Method and system for gasoline particulate filter operations

A particulate filter and filter technology, which is applied to the electrical control and electrical control of machines/engines and exhaust treatment devices, and can solve problems such as low-efficiency exhaust emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

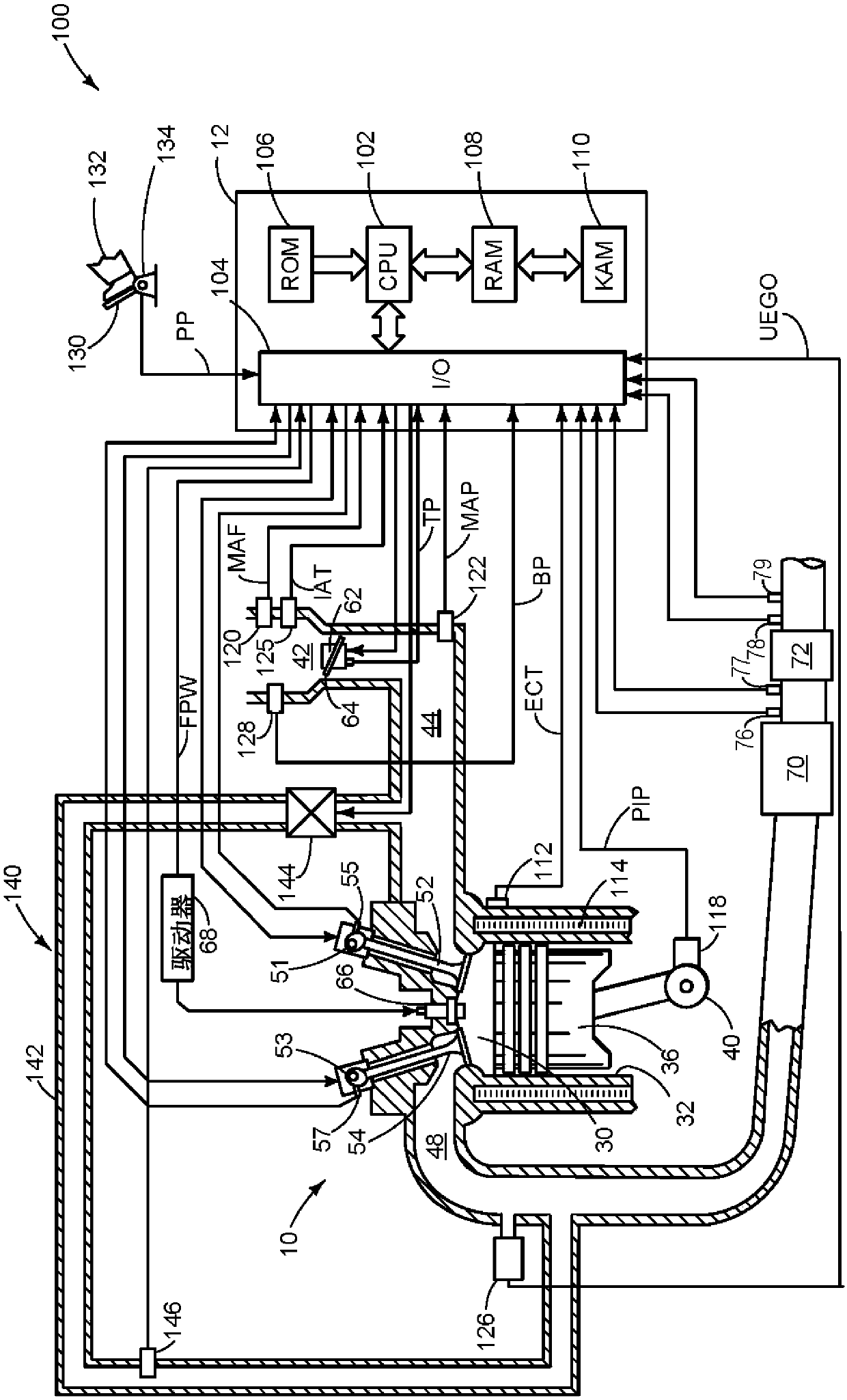

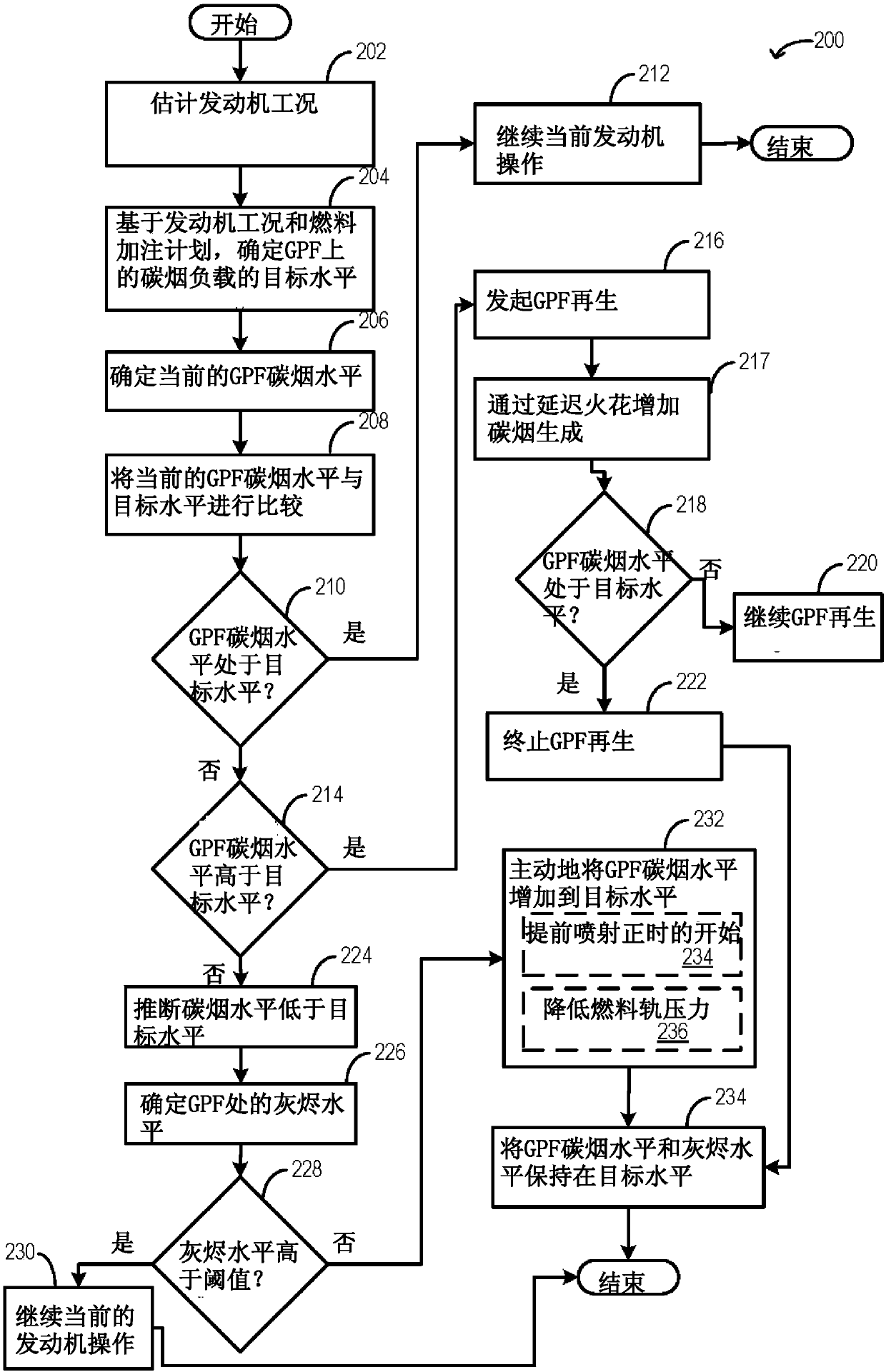

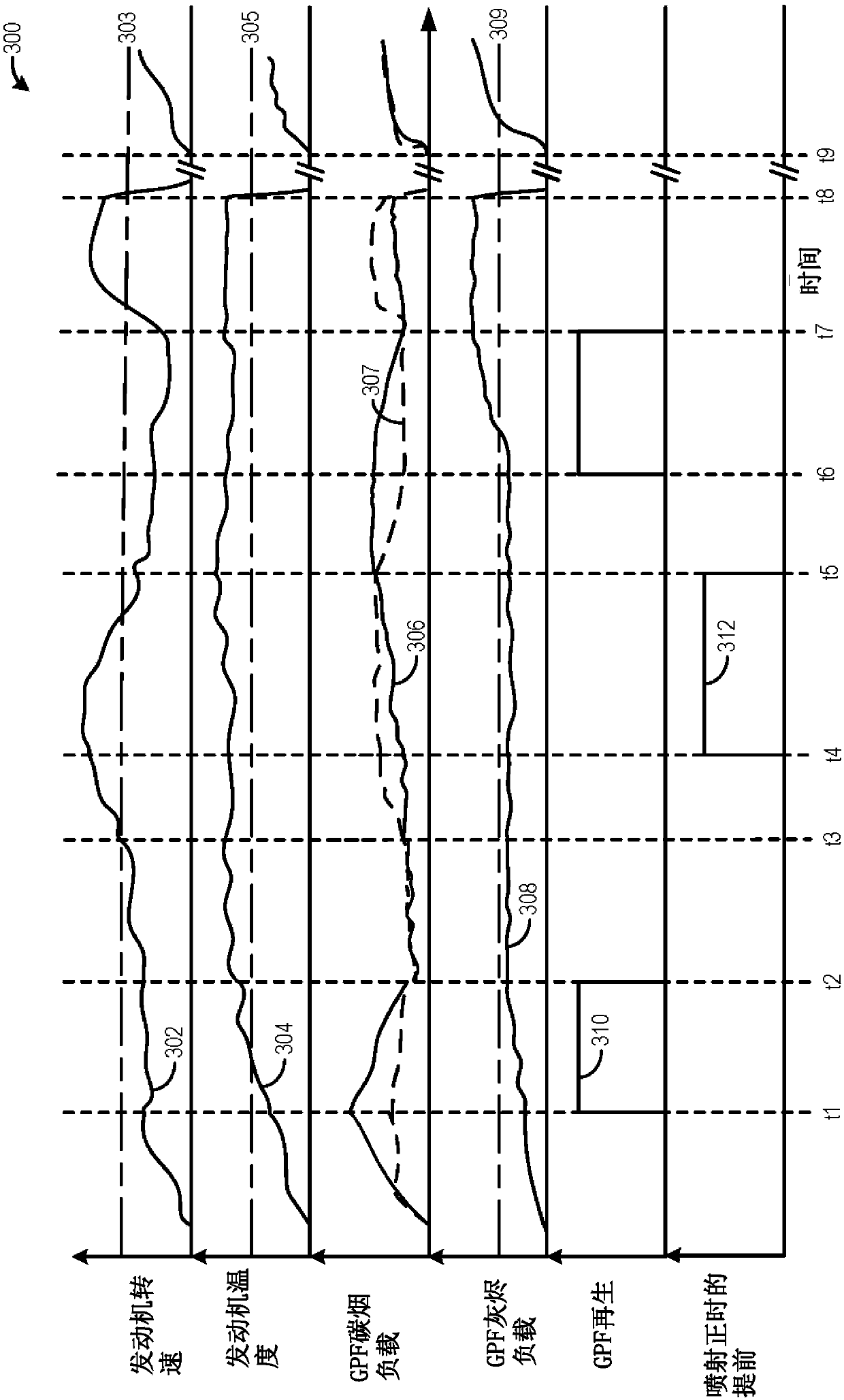

[0012] The following description relates to a system and method for maintaining a target soot level at a gasoline particulate filter (GPF) based on current engine operating conditions in order to improve emission quality. Gasoline particulate filters with lower filtration capacity can be used in engine systems, such as figure 1 shown in . The engine controller can be configured to execute control programs such as figure 2 An example routine to adjust one or more engine operating parameters to maintain desired soot and ash levels at the GPF as determined by the controller. image 3 An example of such adjustments to maintain desired soot and ash levels is shown in .

[0013] figure 1 An example embodiment of a combustion chamber or cylinder of internal combustion engine 10 is shown. Engine 10 may be controlled at least in part by a control system including controller 12 and input from a vehicle operator 130 via input device 132 . In this example, input device 132 includes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com