Preparation method for diesel particulate filter with low back pressure and high soot filtration efficiency

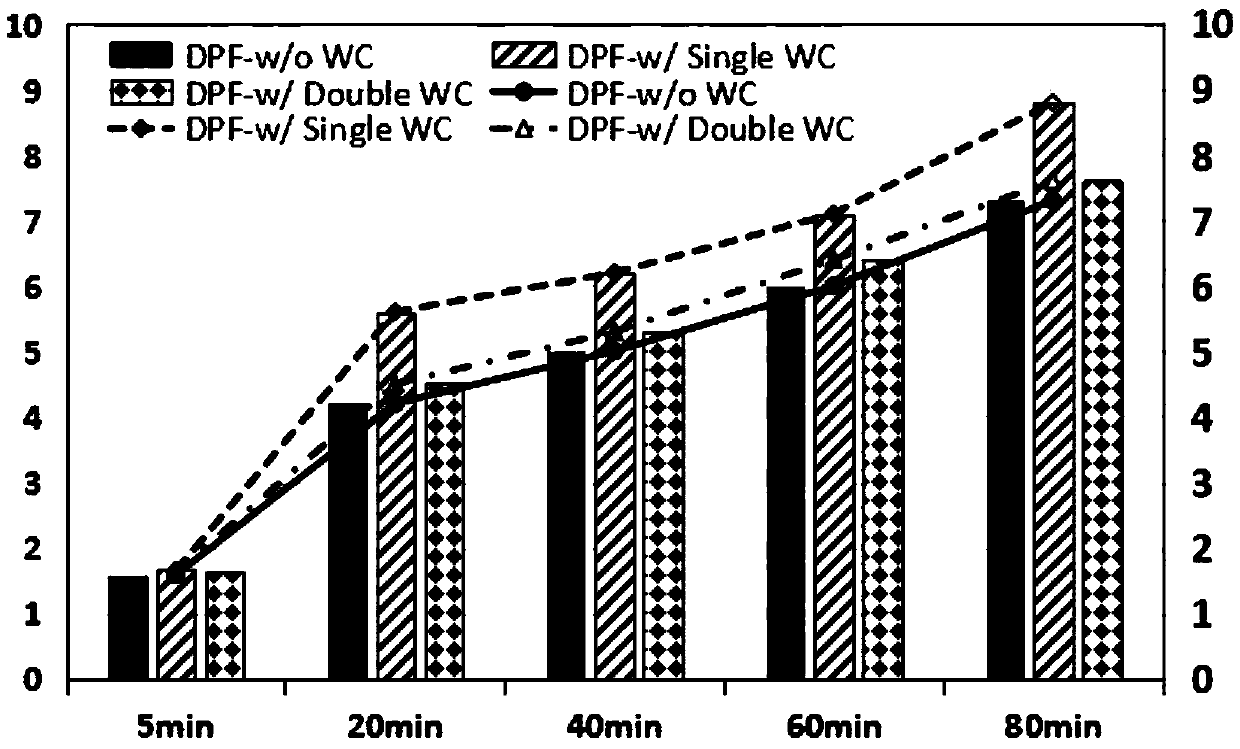

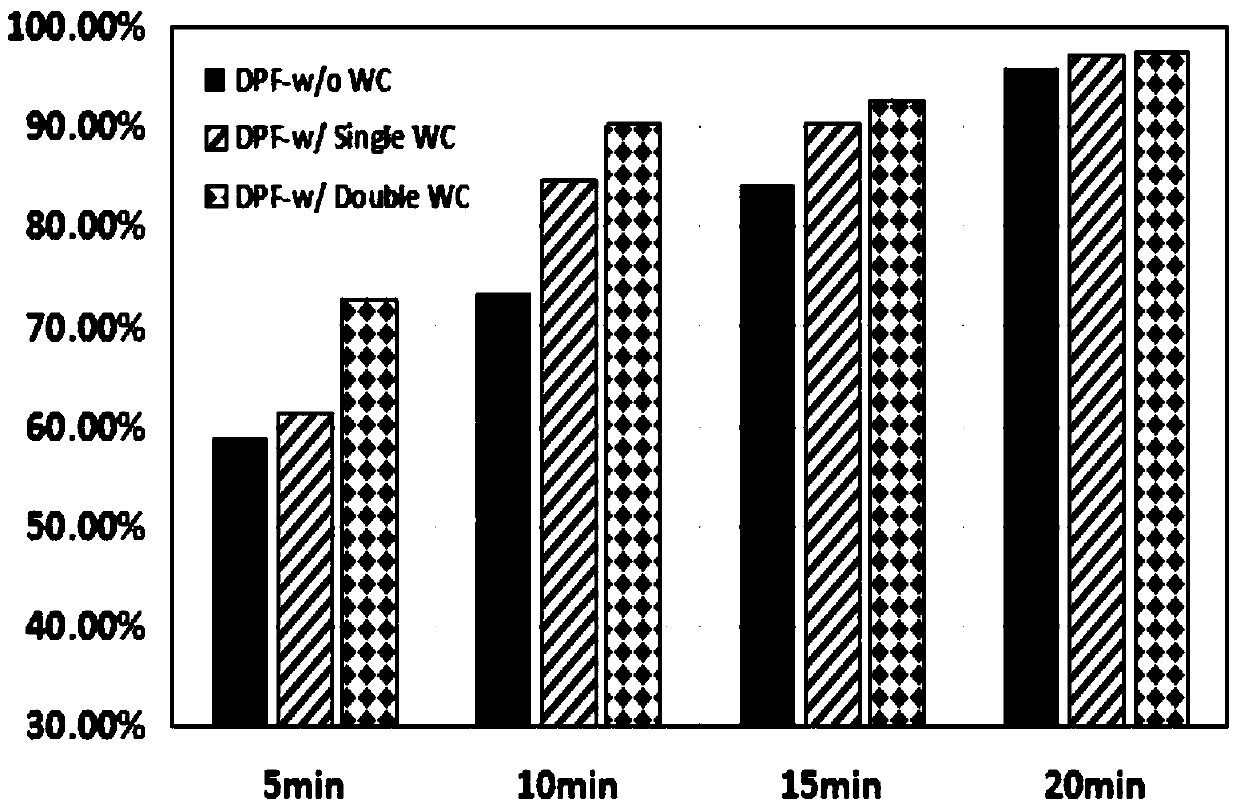

A particle filter and filtration efficiency technology, which is applied in the exhaust gas treatment of marine engines and the field of motor vehicles, can solve the problems of low filtration efficiency, high and low back pressure of soot filters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] A diesel particulate filter preparation technology with low back pressure and high soot filtration efficiency, comprising the following steps:

[0048] 1. Preparation of the bottom layer slurry: mix the components with a weight ratio of deionized water: glacial acetic acid: adhesive = 2:1:1 and use a high-energy ball mill to grind them into glue, then add glass fiber, the mass content is 1.0wt%, And silicon carbide ceramic powder, the size range of which is 200-500nm, the total solid content is 5%, and ball milling is continued for 30 minutes. A bottom slurry is formed.

[0049] Second, the coating of the bottom slurry:

[0050] Using the integral coating method, grouting coating from bottom to top, the height of the slurry poured into the carrier is identified by the liquid level sensor, that is, when the slurry level reaches the set height, the sensor alarm prompts, at this time, you can Stop the pouring of the slurry; it is enough to reach the required coating load...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com