Internal combustion engine having an exhaust gas system

一种排气系统、内燃机的技术,应用在内燃活塞发动机、排气处理、装料系统等方向,能够解决未考虑废气温度额外有利的潜能等问题,达到提高全负荷适用性和使用寿命、减少装载量、流动阻力小的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

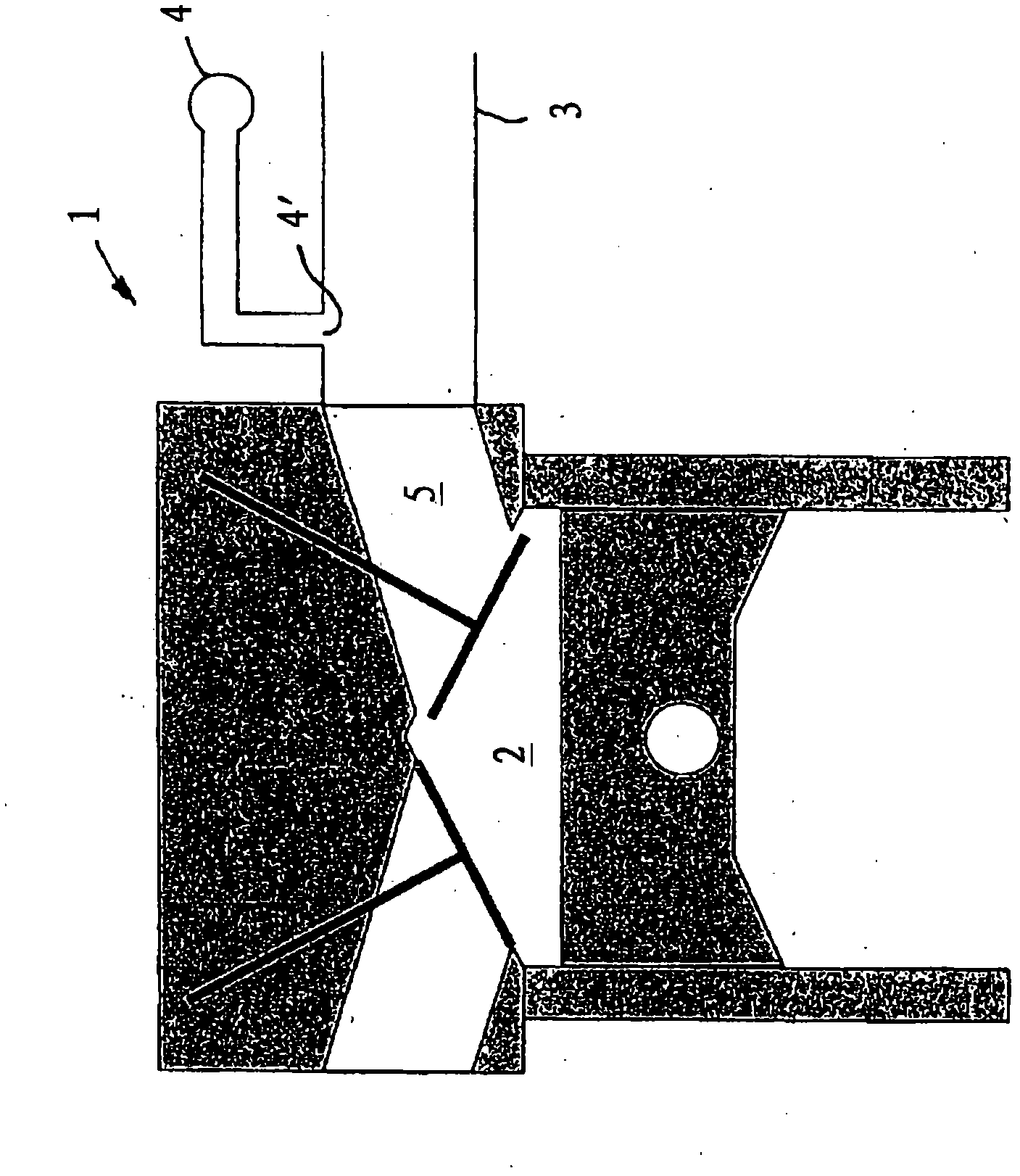

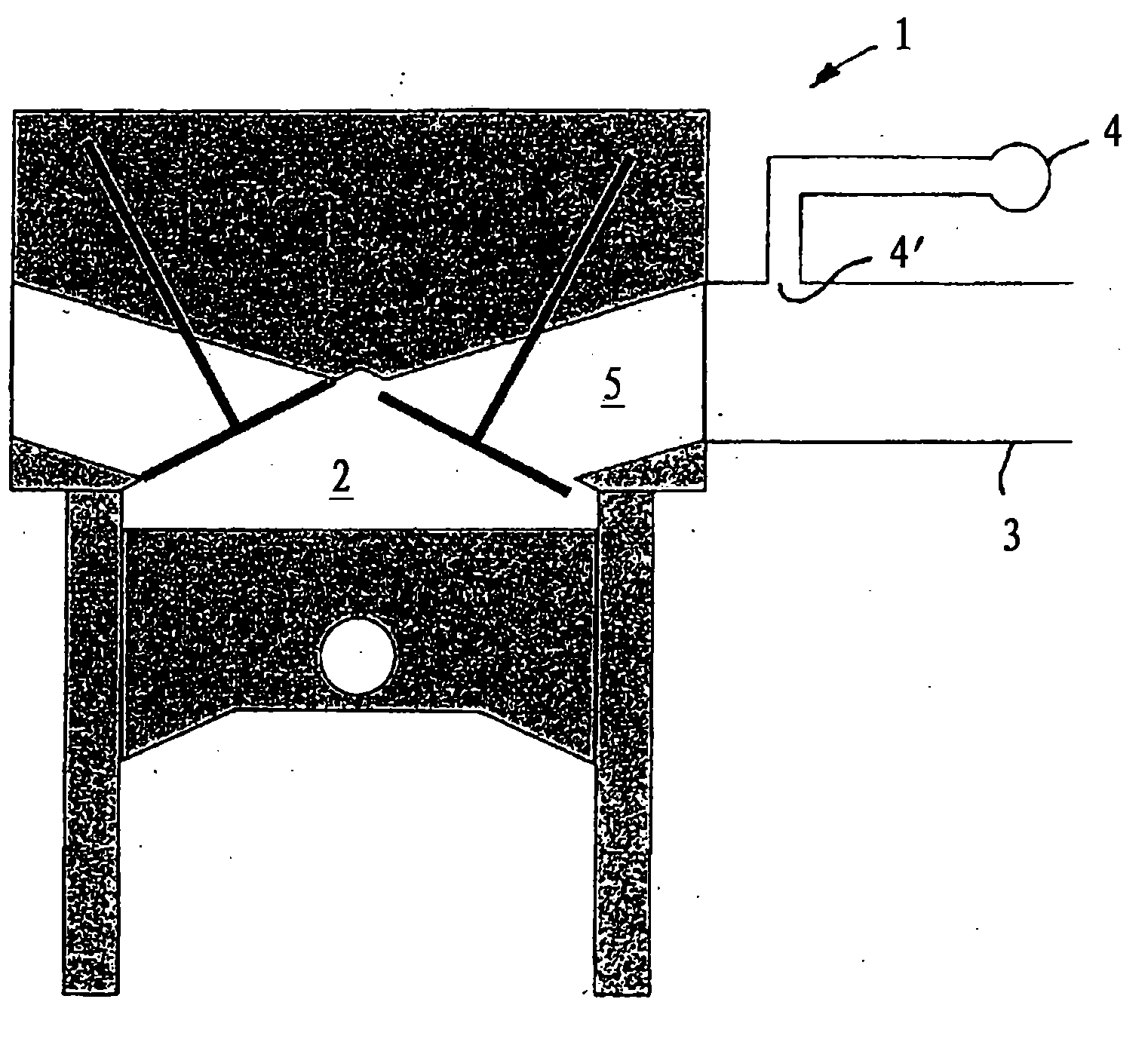

[0014] figure 1 A sectional view of a cylinder head of a SULEV internal combustion engine 1 with a section of an exhaust system 3 is shown, by means of which SULEV limit values can be observed. The combustion chambers 2 of the cylinders are arranged in the cylinder head of the internal combustion engine 1 . When the internal combustion engine 1 is running, the exhaust gas flows from the combustion chamber 2 into the exhaust gas discharge passage 5 in the cylinder head of the internal combustion engine 1 . The direction of flow of exhaust gases is indicated by arrows. Then, the exhaust gas flows into the exhaust system 3 on which the secondary air blowing device 4 is arranged. By means of this secondary air blowing device 4, fresh air (secondary air) is blown into the exhaust line 3 at a secondary air blowing position 4' to start CO and HC thermal afterburning.

[0015] According to the invention, when the internal combustion engine 1 is running and the residual gas conten...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com