Method and system for secondary air injection coordination with exhaust back pressure valve

A technology of exhaust back pressure and secondary air, applied in exhaust devices, charging systems, electrical control, etc., can solve problems such as increasing exhaust temperature, reducing engine efficiency, and increasing combustible gas.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

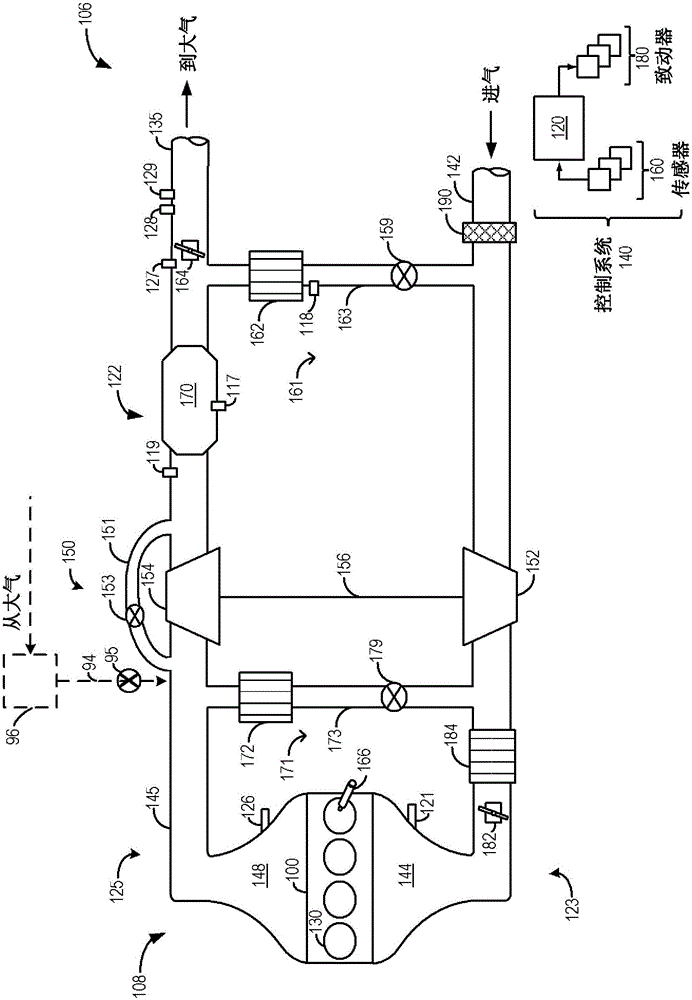

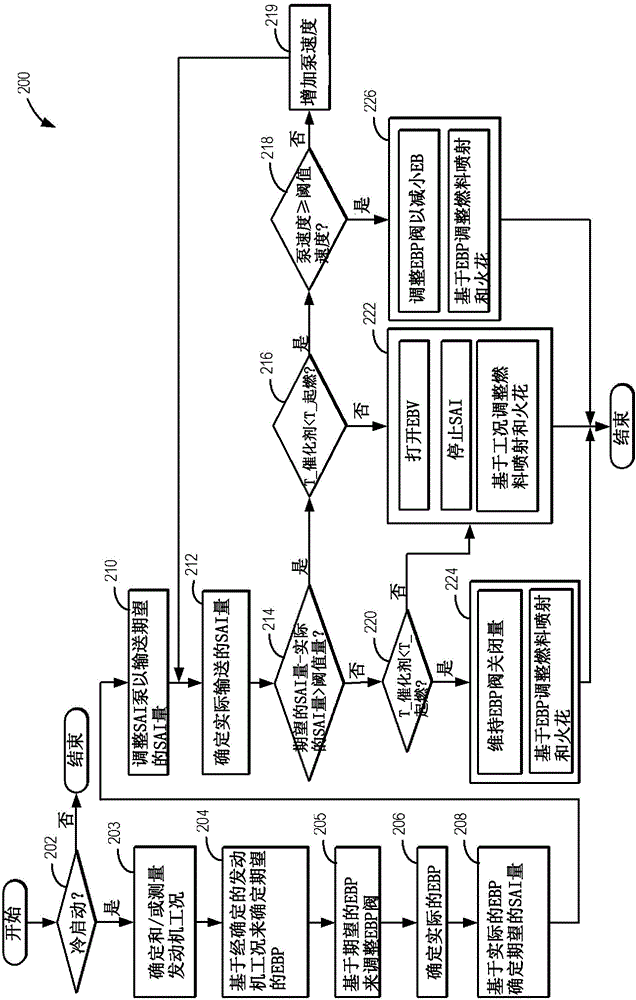

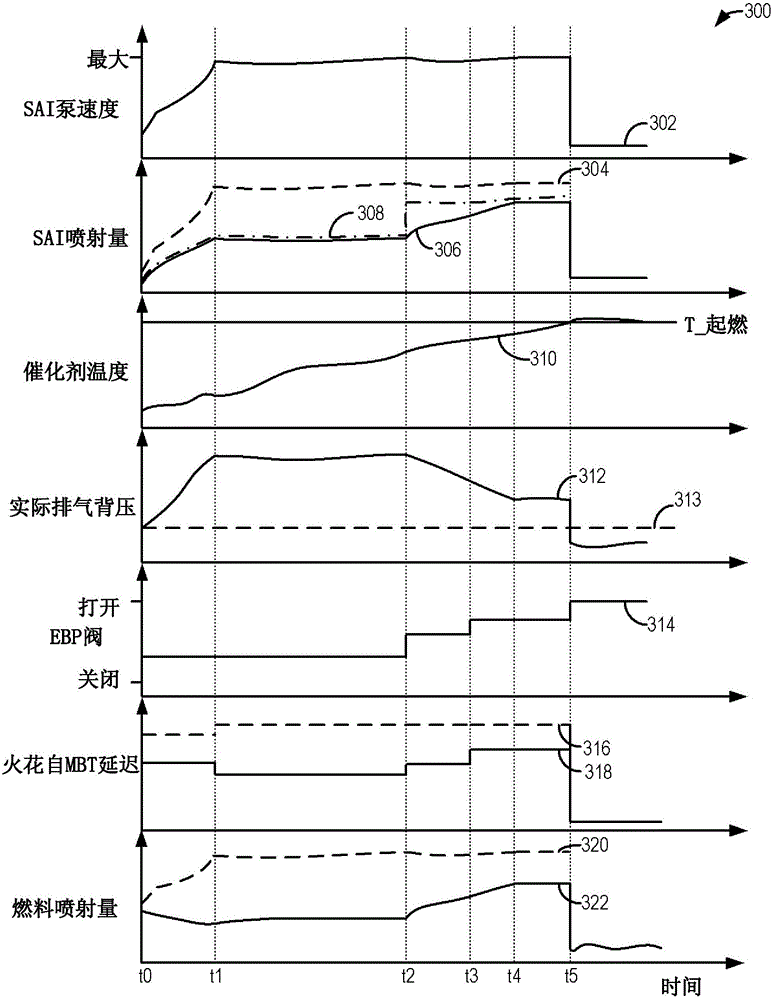

[0011] Provides for accelerating vehicle engines such as figure 1 Engine warm-up and catalyst activation methods and systems in engine systems for During engine cold start, exhaust backpressure and secondary air injection may be advantageously used to rapidly raise the temperature of the exhaust catalyst. The controller can be configured to execute control programs, such as figure 2 Example procedure of ) to adjust an exhaust valve positioned downstream of an exhaust catalyst to raise exhaust backpressure while delivering secondary air. The amount of enrichment and spark retard required can be reduced through the coordinated use of exhaust back pressure increase and secondary air injection. Accordingly, combustion stability, efficiency, and particulate emissions can be improved while achieving rapid catalyst heating. exist image 3 Example backpressure valves and secondary air injection volume adjustments are described at .

[0012] figure 1 A schematic diagram of vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com