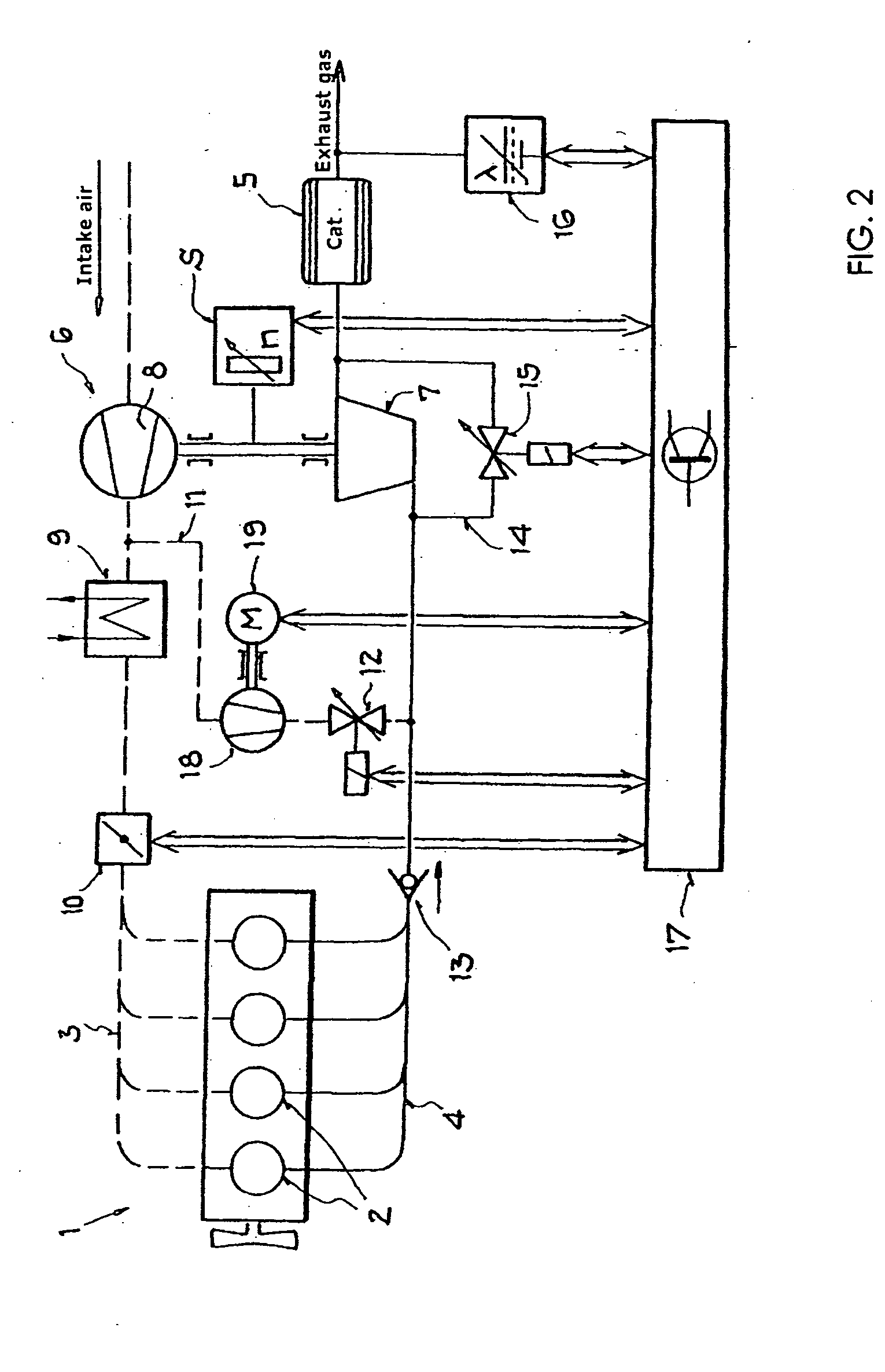

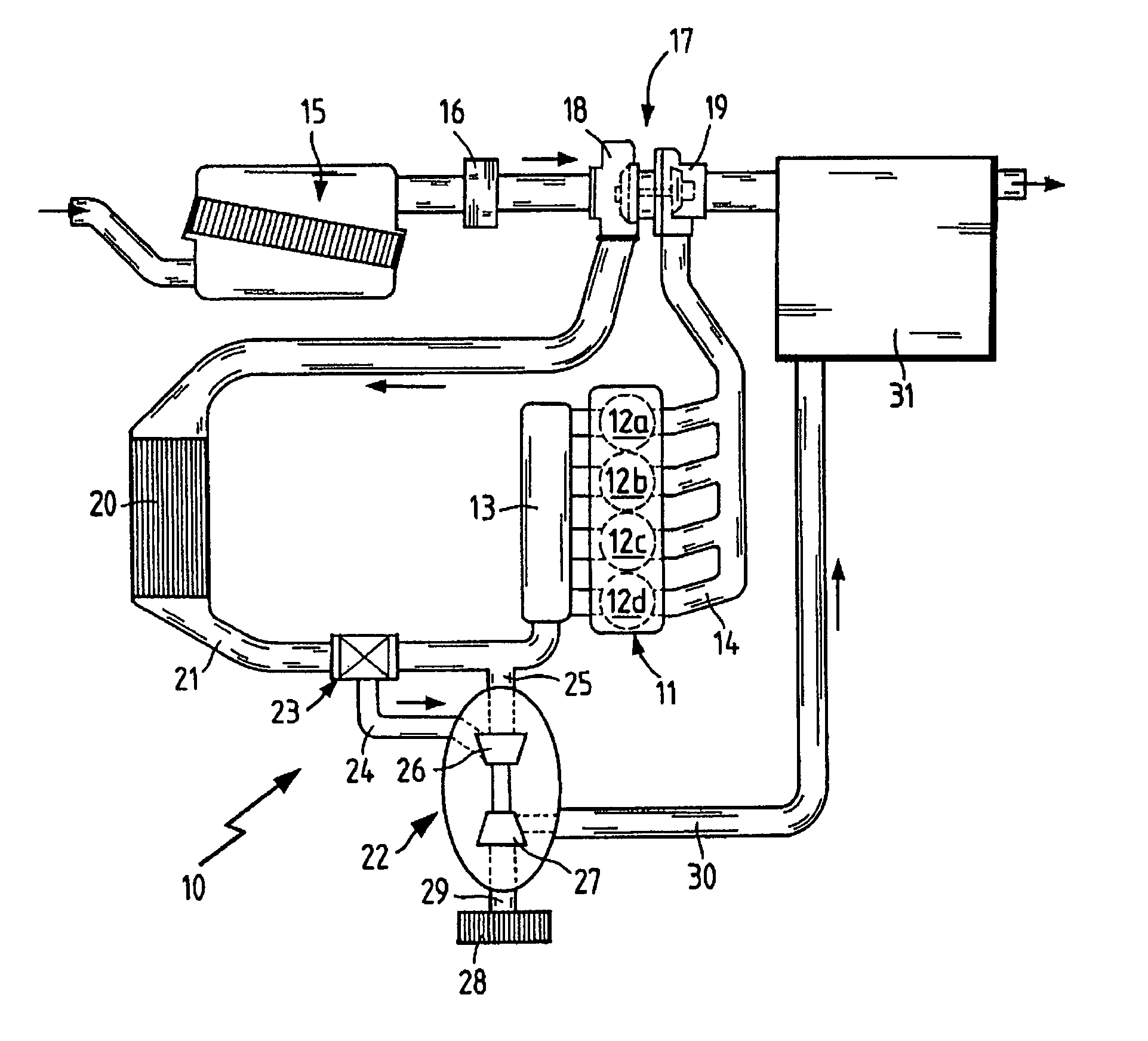

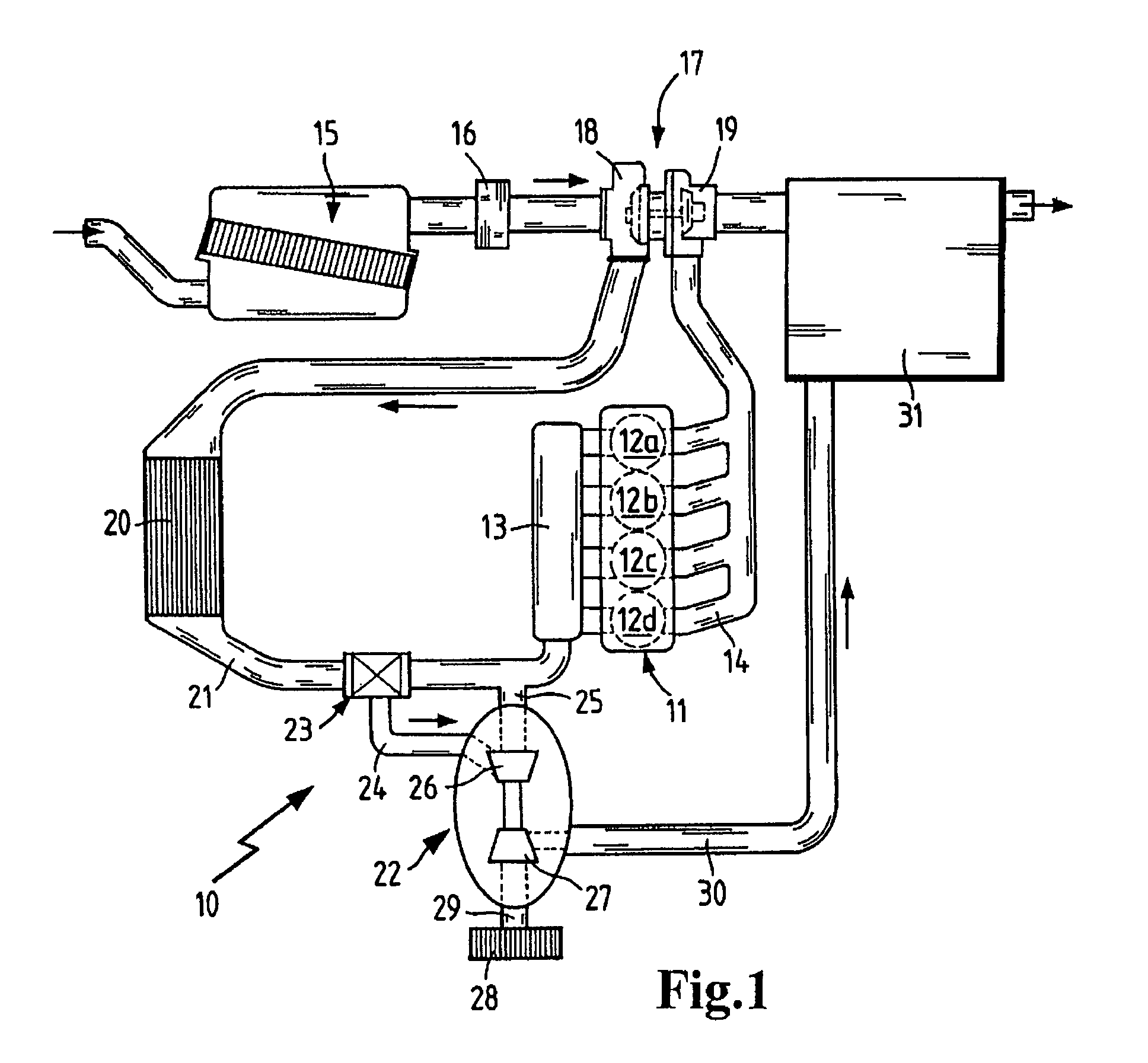

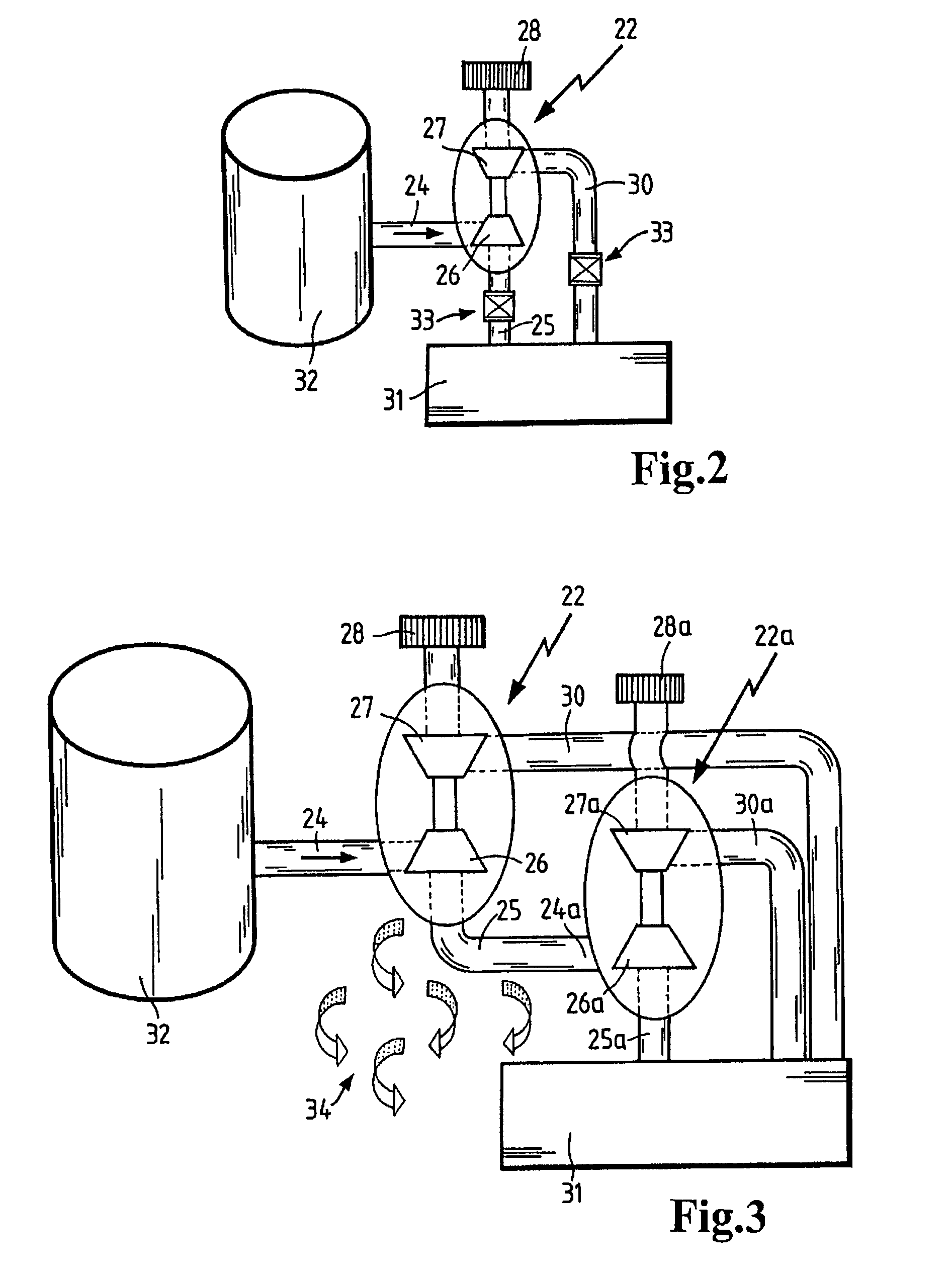

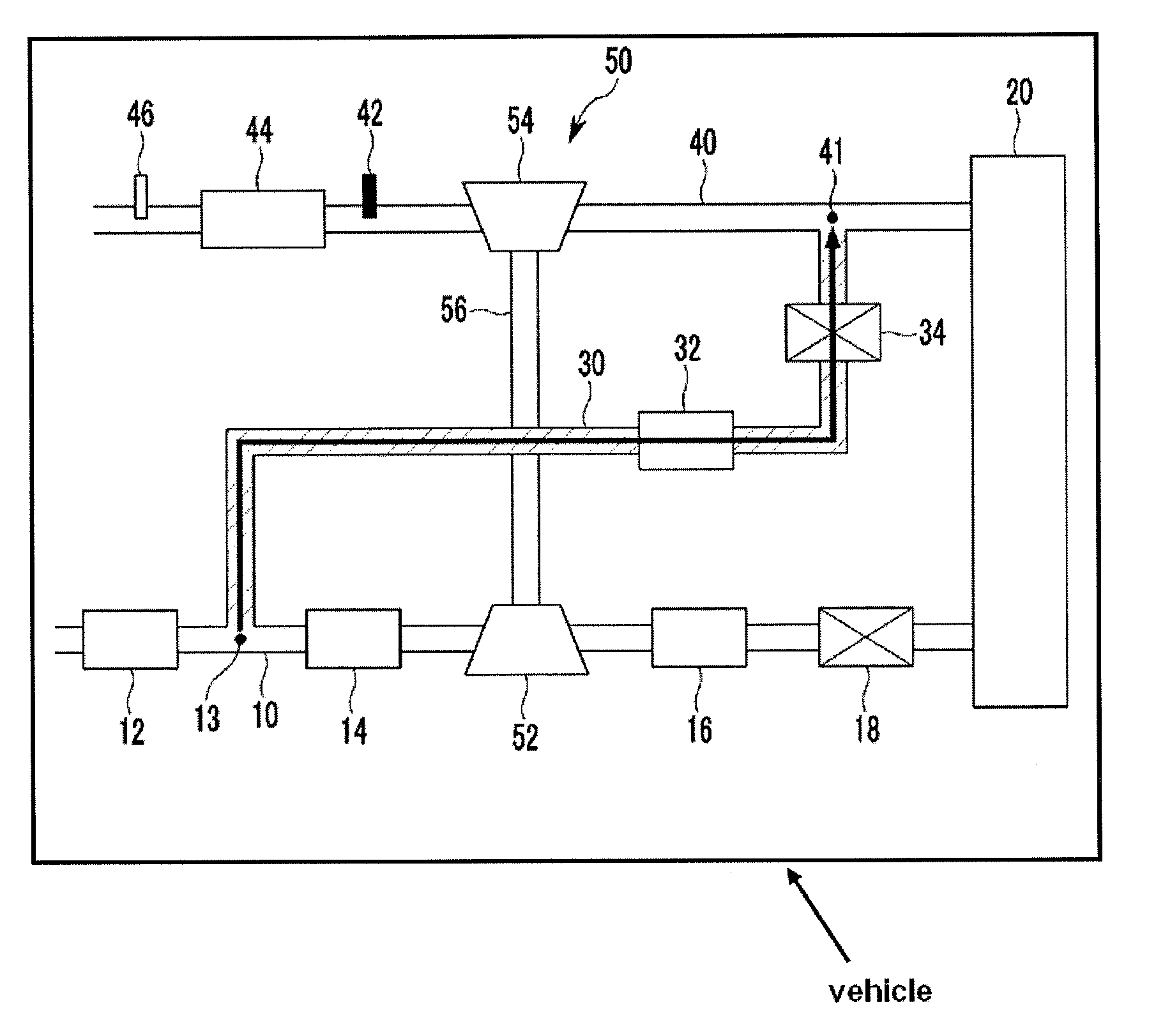

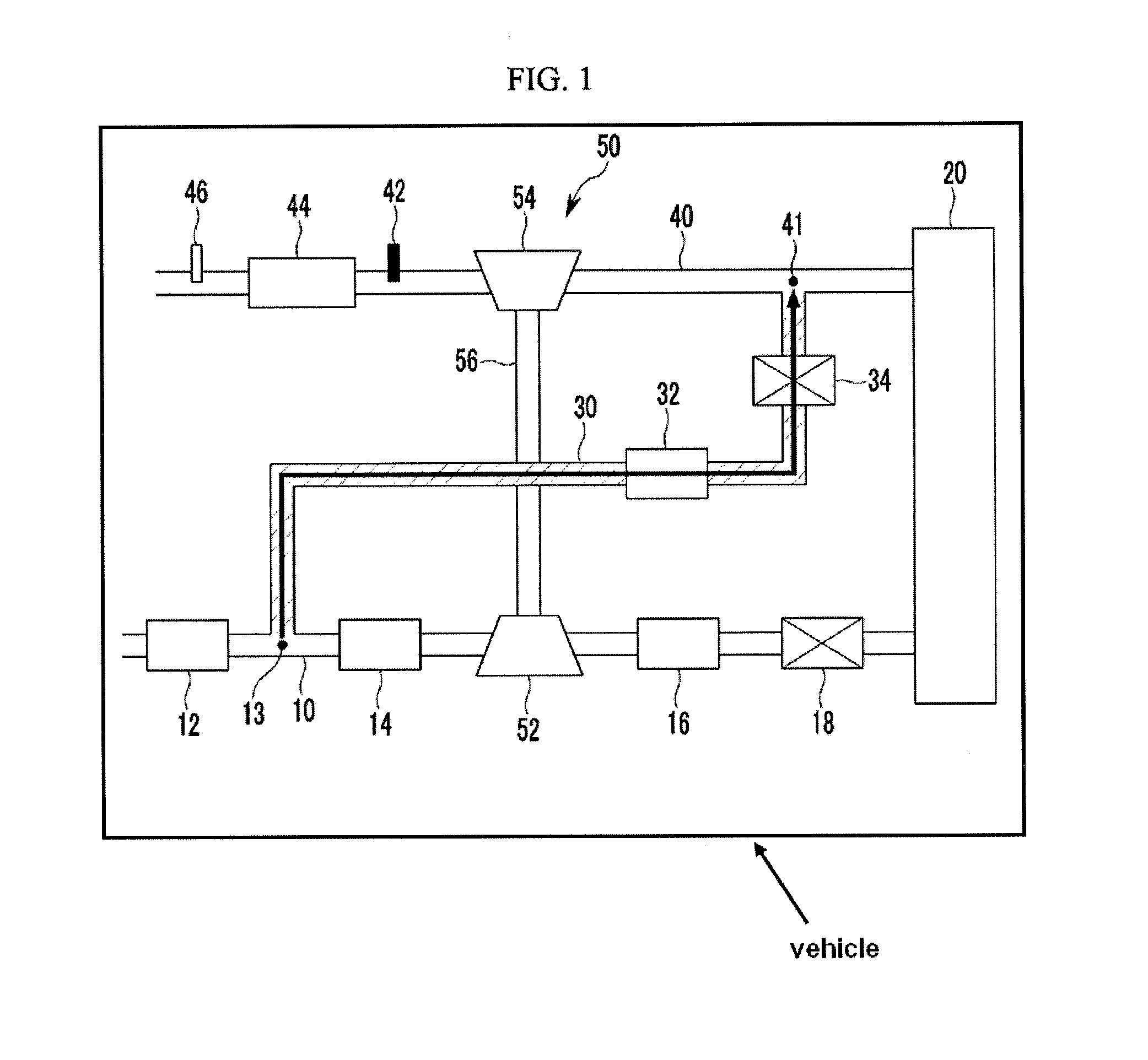

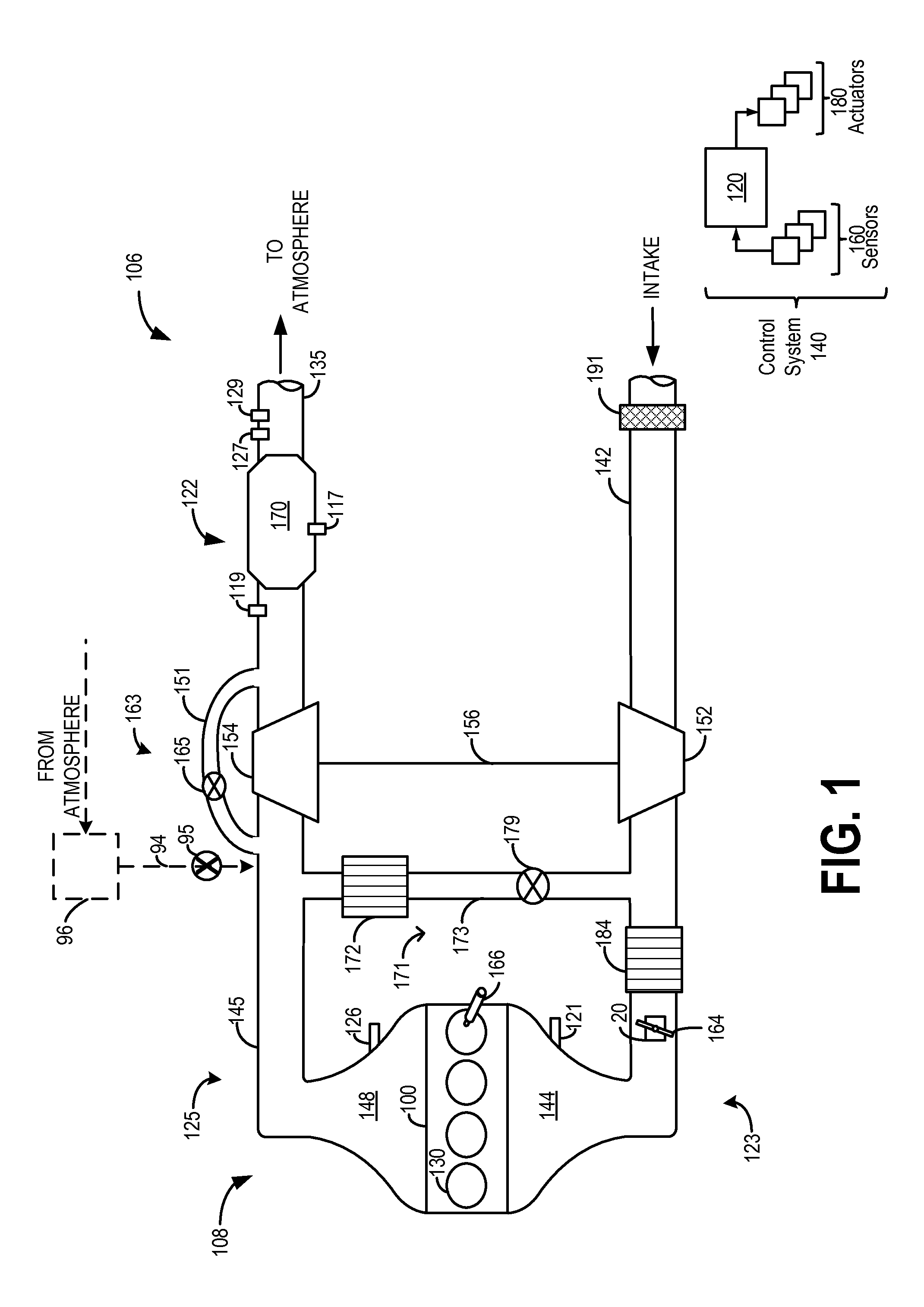

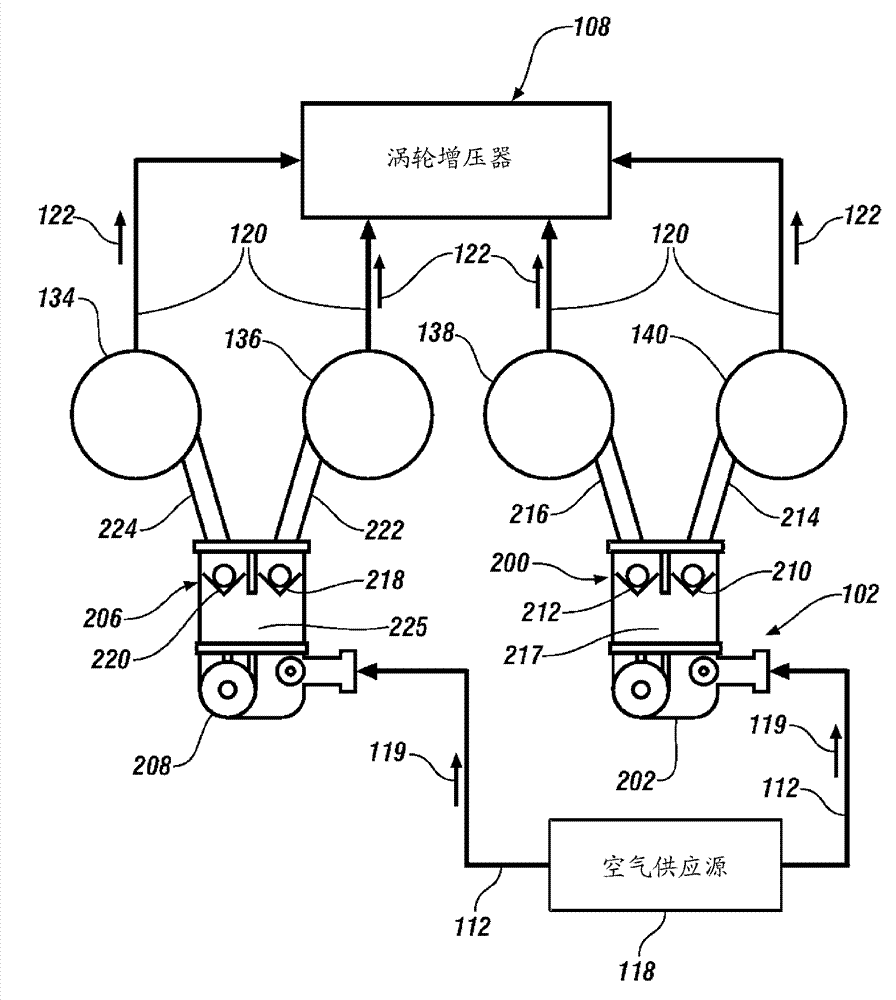

Internal combustion engine with exhaust-gas turbocharger and secondary air injection

InactiveUS20050109029A1Easy to monitorLow costElectrical controlInternal combustion piston enginesTurbochargerMiniaturization

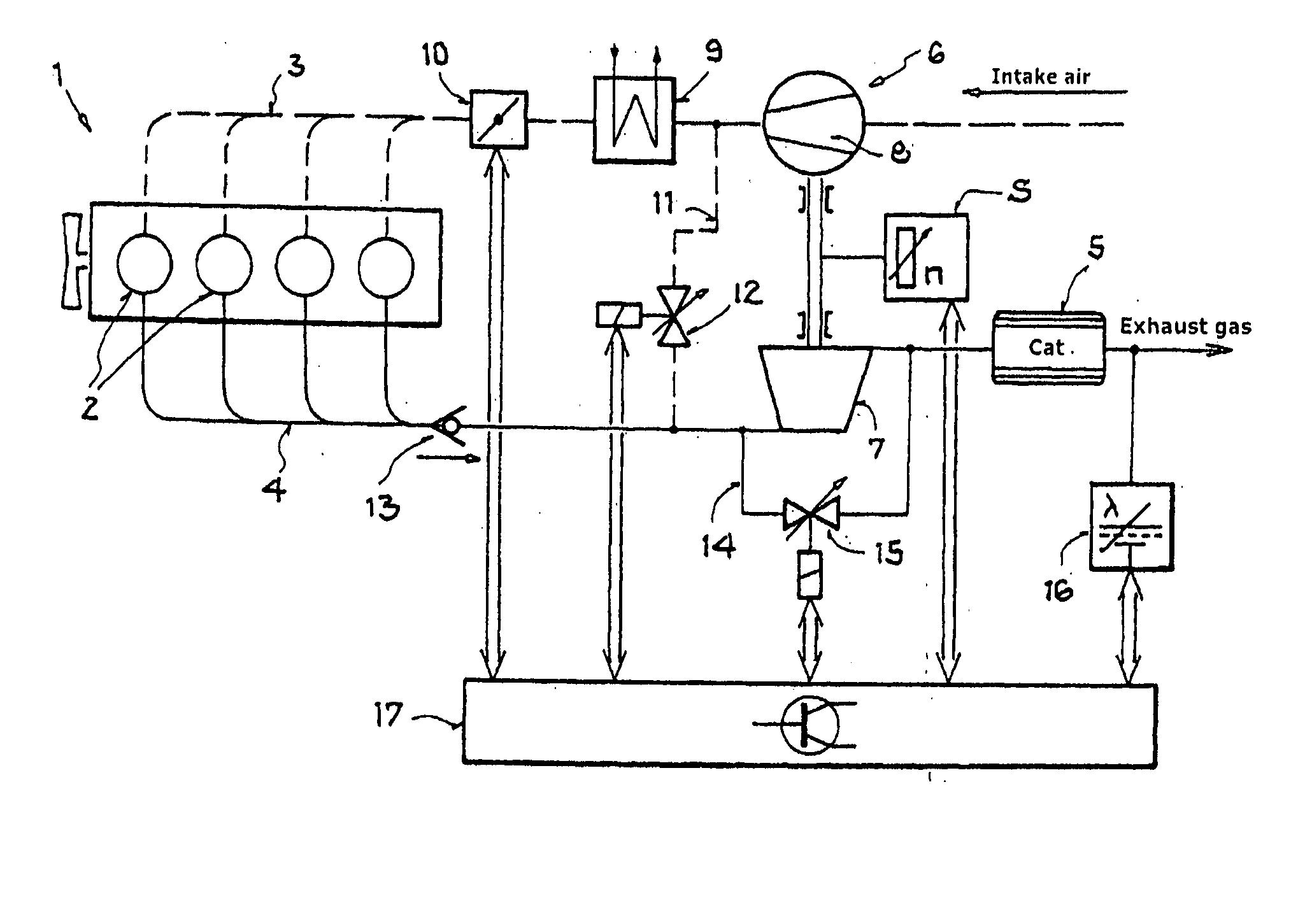

The invention relates to an internal combustion engine which has charge-air supercharging by means of an exhaust-gas turbocharger and secondary air injection, the flow path of which is selected in such a way that the quantity of secondary air injected has an influence on the rotational speed of the turbocharger. By monitoring the rotational speed of the turbocharger, an increase in the rotational speed caused by the secondary air injection is determined, and the quantity of secondary air injected is worked out from the increase in rotational speed. This has the advantage that there is no need for complex temperature-measuring methods as have hitherto been employed. Rotational speed measurement can be carried out contactlessly and with absolutely no wear in particular by means of inductive rotational-speed sensors. Moreover, these inductive rotational-speed sensors can be miniaturized and produced at extremely low cost.

Owner:DAIMLER AG

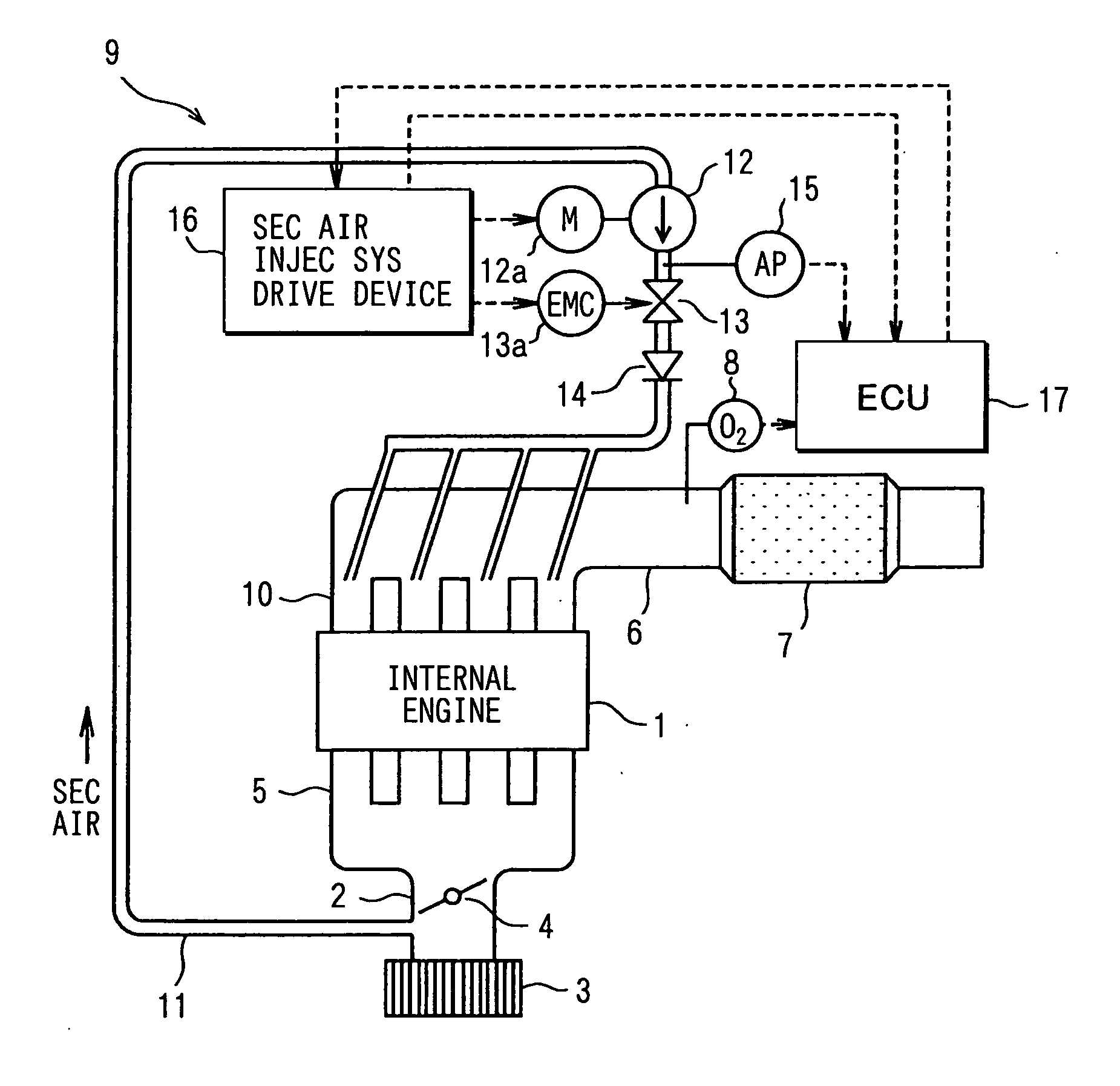

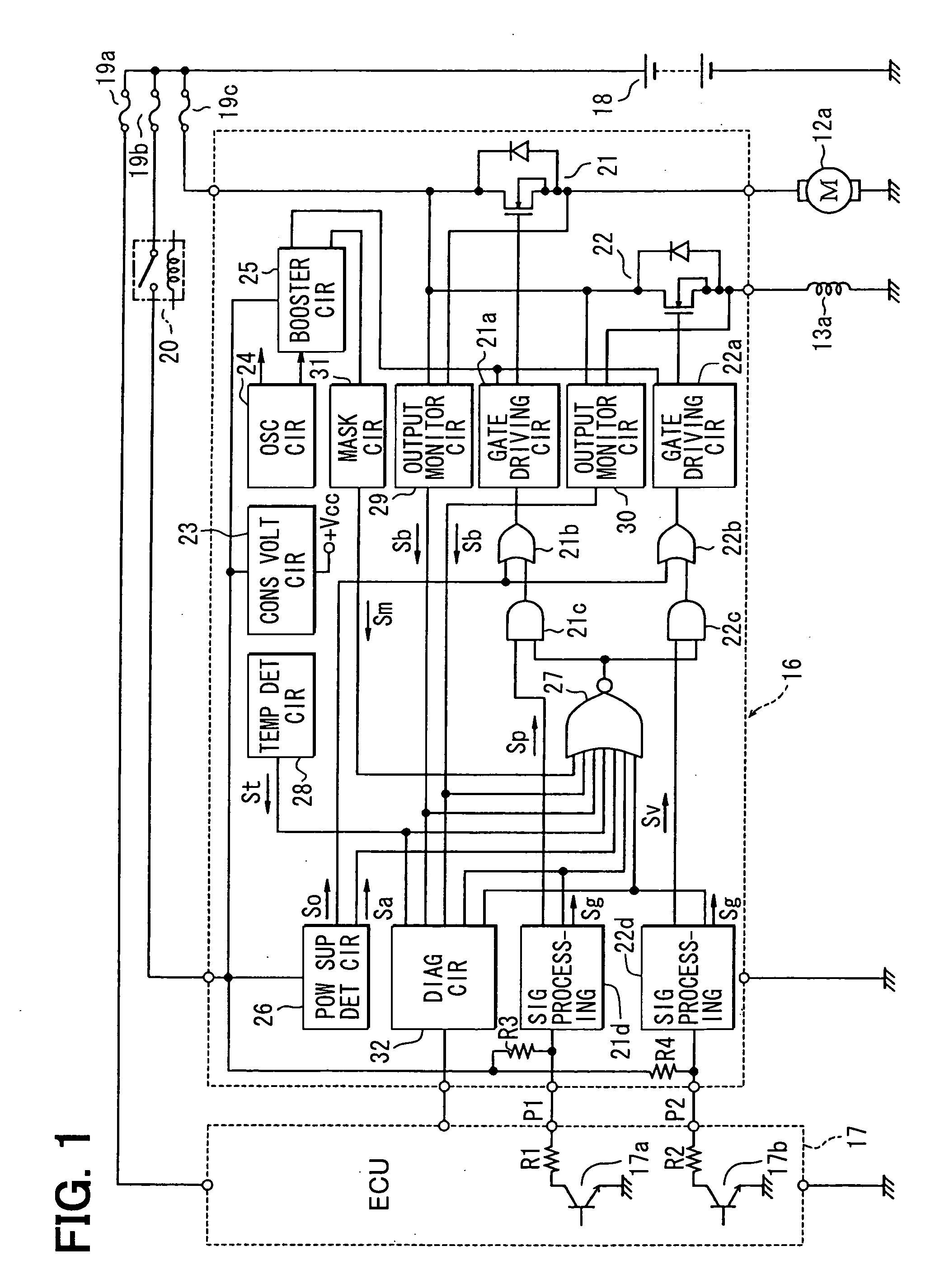

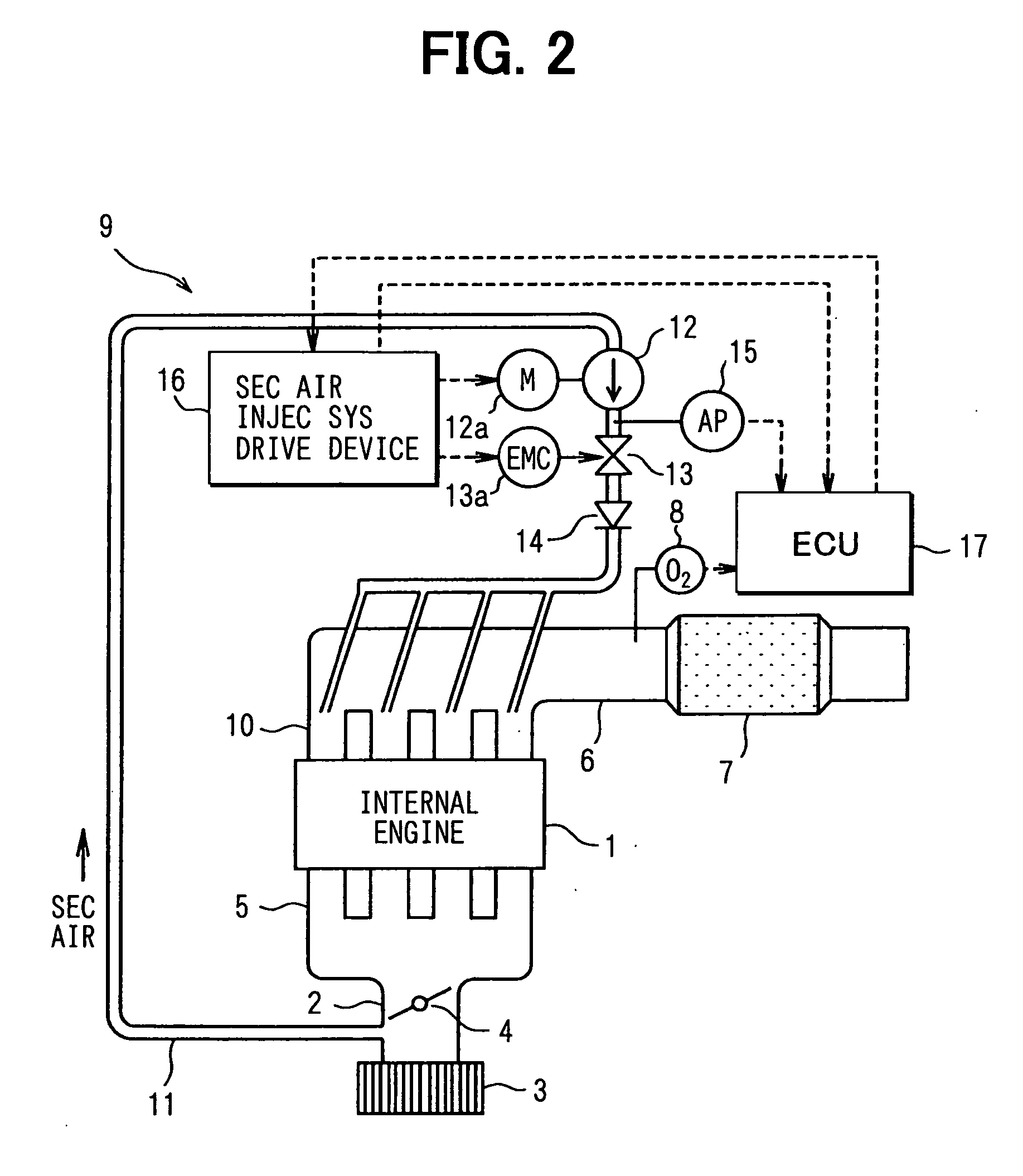

Drive device for a secondary air injection system

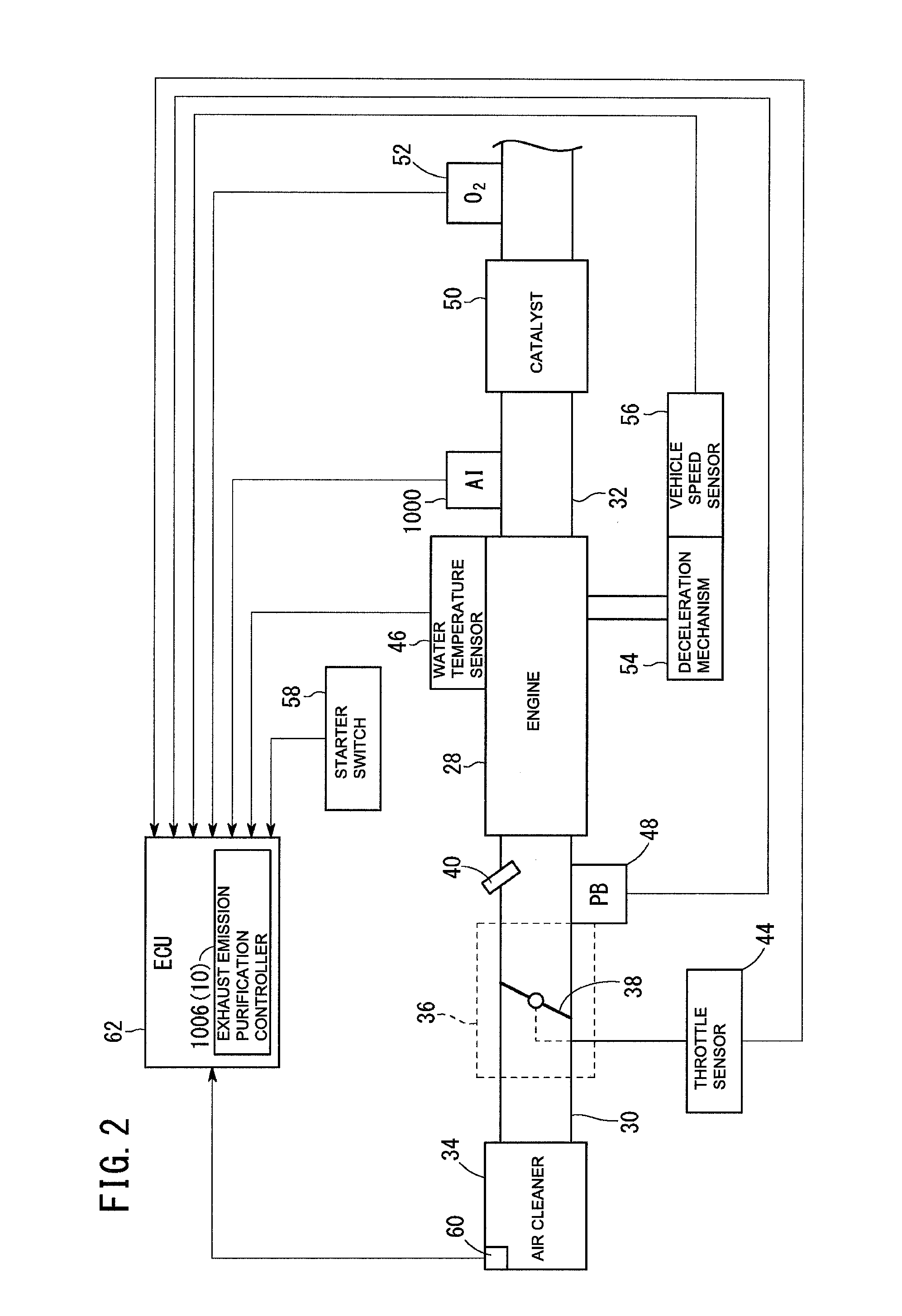

ActiveUS20050210866A1Possible to determineAccurate judgmentElectrical controlInternal combustion piston enginesMOSFETSignal processing circuits

In a secondary air injection system, MOSFETs control supply of electric current to an air pump and to a motor for driving an electromagnetic valve and to an electromagnetic coil to introduce secondary air into an exhaust gas passage upstream of a catalyst for purifying the exhaust gas of an internal combustion engine. Gate drive circuits control the MOSFETs based on an instruction from an ECU via input signal processing circuits. Abnormal conditions in the operation for controlling the air pump and the electromagnetic valve are detected, and, when an abnormal condition is detected, forcibly turn the MOSFETs off to interrupt the current to the motor and to the electromagnetic coil. A diagnosing circuit sends to the ECU diagnosis signals representing the state of controlling the load.

Owner:DENSO CORP

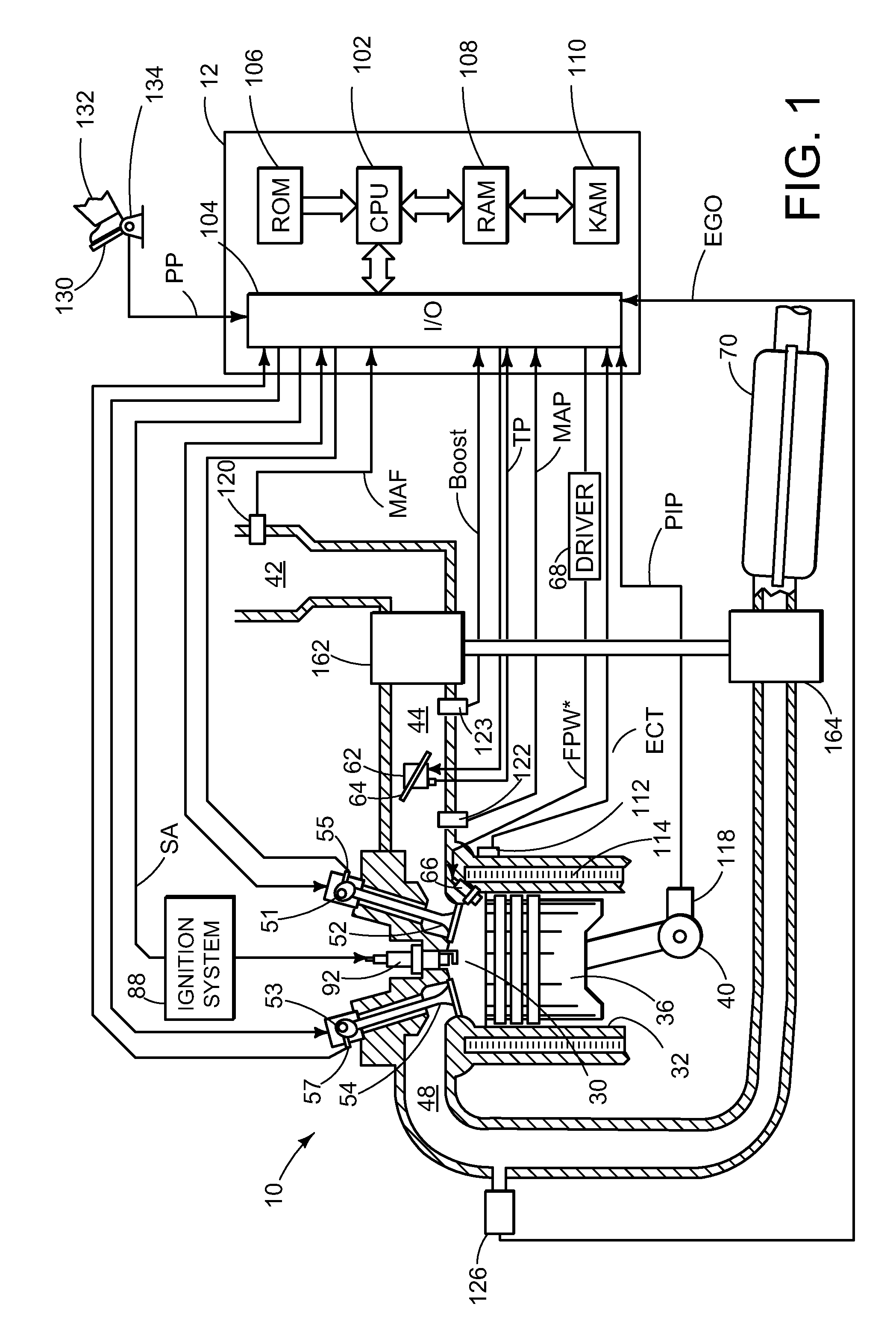

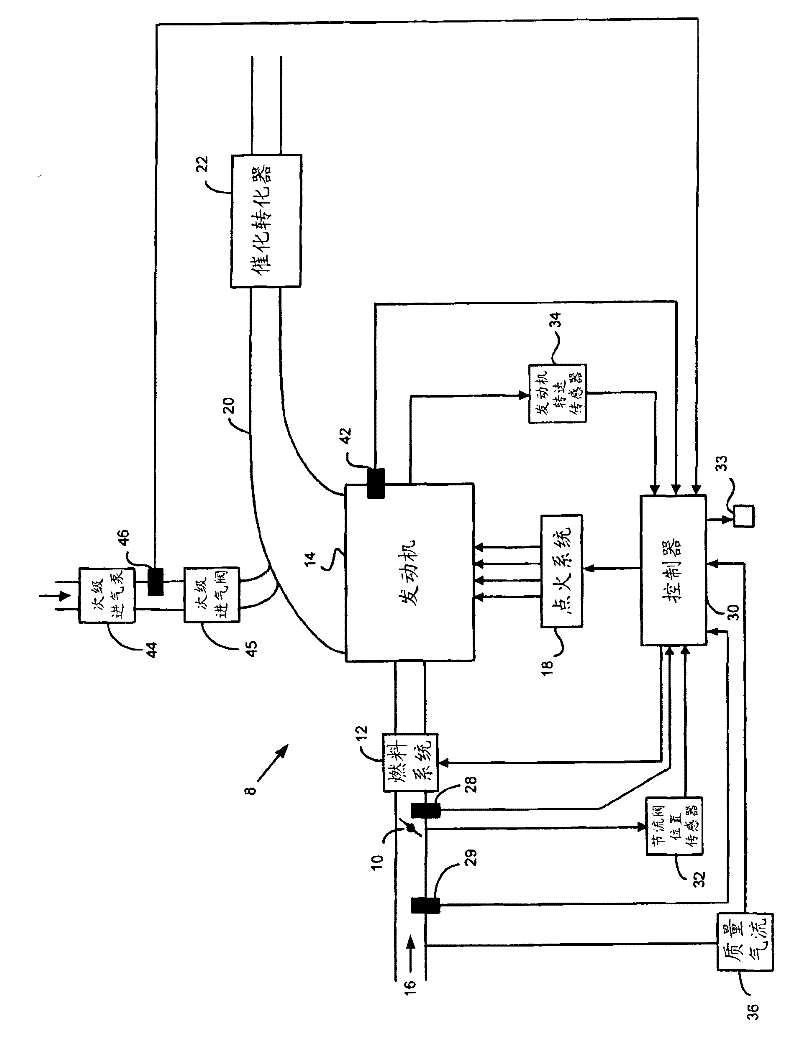

Method and apparatus for engine torque disturbance reduction during cranking

InactiveUS7128035B2Reduce torsional disturbancesElectrical controlInternal combustion piston enginesInlet manifoldStart up

An internal combustion engine's start-up torsional disturbances are reduced by drawing down intake manifold pressure prior to engine cranking. In a preferred arrangement, a secondary air injection reaction pump is adapted for evacuating the intake manifold to effect the desired draw down of the intake manifold pressure.

Owner:GM GLOBAL TECH OPERATIONS LLC

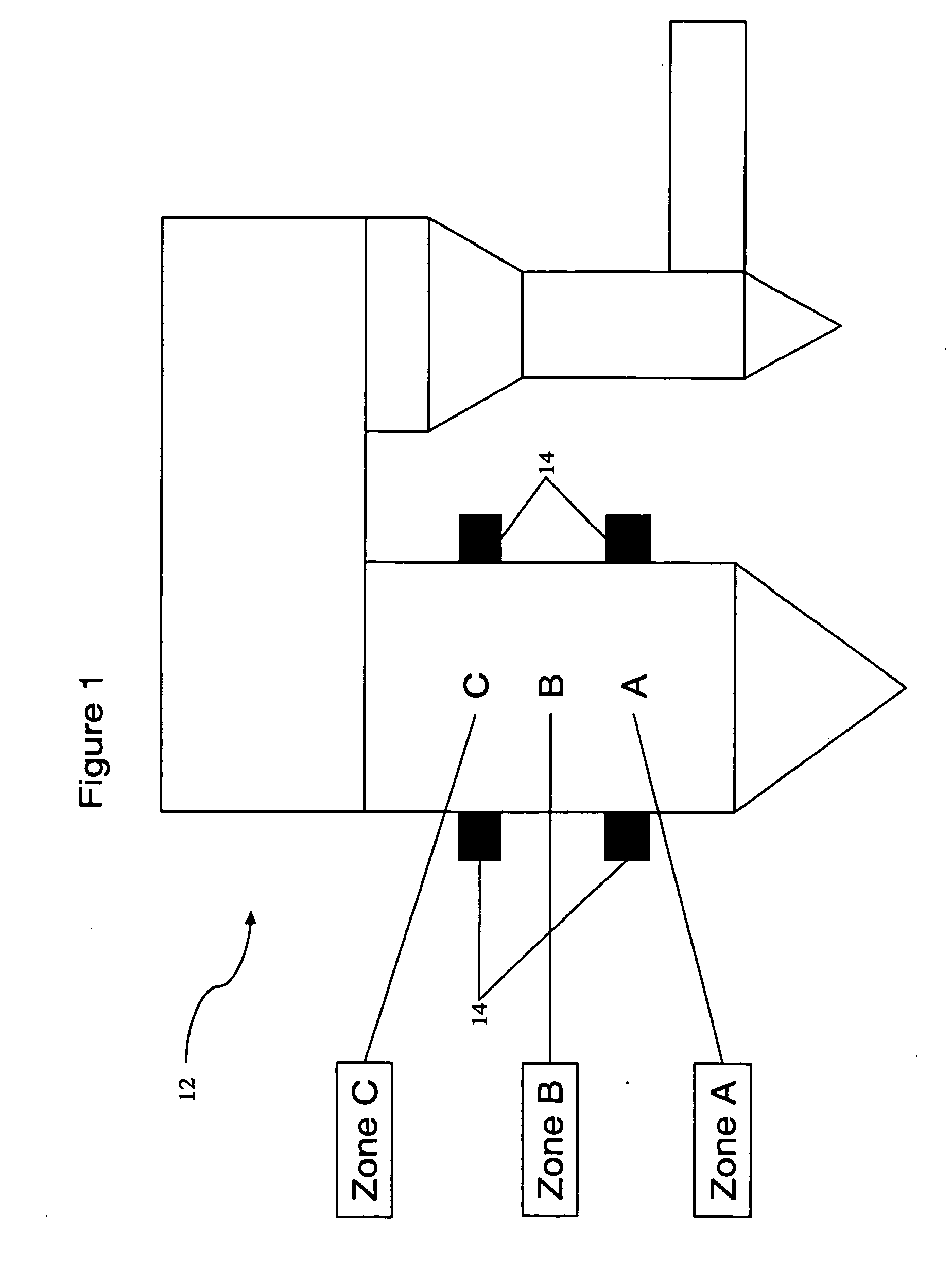

Apparatus for low NOx, rapid mix combustion

InactiveUS6071115ASuppression temperatureIncrease speedCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberNitrogen oxide

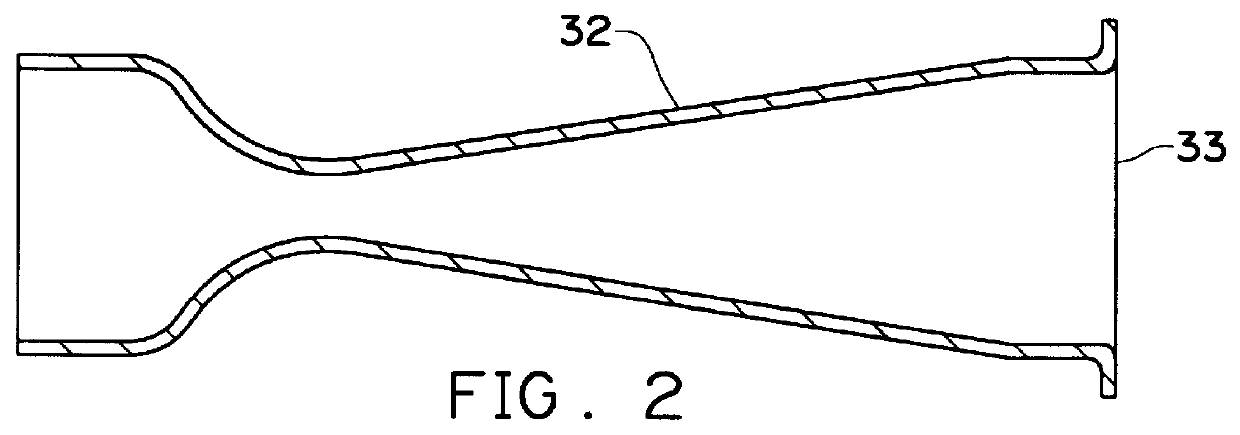

A process and apparatus for combusting fuel which results in reduction of nitrogen oxides and carbon monoxides emissions. Fuel and primary air are preferably premixed and introduced into a combustion chamber. Secondary air is introduced through a plurality of secondary air ports, each preferably shaped as a slot, which are positioned about a venturi nozzle or flame holder disk mounted with respect to a combustion chamber wall. The secondary air flowing through the secondary air ports forms relatively high velocity and momentum secondary air jets that promote rapid mixing of the fuel and primary air mixture into the secondary air flow, such that a combustion flame is established at a partial periphery of the secondary air jets.

Owner:GAS TECH INST

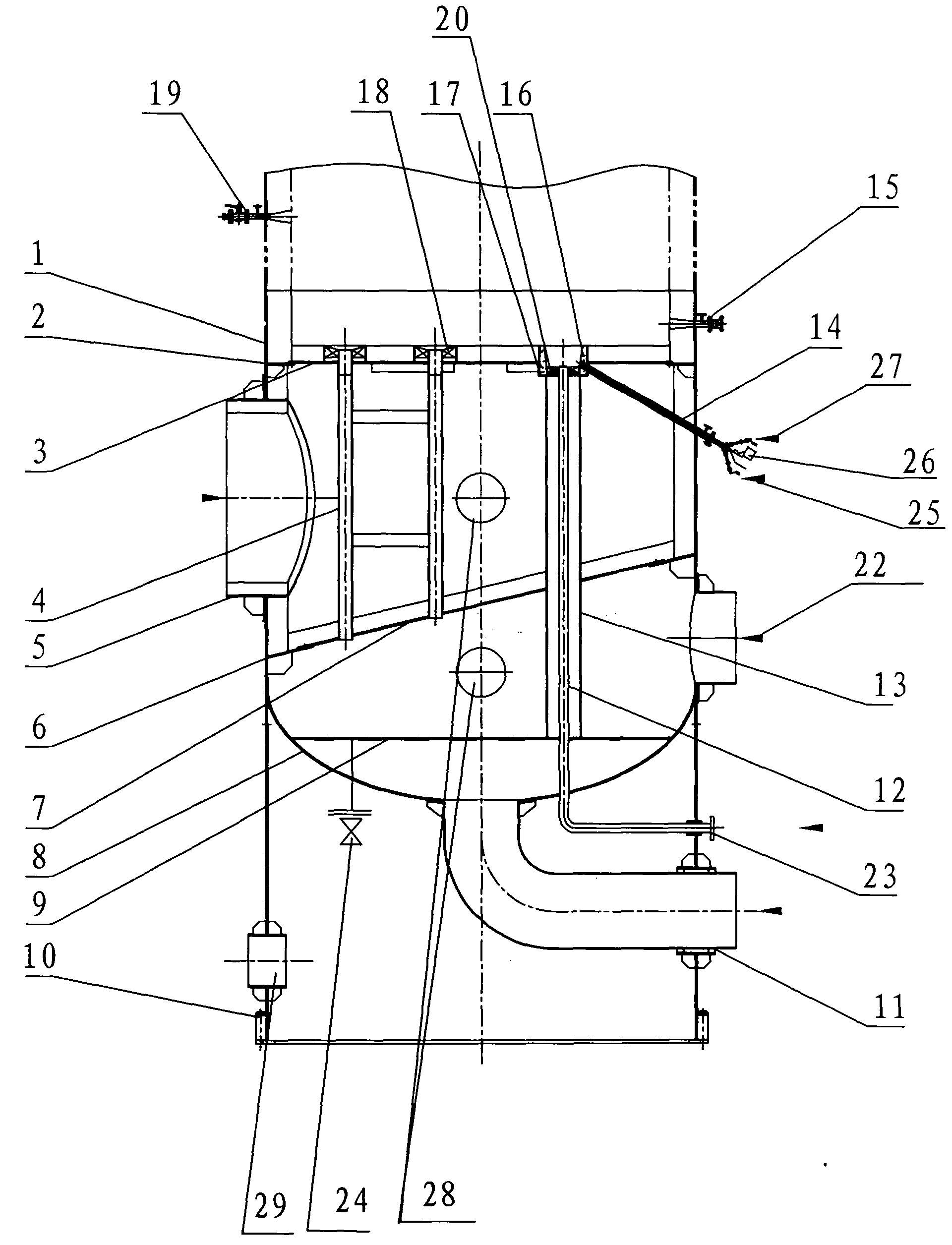

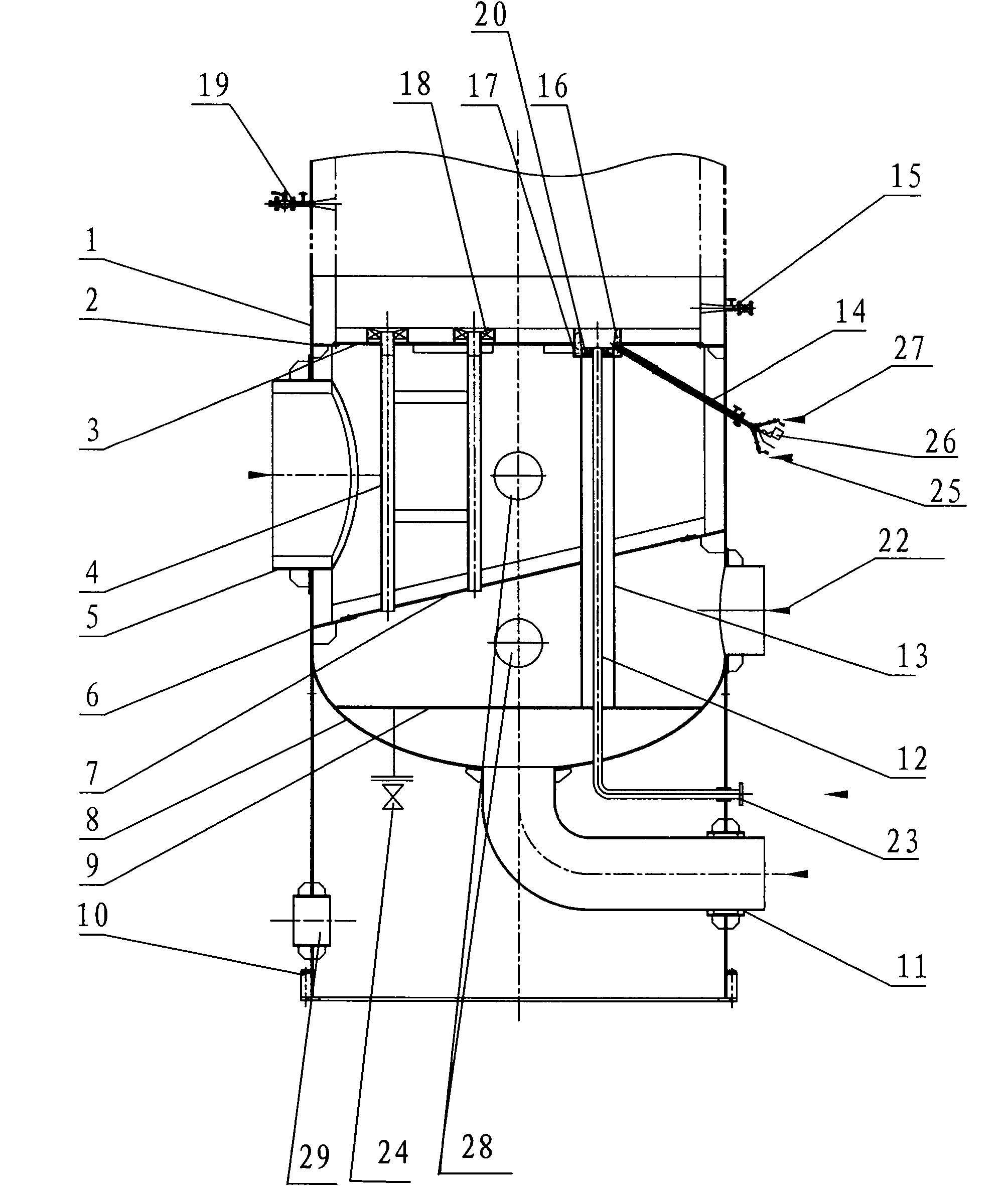

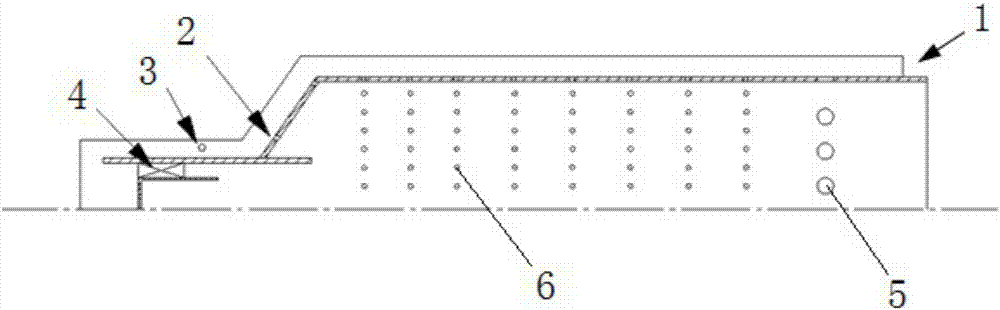

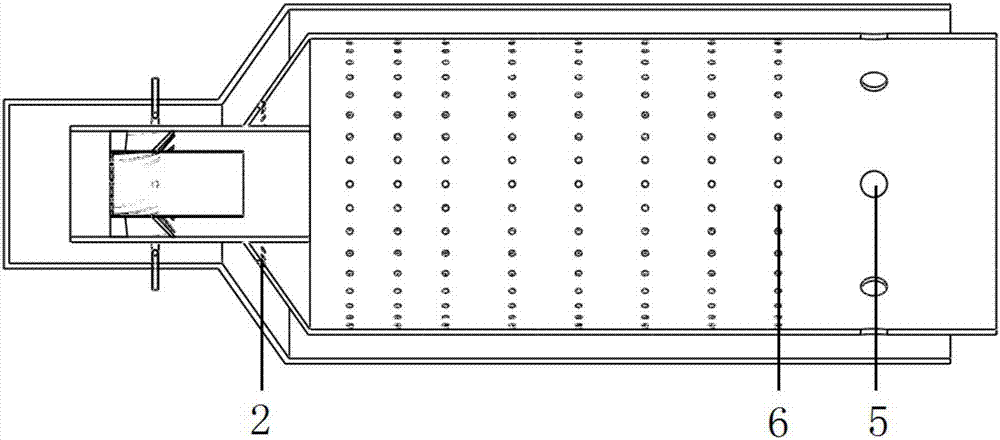

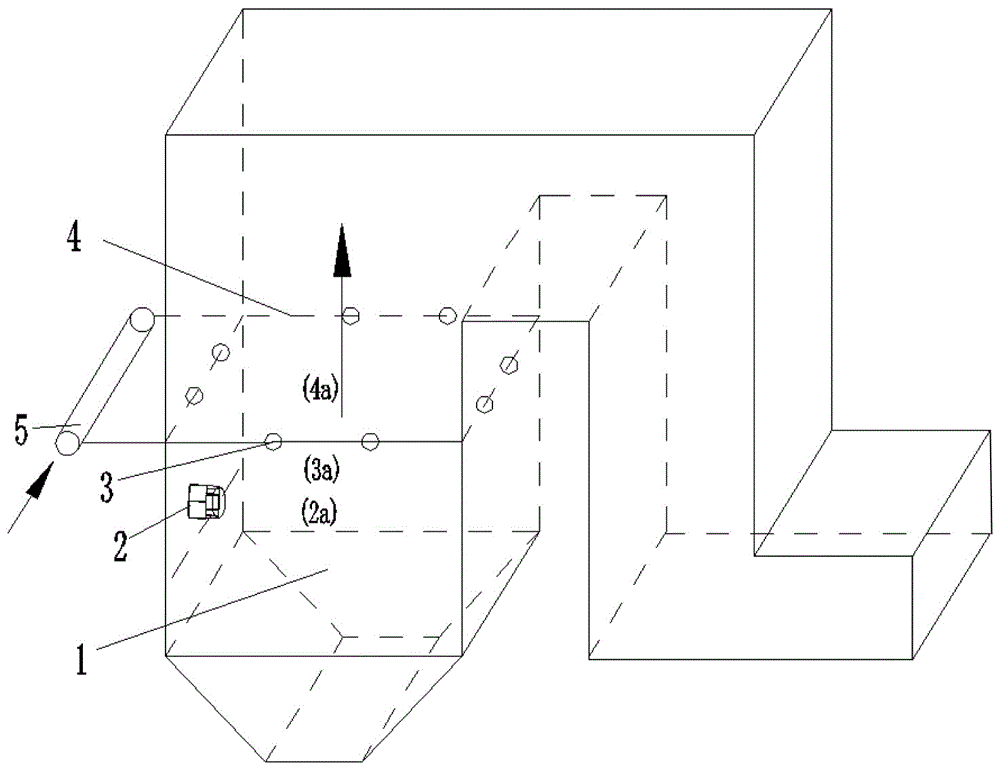

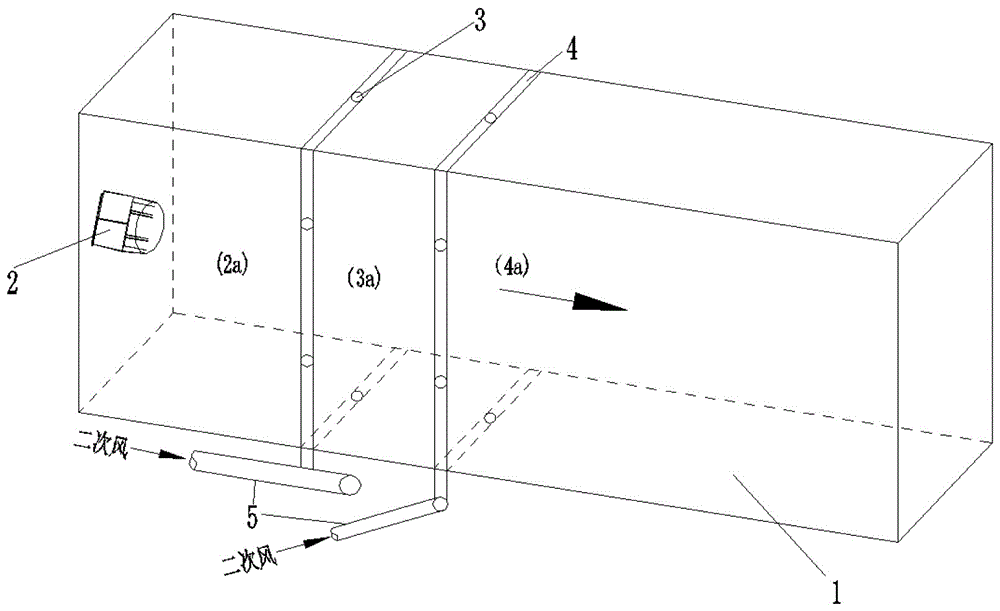

Device used for biomass gasification and active carbon combined production

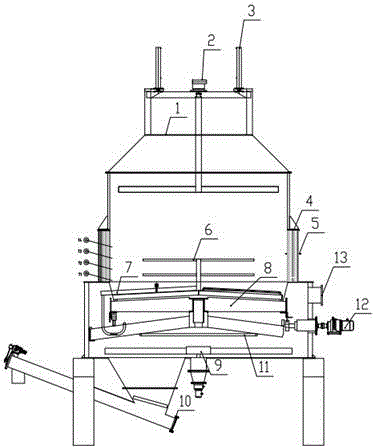

ActiveCN103980942AIncreasing the thicknessTemperature controlCarbon compoundsCombustible gas productionActivated carbonCombustible gas

The invention relates to a device used for biomass gasification and active carbon combined production. The upper part of the device is provided with a material inlet, a material levelling device and a hydraulic lifting and descending mechanism. The middle part of the device is provided with a gasification reaction cavity. The gasification reaction cavity is provided with a secondary air injection pipe, a steam distribution pipe, a bridging-breaking driving lever, a carbon blocking device, a rotary fire gate and a fire-gate rotation rail. An external clamping cavity of the rotary fire gate is provided with a gasified gas extraction opening. The lower part of the device is provided with an active-carbon discharging cavity. The bottom of the device is provided with a sealing active carbon cooler. The device used for biomass gasification and active carbon combined production is advantageous in that: secondary air injection and an air-exhaust motor of combustible gas are adopted to control the thickness of a reaction layer and to provide the temperature needed for steam activation; steam and air mixing and forced gas distribution are adopted to achieve further activation of the gasified carbon, the produced combustible gas after purification can be used for electricity generation or burned in a boiler, and an active carbon product can be obtained at the same time. The device overcomes a problem of single product of traditional active carbon production devices, efficiently utilizes the biomass resources, increases the economic benefit, and is environmental friendly.

Owner:HEFEI DEBO BIOENERGY SCI & TECH

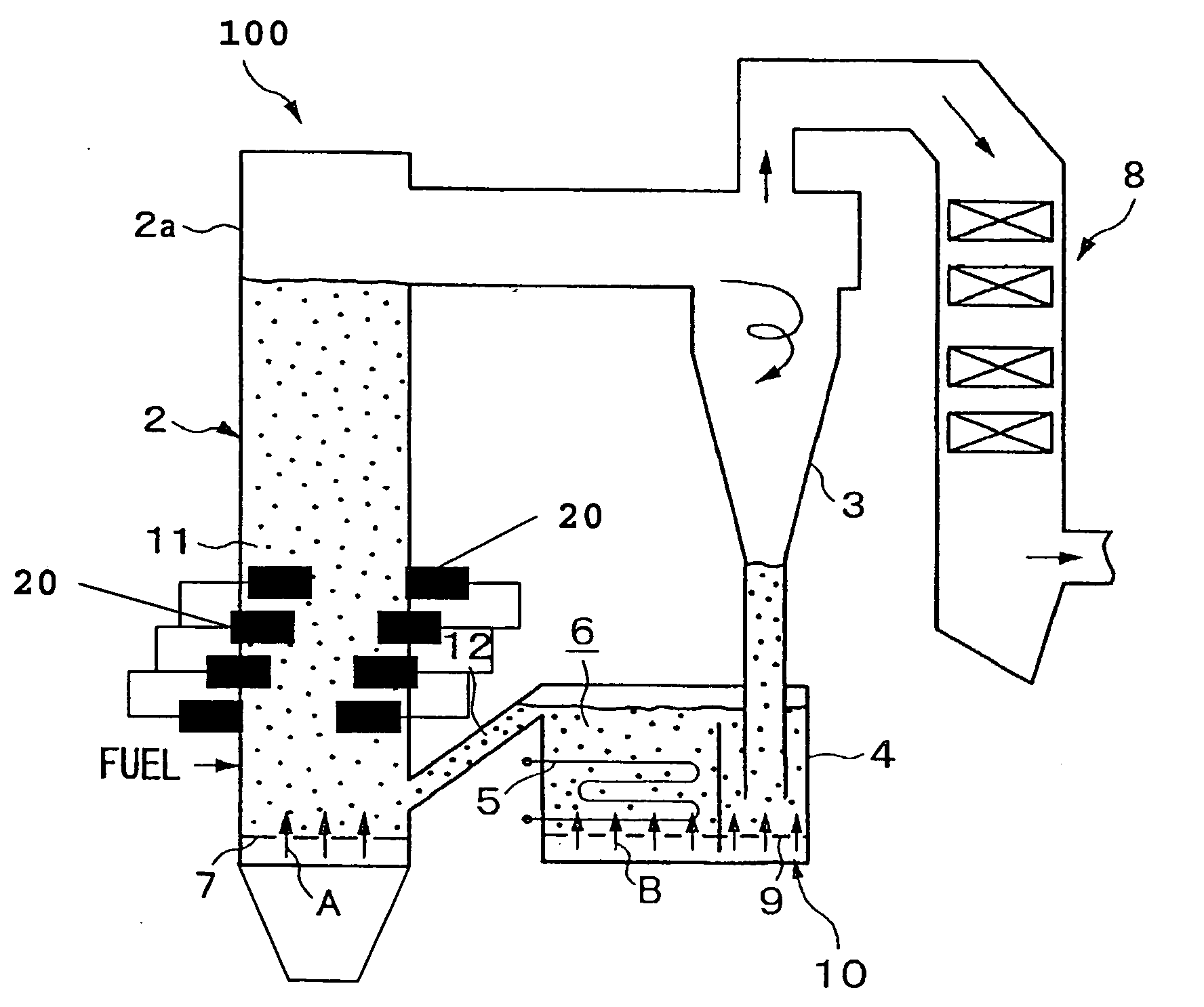

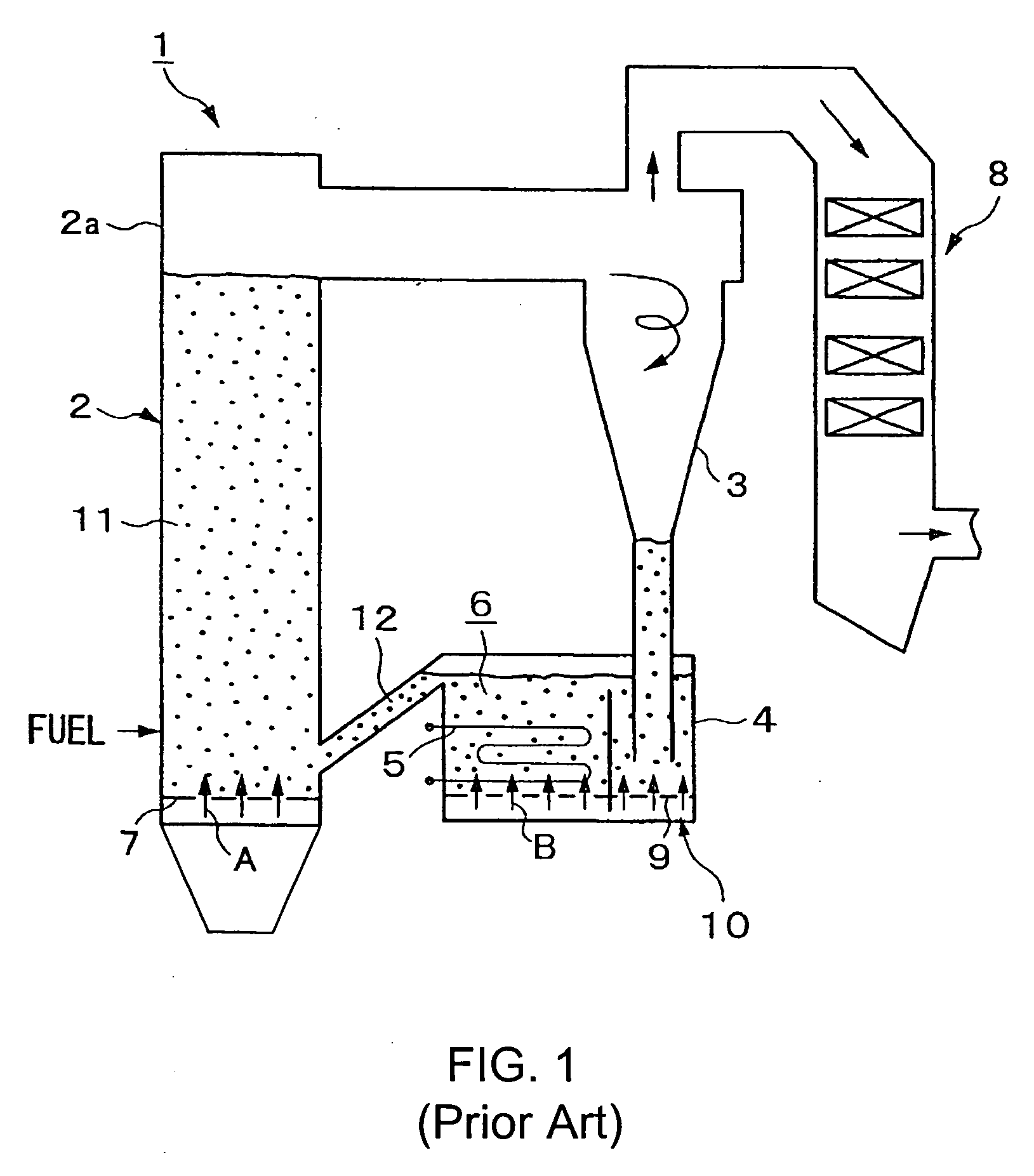

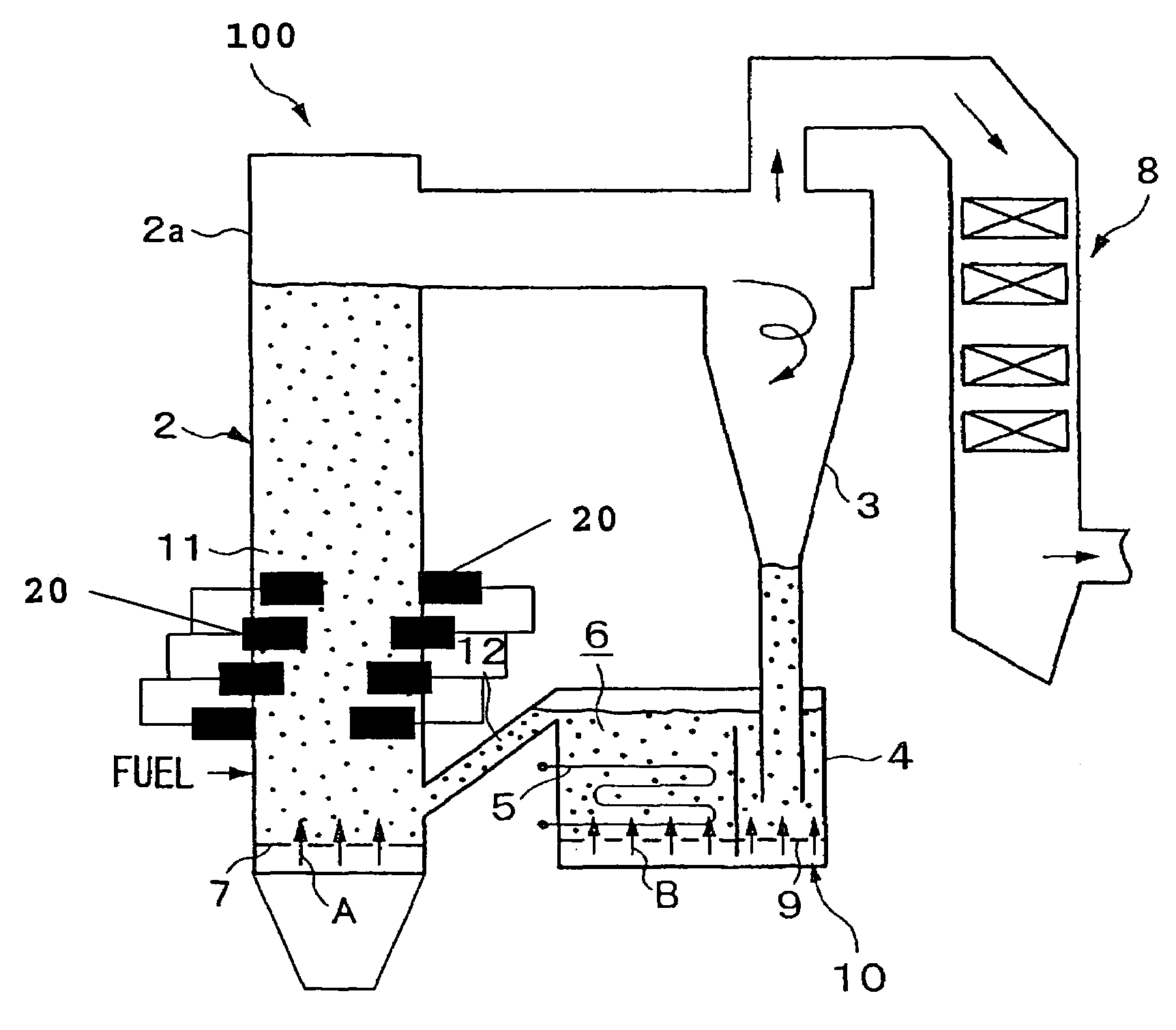

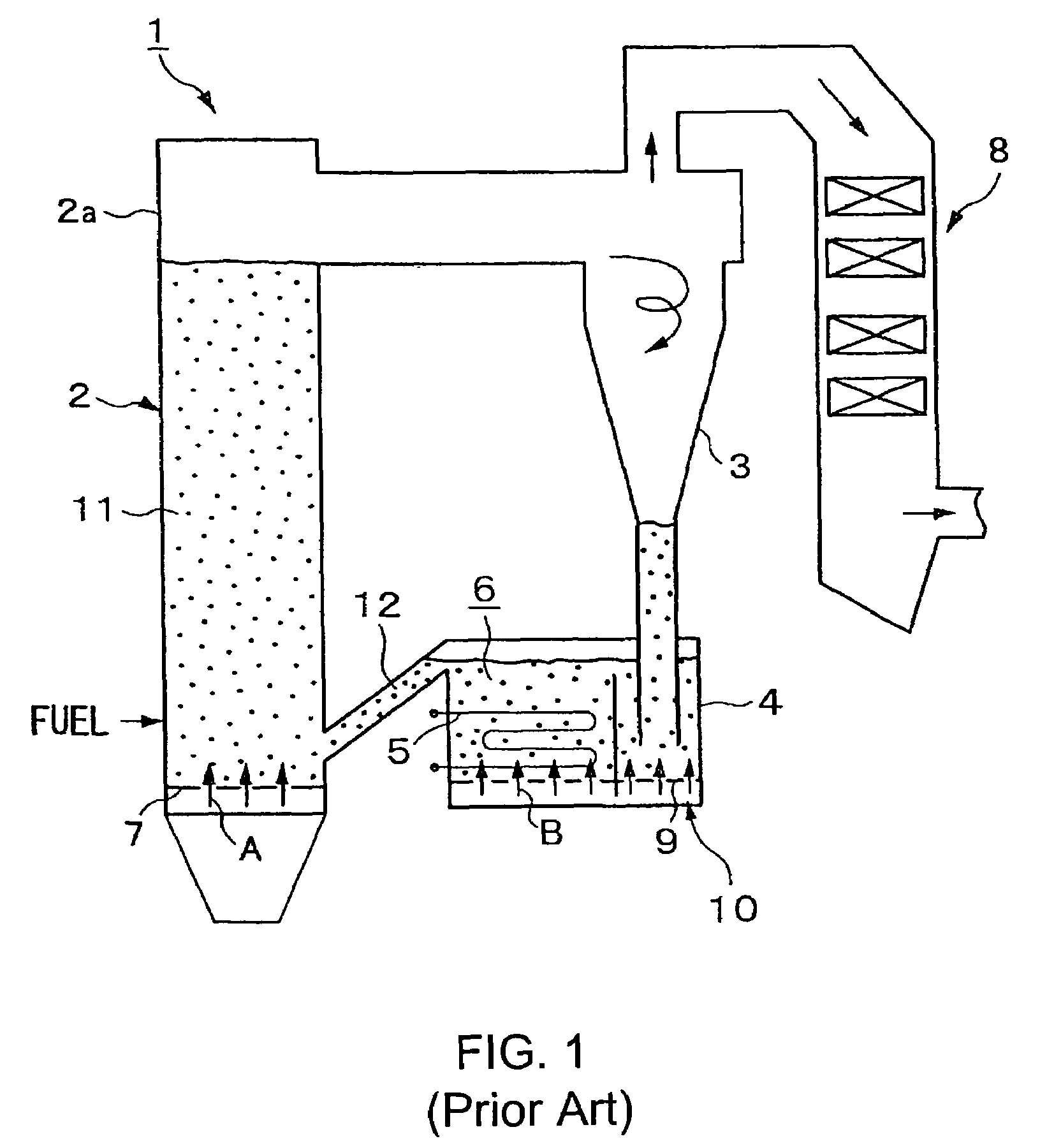

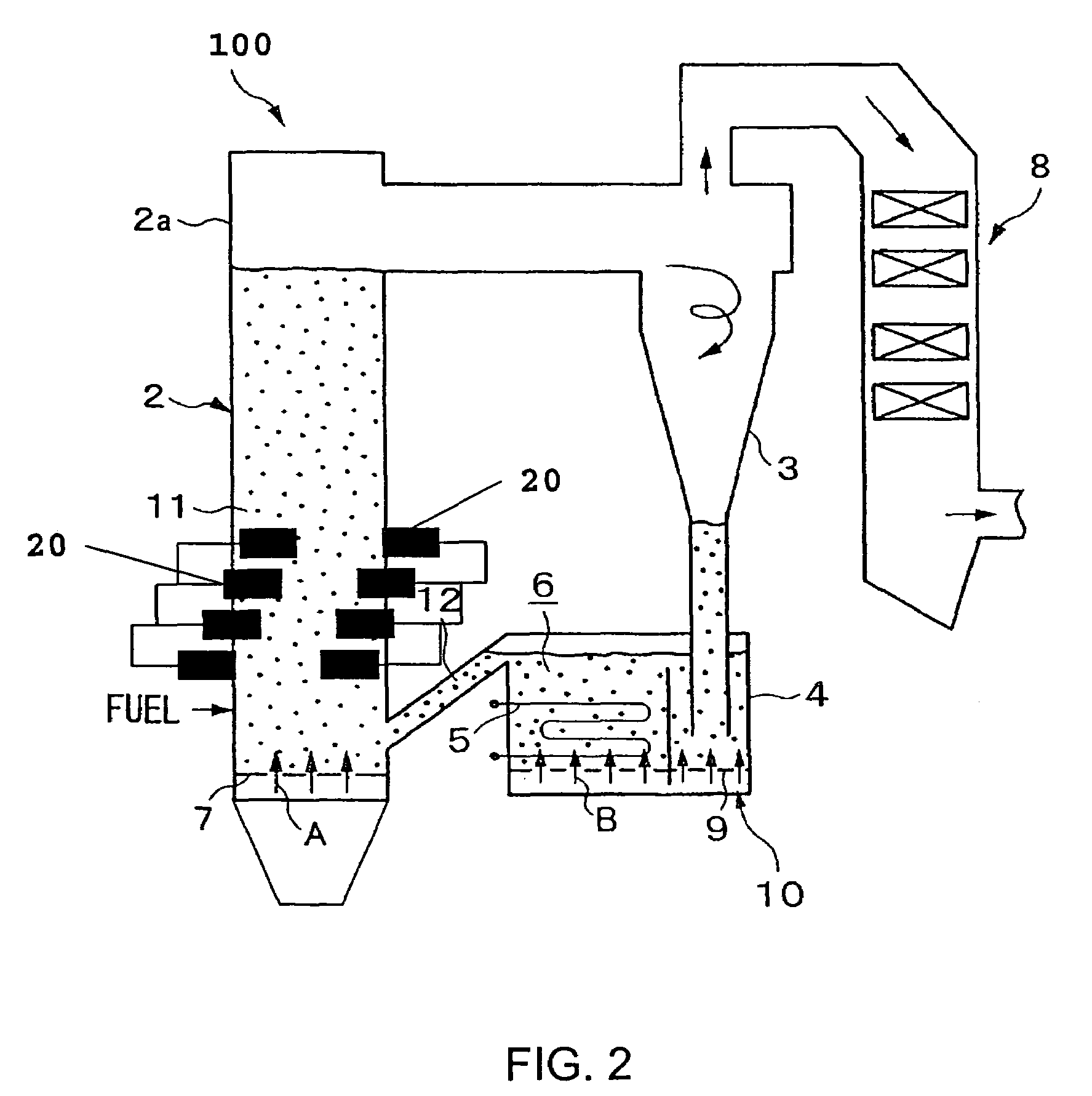

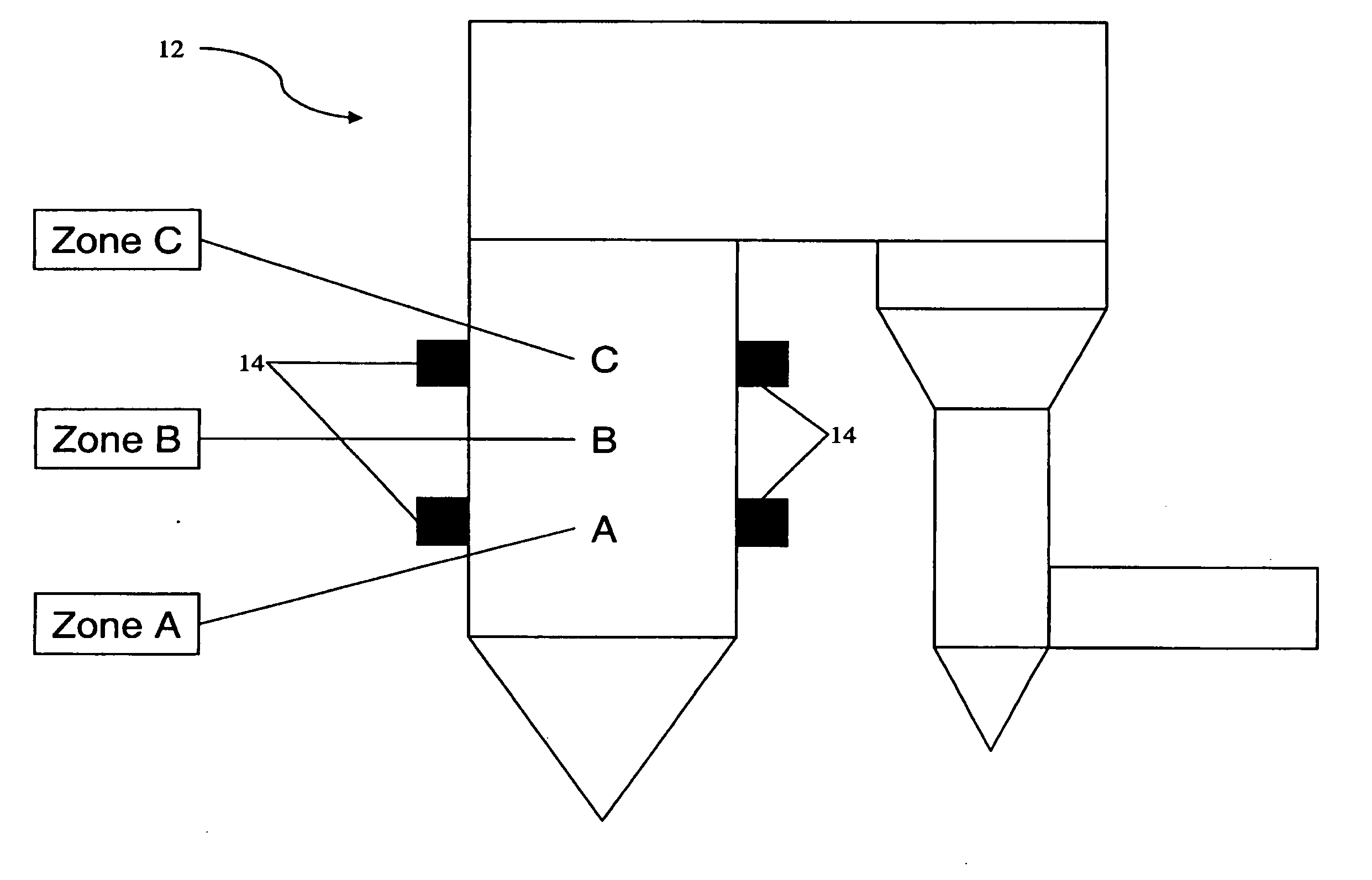

Circulating fluidized bed boiler having improved reactant utilization

InactiveUS20070119387A1Improved reactant utilizationEmission reductionFluidized bed combustionFluidised-bed furnacesFluidized bedFlue gas

A circulating fluidized bed boiler having improved reactant utilization. The circulating fluidized bed boiler includes a circulating fluidized bed having a dense bed portion; a lower furnace portion adjacent to the dense bed portion; and an upper furnace portion, wherein the dense bed portion of the circulating fluidized bed boiler is maintained below the stoichiometric ratio (fuel rich stage) and the lower furnace portion is maintained above the stoichiometric ratio (fuel lean stage), thereby reducing the formation of NOx.; a reactant to reduce the emission of at least one combustion product in the flue gas; and a plurality of secondary air injection ports downstream of the circulating fluidized bed for providing mixing of the reactant and the flue gas in the furnace above the dense bed, wherein the amount of reactant required for the reduction of the emission of the combustion product is reduced. In a preferred embodiment, the circulating fluidized bed boiler may further include a return system for returning carry over particles from the flue gas to the circulating fluidized bed.

Owner:THE POWER IND GRP

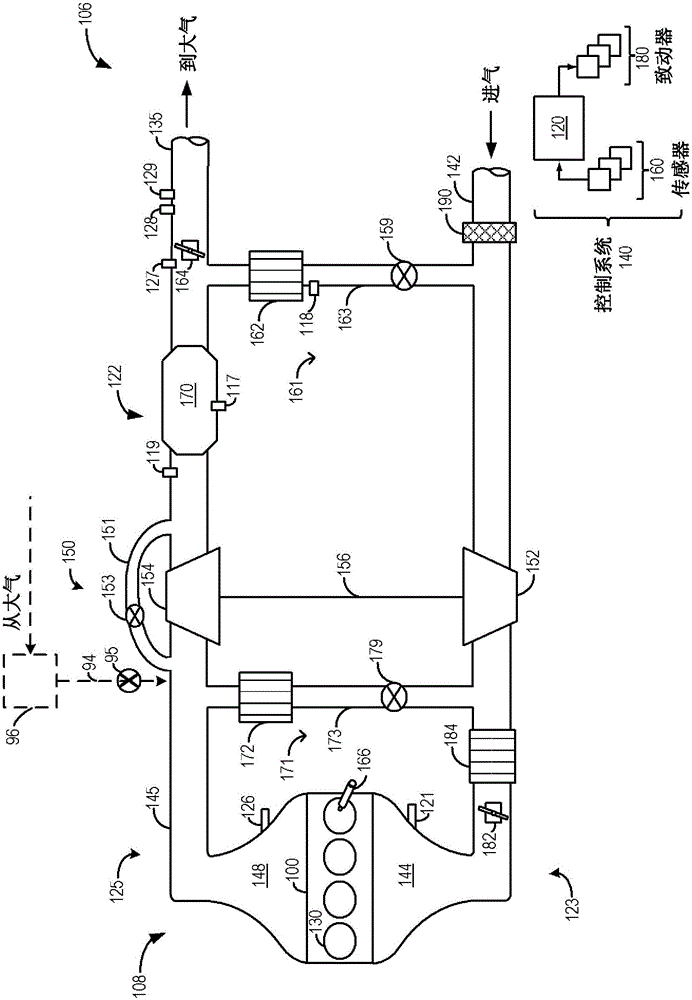

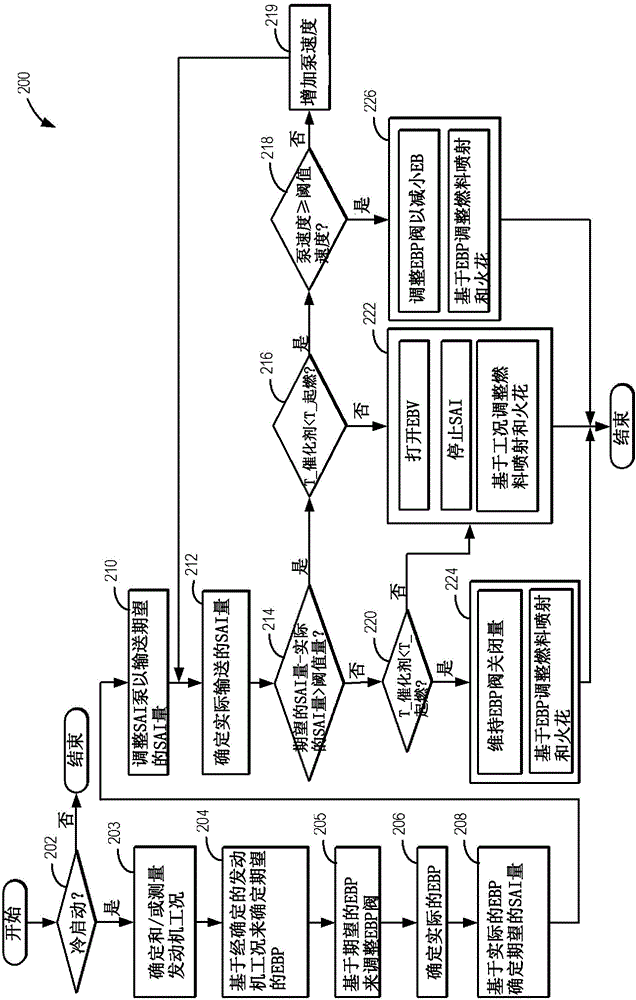

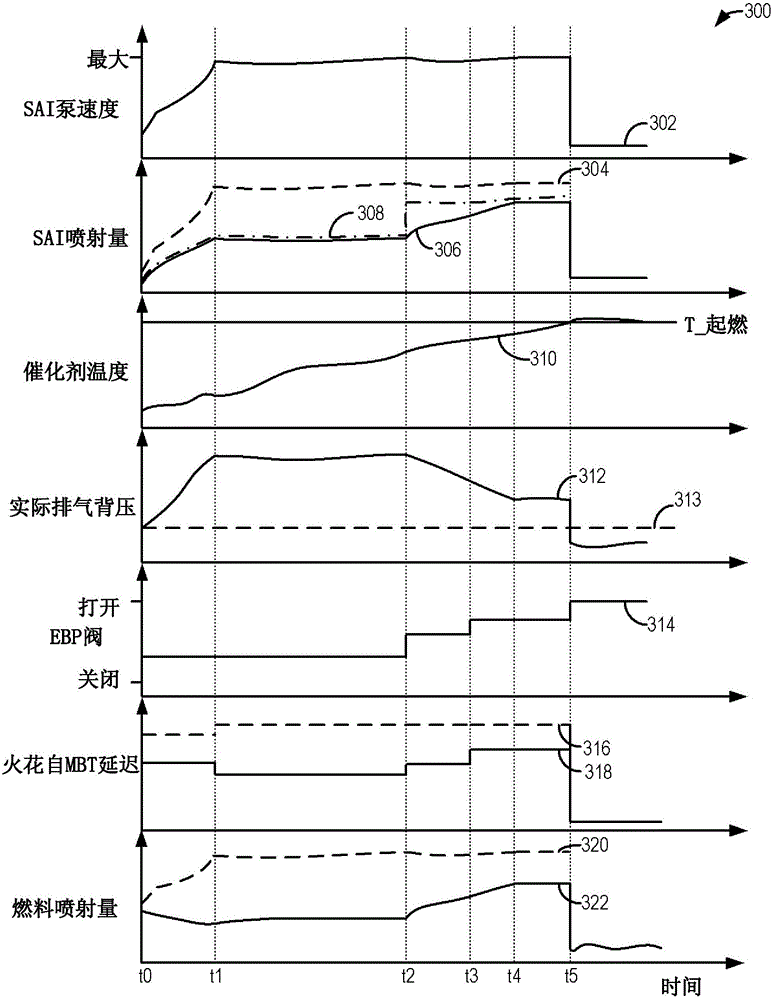

Method and system for secondary air injection coordination with exhaust back pressure valve

ActiveCN105275651AElectrical controlInternal combustion piston enginesPtru catalystMechanical engineering

Methods and systems are provided for controlling and coordinating control of a post-catalyst exhaust back pressure valve and secondary air injection to expedite catalyst heating. By adjusting the exhaust back pressure valve to increase the exhaust backpressure and injecting secondary air into an exhaust passage upstream of the catalyst during cold start conditions, exhaust catalyst activation may be expedited.

Owner:FORD GLOBAL TECH LLC

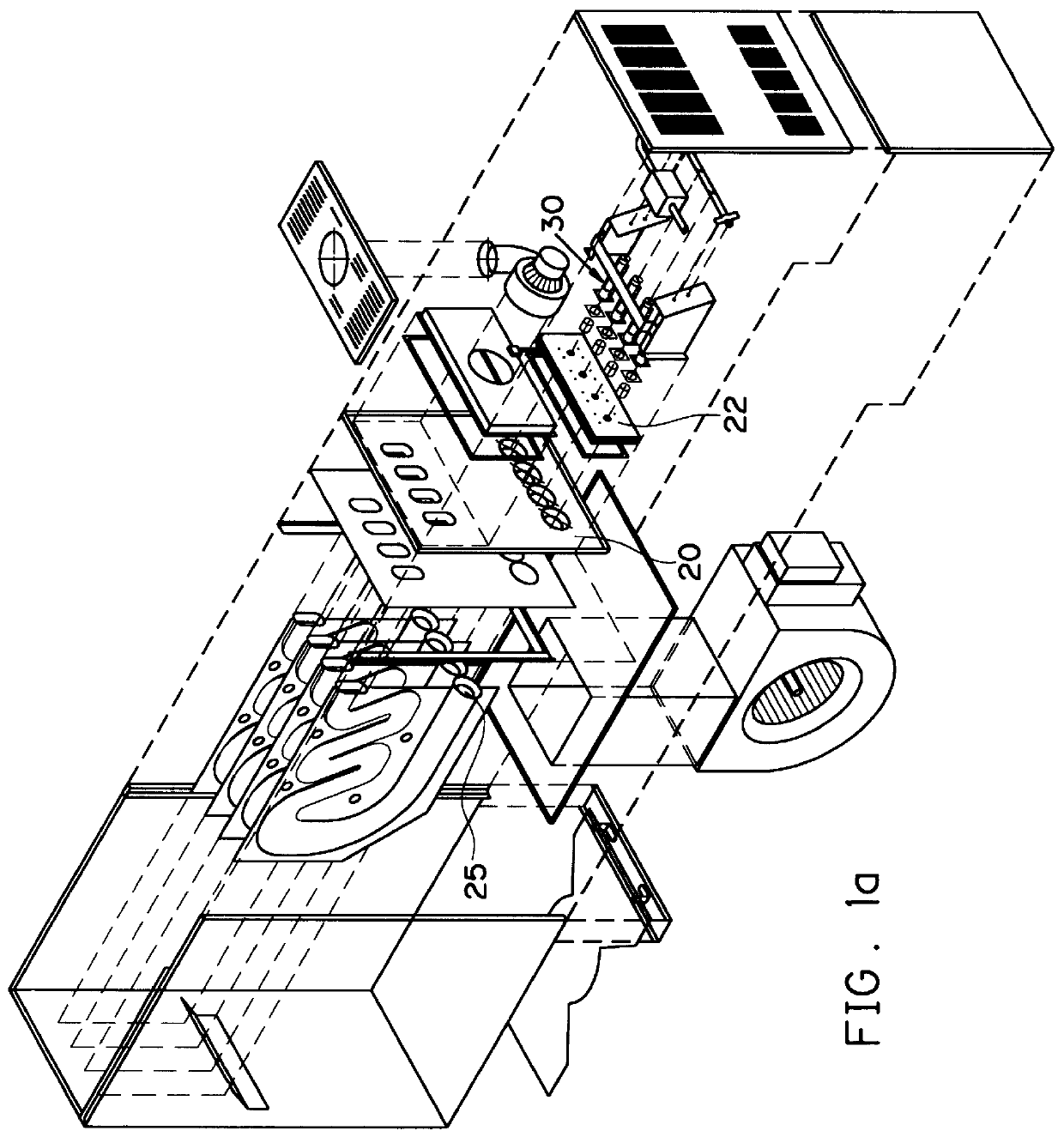

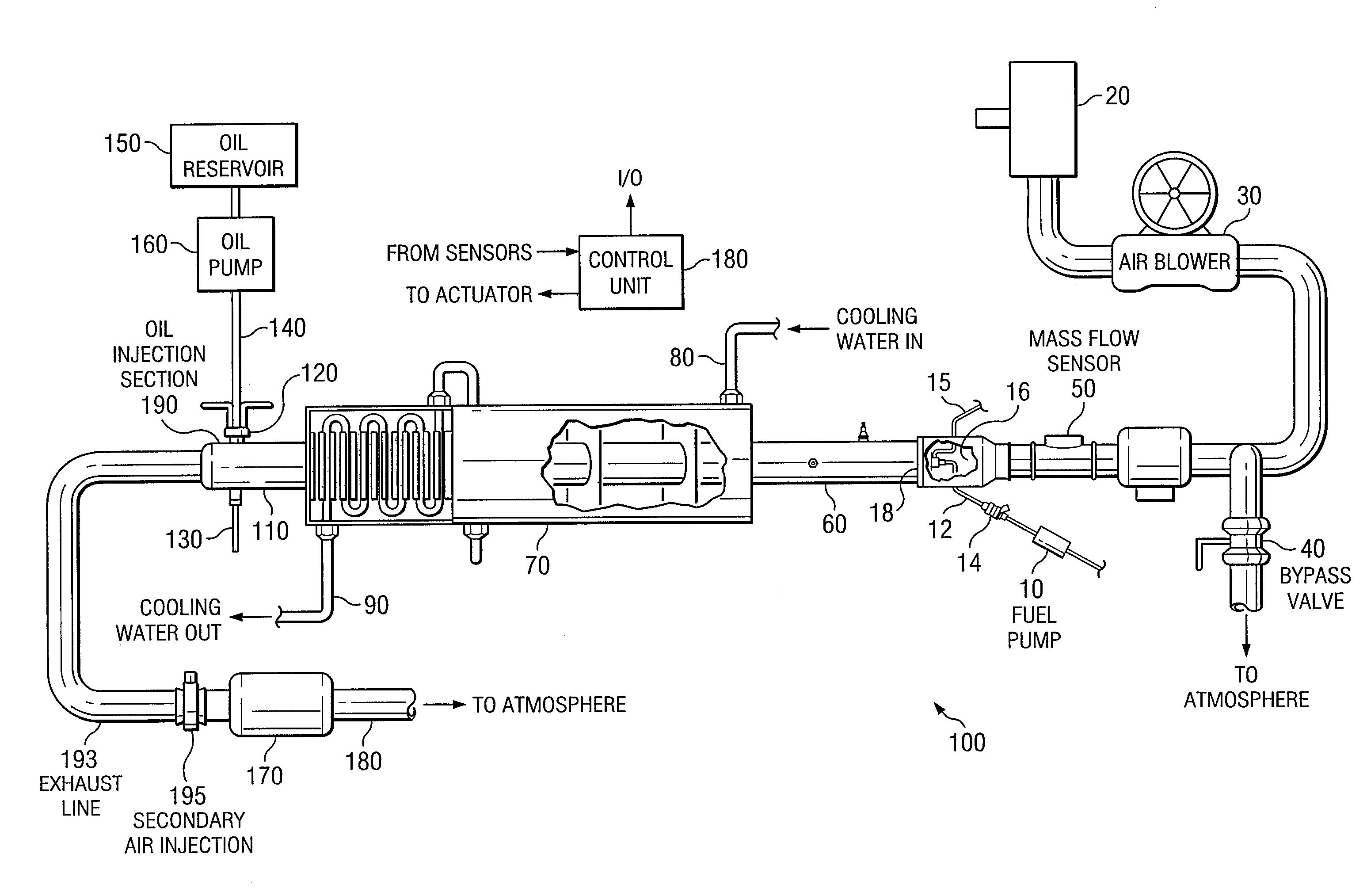

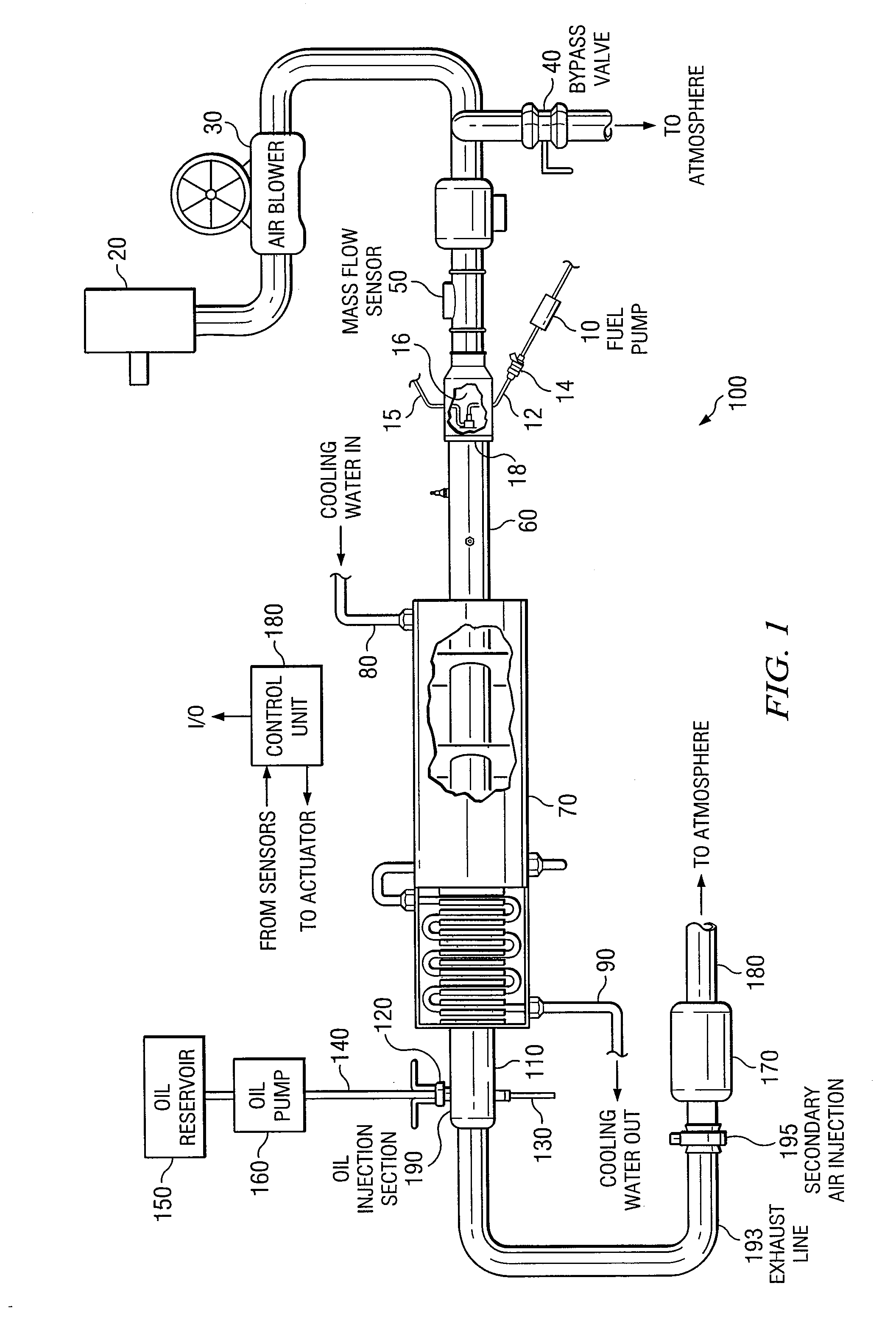

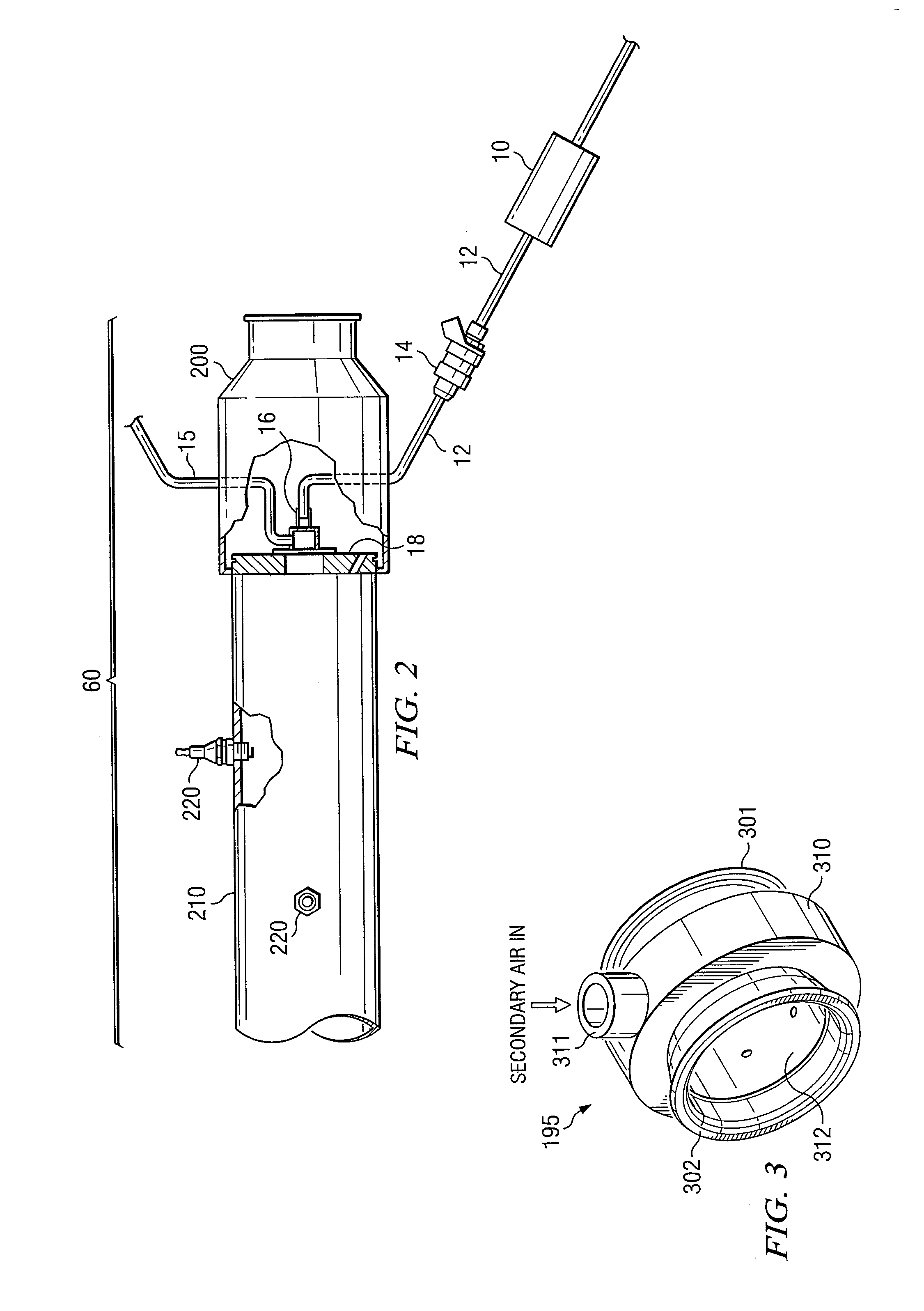

Secondary Air Injector For Use With Exhaust Gas Simulation System

A secondary air injector for use with an exhaust flow simulation system. A typical exhaust flow simulator is a burner-based system, in which exhaust from a combustive burner is exhausted through an exhaust line. The secondary air injector is placed downstream the burner to create a desired thermal condition or composition of the exhaust gas. The injector comprises a hollow ring fitted around the exhaust line, with multiple holes for evenly injecting the air into the exhaust line.

Owner:SOUTHWEST RES INST

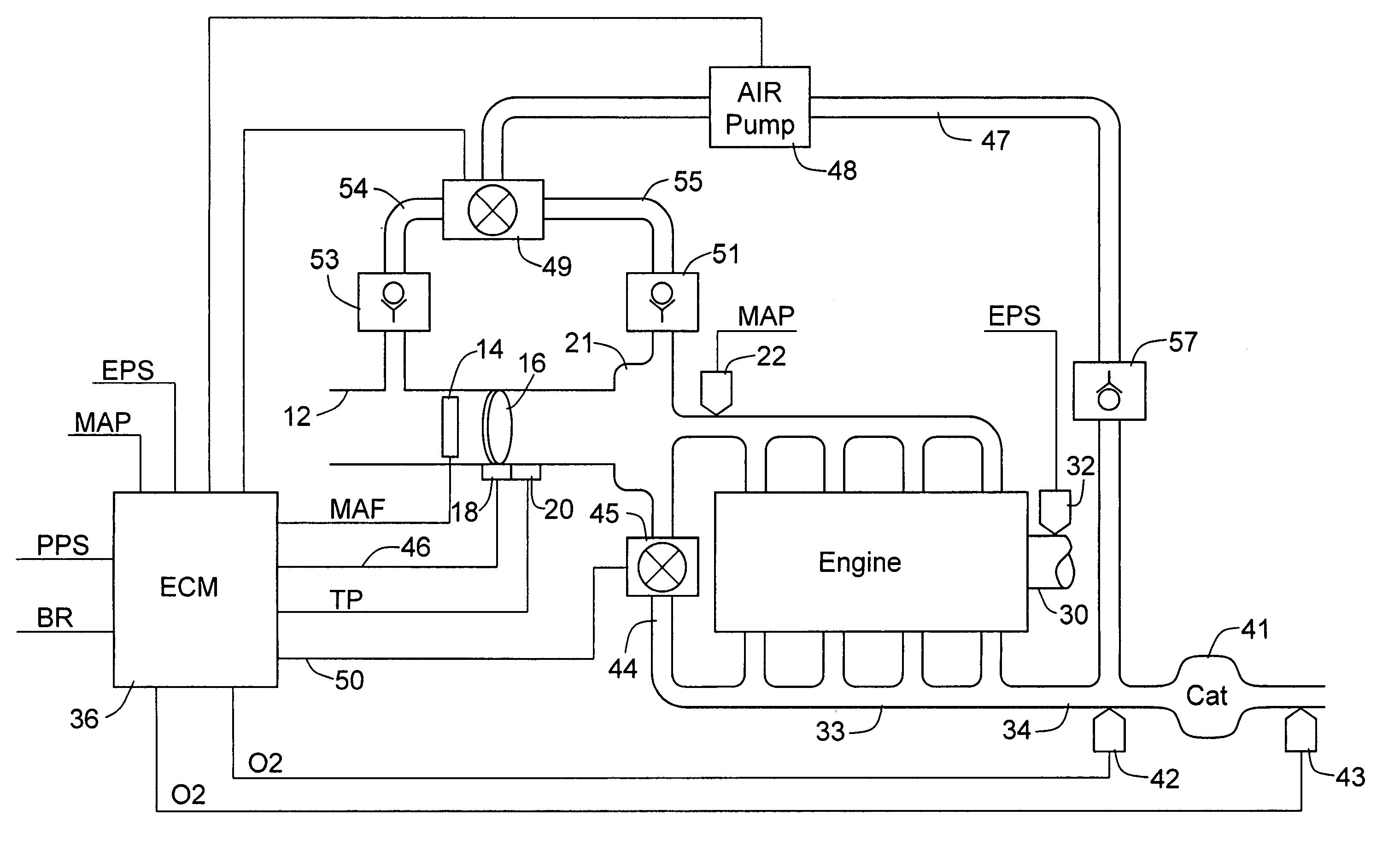

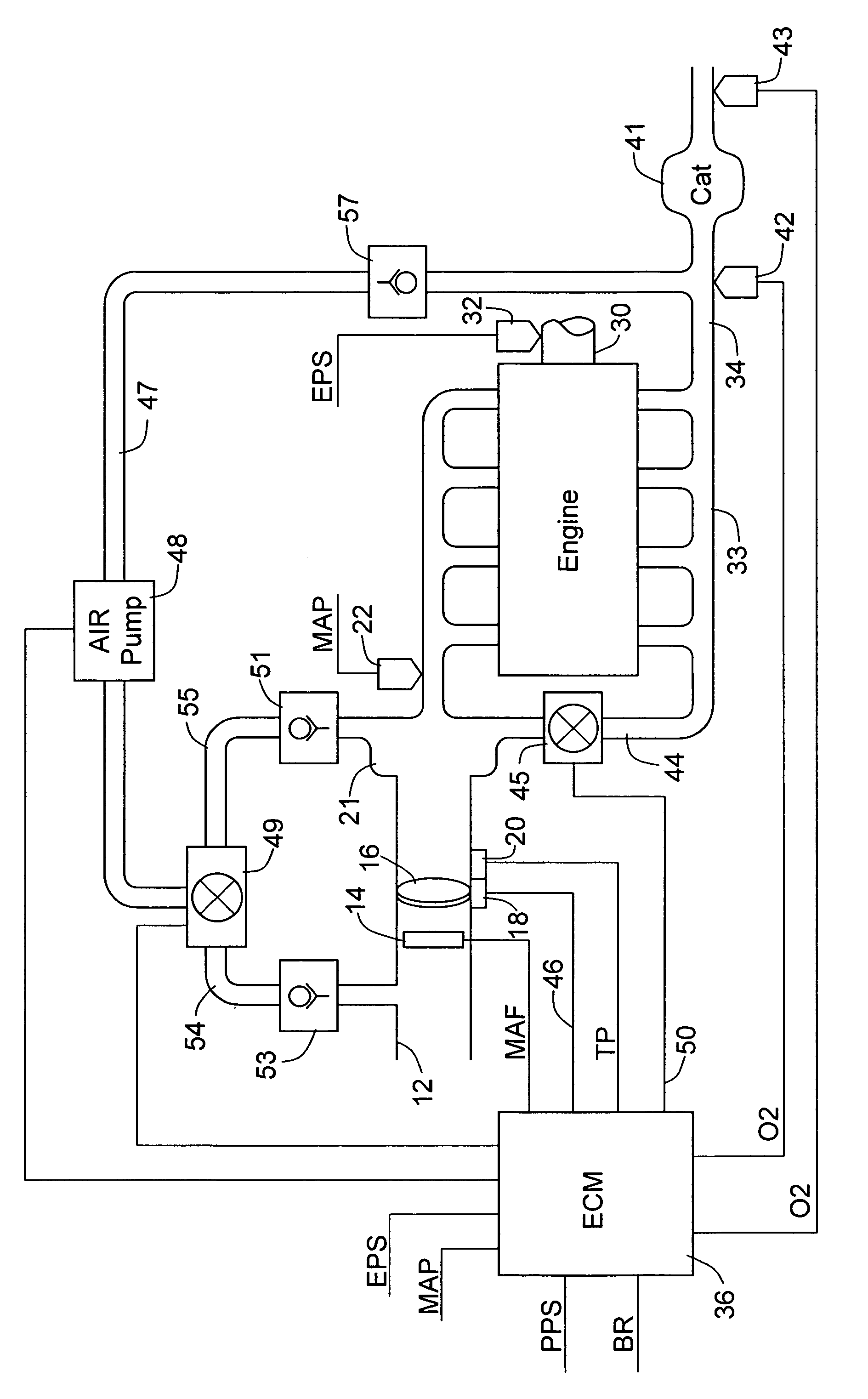

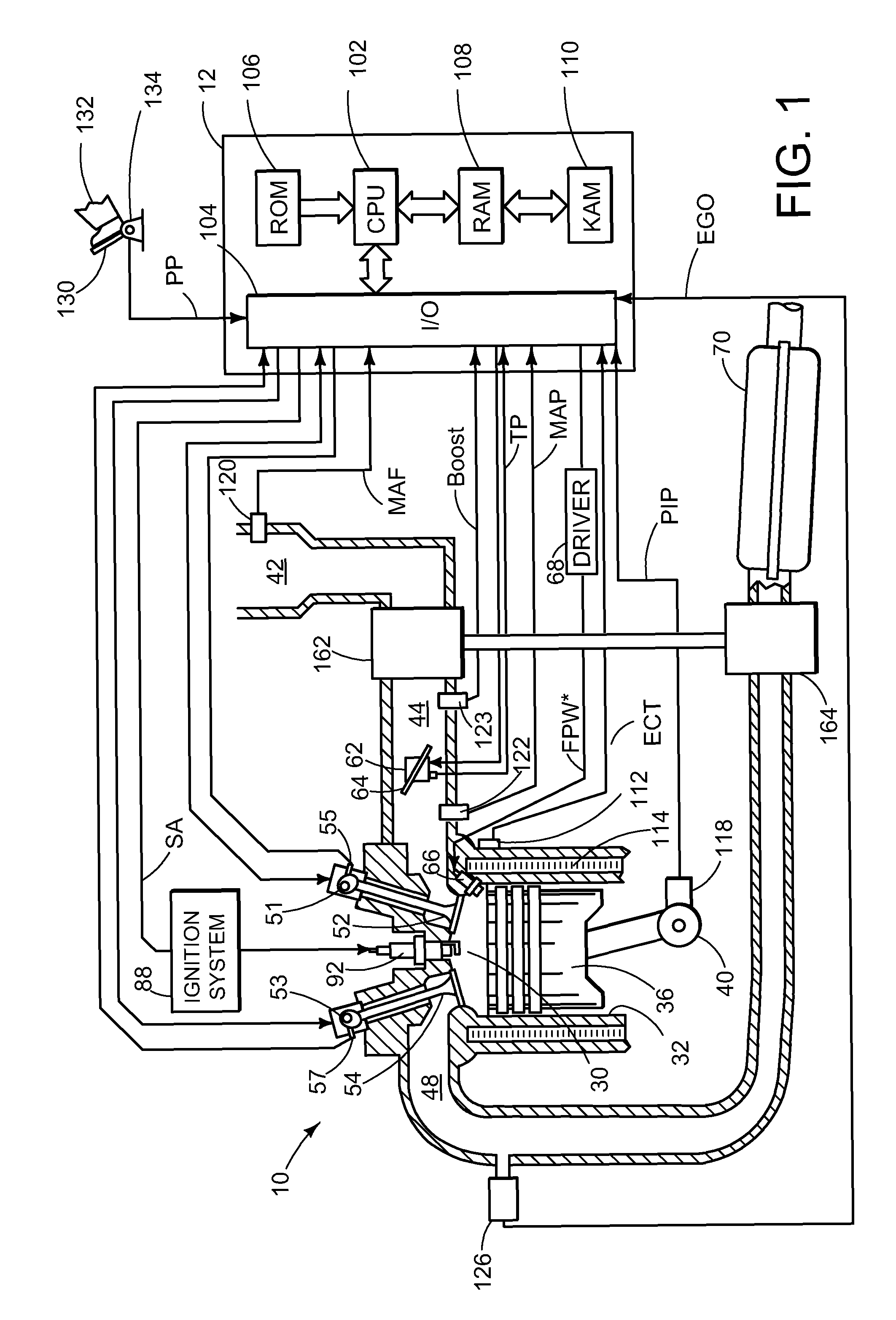

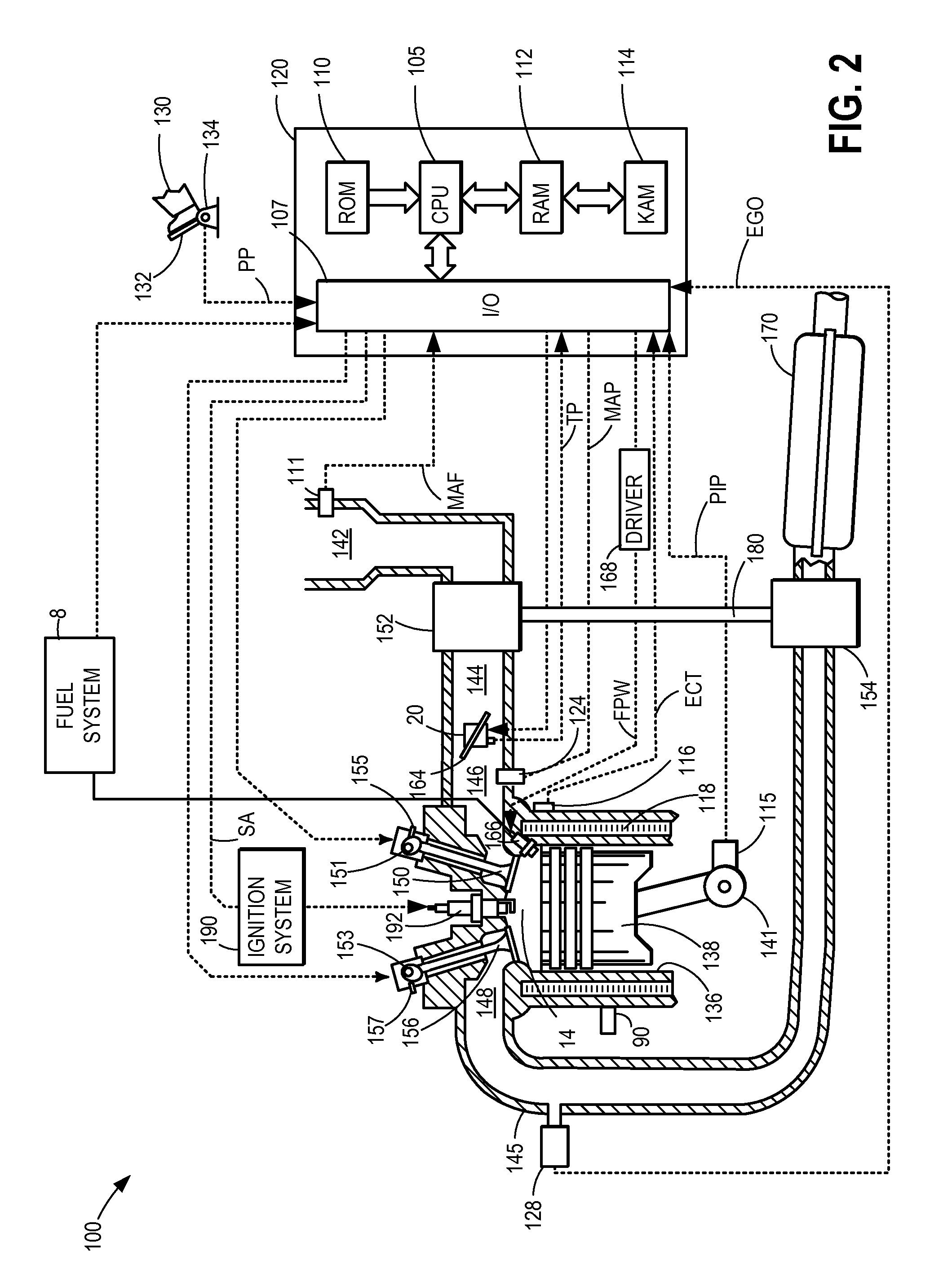

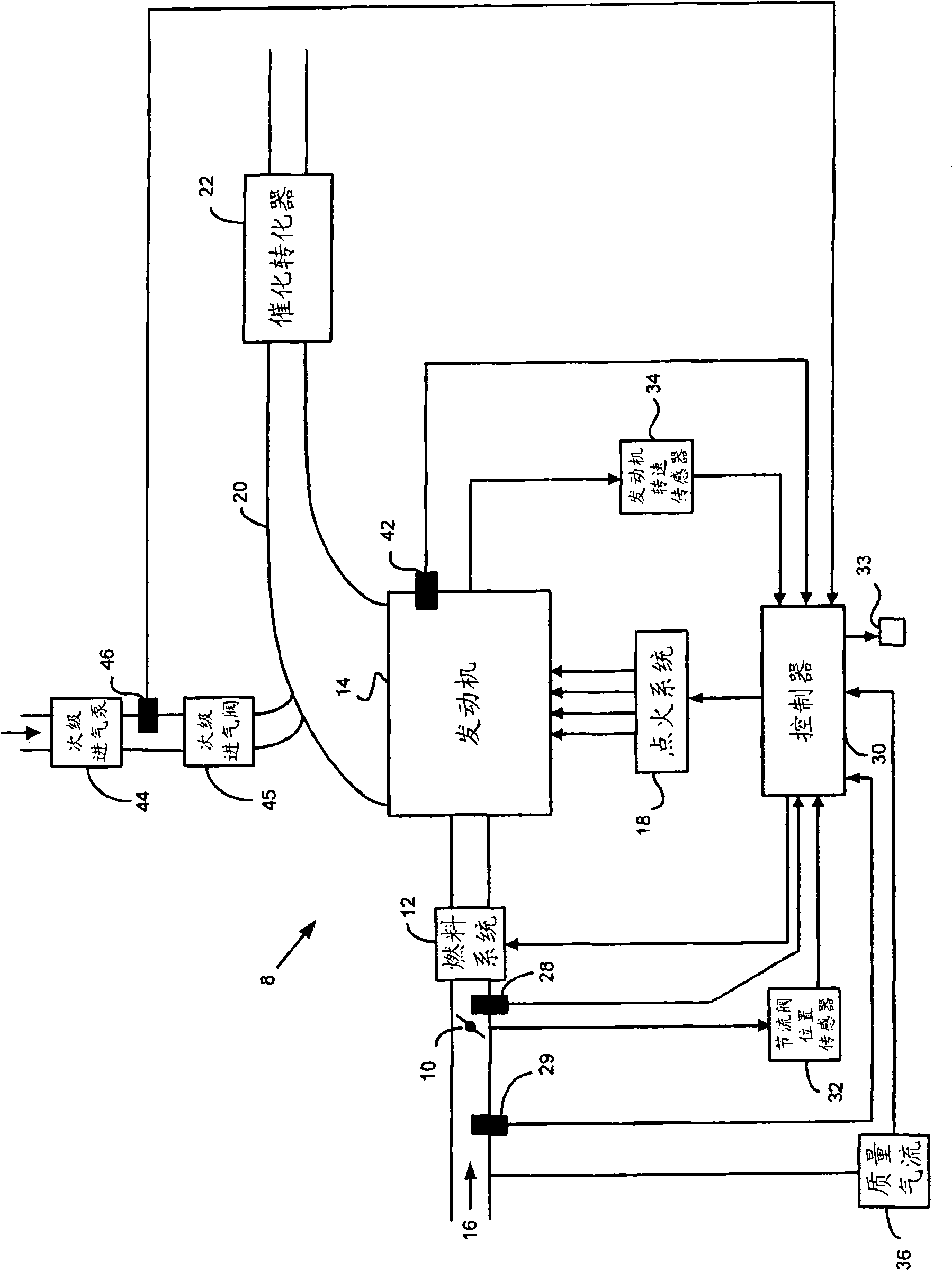

Fuel control compensation for secondary air system flow variation

An engine control system and method maintains an optimum exhaust fuel to air ratio in an internal combustion engine. A secondary air injection (SAI) pressure is measured in an SAI system. The SAI pressure measurement is converted into an SAI flow value. A fuel compensation value is obtained based on the SAI flow value. Fuel delivery is compensated to the engine based on the fuel compensation value. In a second embodiment, the fuel compensation value is obtained based on the SAI pressure measurement. Fuel delivery is compensated to the engine based on the fuel compensation value. In a third embodiment, a primary flow value is calculated at an air intake of the engine. A fuel compensation value is calculated based on the SAI flow and primary flow values. Fuel delivery to the engine is compensated based on the fuel compensation value.

Owner:GM GLOBAL TECH OPERATIONS LLC

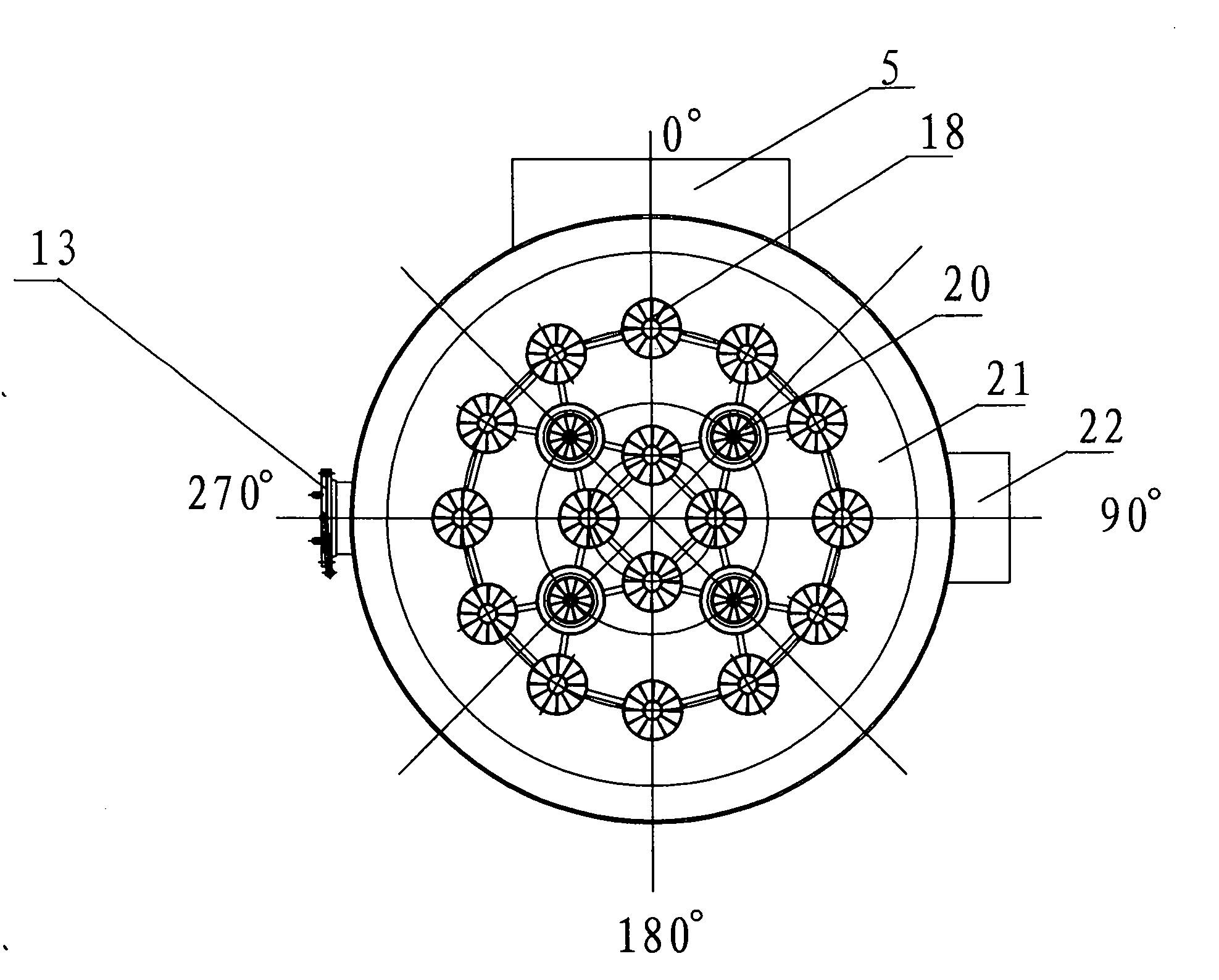

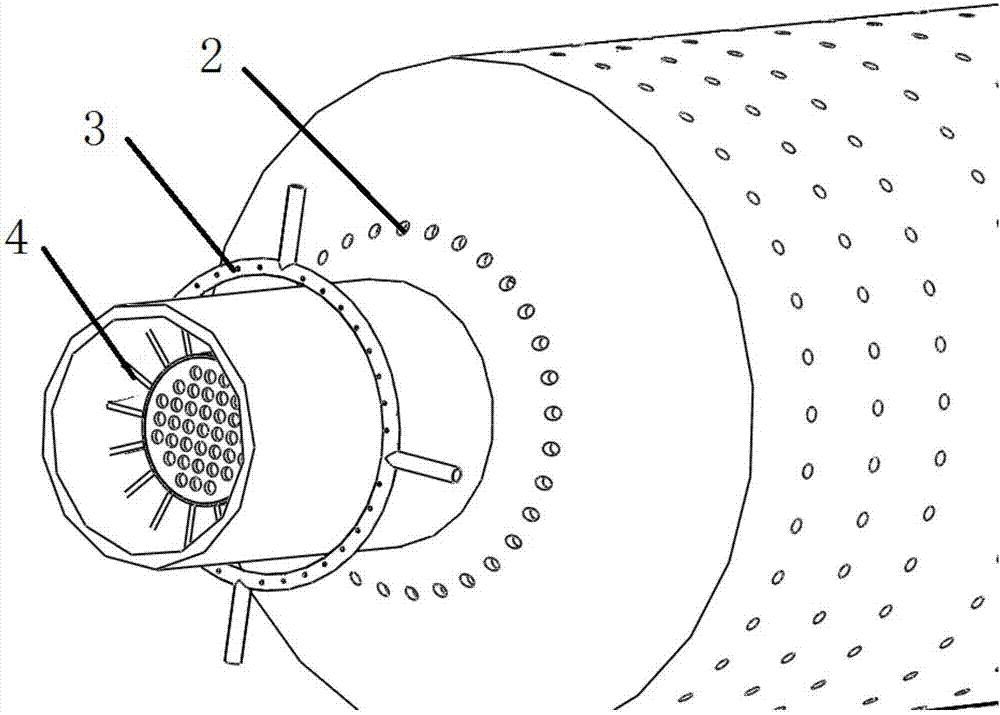

Built-in integrated smoke exhaust-heat boiler burner for catalysis device

ActiveCN101813320AImprove integrityNice appearanceIncinerator apparatusGaseous fuel burnerCycloneCombustor

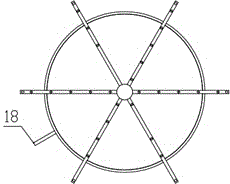

The invention belongs to a burner technique and discloses a built-in integrated smoke exhaust-heat boiler burner for a catalysis device. The burner is positioned on the lower part of the furnace body of an incinerator of an exhaust-heat boiler; a plurality of primary air branches 13 are respectively coaxial with a corresponding fuel air gun and are arranged around the fuel air gun; an air cyclone 20 is arranged at an outlet of the primary air branch; an outlet of the fuel air gun and the primary air cyclone are arranged in a corresponding burning channel; an upper end face of a regenerated smoke distributing cavity is provided with a plurality of regenerated smoke cyclones 18; an outlet of each secondary air injection pipe 4 is arranged opposite to the cyclone; a plurality of burning channels of fuel mixture distributed along a circumference are positioned between mixed regenerated smoke outlets formed along inner and outer layers of circumferences; and the mixed regenerated smoke and the mixed fuel gas are uniformly distributed as a mixing burning ring with separated inner and outer layers. The burner of the invention has the advantages of integration, simple and reliable structure, convenient operation, low cost, complete burning and high heat efficiency.

Owner:LUOYANG RUICHANG PETROCHEM EQUIP

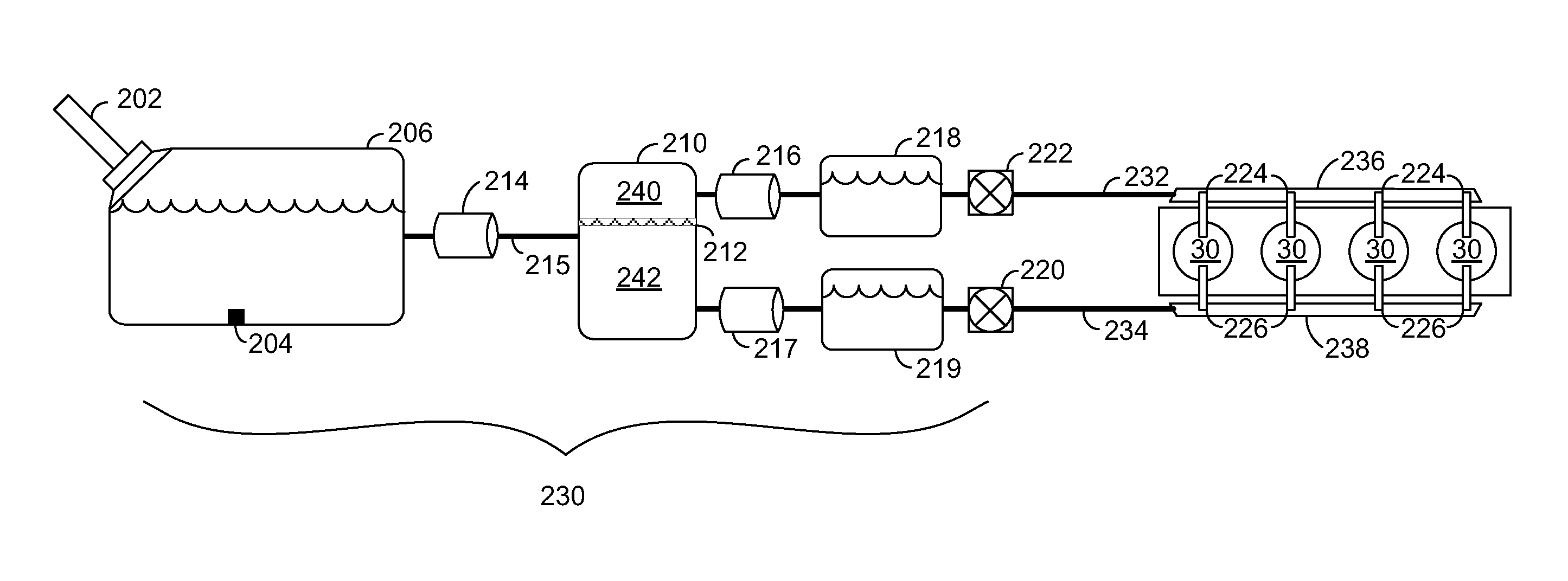

Octane separation system and operating method

ActiveUS20150052876A1Decrease and eliminate fuel stalenessReadily combustibleElectrical controlInternal combustion piston enginesAtmospheric airFuel tank

An engine method, comprising delivering high octane fuel to a high octane fuel tank and delivering low octane fuel to a low octane fuel tank and injecting atmospheric air into an exhaust system for secondary air injection in response to delivering low octane fuel to an engine.

Owner:FORD GLOBAL TECH LLC

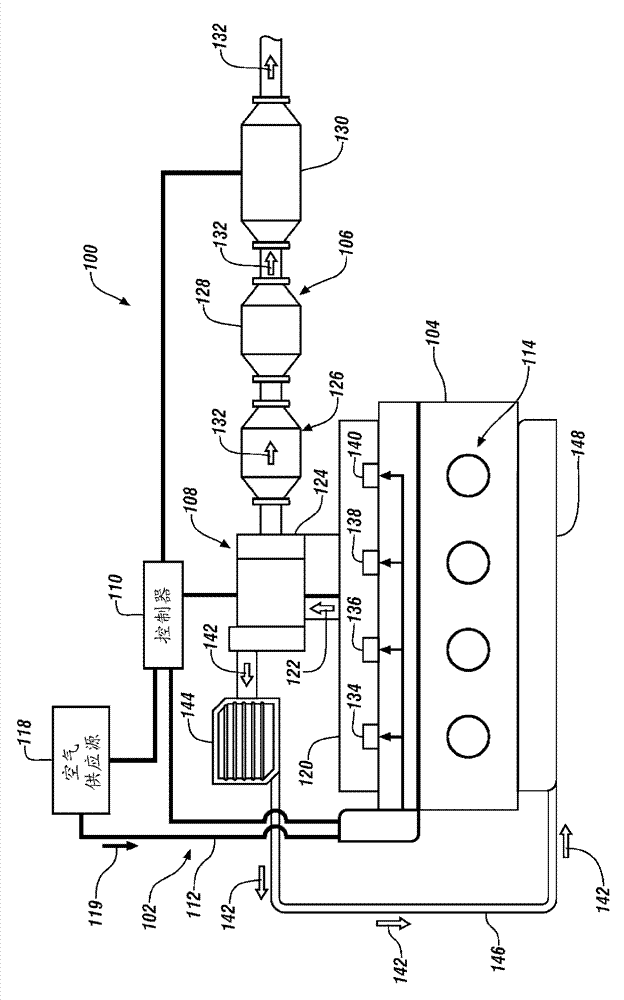

Internal combustion engine with secondary air injection system

InactiveUS7913488B2Increase torqueLarge air volumeInternal combustion piston enginesExhaust apparatusExternal combustion engineAir compressor

A method for operating a diesel internal combustion engine having a compressed air source, a diesel particulate filter situated in the exhaust gas system, and a secondary air line and secondary air compressor for introducing secondary air into the exhaust gas system of the internal combustion engine, in which the compressed air source is used to drive the secondary air compressor.

Owner:MANN HUMMEL GMBH

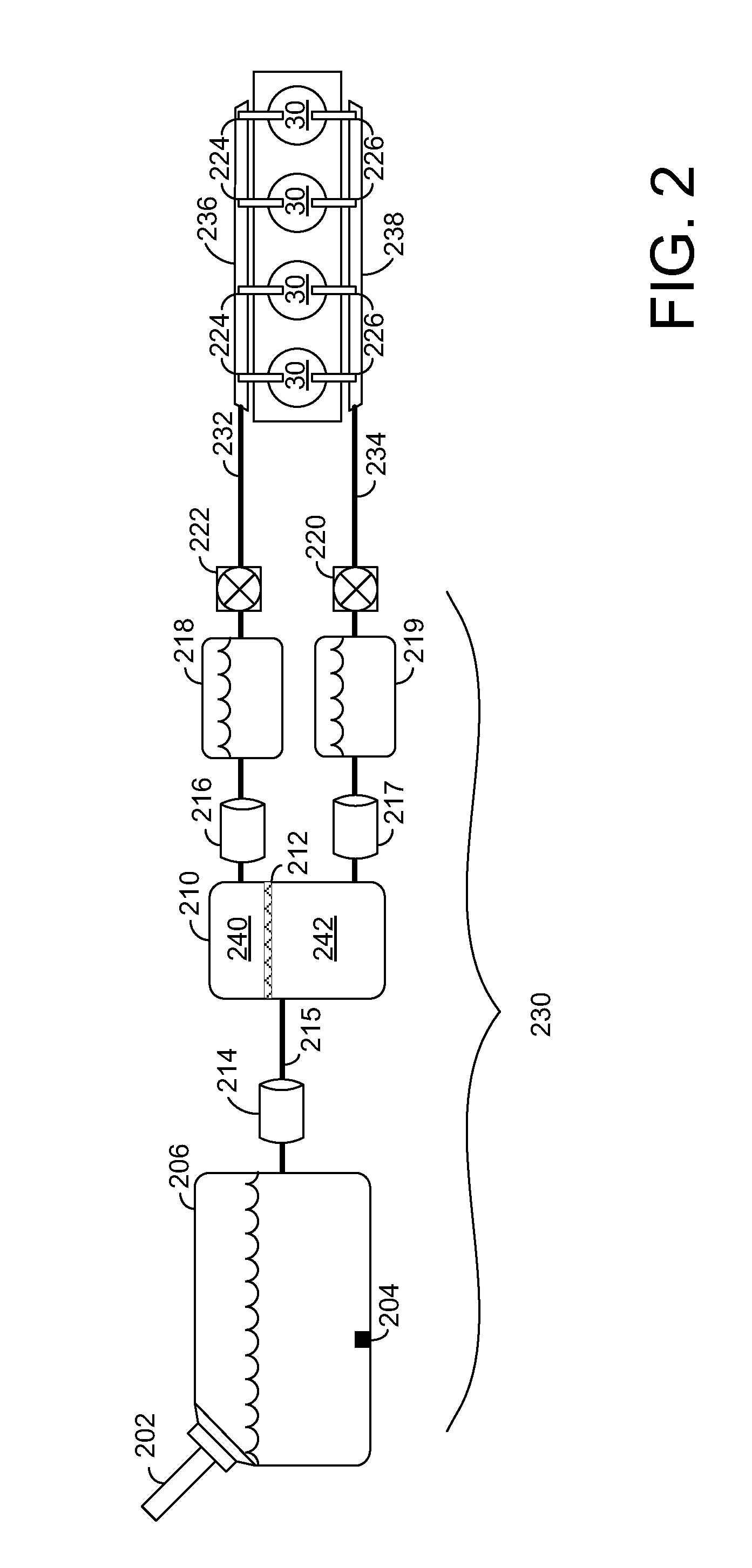

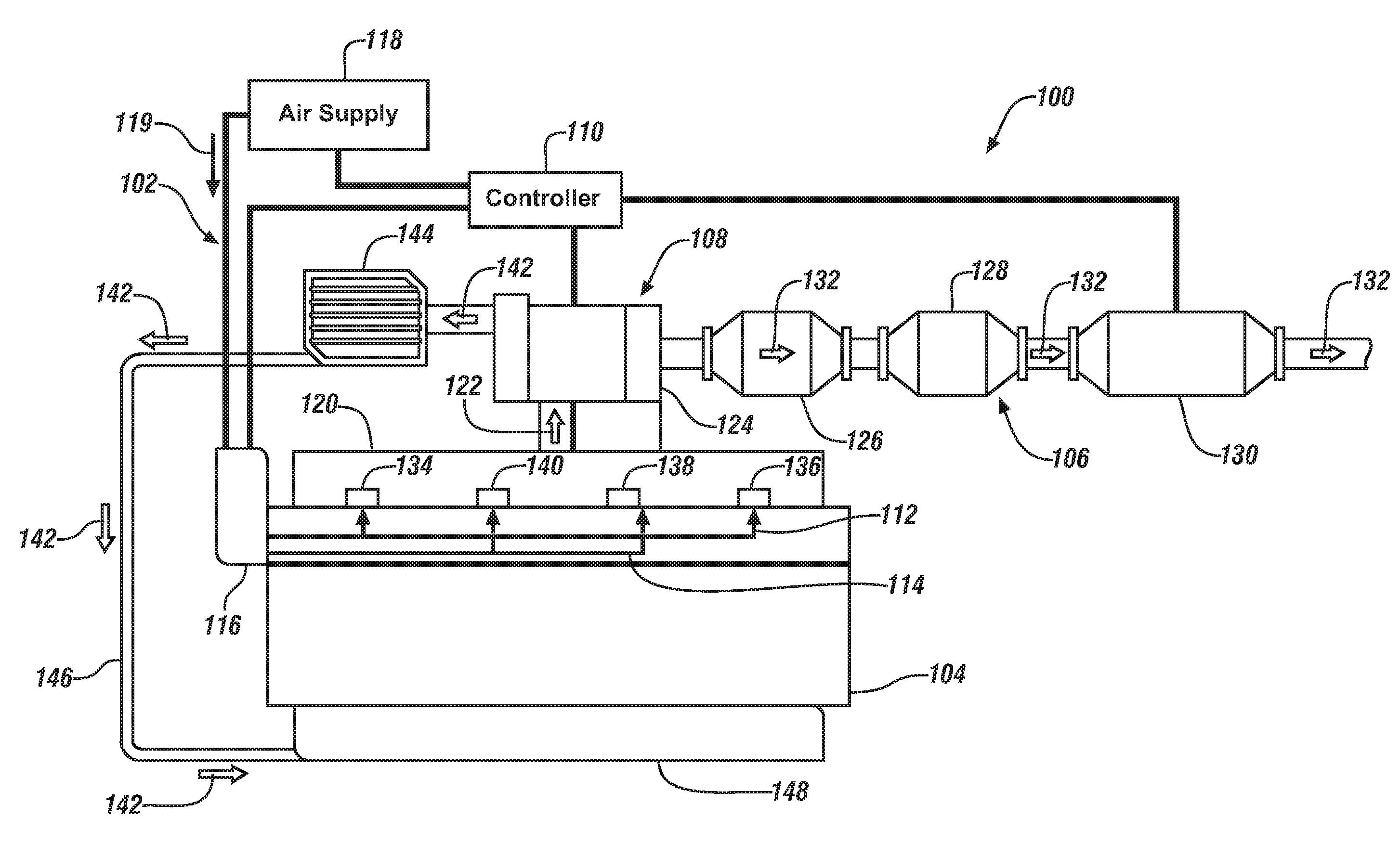

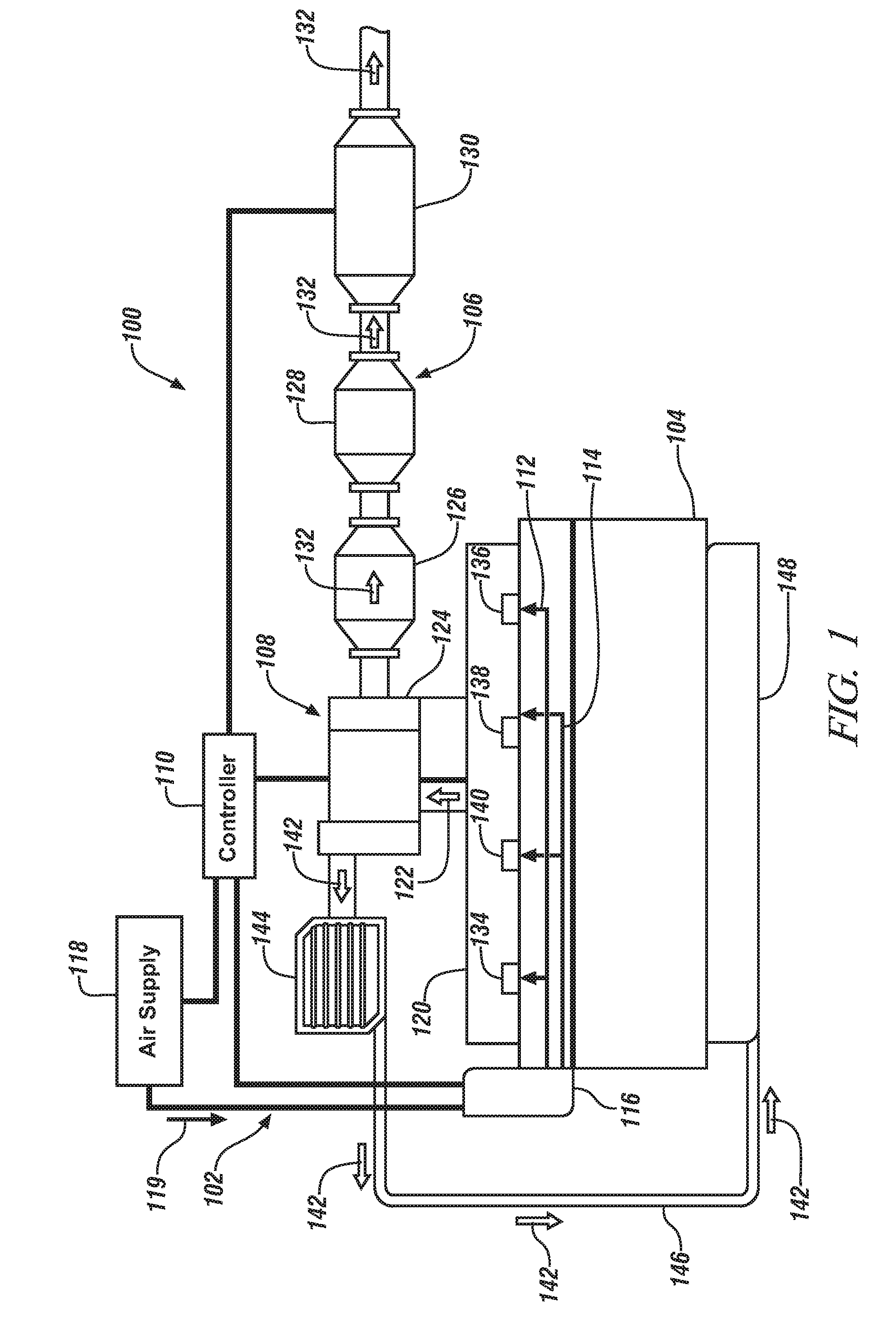

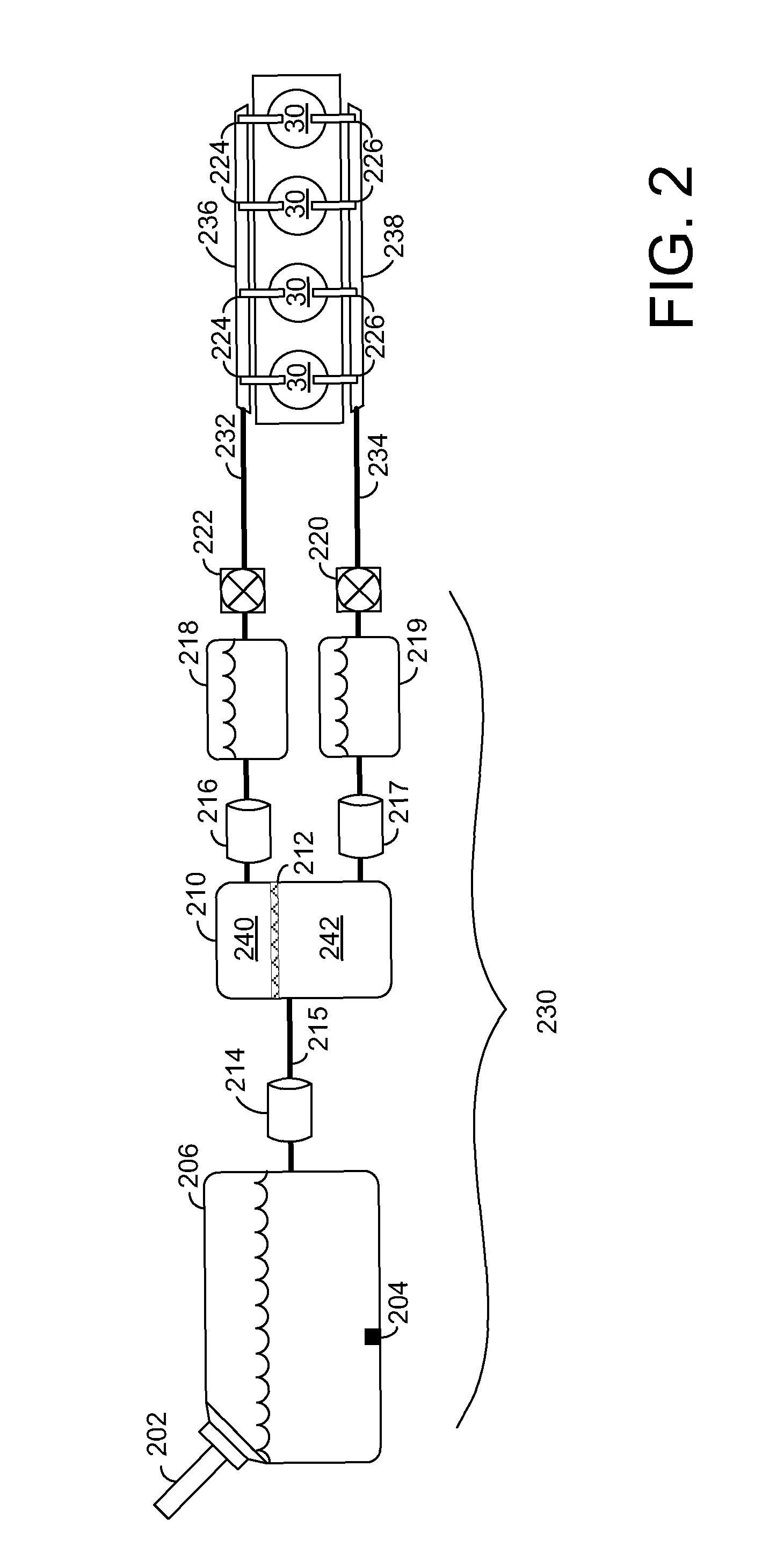

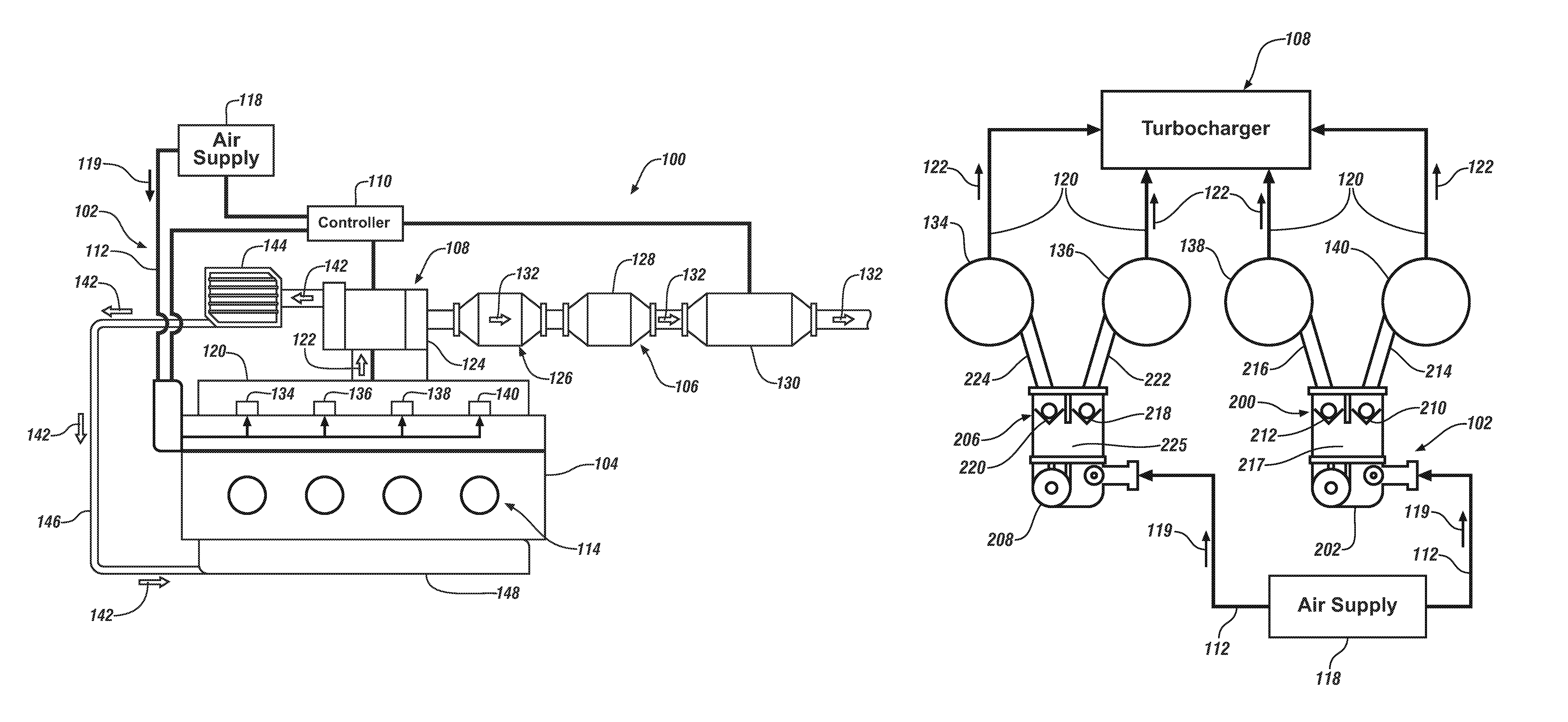

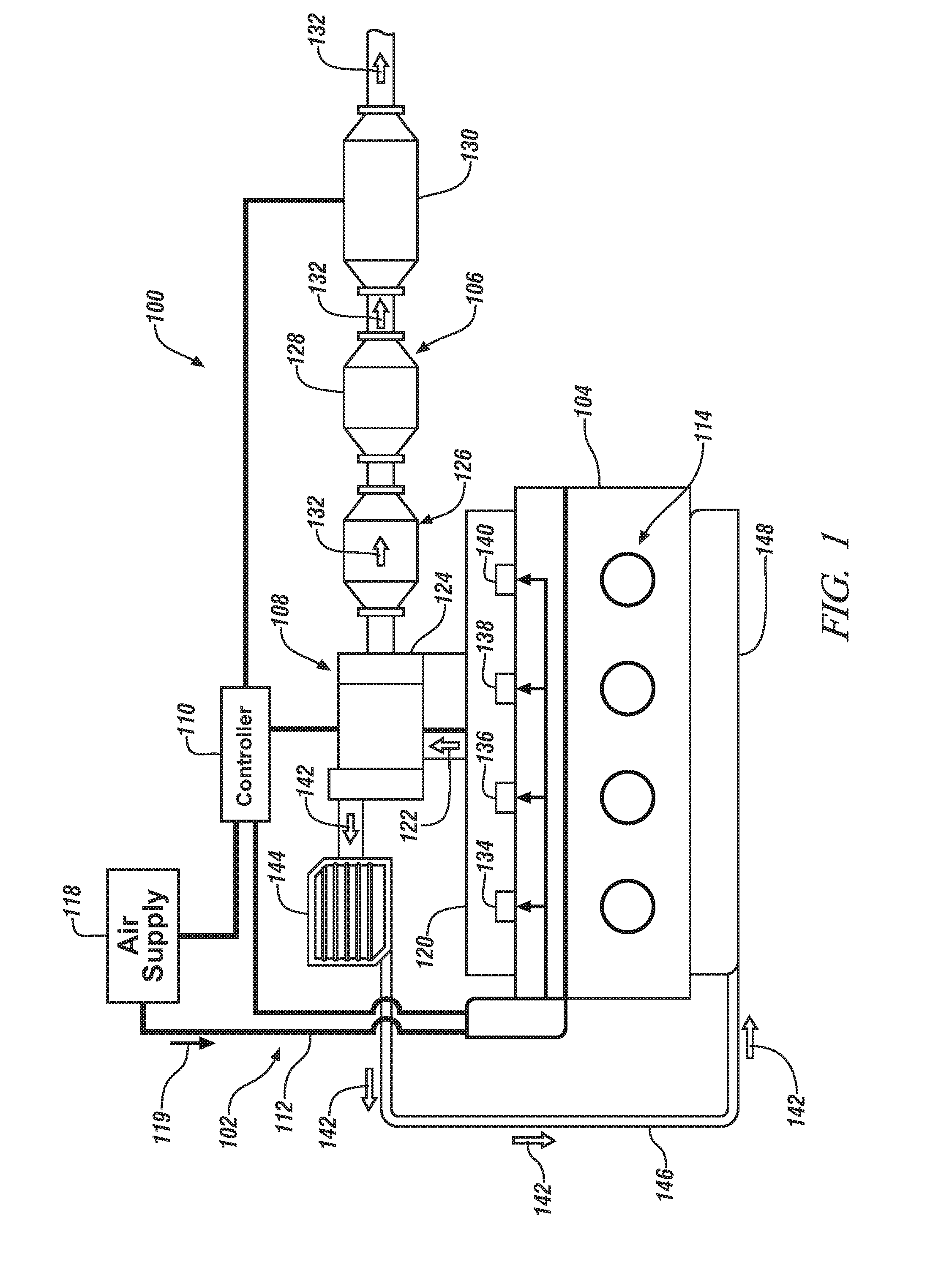

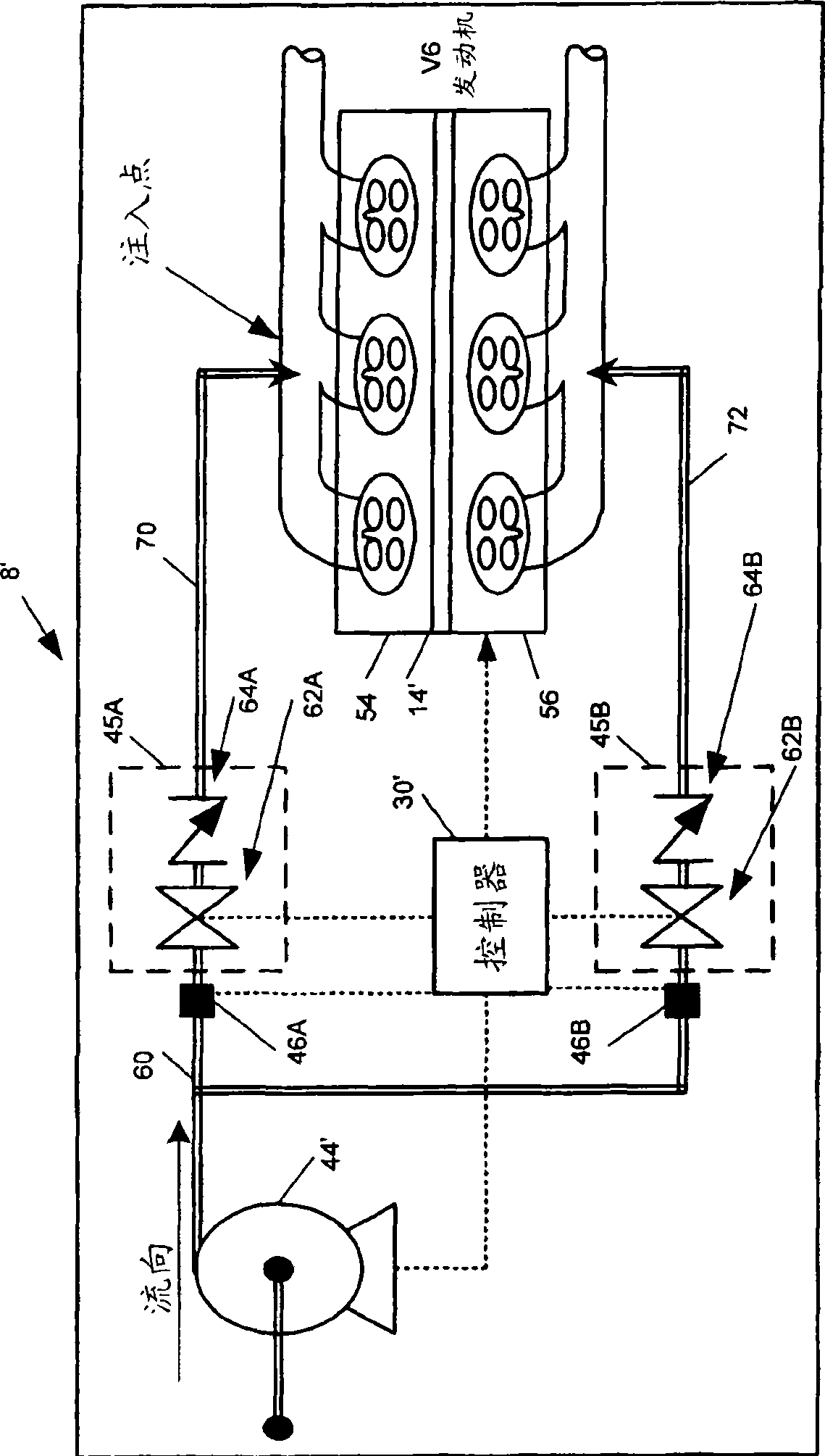

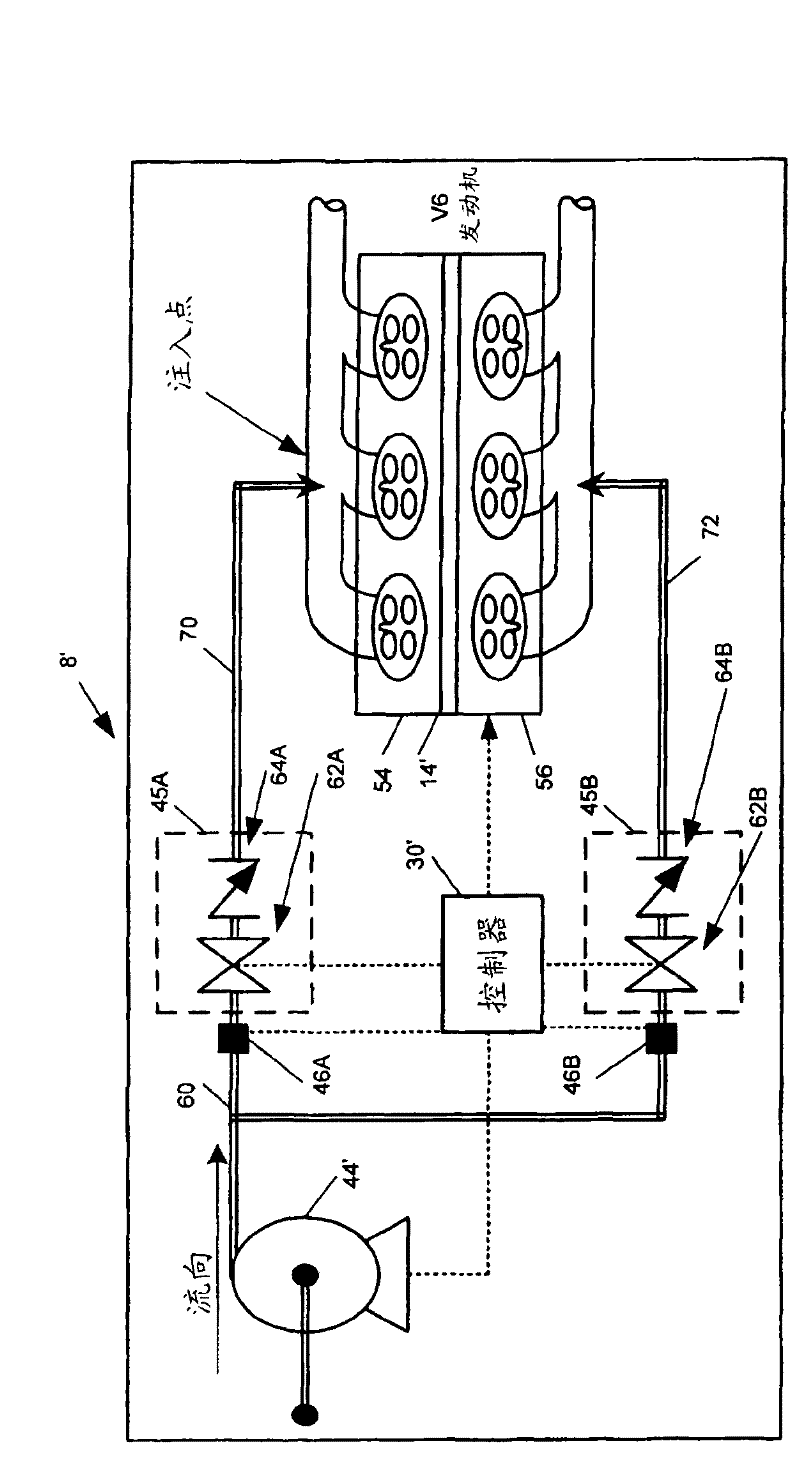

Secondary air injection system and method

InactiveUS20120210712A1Internal combustion piston enginesNon-fuel substance addition to fuelTurbochargerEngineering

According to one embodiment of the invention, a secondary air injection system includes a first conduit in fluid communication with at least one first exhaust passage of the internal combustion engine and a second conduit in fluid communication with at least one second exhaust passage of the internal combustion engine, wherein the at least one first and second exhaust passages are in fluid communication with a turbocharger. The system also includes an air supply in fluid communication with the first and second conduits and a flow control device that controls fluid communication between the air supply and the first conduit and the second conduit and thereby controls fluid communication to the first and second exhaust passages of the internal combustion engine.

Owner:GM GLOBAL TECH OPERATIONS LLC

Circulating fluidized bed boiler having improved reactant utilization

InactiveUS7410356B2Improved reactant utilizationReduce formationFluidized bed combustionFluidised-bed furnacesFluidized bedFlue gas

A circulating fluidized bed boiler having improved reactant utilization. The circulating fluidized bed boiler includes a circulating fluidized bed having a dense bed portion; a lower furnace portion adjacent to the dense bed portion; and an upper furnace portion, wherein the dense bed portion of the circulating fluidized bed boiler is maintained below the stoichiometric ratio (fuel rich stage) and the lower furnace portion is maintained above the stoichiometric ratio (fuel lean stage), thereby reducing the formation of NOx.; a reactant to reduce the emission of at least one combustion product in the flue gas; and a plurality of secondary air injection ports downstream of the circulating fluidized bed for providing mixing of the reactant and the flue gas in the furnace above the dense bed, wherein the amount of reactant required for the reduction of the emission of the combustion product is reduced. In a preferred embodiment, the circulating fluidized bed boiler may further include a return system for returning carry over particles from the flue gas to the circulating fluidized bed.

Owner:THE POWER IND GRP

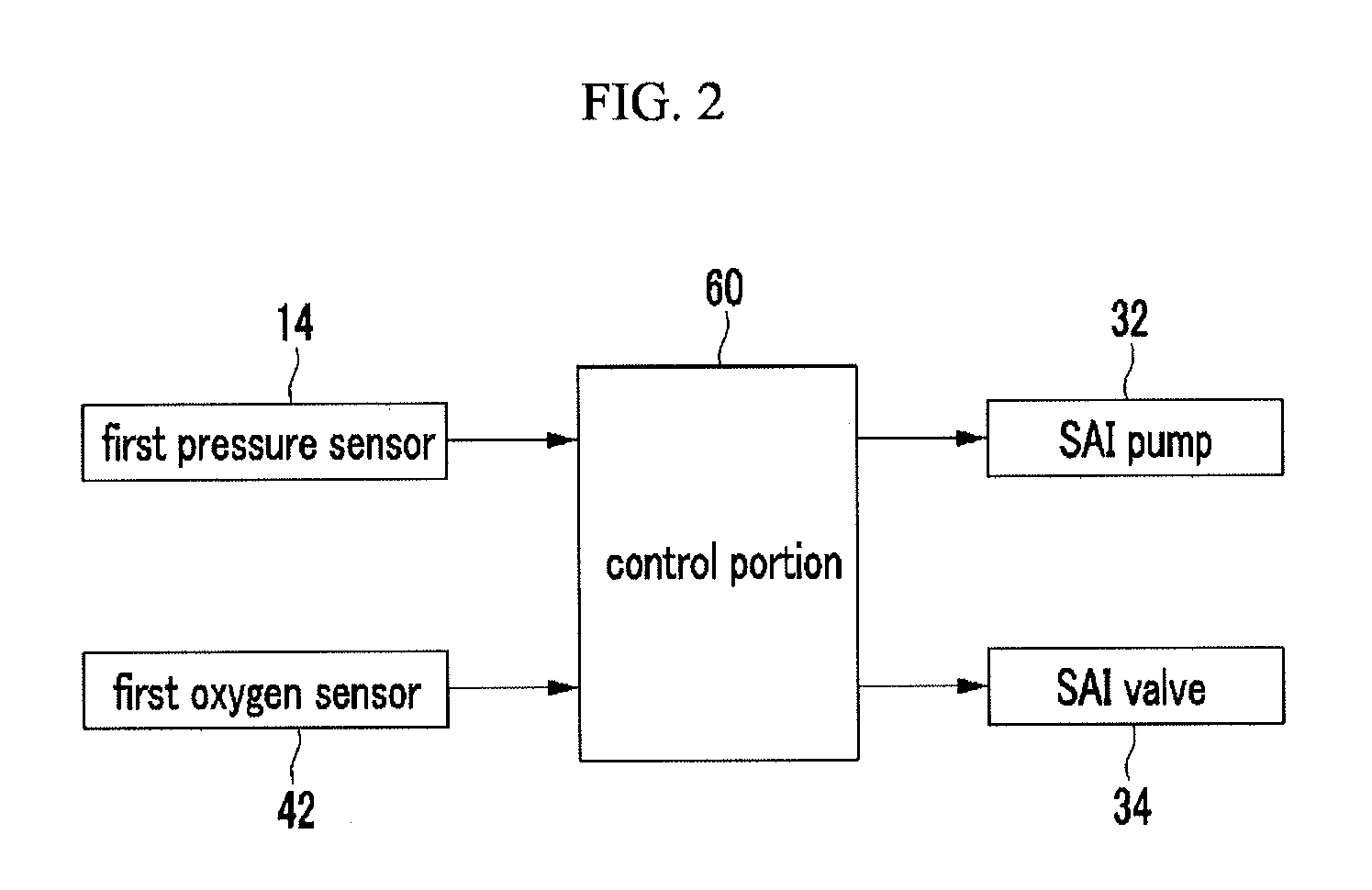

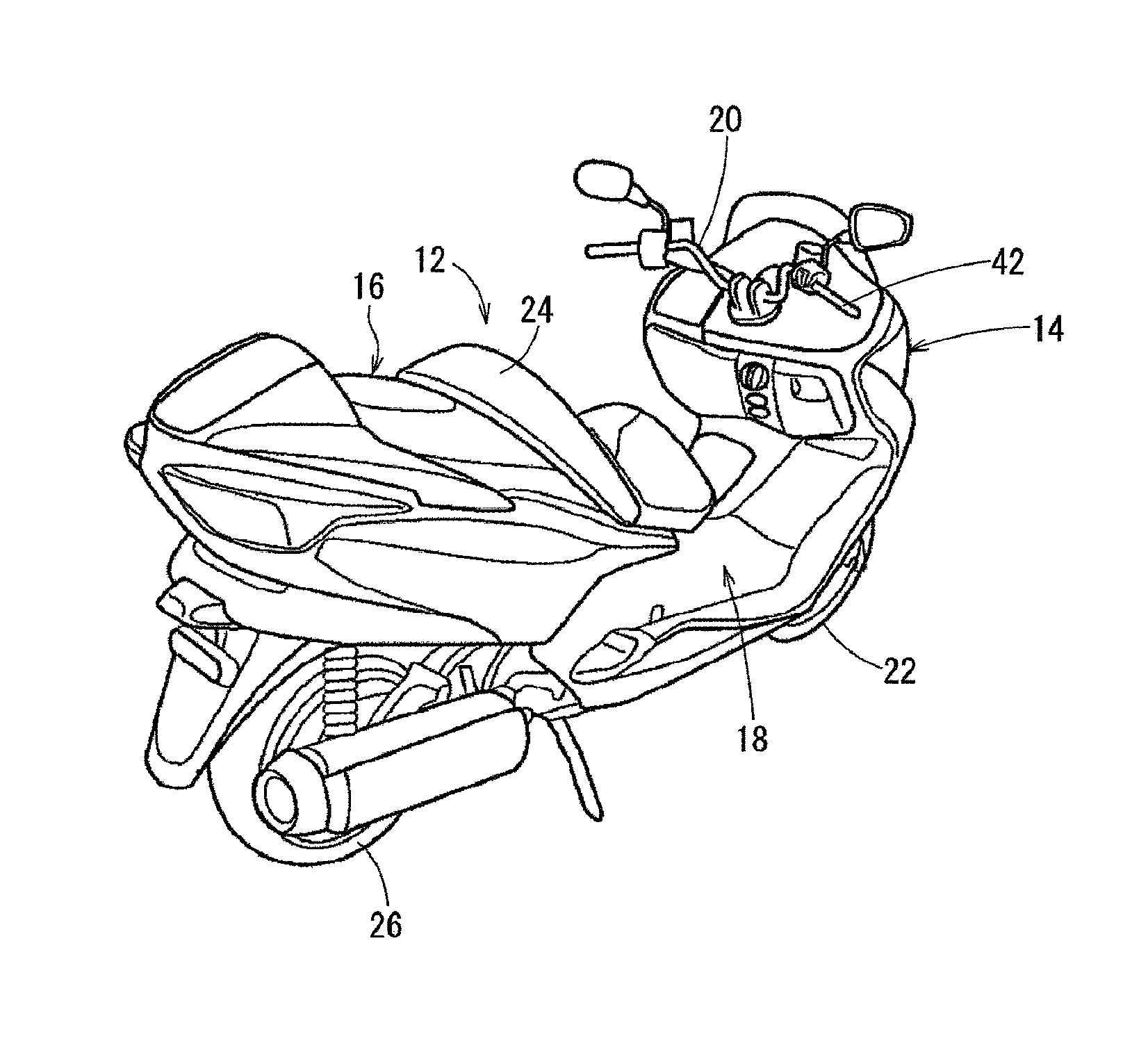

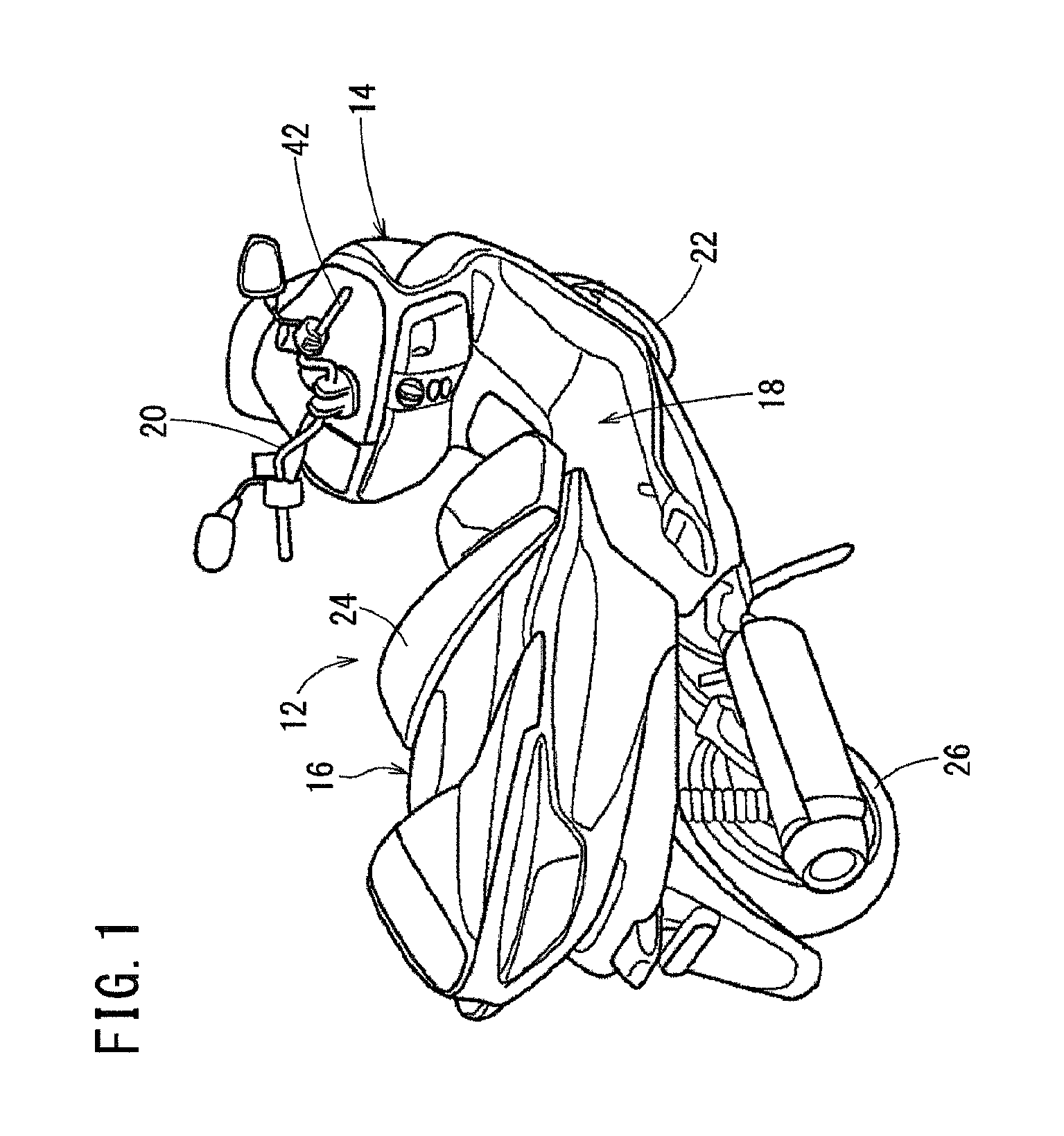

Vehicle having system and method of diagnosing secondary air injection apparatus

A system and a method of diagnosing a secondary air injection apparatus may include an intake line supplying air to an engine, an exhaust line exhausting exhaust gas, a secondary air injection (SAI) line branching off at a branch point of the intake line and being joined to the exhaust line at a joining point of the exhaust line, a first pressure sensor mounted at the intake line to detect pressure or amount of intake air flowing through the intake line, a catalytic converter, a first oxygen sensor mounted at the exhaust line, an SAI pump mounted at the SAI line and pumping the air flowing through the intake line to the SAI line, an SAI valve mounted at the SAI line and selectively communicating the SAI line with the exhaust line, and a control portion controlling the SAI pump and the SAI valve to perform catalyst heating.

Owner:HYUNDAI MOTOR CO LTD +1

Urea-based mixing process for increasing combustion efficiency and reduction of nitrogen oxides (NOx)

InactiveUS20070003890A1Reduce the formation of nitrogen oxidesNitrogen compoundsUsing liquid separation agentNitrogen oxidesEngineering

A method for reducing NOx formation, including the steps of: providing a furnace with a plurality of secondary air injection ducts, asymmetrically positioned in an opposing manner; injecting fuel with primary air through a first stage prior to injection of a second air; injecting secondary air and aqueous urea solution through the plurality of reagent injection ducts; controlling the asymmetrical injection to produce a high velocity mass flow and a turbulence resulting in dispersion of the urea solution into the combustion space, thereby providing reduced NOx formation in the combustion process.

Owner:THE POWER IND GRP

Octane separation system and operating method

InactiveUS9121355B2Reduce weightReduce spacingElectrical controlInternal combustion piston enginesAtmospheric airFuel tank

An engine method, comprising delivering high octane fuel to a high octane fuel tank and delivering low octane fuel to a low octane fuel tank and injecting atmospheric air into an exhaust system for secondary air injection in response to delivering low octane fuel to an engine.

Owner:FORD GLOBAL TECH LLC

Gas turbine combustion chamber with pre-mixing low-swirl nozzle

PendingCN107013942AReduce the temperatureSimple structureContinuous combustion chamberCombustion chamberGas turbines

The invention discloses a gas turbine combustion chamber with a pre-mixing low-swirl nozzle. The gas turbine combustion chamber comprises a combustion chamber shell and a combustion barrel arranged in the combustion chamber shell, and an air inlet cavity is formed between the combustion chamber shell and the combustion barrel; the front end of the air inlet cavity is closed, and the rear end of the air inlet cavity is provided with an air inlet; a swirl area internally provided with a swirler, an injection part with the head provided with injection holes and a barrel body part are sequentially arranged in the combustion barrel from front to back; and the barrel body part is divided into a rear mixing area with the outer wall provided with mixing holes and a front main combustion area with the outer wall provided with cooling holes, and the main combustion area is close to one side of the injection part. According to the gas turbine combustion chamber with the pre-mixing low-swirl nozzle, stable and clean combustion can be achieved, the temperature of the combustion chamber is lowered, and the combustion chamber is lowered; meanwhile, the number of strong backflow areas is reduced, the retaining time of combustion products at high-temperature areas is shortened, and thus forming of thermal NOx is reduced, and NOx emission is reduced; and the structure of the combustion chamber is simplified, and primary and secondary air injection holes are decreased.

Owner:DALIAN MARITIME UNIVERSITY

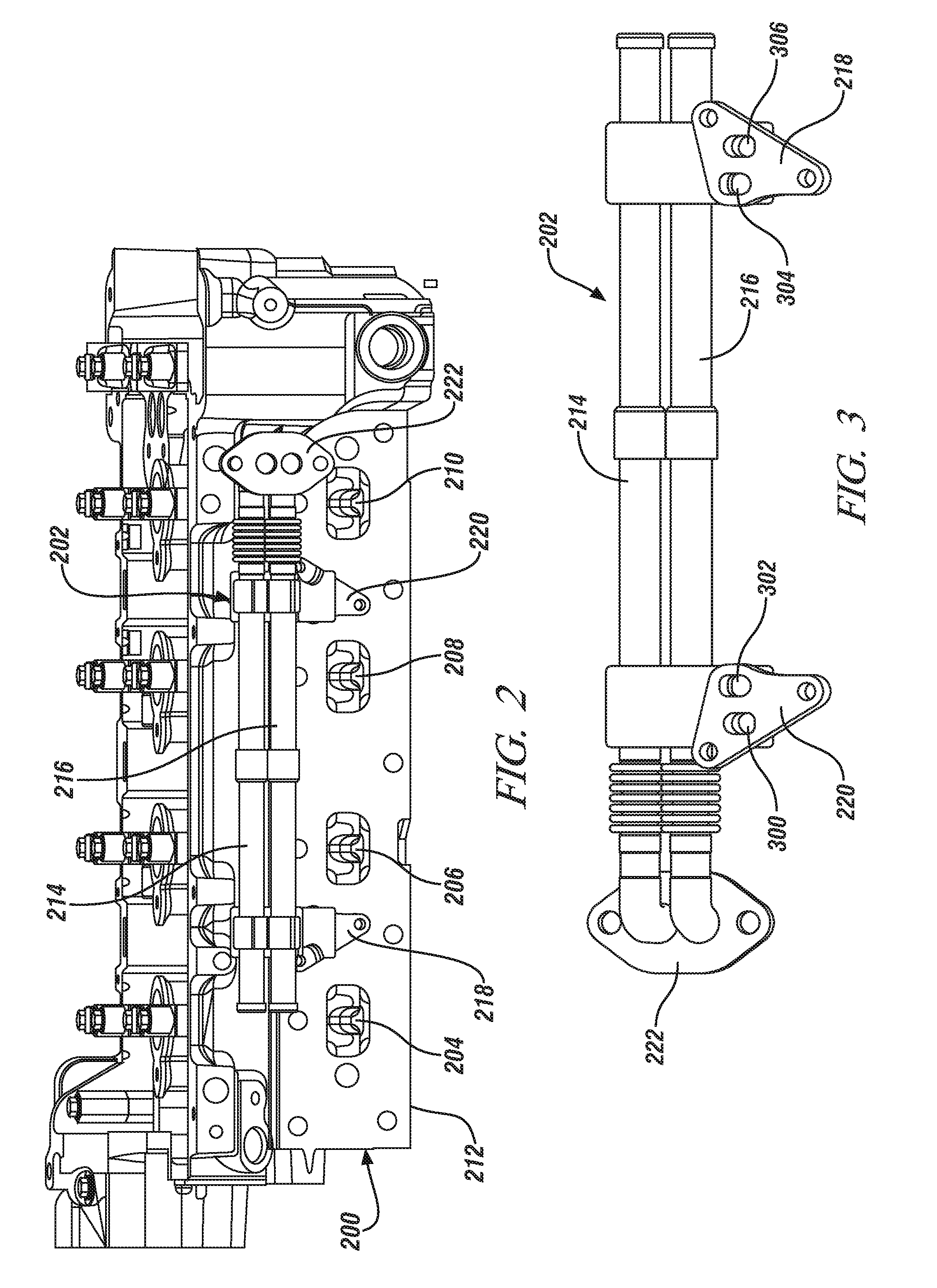

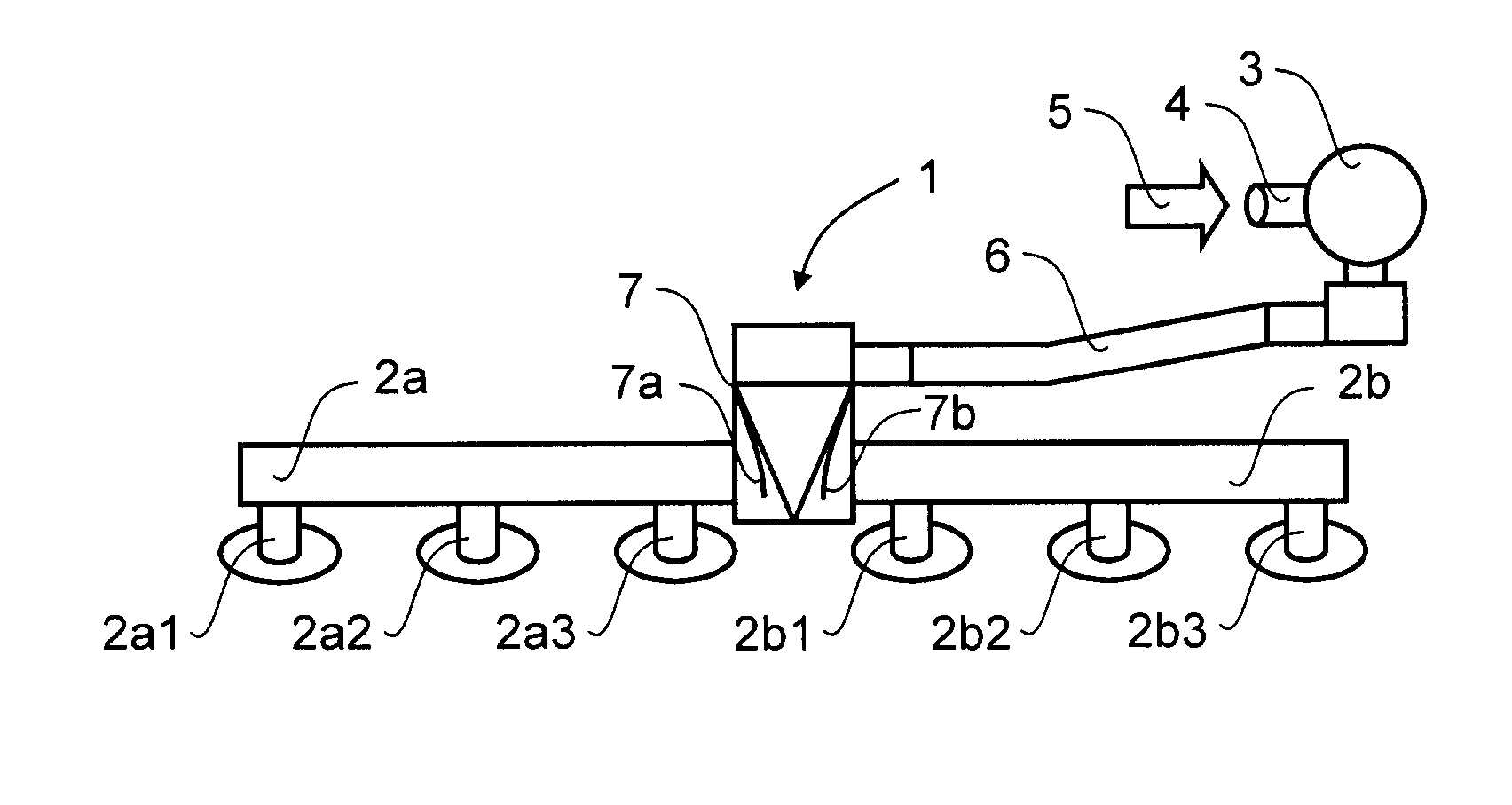

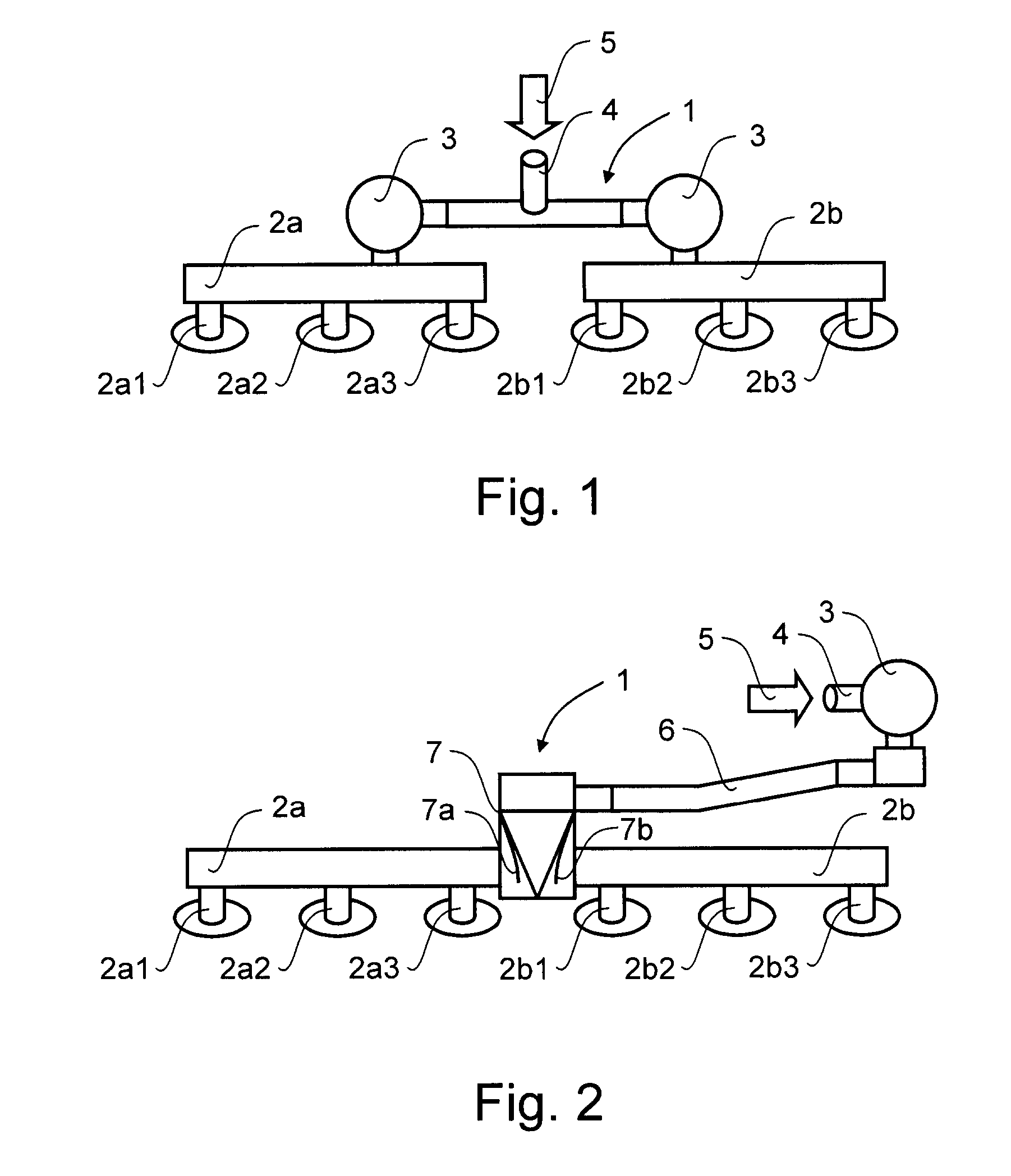

Secondary air injection system for an internal combustion engine

InactiveUS20070068145A1Less-costly and complex to manufactureEasy to operateInternal combustion piston enginesExhaust apparatusRestricted AirflowInternal combustion engine

The present invention relates to a secondary air injection system for an internal combustion engine, and an automotive vehicle comprising such a secondary air injection system. The arrangement includes shut-off valve for selectively passing on or restricting airflow form the secondary air injection system. A flexible connector is arranged to receive the airflow and pass it on to at least two reed-type non-return valves arranged to substantially only allow airflow in the downstream direction. At the downstream side of each respective reed-type non-return valve a conduit for communicating any airflow passed there through to an associated exhaust bank of the internal combustion engine.

Owner:VOLVO CAR CORP

Method and system for particulate filter regeneration

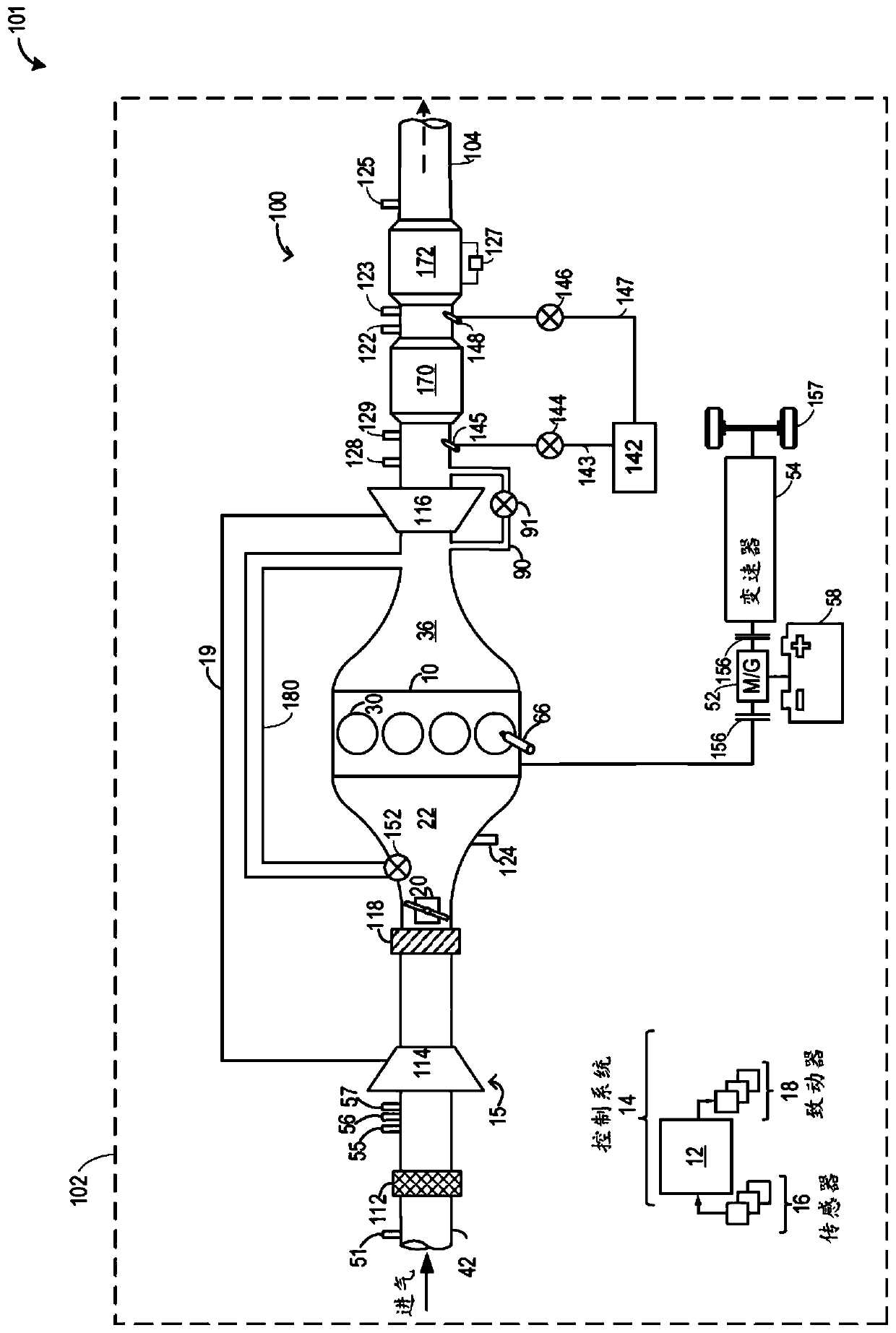

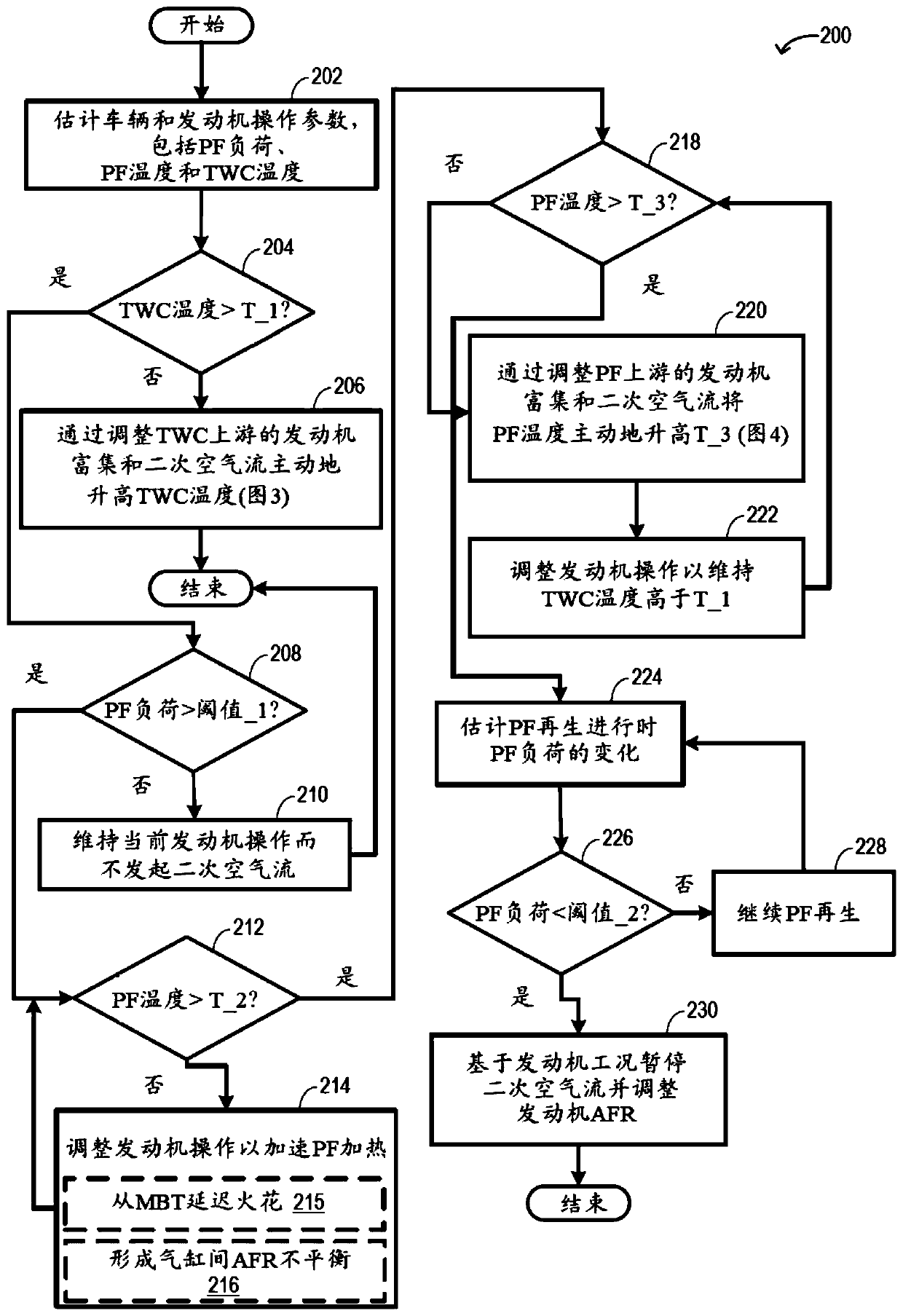

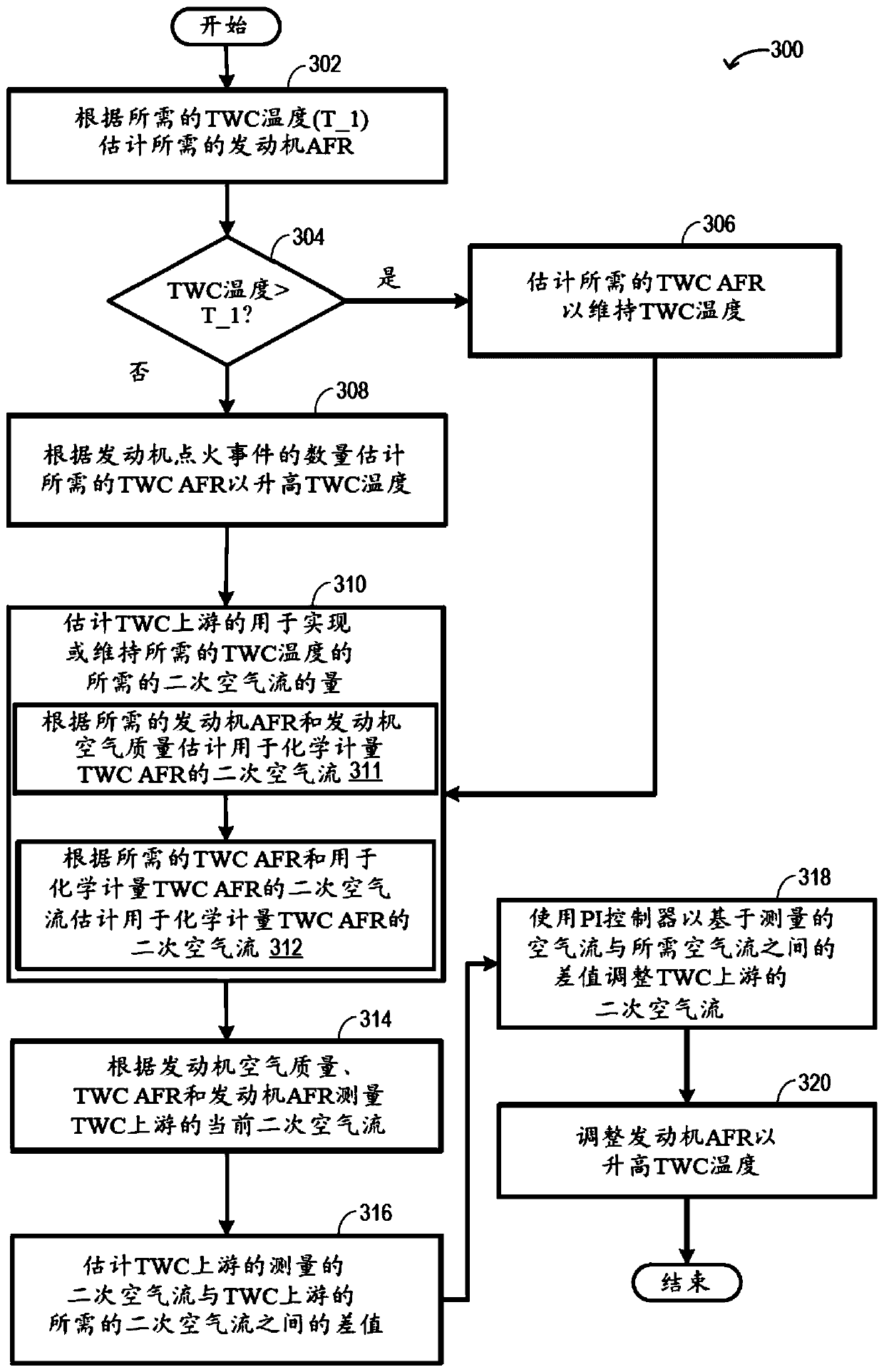

PendingCN110469386AShorten the timeIncrease heat releaseElectrical controlInternal combustion piston enginesParticulatesEngineering

The present disclosure provides methods and systems for particulate filter regeneration. Methods and systems are provided for heating an exhaust particulate filter (PF) to enable filter generation. Inone example, a method may include adjusting engine air fuel ratio and injecting secondary air flow upstream of the PF to increase PF temperature. The level of engine air fuel ratio adjustment and theamount of secondary air injection upstream of the PF may be adjusted to account for enrichment induced cooling at a three-way catalyst (TWC) positioned upstream of the PF.

Owner:FORD GLOBAL TECH LLC

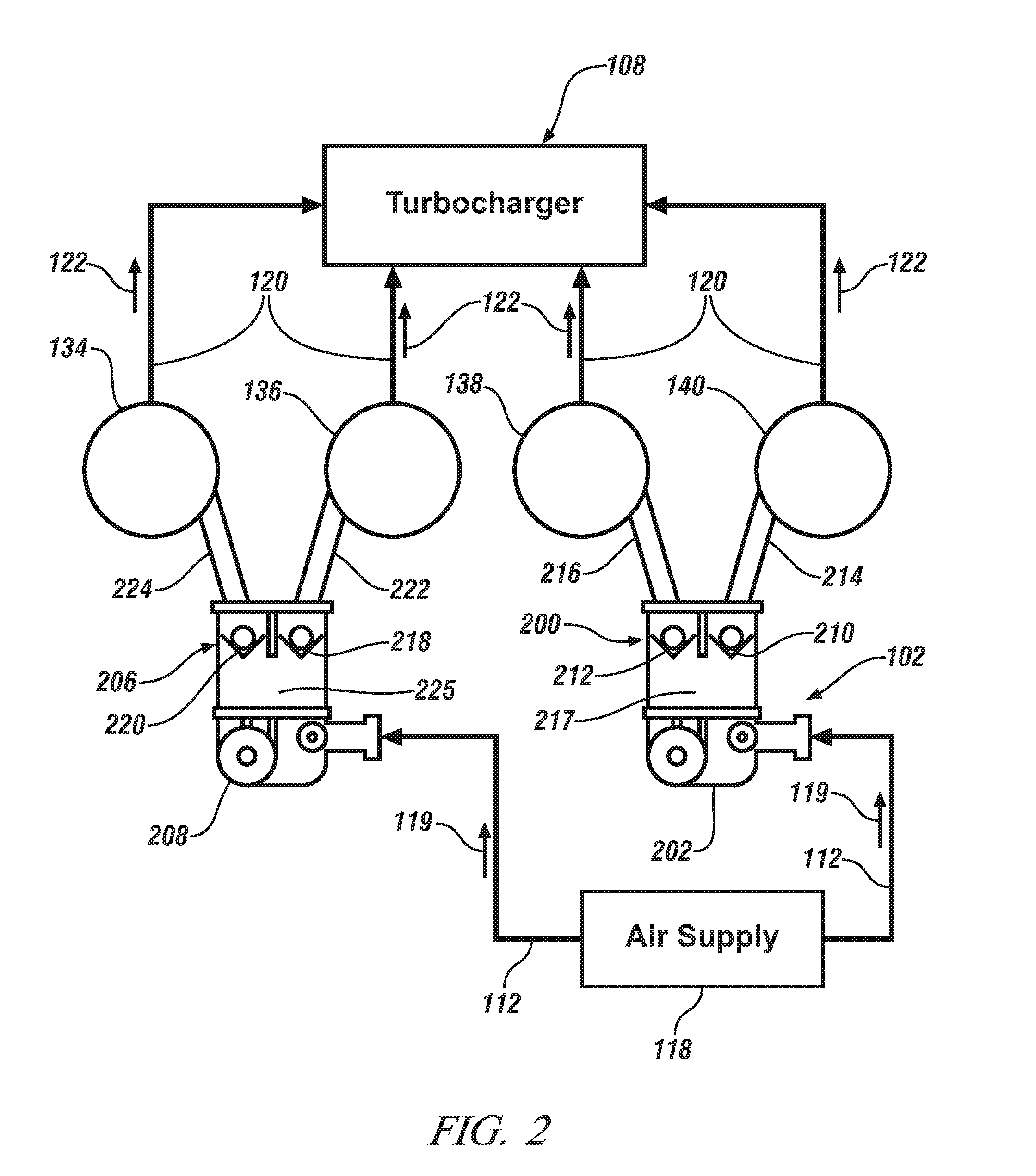

Secondary air injection system and method

According to one embodiment of the invention, an internal combustion engine includes a first exhaust port in a cylinder head of the internal combustion engine, a first one way valve coupled to a secondary air system, the first one way valve configured to restrict fluid communication from the first exhaust port to the secondary air system. The engine also includes a second exhaust port in the cylinder head and a second one way valve coupled to the secondary air system, the second one way valve configured to restrict fluid communication from the second exhaust port to the secondary air system, wherein the first and second exhaust ports are in fluid communication with a turbocharger.

Owner:GM GLOBAL TECH OPERATIONS LLC

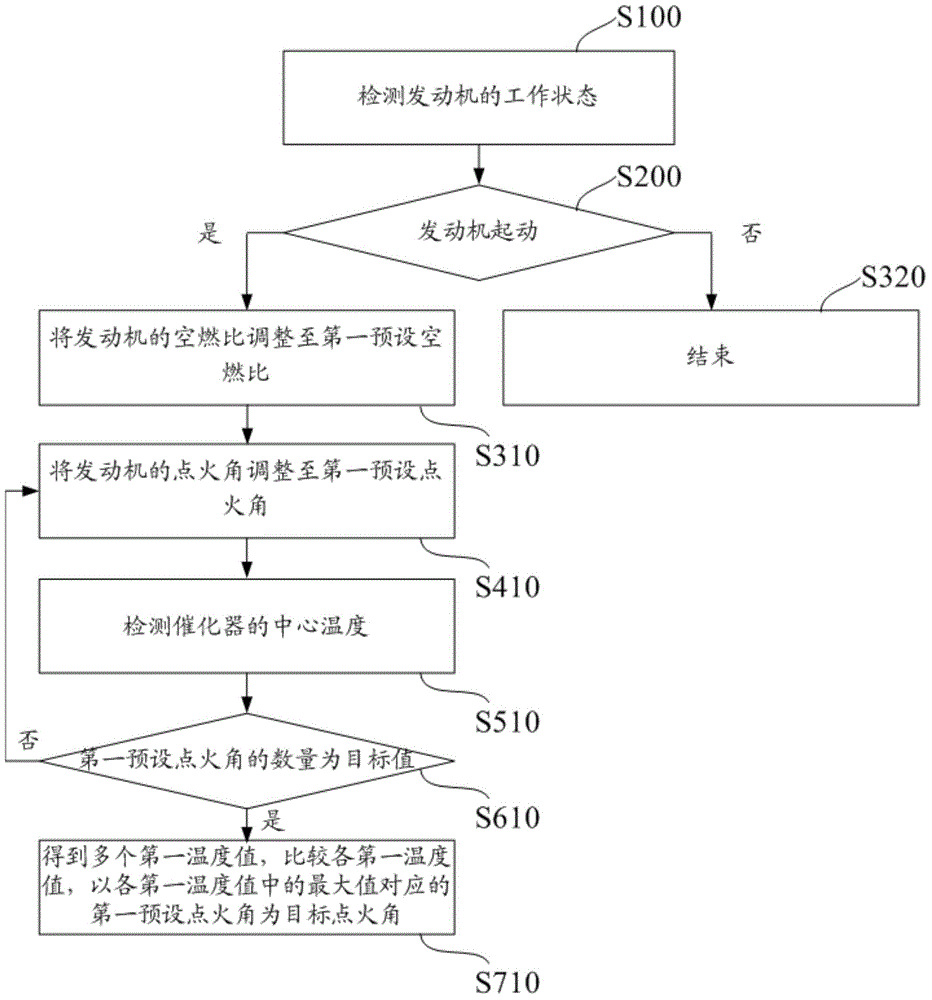

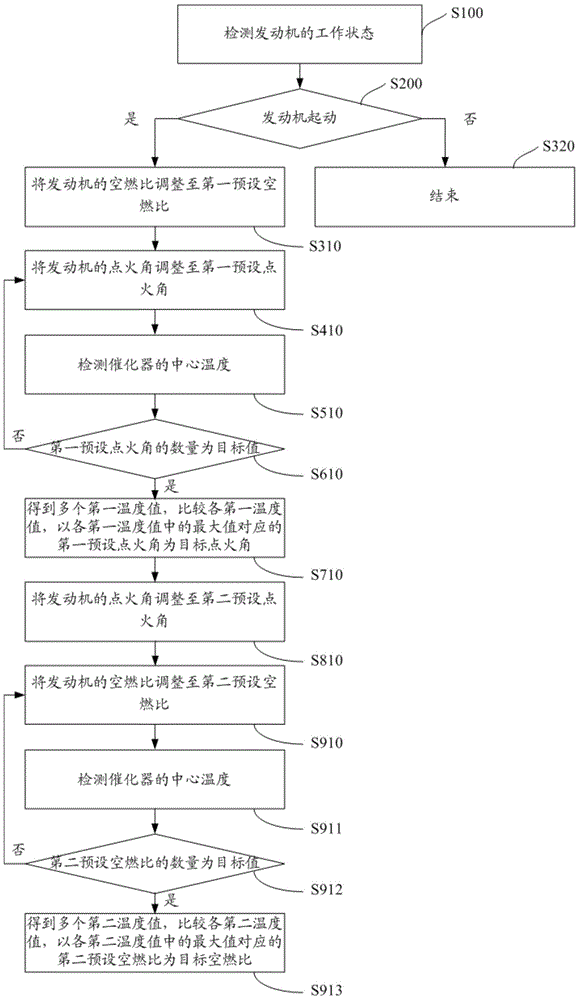

Combustion parameter adjusting method and combustion parameter adjusting device of supercharged engine

ActiveCN104533646AEasy to handleReduce adverse effectsElectrical controlMachines/enginesEngineeringAir–fuel ratio

The invention discloses a combustion parameter adjusting method of a supercharged engine. The combustion parameter adjusting method is applied to the supercharged engine with a secondary air injection system. The method comprises the following steps that firstly, whether the engine is started or not is detected, and if yes, the second step is executed; secondly, the air-fuel ratio of the engine is adjusted to a first preset air-fuel ratio; thirdly, the ignition angles of the engine are adjusted to first preset ignition angles; fourthly, the center temperature of a catalyst is detected; fifthly, the third step and the fourth step are circularly executed so that a plurality of first temperature values corresponding to the different first preset ignition angles in a one-to-one corresponding mode can be obtained; sixthly, the first temperature values are compared so that the first preset ignition angle corresponding to the maximum value in the first temperature values is the target ignition angle. According to the combustion parameter adjusting method, the adverse effect of exhaust of the supercharged engine to the environment can be relieved. The invention further discloses a combustion parameter adjusting device of the supercharged engine.

Owner:ANHUI JIANGHUAI AUTOMOBILE GRP CORP LTD

Exhaust emission purification control device for engine

ActiveUS20140294678A1Accurate estimateElectrical controlInternal combustion piston enginesPtru catalystReduction treatment

An exhaust emission purification control device for an engine that accurately estimates an accumulated oxygen amount of a catalyst at a terminating time of a reduction treatment using a simple method. An exhaust emission purification control device for an engine includes a secondary air injector that injects secondary air within an exhaust path. An O2 sensor detects an air-fuel ratio in a downstream side of a catalyst. A count-value accumulator estimates an accumulated oxygen amount (a count value) in the catalyst during the secondary air injection. A rich spike controller performs rich injection after the secondary air injection. This device includes a count-value corrector that multiplies the count value after the secondary air injection by a correction coefficient derived from an output value SVO2 of the O2 sensor during termination of reduction treatment, so as to estimate the accumulated oxygen amount during the termination of the reduction treatment.

Owner:HONDA MOTOR CO LTD

Internal combustion engine having an exhaust gas system

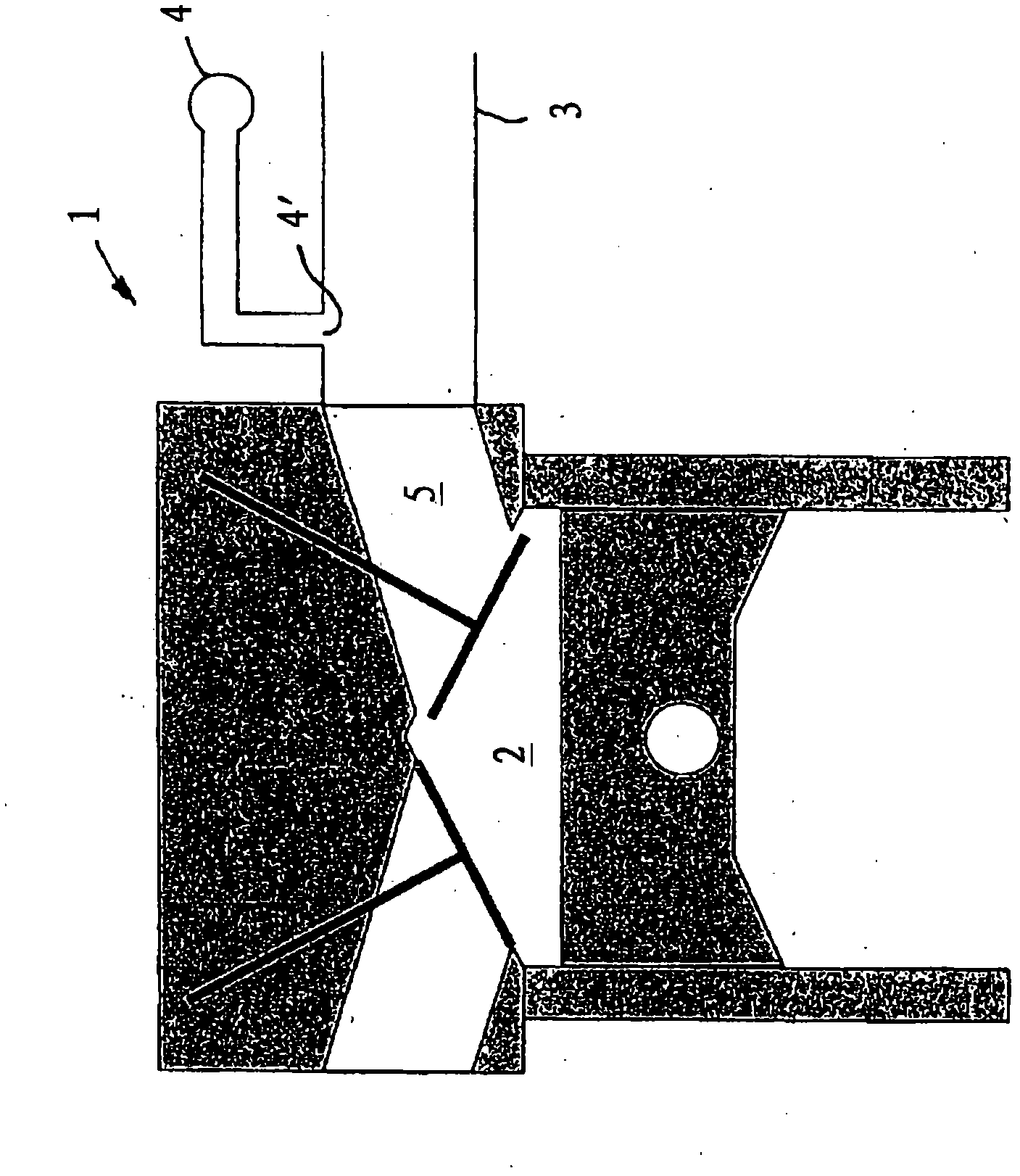

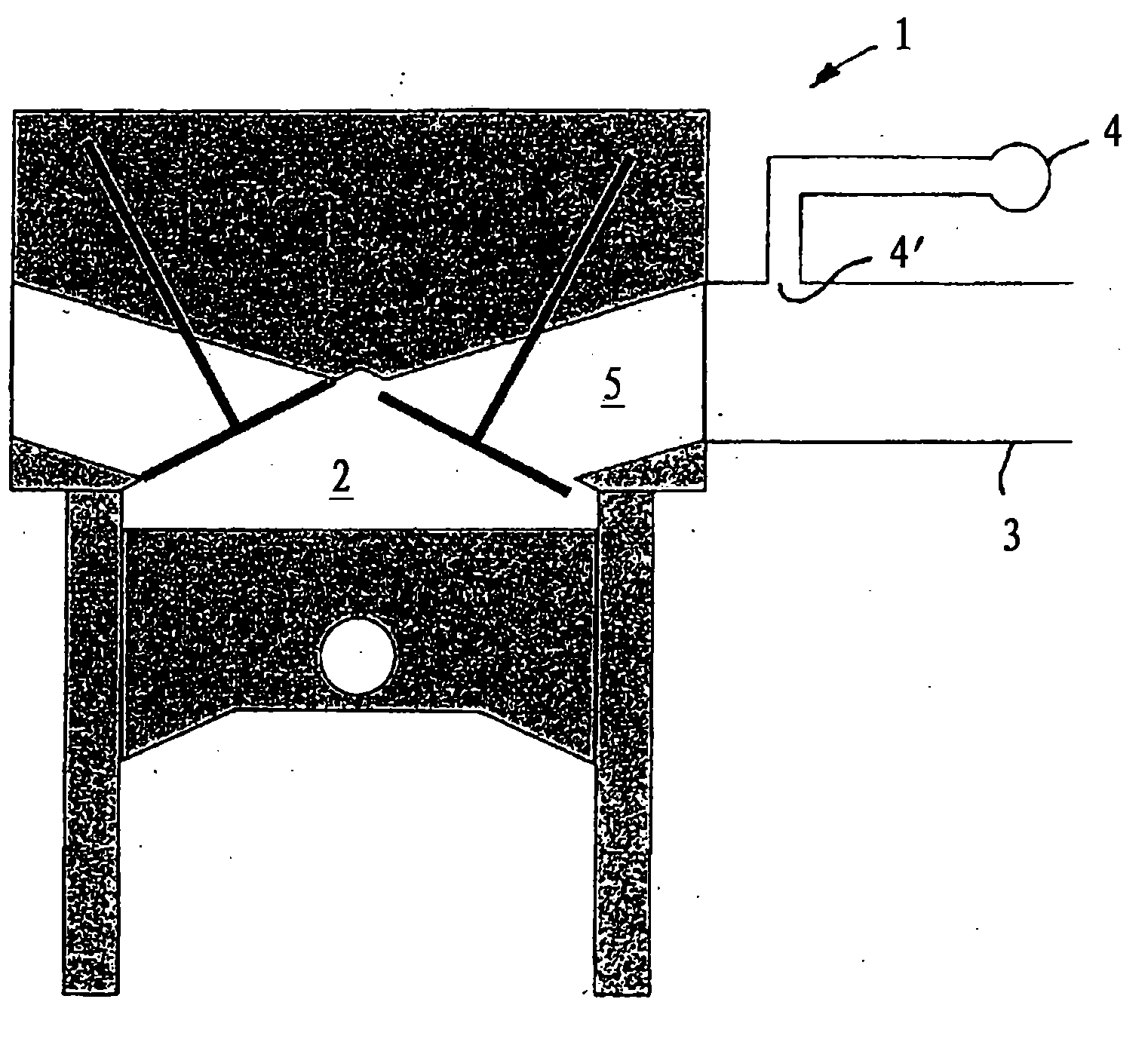

InactiveCN102656346AReduce exhaust back pressureReduce loadElectrical controlNon-fuel substance addition to fuelCombustion chamberTurbocharger

The invention relates to an internal combustion engine (1), comprising at least one combustion chamber (2) and an exhaust gas system (3) arranged on an exhaust gas outlet channel (5), the exhaust gas system having at least one secondary air injection device (4) for injecting secondary air into the exhaust gas system (3) between the combustion chamber (2) and an exhaust emission control system (5) arranged in the exhaust gas system (3), wherein during operation of the internal combustion engine (1), a residual gas content in the combustion chamber (2) can be changed, and a secondary air injection point (4') on the exhaust gas system (3) is arranged so far from the combustion chamber (2) that injected secondary air flows back into the exhaust gas outlet channel (5) due to backflowing exhaust gas in the exhaust gas system (3) but does not flow back into the combustion chamber (2). The embodiment according to the invention makes it possible to comply with SULEV emissions limits even for engines having many combustion chambers and / or exhaust gas turbochargers, for which a SULEV certification previously seemed impossible.

Owner:BAYERISCHE MOTOREN WERKE AG

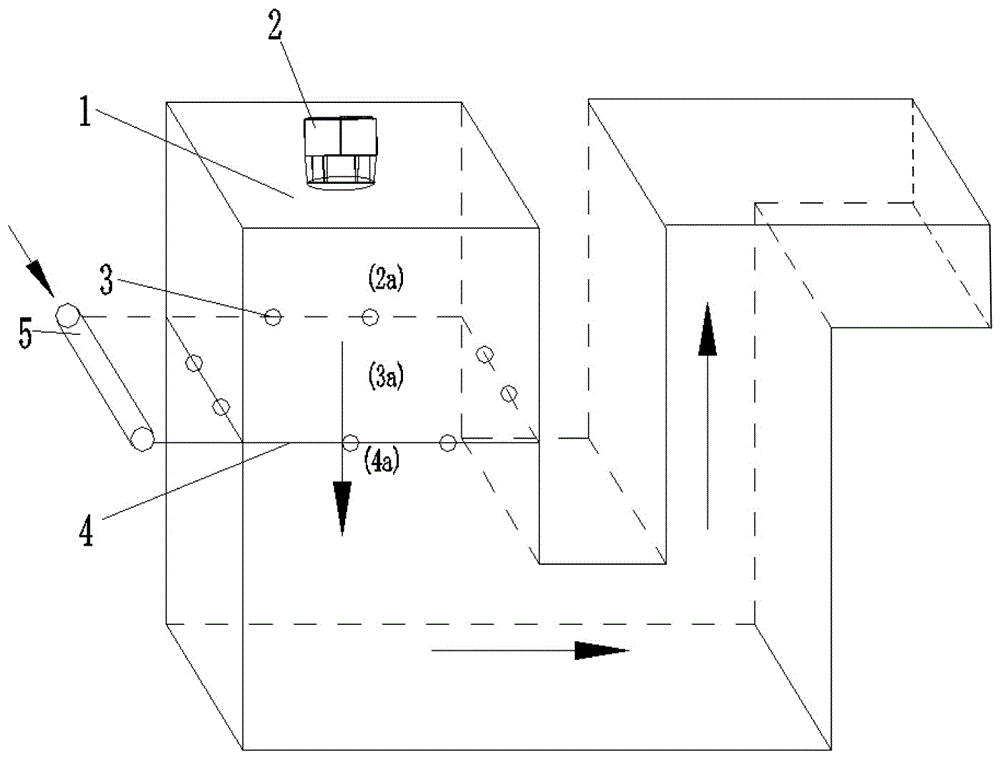

Secondary air gas-fired boiler combustor and configuration method of secondary air

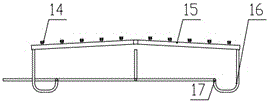

PendingCN106439815AReduce generationAvoid burnsNon-combustible gases/liquids supplyGaseous fuel burnerCombustorFlue gas

The invention relates to a secondary air gas-fired boiler combustor and a configuration method of secondary air, and belongs to the technical field of gas-fired boiler emission reduction. The technical aims that NOx emissions are reduced through a gas-fired boiler, and meanwhile the heat efficiency of the boiler is not reduced are achieved. The secondary air gas-fired boiler combustor is characterized in that an inner cavity of a hearth is sequentially divided into a main combustion area, a secondary air injection area and an after-combustion area in the flue gas flowing direction starting from a gas combustor; the distance between the main combustion area and the gas combustor ranges from 0 m to 1 m, and 70%-95% of the air volume is supplied by the gas combustor; and the distance between the secondary air injection area and the gas combustor ranges from 1 m to 9 m, the furnace wall of the hearth is provided with a plurality of secondary air nozzles connected with a secondary air conveying pipeline, and 5%-30% of the air volume is supplied by the secondary air nozzles. The secondary air gas-fired boiler combustor has the beneficial effects that the secondary air nozzles are formed in the downstream portion of the gas combustor, the combustion temperature of the main combustion area is reduced, the reducibility atmosphere of the main combustion area is made, and generated thermal NOx and generated fuel NOx are restrained; and the secondary air guarantees that gas fuel is completely combusted, and the heat efficiency of the boiler is not reduced.

Owner:SHANGHAI WISEBOND TECH

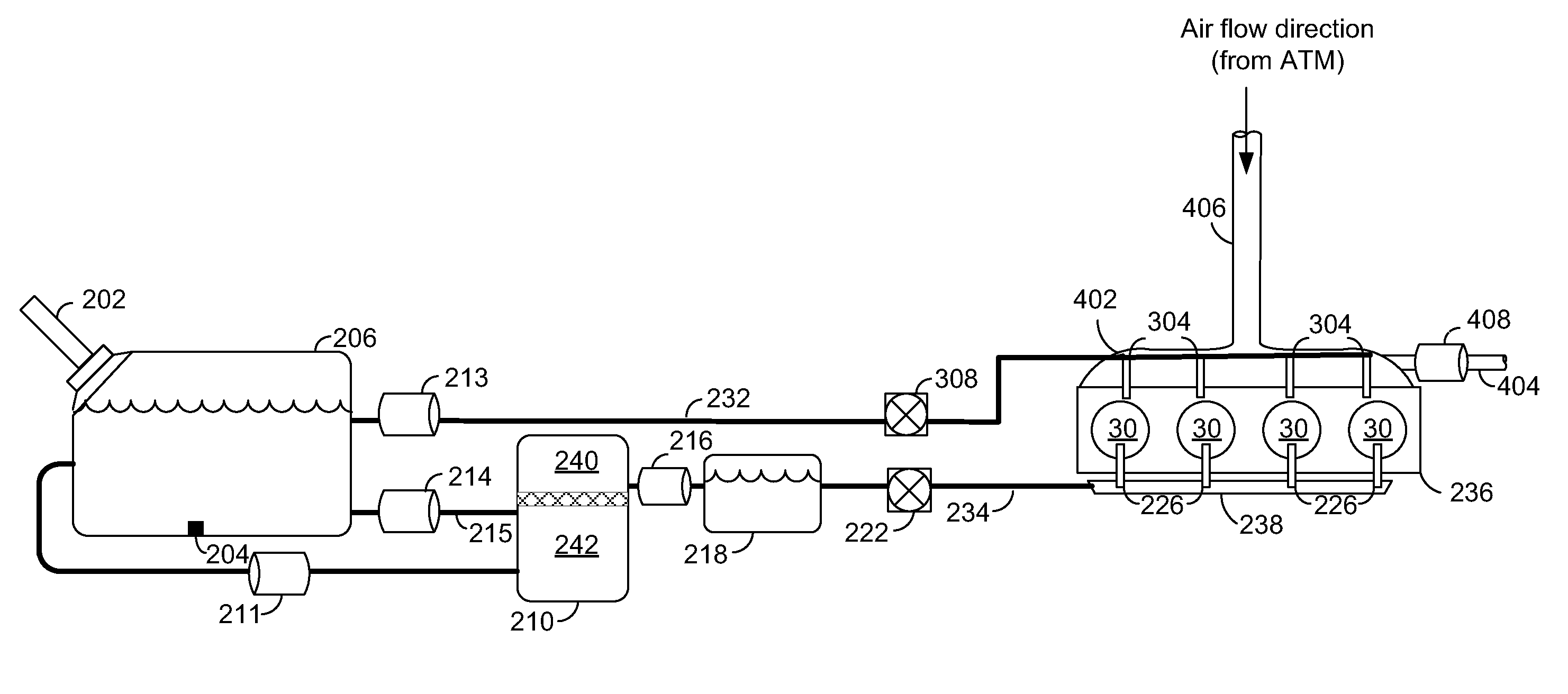

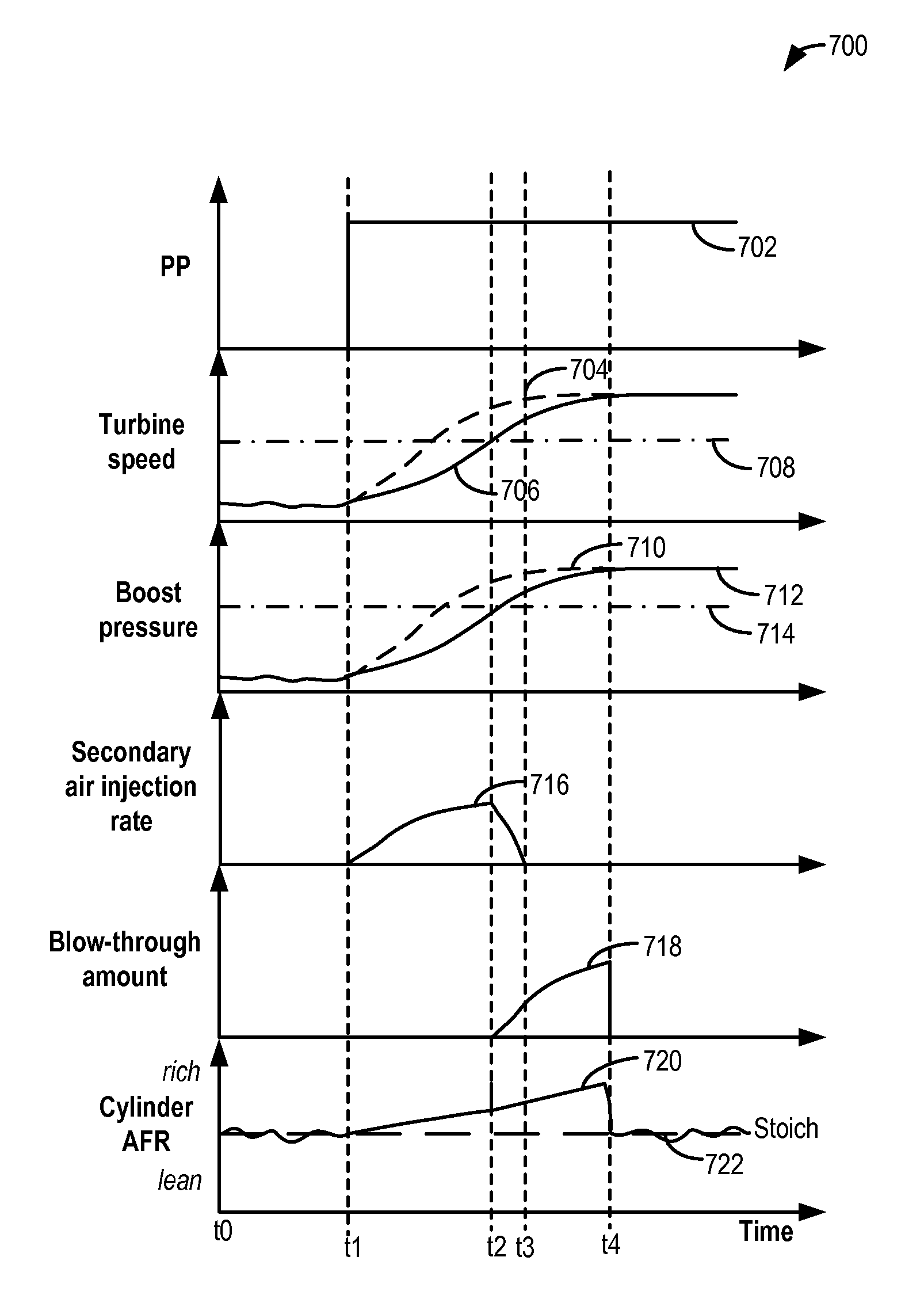

Coordination of secondary air and blow-through air delivery

Methods and systems are provided for controlling and coordinating secondary air injection and blow-through to reduce turbo lag. By utilizing secondary air injection prior to providing blow-through, and deactivating the secondary air pump when a desired boost pressure for blow-through is achieved, turbine spin-up to a desired speed may be expedited and initial torque output may be increased.

Owner:FORD GLOBAL TECH LLC

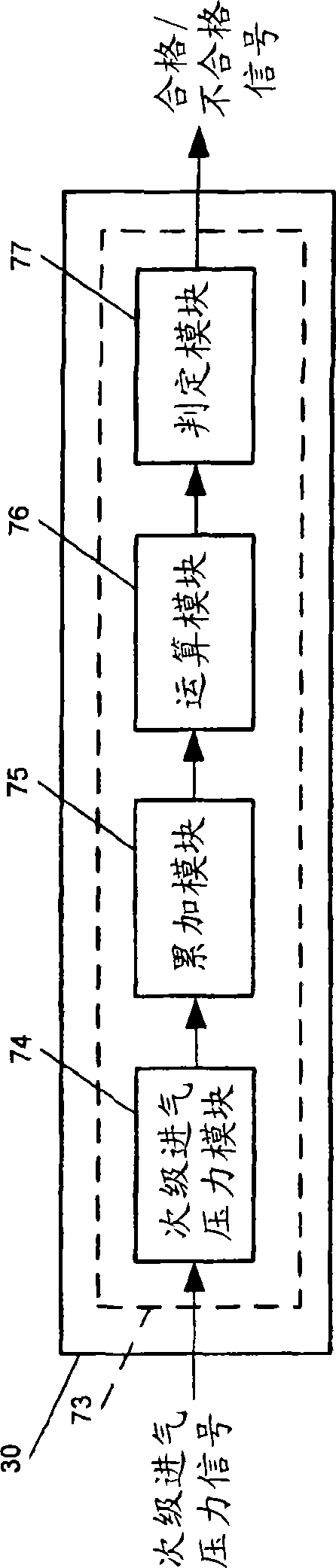

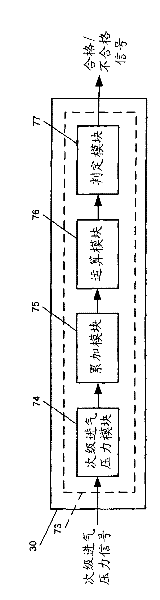

Algorithm to diagnose leaks or blockages downstream of the secondary air injection reaction (sair) pressure sensor

The invention relates to a secondary gas injection rection pressure sensor downstream leakage or block indentification algorithm. A control module and method for an exhaust system of an engine can include a secondary air intake (SAI) pressure module that monitors SAI pressure. An accumulation module can accumulate an SAI string length based on the monitored SAI pressure. A calculation module can determine an average SAI string length based on the accumulated SAI string length. A determination module can determine an operating characteristic of the vehicle exhaust based on the average SAI string length.

Owner:GM GLOBAL TECH OPERATIONS LLC

Secondary air injection system and method

According to one embodiment of the invention, an internal combustion engine includes a first exhaust port in a cylinder head of the internal combustion engine, a first one way valve coupled to a secondary air system, the first one way valve configured to restrict fluid communication from the first exhaust port to the secondary air system. The engine also includes a second exhaust port in the cylinder head and a second one way valve coupled to the secondary air system, the second one way valve configured to restrict fluid communication from the second exhaust port to the secondary air system, wherein the first and second exhaust ports are in fluid communication with a turbocharger.

Owner:GM GLOBAL TECH OPERATIONS LLC

Algorithm to diagnose leaks or blockages downstream of the secondary air injection reaction (sair) pressure sensor

The invention relates to a secondary gas injection rection pressure sensor downstream leakage or block indentification algorithm. A control module and method for an exhaust system of an engine can include a secondary air intake (SAI) pressure module that monitors SAI pressure. An accumulation module can accumulate an SAI string length based on the monitored SAI pressure. A calculation module can determine an average SAI string length based on the accumulated SAI string length. A determination module can determine an operating characteristic of the vehicle exhaust based on the average SAI string length.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com