Method and system for particulate filter regeneration

A particle filter, engine technology, applied in machine/engine, spark ignition controller, electronic control of exhaust treatment devices, etc., can solve problems such as undesired driving experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

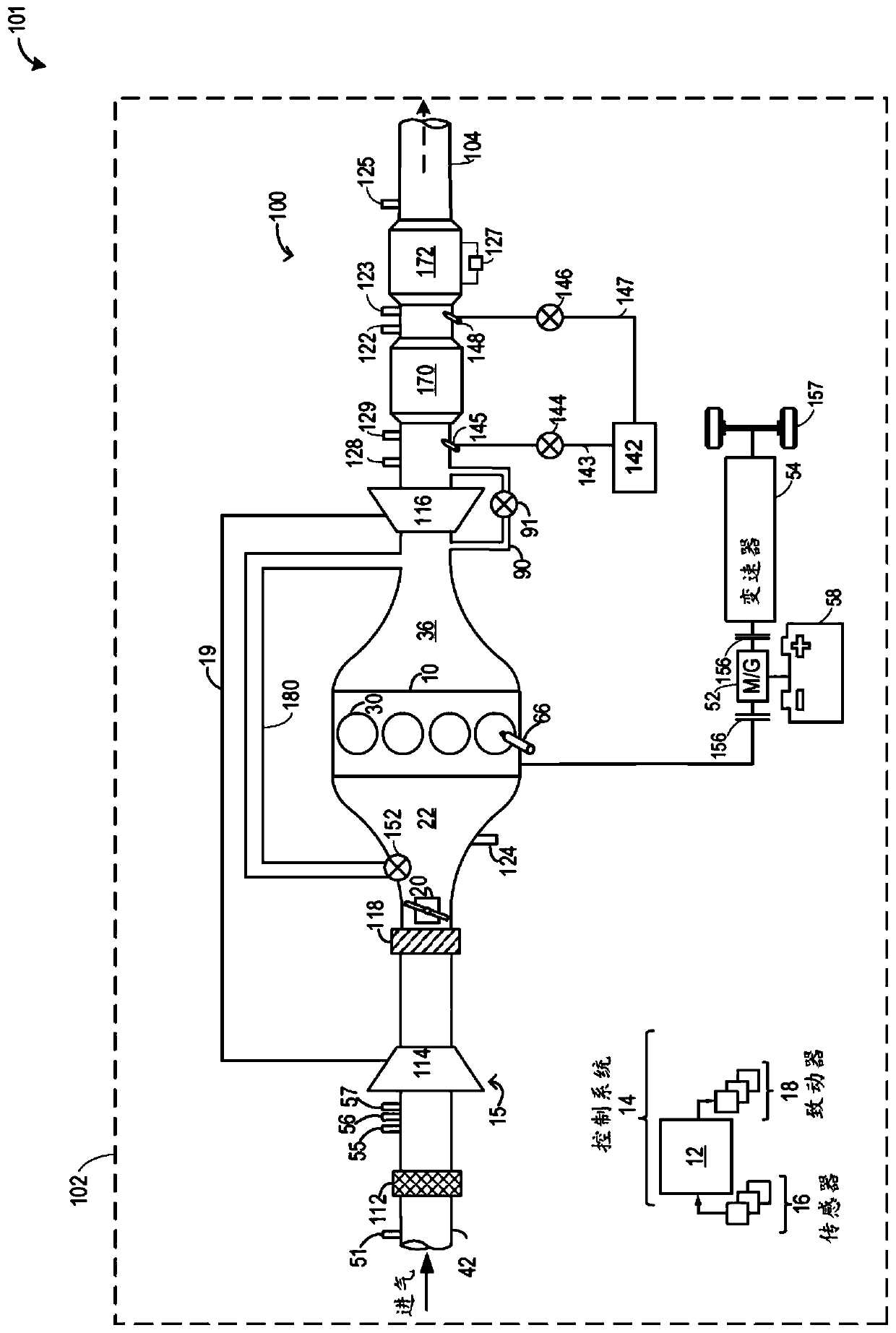

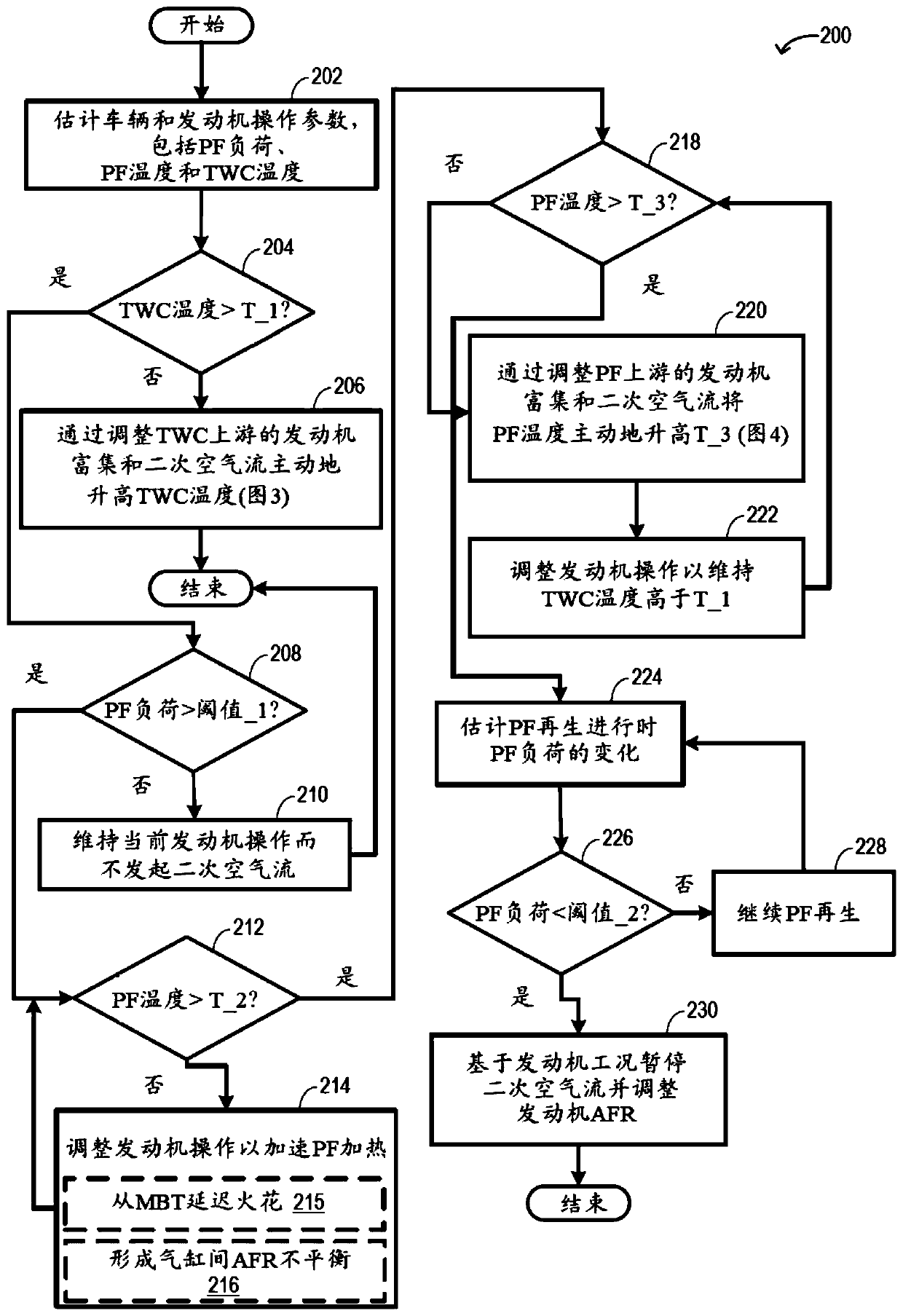

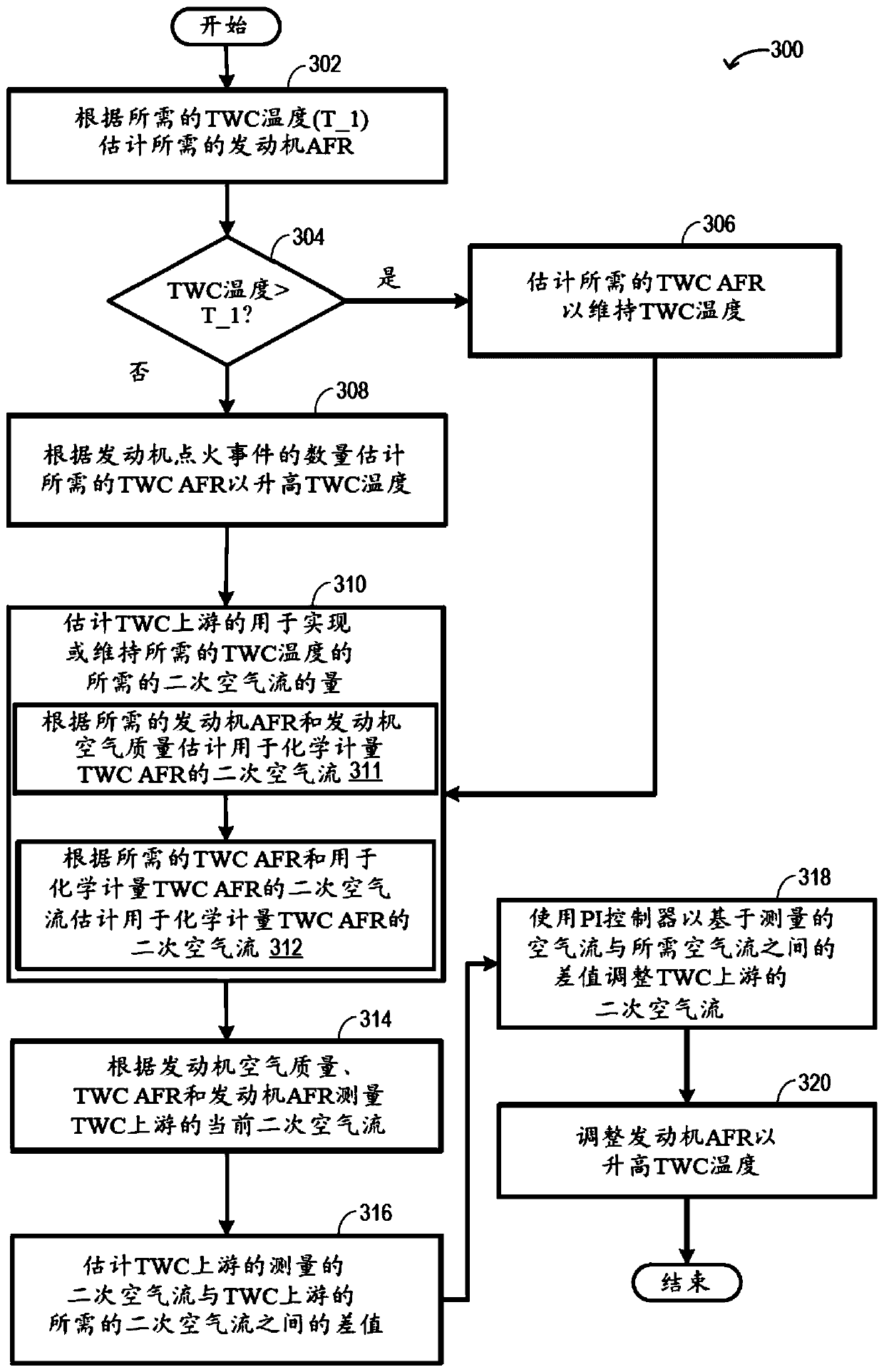

[0016] The following description relates to systems and methods for heating an exhaust particulate filter (PF) for filter generation. PF can be coupled to engine systems such as figure 1 The engine system of the engine system also includes an exhaust pump and one or more exhaust injectors to achieve accelerated heating of the PF and exhaust catalyst. The engine controller can be configured to execute control programs such as Figure 2 to Figure 4 An exemplary procedure for accelerating particulate filter heating to an operating temperature at which regeneration may be initiated while maintaining a catalyst temperature above a catalyst light-off temperature. Specifically, the controller may rely on heat release via engine air-fuel ratio adjustments enhanced using secondary air injection upstream of the PF and / or catalyst. Figure 5 A predictive example of coordinating secondary air injection with engine air-fuel ratio adjustments for PF heating and catalyst heating is shown. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com