Device used for biomass gasification and active carbon combined production

A technology of activated carbon and biomass, applied in the fields of biomass energy and chemical engineering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

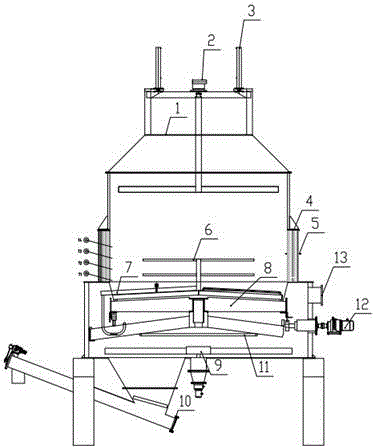

[0018] Control attached figure 1 , used for biomass gasification and activated carbon cogeneration device, its structure includes feed inlet 1, leveling device 2, hydraulic lifter 3, gasification reaction chamber 4, secondary air supply pipe 5, bridge breaking lever A 6, Steam distribution pipe 7, rotary grate 8, rotary scraper 9, carbon cooler 10, spray cooling pipe 11, grate power mechanism 12, air outlet 13 ;in The feeding port 1, the leveler 2 driven by the deceleration motor and the hydraulic lifter 3 are arranged on the top of the device, the hydraulic lifter 3 is connected with the leveler 2, and the leveler 2 is driven by the hydraulic lifter 3 , and rise and fall according to the change of the material level, so that the raw materials entering the device from the feed port 1 are evenly distributed, and the height of the leveler 2 can be adjusted by the hydraulic lifter 3 to meet the requirements of material height changes.

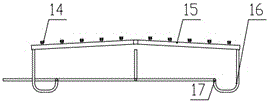

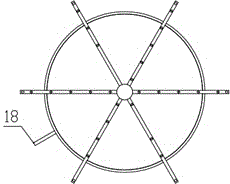

[0019] The gasification reaction chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com