High oxygen-enriched bottom blowing low power consumption molten pool melting technology

A molten pool smelting and low energy consumption technology, applied in the field of high oxygen-enriched bottom blowing low energy consumption molten pool smelting technology, can solve the problems of fast loss of equipment parts, frequent repairs and maintenance, low metal capture rate, etc., and achieve saving Fuel, avoid instability and other hazards, long-range effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

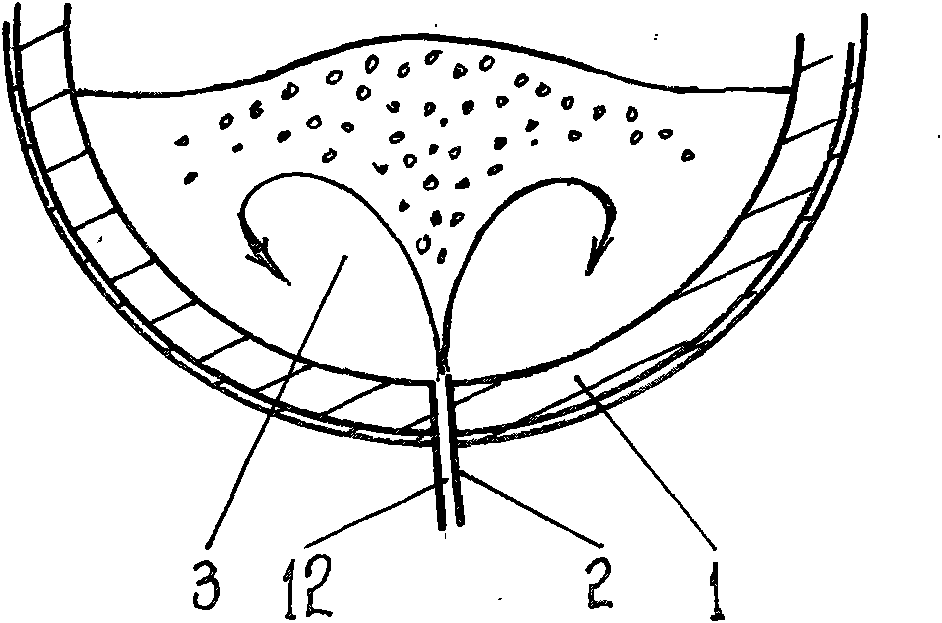

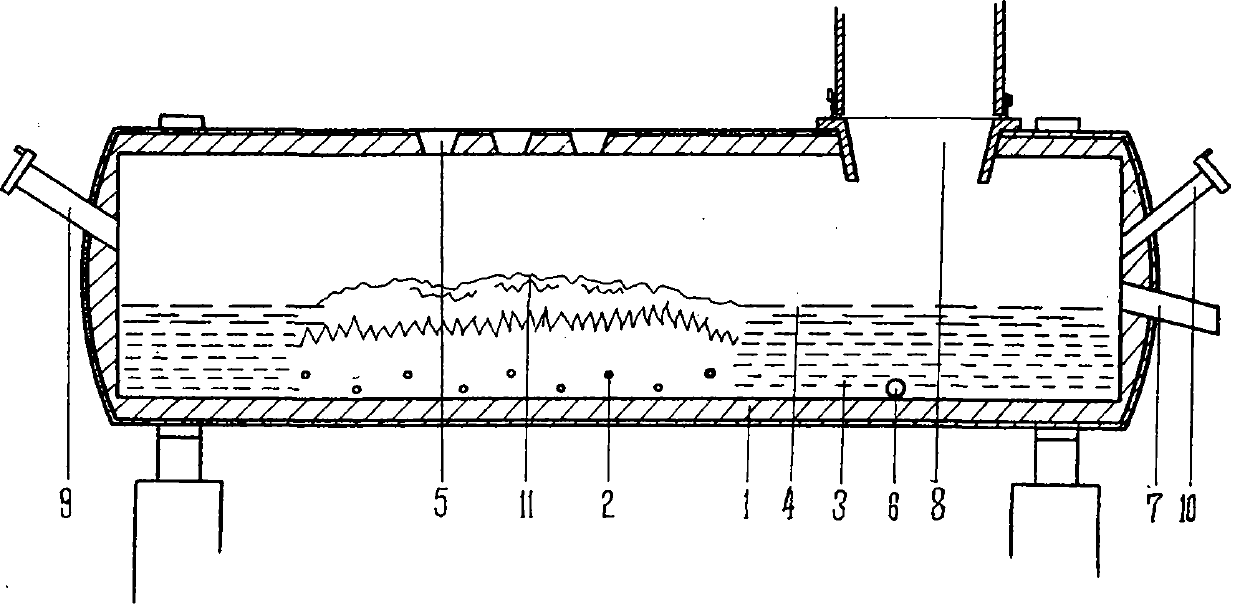

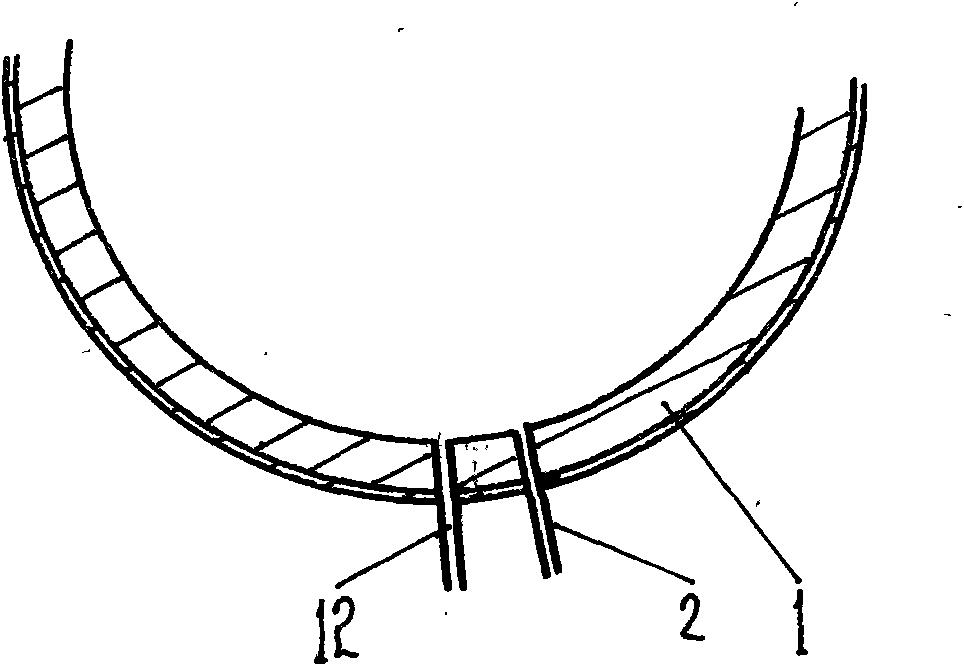

[0018] With reference to the instructions and accompanying drawings, the high-oxygen-enriched bottom-blown low-energy-consumption molten pool smelting technology of the present invention is described in detail as follows:

[0019] A high-oxygen-enriched bottom-blown low-energy molten pool smelting technology, the oxygen lances 2 are arranged in double rows vertically at a certain angle, and are arranged crosswise at the bottom of the furnace body 1 and one side within three-fifths of the end of the main burner 9, The feed port 5 is set at the upper part of the furnace body 1 corresponding to the oxygen lance 2, and the matte discharge port 6 is set at the bottom of the furnace body 1 at the end of the auxiliary burner 10. The slag outlet 7 is arranged at the middle and lower part of the end face of the furnace body 1, and the flue dust duct 8 is arranged at the upper part of the furnace body 1 at the end of the auxiliary burner 10.

[0020] The high-oxygen-enriched bottom-blow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com