Patents

Literature

203results about How to "Realize joint production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

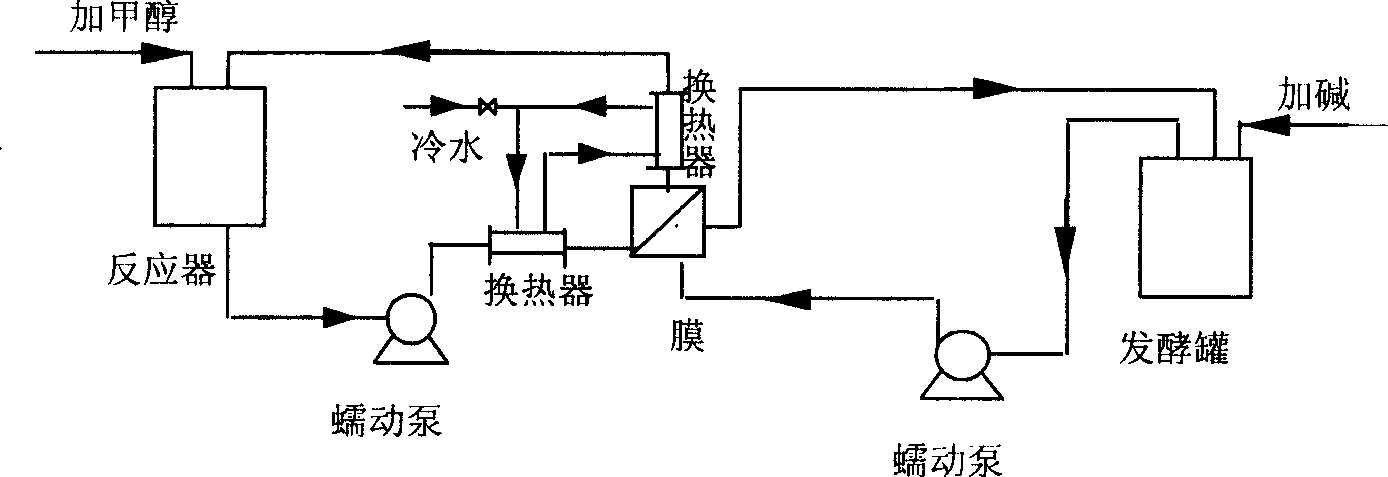

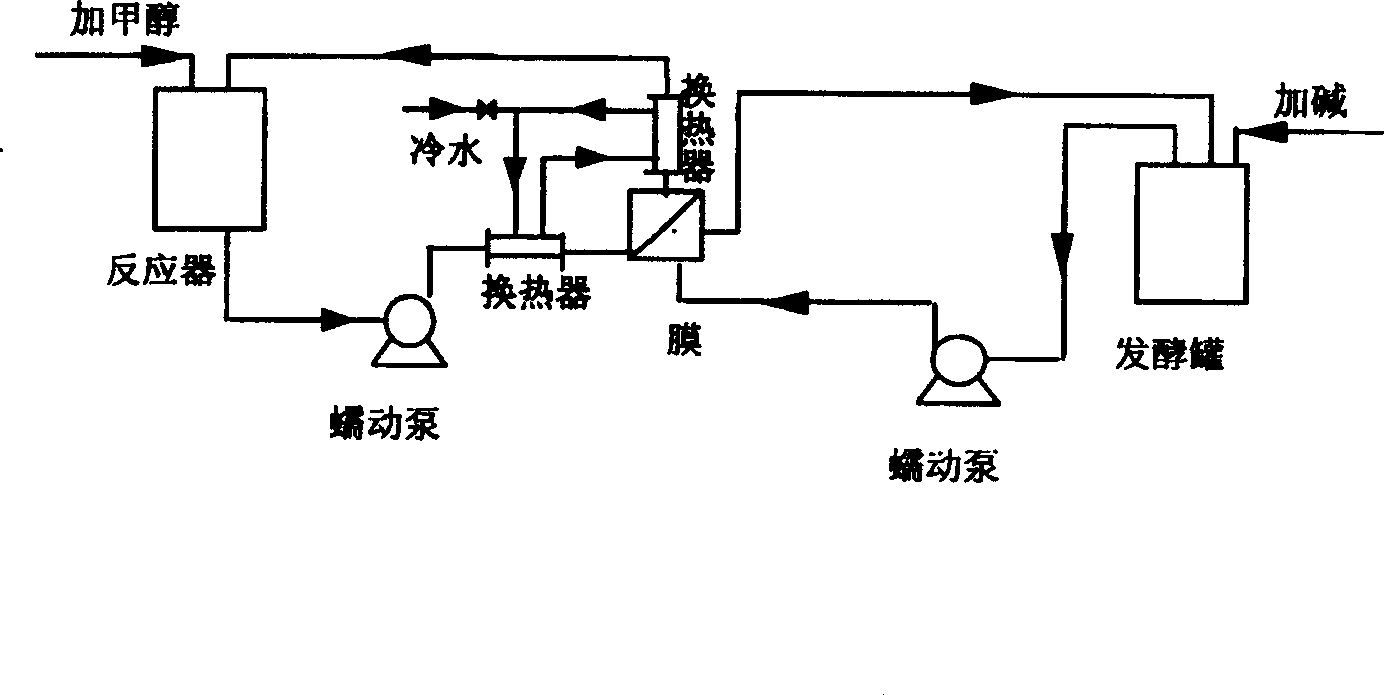

Process for coupling producing bioloigical diesel oil and 1,3-propylene glycol

InactiveCN1648207AReduce or even eliminate poison inactivationSave on separation costsOrganic chemistryLiquid hydrocarbon mixture productionBiodieselMicrobial transformation

The present invention belongs to the field of bioengineering technology, and especially a kind of couple producing biological diesel oil and 1, 3-propylene glycol. The present invention features that the course of lipase catalyzed reaction between methanol or ethanol and fat to produce biological diesel oil and the course of biologically converting glycerin into 1, 3-propylene glycol are coupled via membrane filtering for simultaneous proceeding. The present invention has the effects of eliminating the suppression of short-chain alcohol and glycerin on lipase, prolonging the service life of immobilized enzyme, omitting the glycerin separating and extracting step, lowering the production cost, saving time, raising production efficiency and providing economic and feasible process for producing biological diesel oil and 1, 3-propylene glycol.

Owner:DALIAN UNIV OF TECH

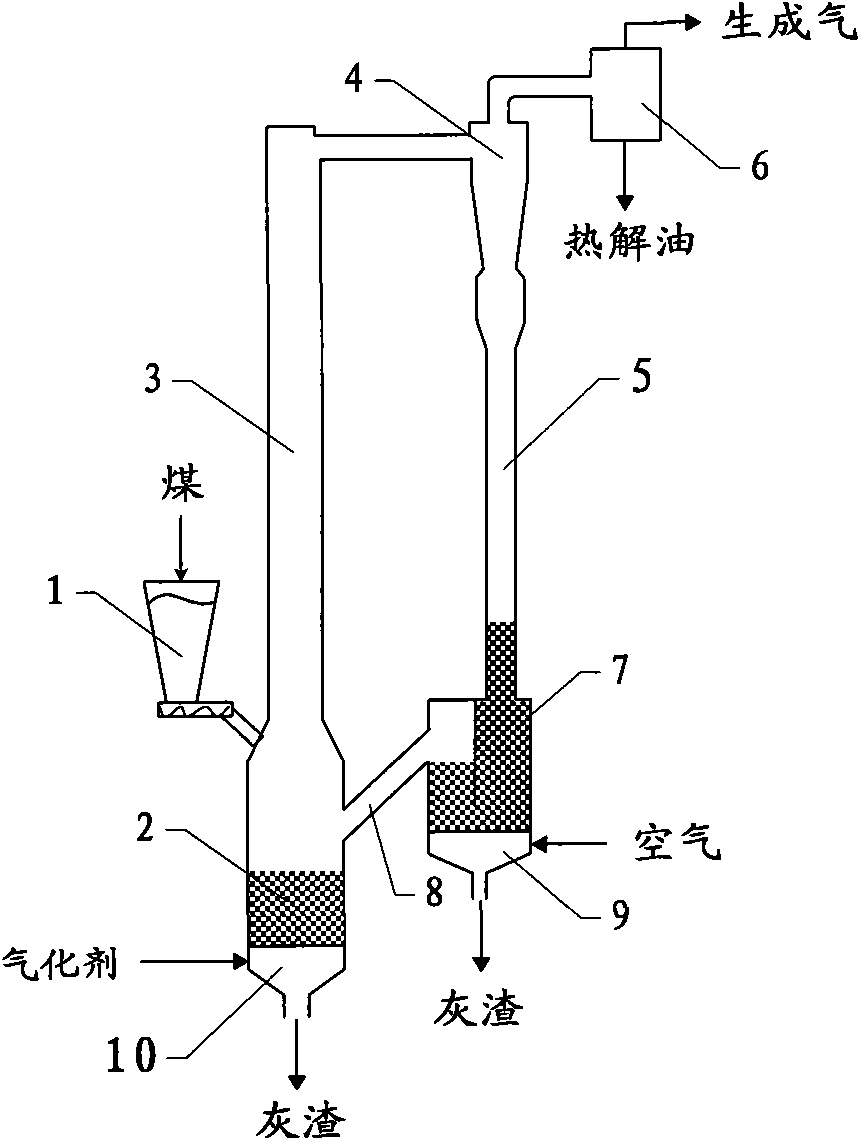

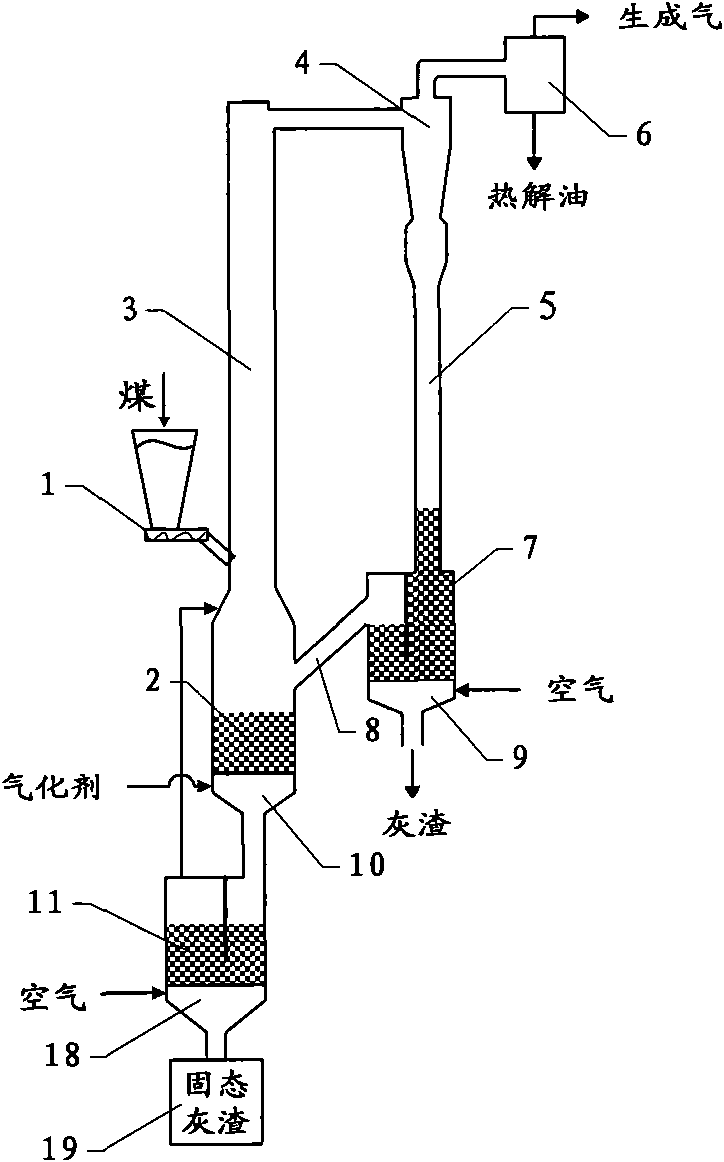

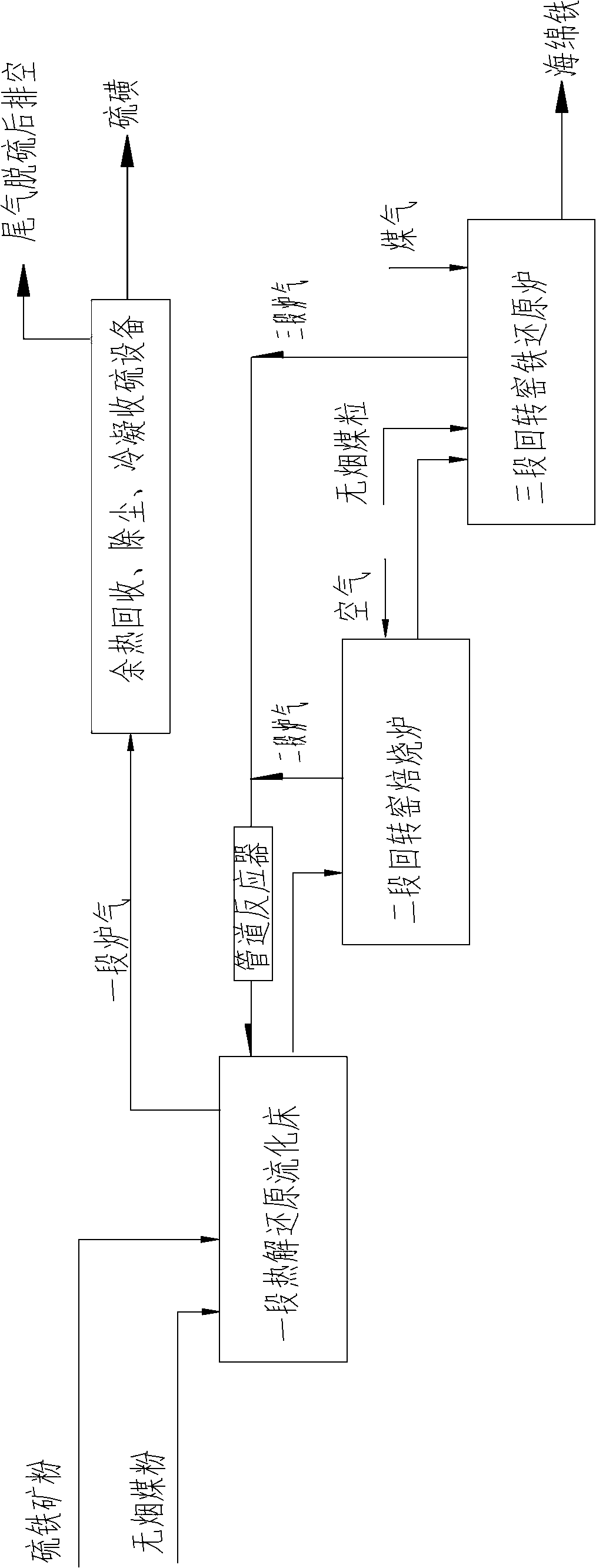

Method and device for utilizing high value through pyrolysis and gasification of coal

ActiveCN101781583ARealize joint productionFast pyrolysisLiquid hydrocarbon mixture productionCombined combustion mitigationOrganic structureFluidized bed

The invention relates to a method and a device for utilizing high value through pyrolysis and gasification of coal. The pyrolysis and gasification processes of the coal are separated in a mode of coupling a dilute phase conveying bed and a dense phase fluidized bed; and the coal is partially or wholly pyrolyzed before gasification, and co-production of pyrolysis gas, gasification generated gas and pyrolysis oil is realized. The dilute phase conveying bed and the dense phase fluidized bed can be coupled in two modes, namely upper-lower coupling and left-right coupling, and are applied to treating the coal in wide particle diameter distribution. High-value organic structures in the coal can be extracted before the gasification of the coal, and the utilization value of the coal is improved.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

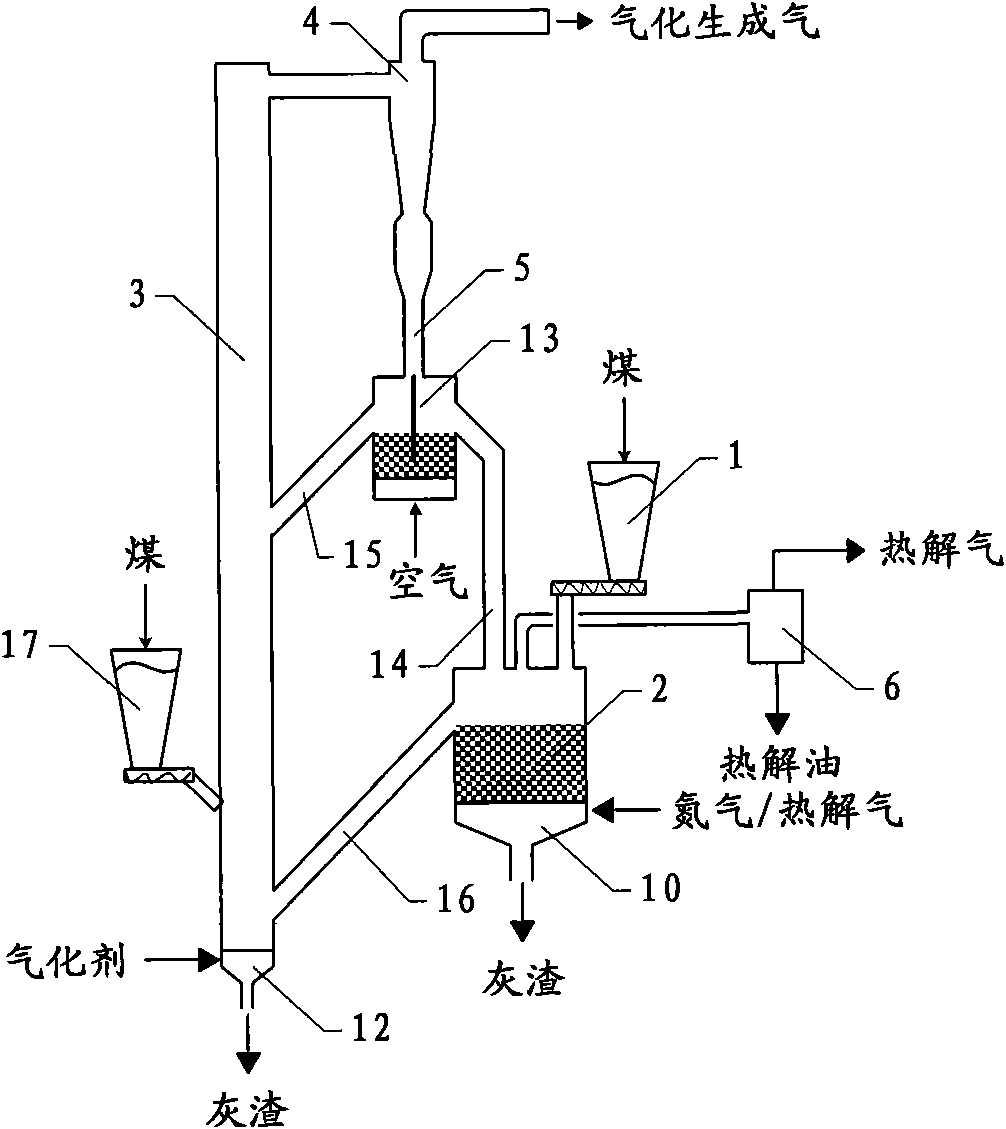

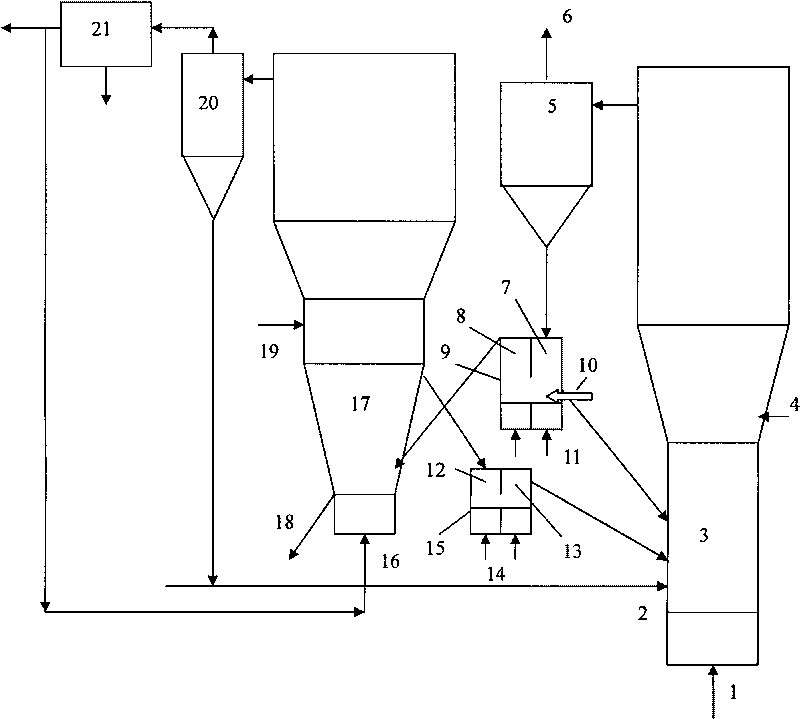

Coal-grading conversion poly-generation device and method for producing coal gas, tar and carbocoal on circulating fluid bed

ActiveCN101691501ARealize joint productionReasonable useSpecial form destructive distillationCombustible gas productionTarProcess engineering

The invention discloses a coal-grading conversion poly-generation device and a method for producing coal gas, tar and carbocoal on a circulating fluid bed. The device combines a circulating fluid bed gasification-furnace with a fluid bed gas retort. The gas retort is a normal-pressure fluid bed and uses circulating coal gas as the fluidizing medium; fuel is firstly heated and cracked in the gas retort to precipitate high-heating-value fugitive constituents comprising coal gas and tar; the heat absorbed by the gas retort is provided by a high-temperature thermal-circulation material in the circulating fluid bed gasification-furnace; the carbocoal part obtained after the coal is retorted is cooled and discharged through the bottom of the gas retort, and part of the carbocoal is conveyed to the circulating fluid bed gasification-furnace along with the circulating material to heat the circulating material; and the medium-temperature coal gas from the gas retort is processed in a dust removal way and cooled by a coal gas purification system, the tar is recycled, and the purified coal gas is output for industrial and civil use, thereby realizing the poly-generation of coal gas, tar and carbocoal in one set of device and realizing the grading conversion and the high-efficiency comprehensive utilization of coal.

Owner:ZHEJIANG UNIV

Combined pretreatment method for efficiently separating bagasse biomass components

InactiveCN102180994ANo pollution in the processReduce energy consumptionBiofuelsFermentationAlkaline waterPretreatment method

The invention discloses a combined pretreatment method for efficiently separating bagasse biomass components, which mainly comprises the following steps: preimpregnating in dilute sulfuric acid; carrying out steam explosion treatment; washing with hot water; extracting; and carrying out enzymolysis. In the combined pretreatment method disclosed by the invention, on the basis of different physicochemical properties and structural features of the three components (hemicellulose, cellulose and lignin) in the bagasse, the component hemicellulose is sufficiently degraded and separated by dilute acid preimpregnation-steam explosion pretreatment, thereby reserving most of the cellulose and lignin; and the lignin is extracted by using a lower alcohol-alkaline water system, leaving high-cellulose-content residues. On the premise of low concentration of the added enzyme, the invention obviously increases the enzymolysis rate, and raises the conversion rate and comprehensive utilization rate of the bagasse biomass resource.

Owner:GUANGZHOU YOURUI BIOSCI

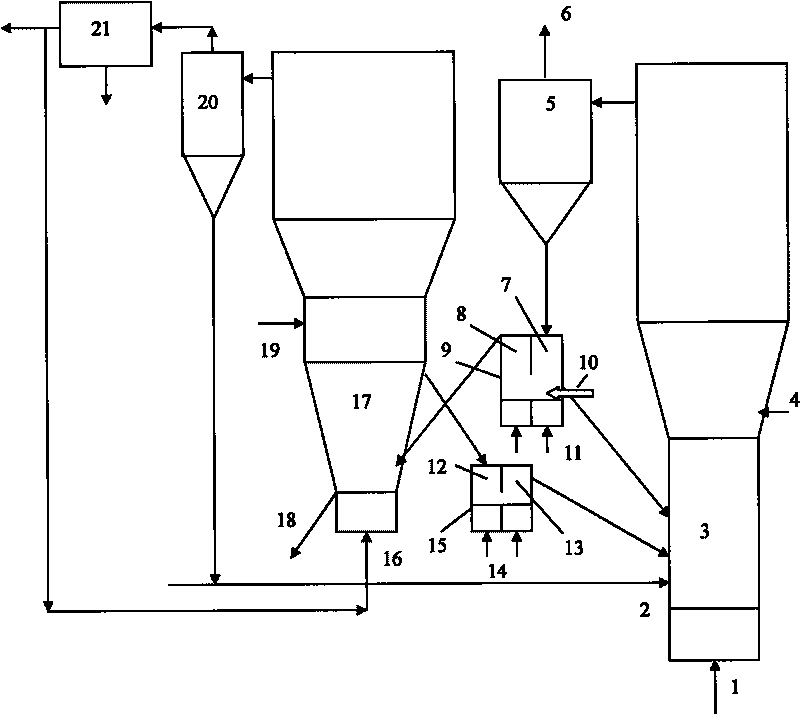

Method for producing sulfur by using pyrolysis-reducing united technique

ActiveCN103011090AIncrease profitIncrease concentrationEnergy inputSulfur preparation/purificationThermal energySlag

The invention discloses a method for producing sulfur and co-producing sponge iron by using a pyrolysis-reducing united technique, which comprises the following steps of: firstly carrying out first-step desulfurization-high temperature pyrolysis on sulfur-iron ores on a section of pyrolysis-reducing fluidized bed so as to generate sulfur steam and ferrous sulfide, wherein heat required by the pyrolysis process is mainly supplied by high-temperature flue gas from a pipe reactor and part of material combustion heat produced in the process; and 2, reducing iron oxide slag of a second-section furnace by using a coal-based rotary kiln direct reduction method, namely that on the basis of adopting a mature sponge iron production technology, fully using the high-order heat energy and high activity of the iron oxide slag discharged from the second-section furnace, therefore, effects of remarkably saving energy and reducing consumption as well as improving the production efficiency are achieved. The method is remarkable in energy saving effect, high in comprehensive utilization of mineral resources, environmental-friendly, and especially applicable to the large-scale development and utilization of sulfur-iron resources in sulfur resource-rich areas and the comprehensive utilization of high-sulfur fault coals; and meanwhile, the method also provides a new way for the comprehensive and efficient utilization of associated sulfur resources in the non-ferrous smelting industry.

Owner:新疆中驰恒谊环保科技有限公司

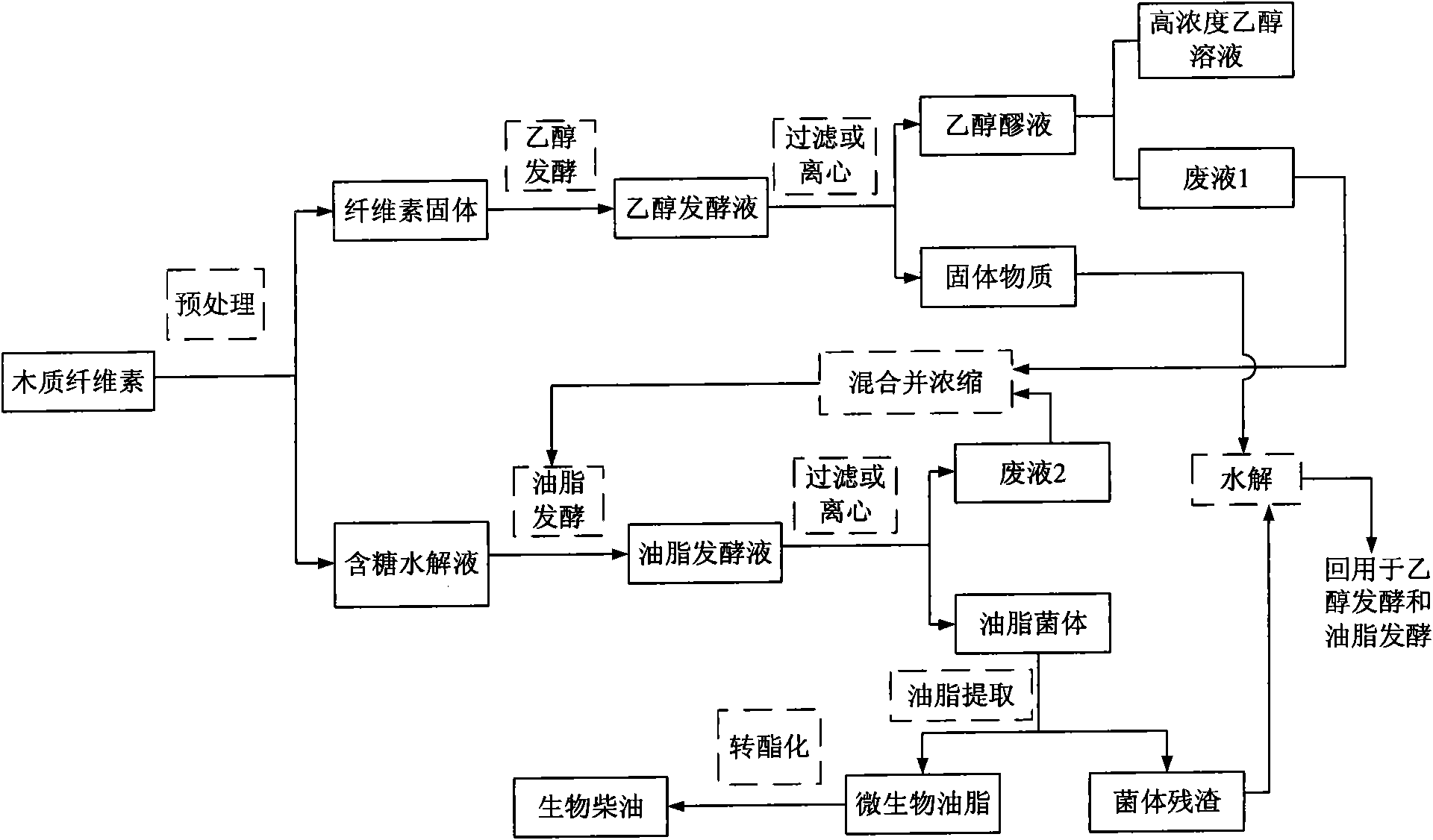

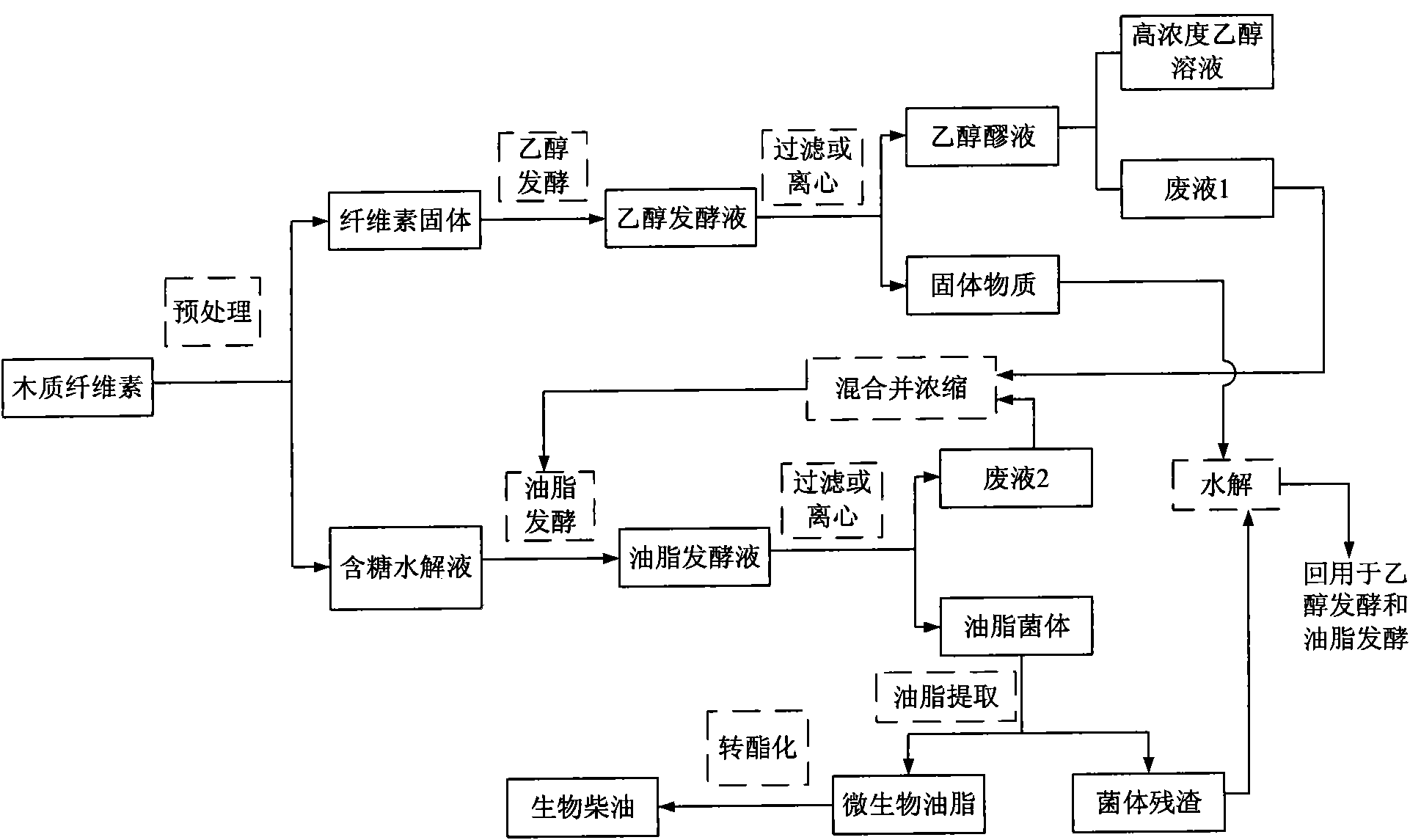

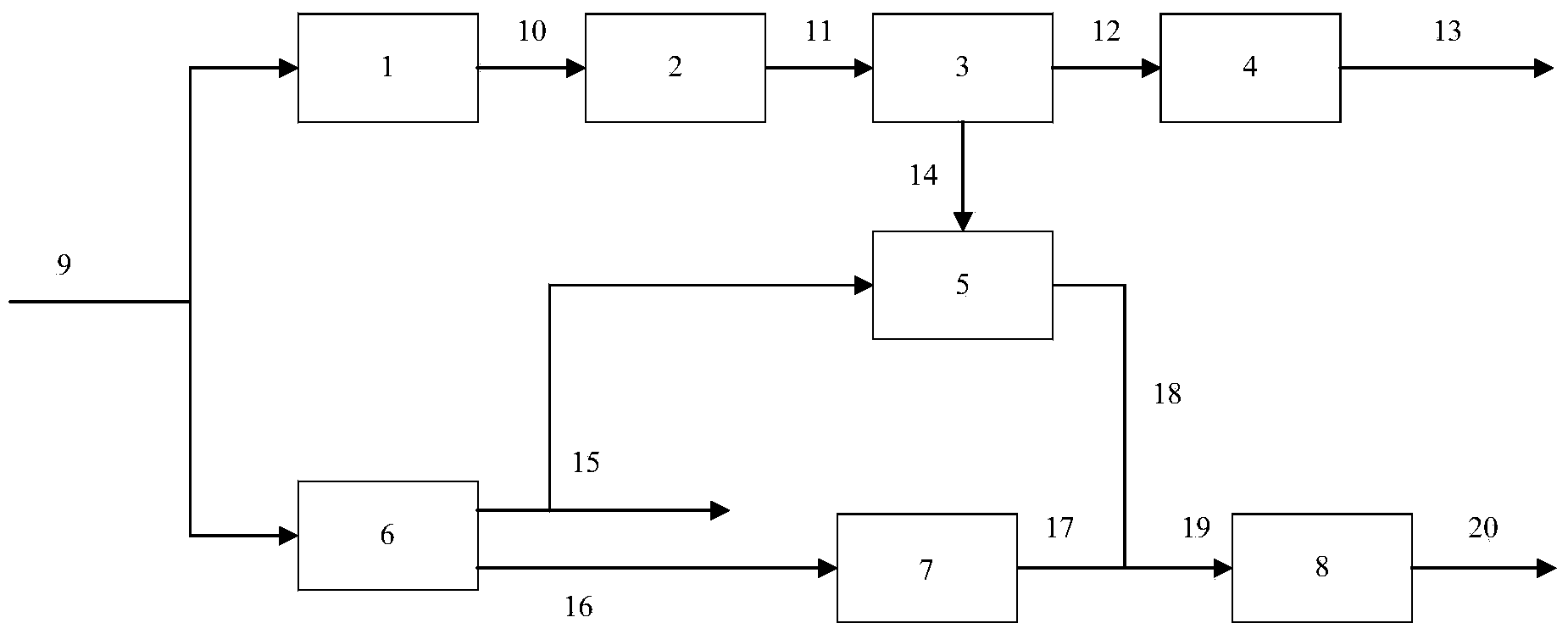

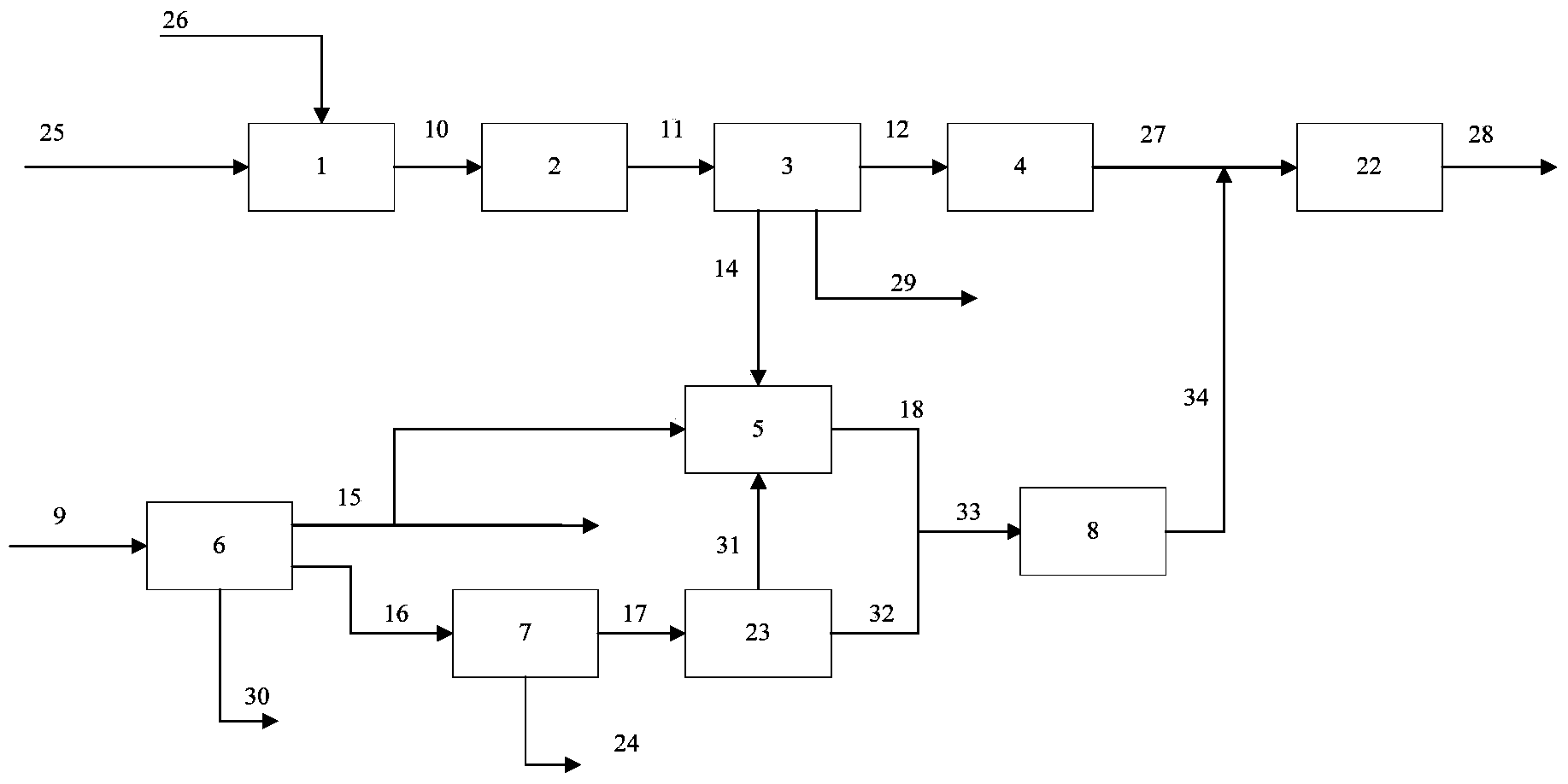

Method for joint production of ethanol and microbial lipid by using methyl cellulose as raw material

The invention provides a method for joint production of biological ethanol and microbial lipid by using methyl cellulose as raw material and then realizing the joint production of ethanol and biodiesel by using the methyl cellulose as the raw material. The method comprises the following steps of: (1) ethanol fermentation is carried out for a cellulose solid obtained after the methyl cellulose is pretreated; (2) a product of hemicellulose hydrolyzation in the pretreatment process is used for microbial lipid fermentation; (3) waste liquor produced after ethanol in ethanol fermentation is recycled and waste liquor produced after microbial lipid is fermented are used for microbial lipid fermentation; and (4) yeast fermented by alcohol and thallus residue produced after lipid extraction are hydrolyzed and then are used as a nitrogen source to be used for ethanol fermentation and microbial fermentation process. The method provided by the invention can convert the methyl cellulose with low grade into two biomass fuels of bioethanol and biodiesel and simultaneously can reduce waste water emission in ethanol production.

Owner:TSINGHUA UNIV

Method for coproducing sodium chloride, magnesium sulfate and potassium chloride

InactiveCN101591030AHigh extraction rateLong cycleMagnesium sulfatesMultistage water/sewage treatmentDecompositionEvaporation

The invention relates to a method for coproducing sodium chloride, magnesium sulfate and potassium chloride. The method for coproducing the sodium chloride, magnesium sulfate and potassium chloride is characterized in that raw material brine is subjected to processes of primary evaporation, cooling and secondary evaporation to gradually extract and separate the sodium chloride and the magnesium sulfate and prepare carnallite; and the carnallite is performed hydrolytic decomposition, and the potassium chloride is produced after washing and dehydration. The method has the advantages of realizing coproduction of three products, namely the sodium chloride, the magnesium sulfate and the potassium chloride. The extraction yield of the sodium chloride is above 85 percent; the extraction yield of the magnesium sulfate is increased to be between 56.95 and 62 percent; the extraction yield of the potassium chloride is improved by over 7 percentage; the quality of the carnallite is improved; and the content of the potassium chloride is between 19 and 23 percent, which provides good-quality raw materials for the next process.

Owner:天津长芦汉沽盐场有限责任公司

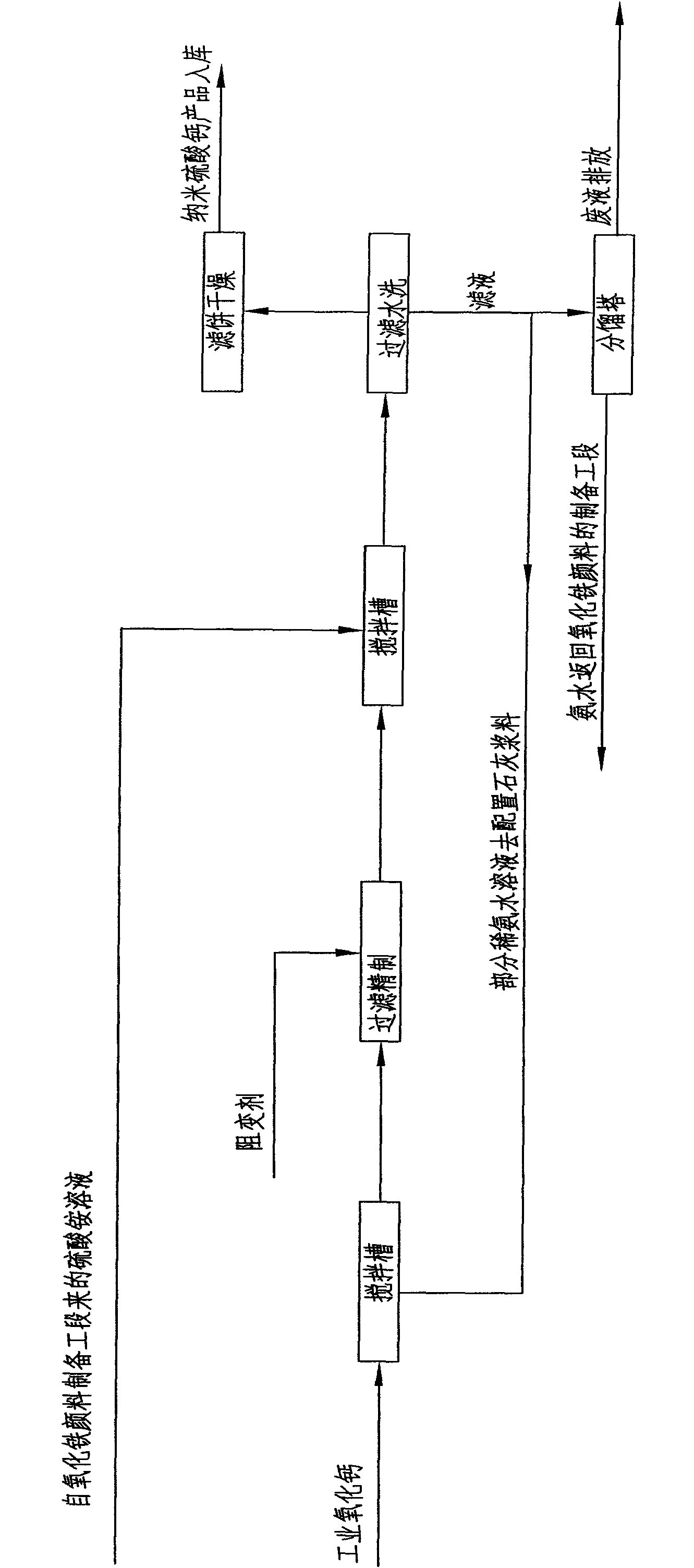

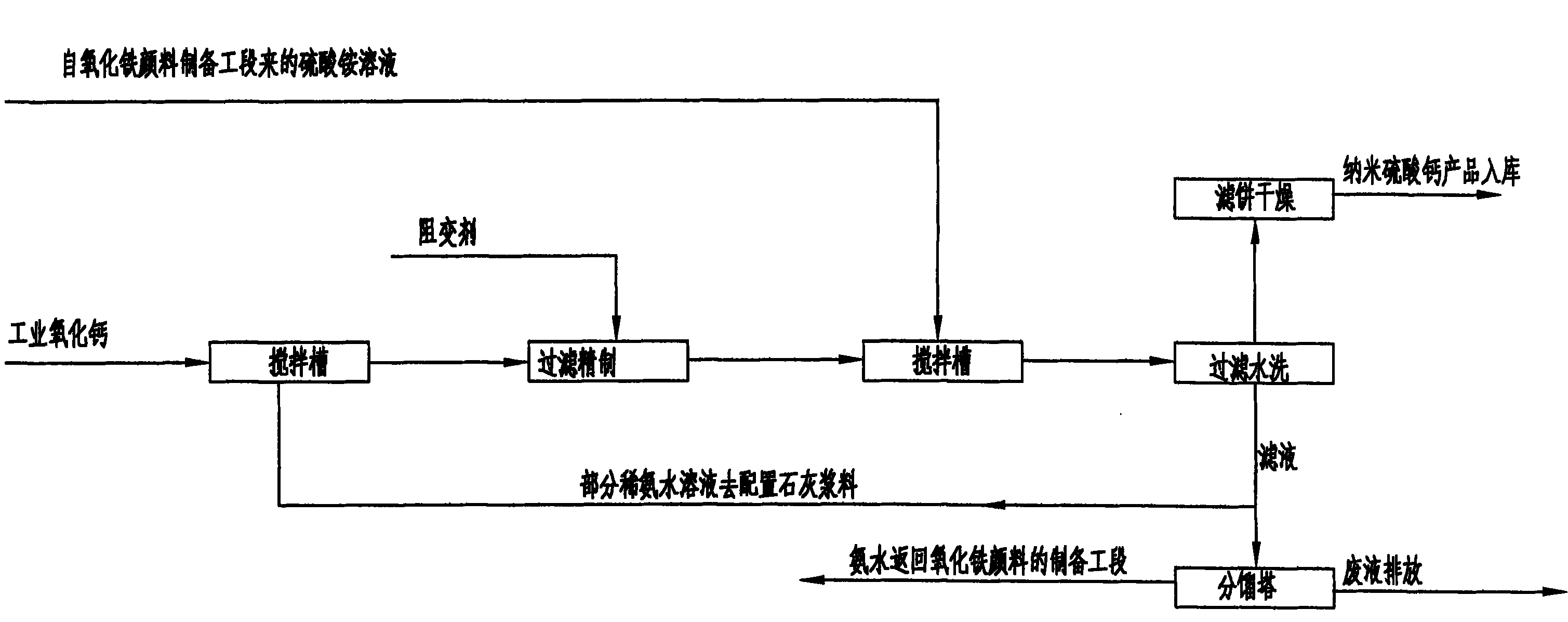

Process for preparing nano calcium sulfate

InactiveCN102234127ALow cost of preparationReduce manufacturing costNanostructure manufactureCalcium/strontium/barium sulfatesAmmonium sulfateIron oxide

The invention discloses a process for preparing nano calcium sulfate by adopting lime and ammonium sulfate as raw materials. The preparation process comprises the following steps of: emulsification of lime calcium oxide; generation of nano calcium sulfate slurry by reacting a calcium hydroxide emulsion containing a change-inhibiting agent with an ammonium sulfate solution; filtering and washing; drying; and the like. The process is suitable for ammonium sulfate solution reclamation and ammonia recycling treatment in a process of producing ferric oxide series pigments by adopting ferrous sulfate as a raw material, and is a critical core technology of the process of preparing the ferric oxide series pigments by using the ferrous sulfate as the raw material. The change-inhibiting agent is introduced in the preparation process, superfine nano calcium sulfate particles formed by the ammonium sulfate and the calcium hydroxide are prevented from growing up in a liquid-phase environment, so that industrial production of a superfine nano calcium sulfate product by adopting a chemical method becomes a possibility.

Owner:陈胜明

Method for directly producing foamed glass by using slag tapping boil slag

The invention relates to a method for directly producing foam glass by utilizing slag of a slag tapping boiler, comprising the following steps that: aiming at coal quality with different compositions, according to the principle of 'lacking what repair what', through adding chunk glass and calcium oxide in the slag tapping boiler, the chemical compositions of the slag are 45 to 65 percent of SiO2, 5 to 30 percent of Al2O3, 0 to 15 percent of Fe2O3, 10 to 30 percent of CaO+MgO and 0 to 14 percent of Na2O+K2O; the obtained slag meeting the requirement directly undergoes water quench in a water quench tank under the slag tapping boiler, vitreous body materials for preparing the foam glass are obtained; the prior technology for preparing the foam glass is adopted, and the foam glass is obtained finally through milling, moulding, foaming, cooling and annealing the obtained vitreous body materials. The method fully utilizes flyash slag and simultaneously reduces the production cost of the foam glass.

Owner:XI AN JIAOTONG UNIV

Coproduction process of pig brain protein hydrolysate and monosialoganglioside

ActiveCN102093440ARealize joint productionImprove utilizationNervous disorderHydrolysed protein ingredientsUltrafiltrationFreeze-drying

The invention discloses a method for obtaining pig brain protein hydrolysate and monosialoganglioside (GM1) from fresh pig brain through fractional extraction. The main process routes are as follows: (1) firstly, adding polar organic solvent homogenate fresh pig brain, and respectively collecting a filter cake and filtrate after filtration; (2) adding a certain amount of low-pole organic solvent and purified water in the filtrate from the step (1) for Folch lamination, then respectively carrying out resin column chromatography, hydrolysis and silicagel column chromatography so as to obtain high pure monosialoganglioside; and (3) adding a certain amount of acetone in the filter cake from the step (1) for degrease, filtering and drying, adding salt buffer solution and hydrolase for hydrolysis, and carrying out inacitivation, ultrafiltration purification, ultrafiltration concentration and vacuum freeze drying so as to obtain medical injection-stage pig brain protein hydrolysate.

Owner:SHANDONG NEWTIME PHARMA

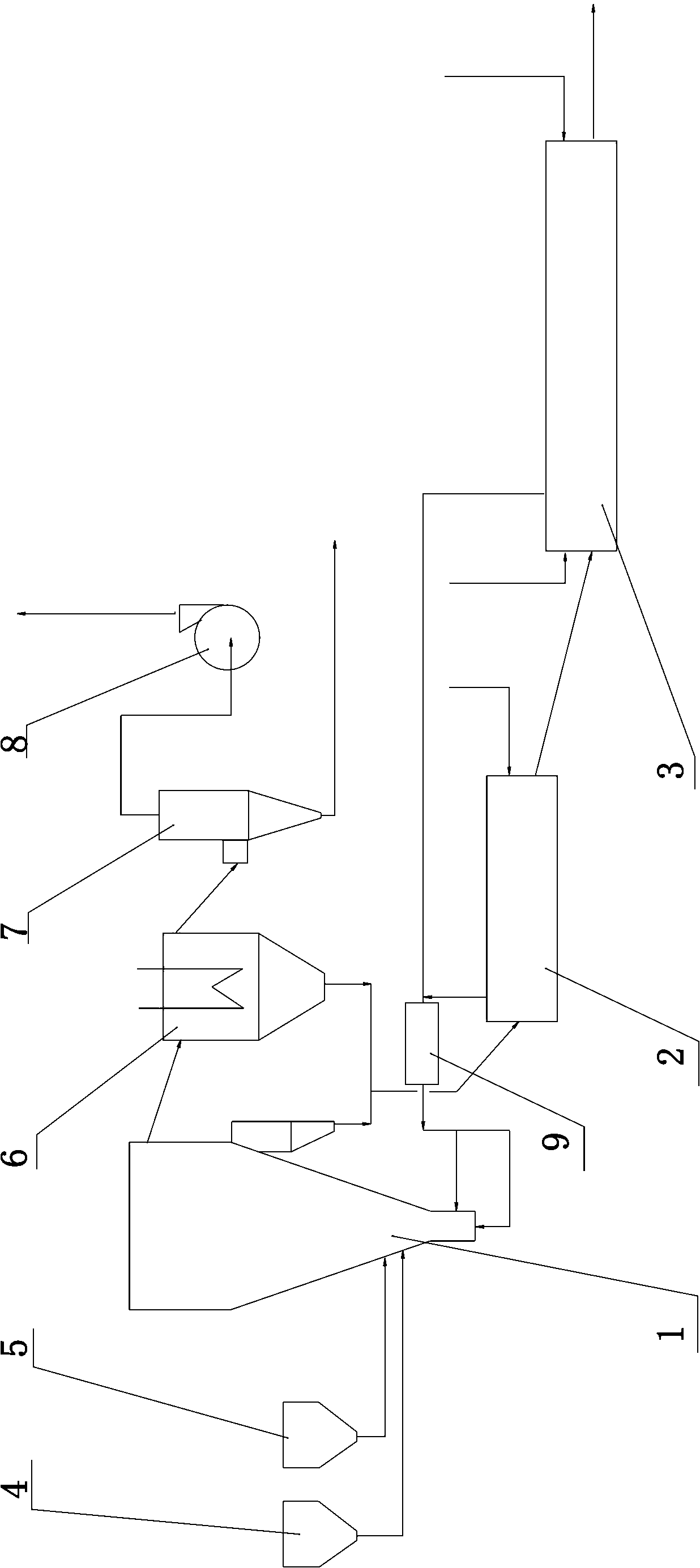

Coal gasification and coal coking co-supply and cogeneration system and method

ActiveCN104004547AReduce utilizationImprove utilization efficiencySpecial form destructive distillationBulk chemical productionChemical synthesisCogeneration

The invention discloses a coal gasification and coal coking co-supply and cogeneration system and method. The method comprises the following steps: preparing a coal-gasified crude synthesis gas from a part of raw material coal by a coal gasification process; obtaining clean coal-gasified crude synthesis gas and carbon dioxide after cooling, transforming and purifying the coal-gasified crude synthesis gas; feeding the clean coal-gasified crude synthesis gas into a chemical synthesis process to prepare a chemical product; preparing coke and a crude coke oven gas from the other part of raw material coal by the coal coking process, enabling a part of obtained coke to react with the carbon dioxide obtained in the coal gasification process to prepare carbon monoxide; purifying the obtained crude coke oven gas to obtain a clean coke oven gas, and then mixing the carbon monoxide with the clean coke oven gas according to a ratio, and then preparing a coal-coked synthesis gas; and feeding the coal-coked synthesis gas into a chemical synthesis process to prepare a chemical product. The coal utilization efficiency is effectively improved while energy conservation and emission reduction are realized in a co-supply manner of recovering CO2 produced in the coal gasification process and transporting to the coal coking process to generate the synthesis gas.

Owner:SOUTH CHINA UNIV OF TECH

Method for enriching precious metal by using yellow phosphorus electric furnace

InactiveCN101148703AImprove the ability to resist market risksRealize joint productionProcess efficiency improvementPhosphorus compoundsHeavy metalsOxide

Owner:GUIZHOU WENGFU YELLOW PHOSPHORUS

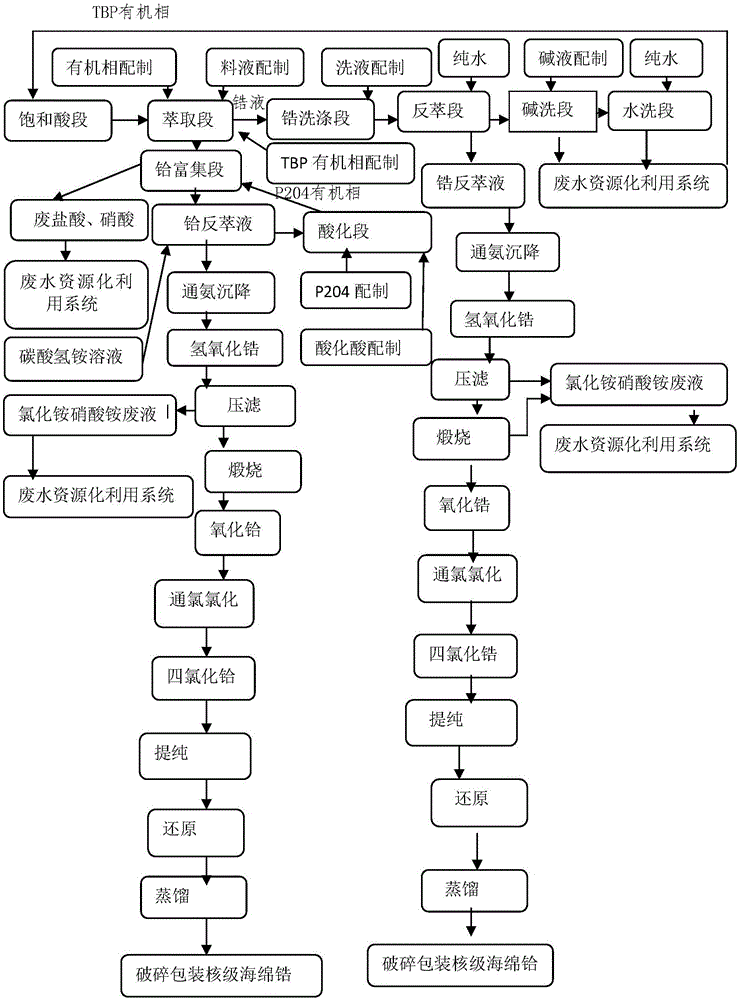

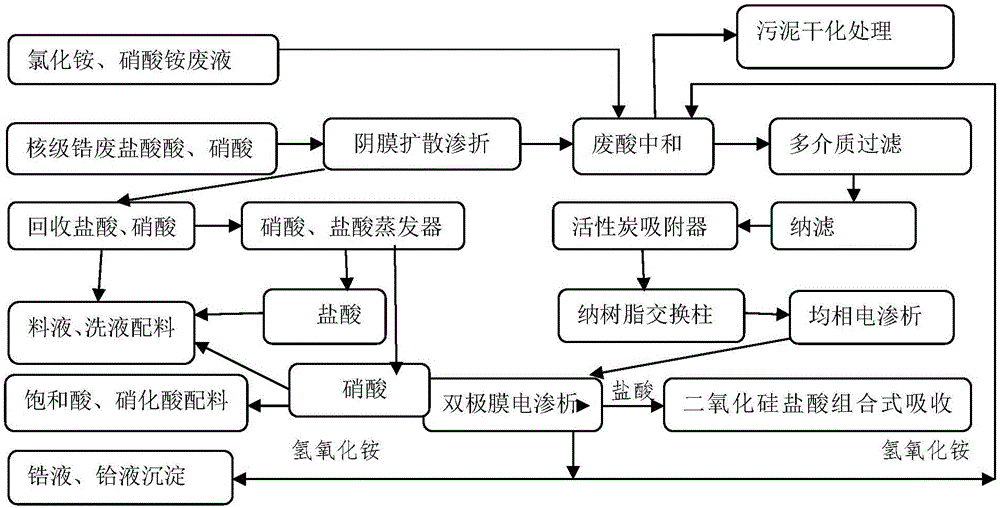

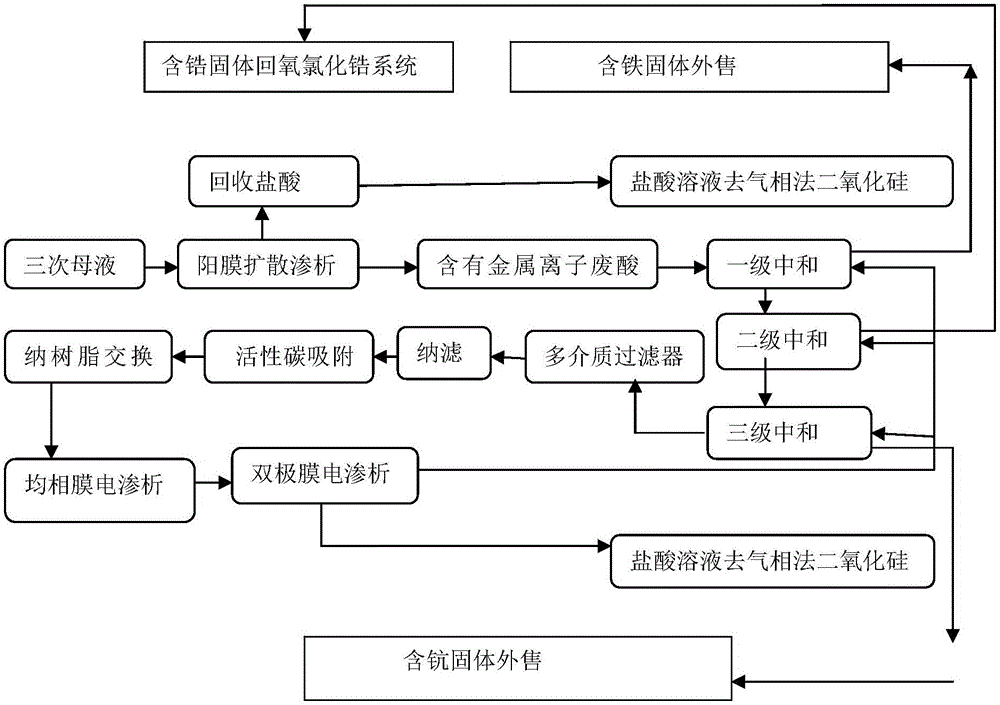

Method for preparing nuclear-grade sponge zirconium and nuclear-grade sponge hafnium

InactiveCN106435221AAchieve recyclingSolve difficult environmental problemsSilicaProcess efficiency improvementNuclear gradeElectrolysis

The invention relates to nuclear-grade sponge zirconium, in particular to a method for preparing nuclear-grade sponge zirconium and nuclear-grade sponge hafnium. Chlorine generated by hydrochloric acid electrolysis is used for producing zirconium tetrachloride and zirconium oxychloride by a zircon sand boiling chlorination method; zirconium and hafnium are seperated to obtain zirconium oxide and hafnium oxide through a TBP-Hcl-HNO3 extraction method; and then, the chlorination and the purification are performed to obtain the nuclear-grade sponge zirconium and the nuclear-grade sponge hafnium. The method radically solves the environmental protecting environment difficultly treated in the zirconium oxychloride industry and the nuclear-grade sponge zirconium industry, and realizes complete industry chain circulation for combined production of the zirconium oxychloride industry, the gas-phase method silicon dioxide industry, the nuclear-grade sponge zirconium industry and the hydrochloric acid electrolysis industry.

Owner:郭爽

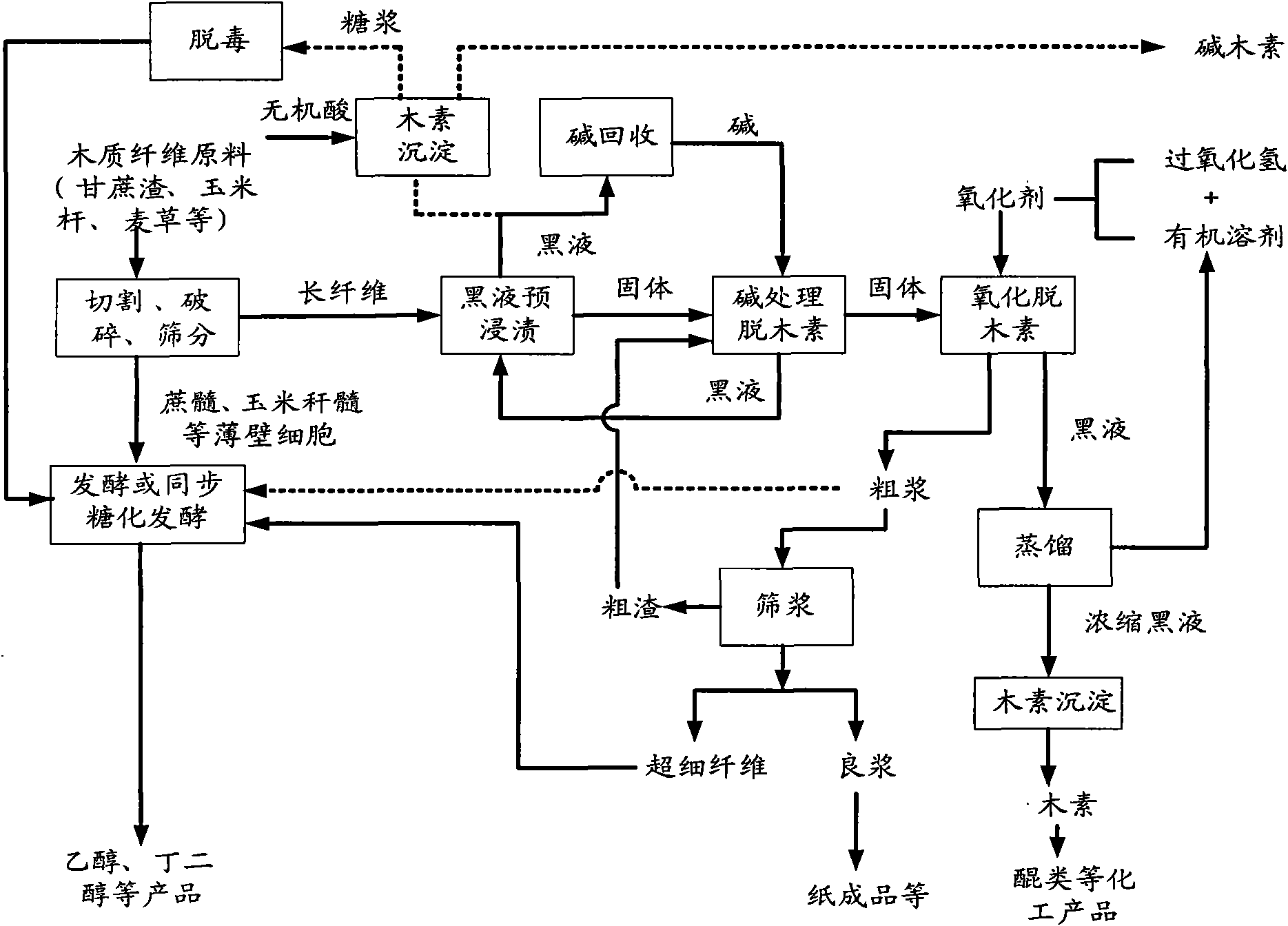

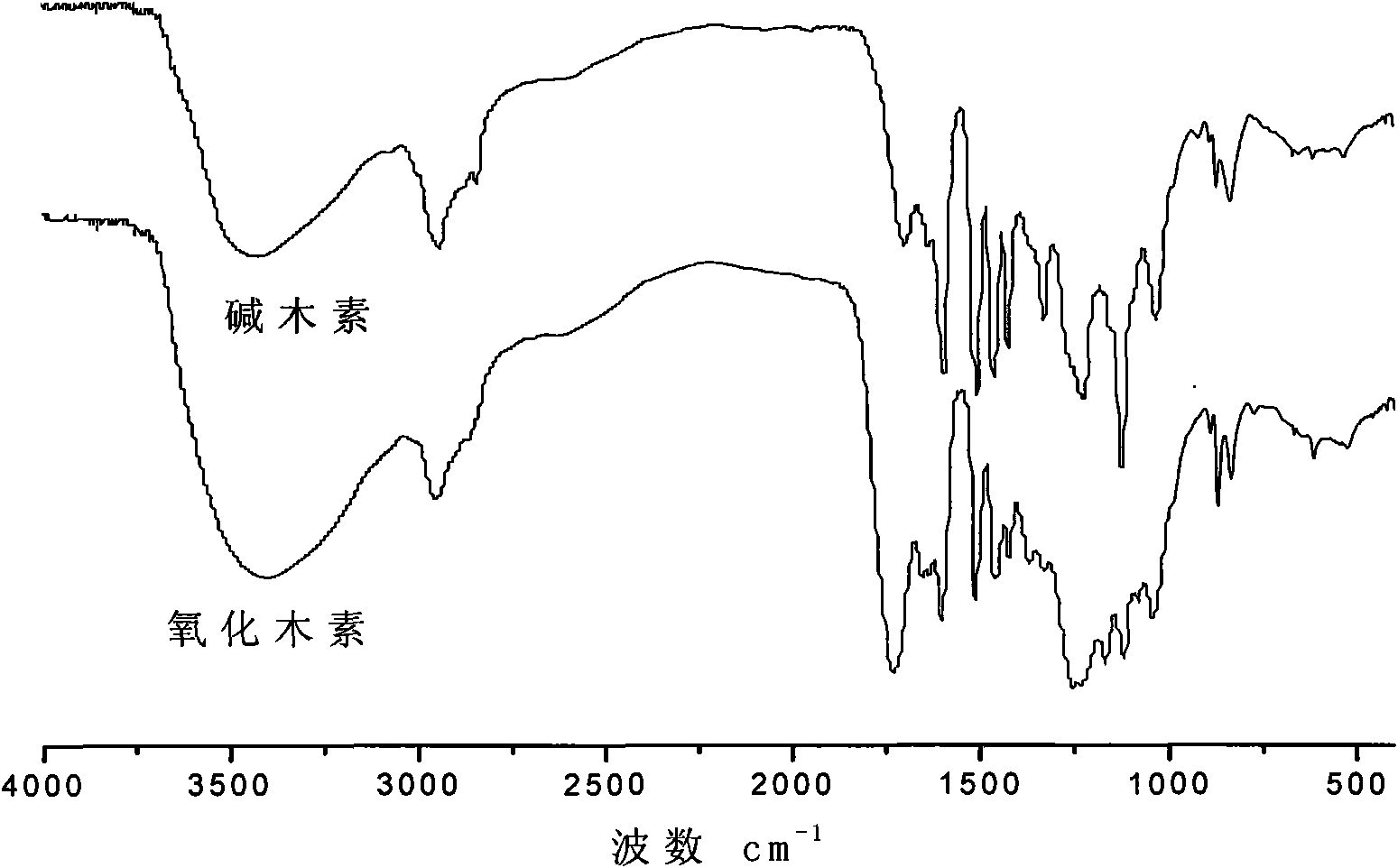

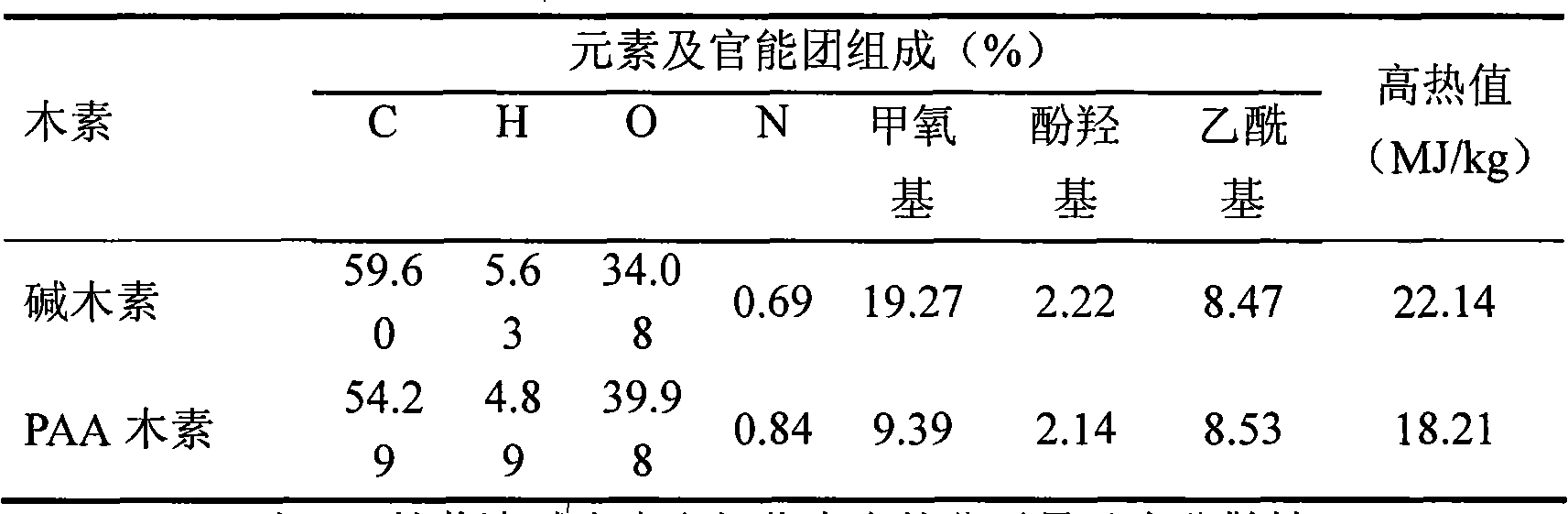

Biorefinery method of wood fiber material

InactiveCN101555667AEfficient removalHigh hydroxyl contentPretreatment with alkaline reacting compoundsBiofuelsFiberCellulose

The invention relates to a biorefinery method of wood fiber material, comprising the following steps of: (1) crushing and screening material so as to obtain long fiber, short fiber and powder; (2) adopting the two-step method of alkaline treatment and oxidation treatment to treat the long fiber obtained by the step (1) and preparing into pulp; and / or implementing synchronous diastatic fermentation on the short fiber and powder obtained by the step (1) and ultra-fine fiber and part of accepts obtained by the step (2) and preparing into alcohol. In the method, black liquid after alkaline treatment is prepared into alkali lignin; and the black liquid after oxidation treatment recovers the solvent and the oxidized lignin is prepared. The method can comprehensively utilize the wood fiber material to produce pulp, alcohol and lignin products. The obtained pulp has higher yield and better pulp performance compared with the sulfate pulp with the same material. The pulp can obtain higher enzymolysis rate with less usage of cellulose. The method has no sulfur and chloride elements, simultaneously reduces discharge of wastewater and has good environment friendliness.

Owner:TSINGHUA UNIV

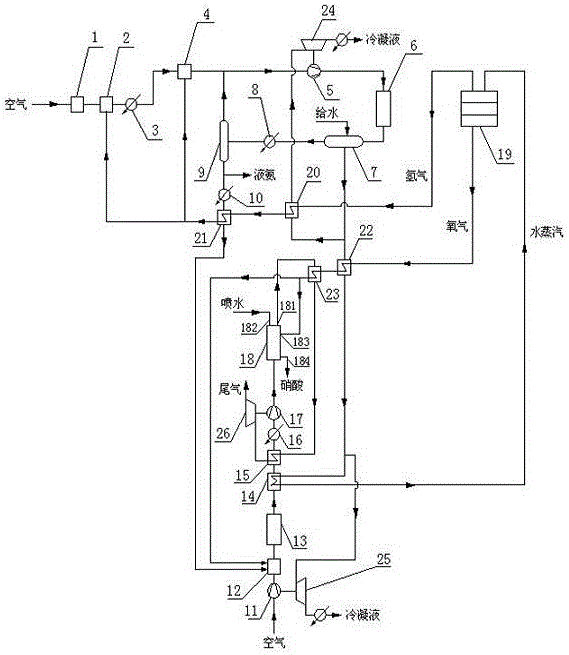

Water vapor electrolytic process based system for joint production of ammonia and nitric acid

ActiveCN106185984ARealize joint productionNot affected by market pricesElectrolysis componentsEnergy inputWater vaporEmission standard

The invention belongs to the technical field of chemical engineering and particularly relates to a water vapor electrolytic process based system for joint production of ammonia and nitric acid. The system comprises a nitrogen generation unit, an ammonia synthesis unit, a nitric acid generation unit, and a solid oxide electrolyzer. The ammonia synthesis unit is used to provide the material ammonia and process vapor for the nitric acid generation unit, no ammonia is externally purchased for the nitric acid generation unit, meanwhile, a heat recovery boiler is eliminated. The reaction heat of the ammonia synthesis unit and the nitric acid generation unit is used to produce high temperature vapor, the high temperature vapor is applied to the solid oxide electrolyzer, the solid oxide electrolyzer produces hydrogen and oxygen, the hydrogen and the oxygen are applied to the ammonia synthesis unit and the nitric acid generation unit, so that a mode of joint production of ammonia and nitric acid by taking air and water as raw materials is achieved, no materials or fuels are externally purchased, only electric energy is used, so that the system has the characteristics of high integration, low production cost, single and convenient energy consumption, reasonable recovery of energy, less environment pollution, conformity to the international emission standard and the like, and has an excellent economic benefit and an excellent application prospect.

Owner:陈志强

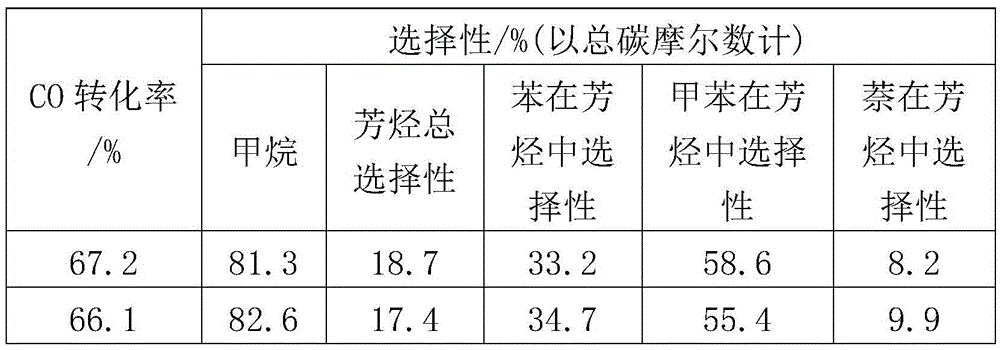

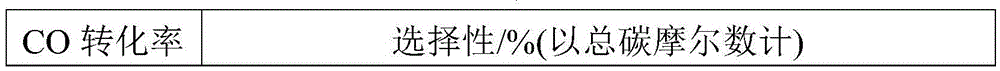

Method for coproduction of aromatic hydrocarbon and methane by direct conversion of synthesis gas

ActiveCN105622305AInhibition formationExtend your lifeHydrocarbon from carbon oxidesMolecular sieve catalystsSyngasMethanation

The invention discloses a method for coproduction of aromatic hydrocarbon and methane by direct conversion of synthesis gas. The method includes: putting a catalyst in a reactor, feeding the synthesis gas for reaction, performing coupled reaction of methanation and methane non-oxidative aromatization to realize coupling of reagents, products and heat of a reaction system, and performing further preparation at 200-500 DEG C to directly obtain aromatic hydrocarbon. By series connection of the methanation reaction and the methane non-oxidative aromatization reaction, heat coupling of the two reactions is realized effectively, carbon deposit is effectively inhibited by effective combination of two active centers, the synthesis gas is directly converted into the aromatic hydrocarbon at a low temperature, and economic benefits are increased substantially. By reaction within 120min, aromatic hydrocarbon selectivity can be stabilized at 15-30%, and after the reaction time reaches 1000h, the conversion rate keeps stable, and the catalyst is still active.

Owner:BEIJING UNIV OF CHEM TECH

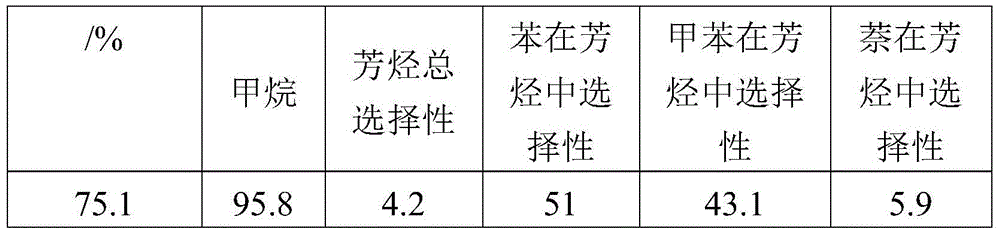

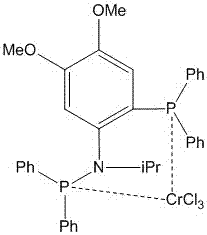

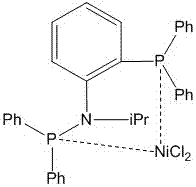

A kind of coordination type catalyst and the method for using the ethylene oligomerization of the catalyst to co-produce 1-hexene and 1-octene

ActiveCN105268480BRealize joint productionAchieve deliveryOrganic-compounds/hydrides/coordination-complexes catalystsHydrocarbons1-OcteneCoordination type

The invention discloses a coordination catalyst and a method for co-producing 1-hexene and 1-octene through ethylene oligomerization using the catalyst. The coordination catalyst provided by the invention contains a structural system capable of transmitting group electron induction or conjugation effects, which can better realize the electron transfer between atoms coordinated with the metal, stabilize the catalytic system, improve catalytic activity, and simultaneously increase the Selectively prepare 1-hexene and 1-octene, the selectivity of terminal olefins is >95%, the highest can exceed 99%, successfully realize the co-production of 1-hexene and 1-octene under the condition of high-end olefin selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +2

Process for preparing nanometer calcium sulfate

InactiveCN101838007AReduce manufacturing costAvoid growing upNanostructure manufactureCalcium/strontium/barium sulfatesCalcium hydroxideEmulsion

The invention discloses a process for preparing nanometer calcium sulfate. In the method, lime and ammonium sulfate are used as raw materials, and the production process comprises the following steps of: emulsifying the lime, generating nanometer calcium sulfate pulp by a reaction between change-inhibiting agent-containing calcium hydroxide emulsion and solution of ammonium sulfate, filtering and water-washing, drying and the like. The technology is suitable to be used for the recovery of the solution of ammonium sulfate and cyclic utilization of ammonia in a process of producing iron oxide series dyes by using ferrous sulfate as a raw material, and is the key technology used in the process of producing the iron oxide series dyes by using the ferrous sulfate as the raw material. In the preparation process, because the change-inhibiting agent is added, superfine nanometer calcium sulfate particles formed by the ammonium sulfate and the calcium hydroxide are avoided growing in a liquid-phase environment, and the industrialized production of the superfine nanometer calcium sulfate products prepared by a chemical method is made possible.

Owner:HUNAN HENGGUANG TECH

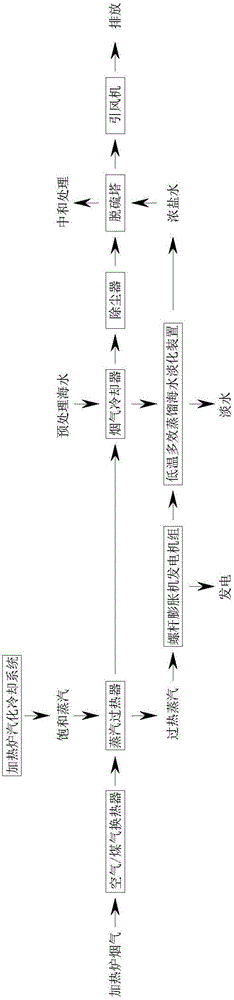

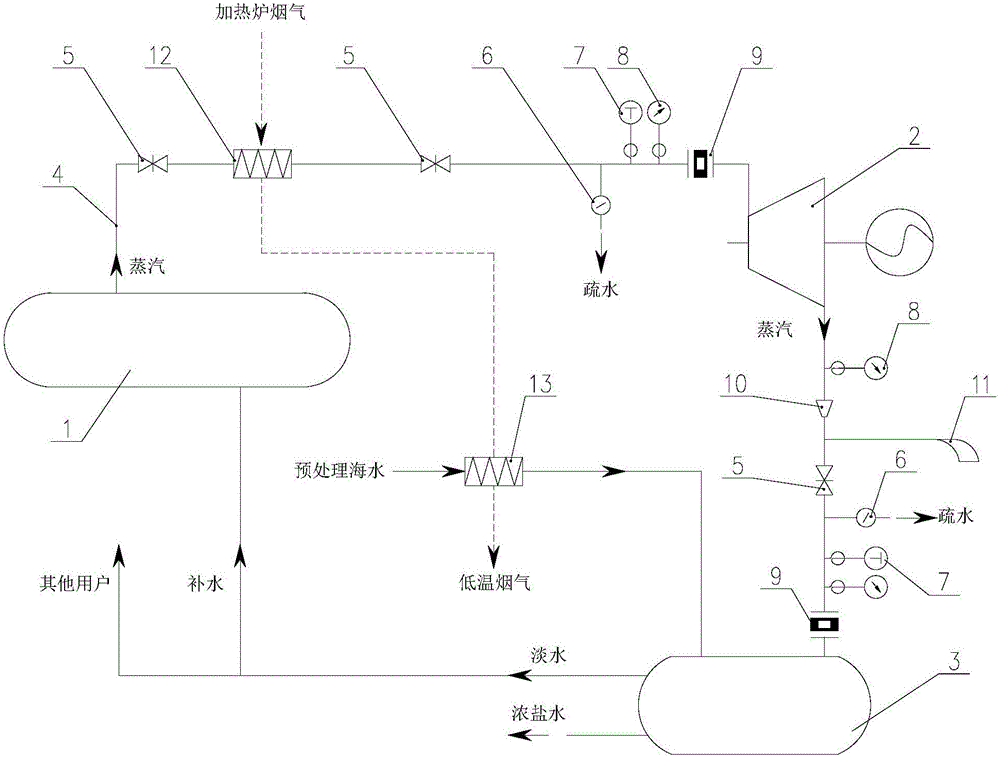

Heating furnace waste heat comprehensive utilization system and method

InactiveCN106052405ARealize cascade utilizationAddressing Adverse Effects of Power GenerationGeneral water supply conservationSeawater treatmentWater desalinationEngineering

The invention discloses a heating furnace waste heat comprehensive utilization system. The heating furnace waste heat comprehensive utilization system comprises a steam superheater, a power generator set and a sea water desalination device. The steam superheater is arranged in a heating furnace flue. Low pressure saturated steam generated by a heating furnace evaporated cooling system flows into the steam superheater and can be heated by heating furnace smoke to form superheated steam. The power generator set communicates with fluid of the steam superheater. The superheated steam generated in the steam superheater flows into the power generator set for power generation. The sea water desalination device communicated with fluid of the power generator set. The steam discharged by the power generator set flows into the sea water desalination device for sea water desalination. The invention further discloses a heating furnace waste heat comprehensive utilization method. Through the heating furnace waste heat comprehensive utilization system and method, gradient utilization of energy of the heating furnace steam is fully achieved, excessive pressure of the steam is used for power generation, and waste heat of the steam is further used for producing fresh water.

Owner:BERIS ENG & RES CORP

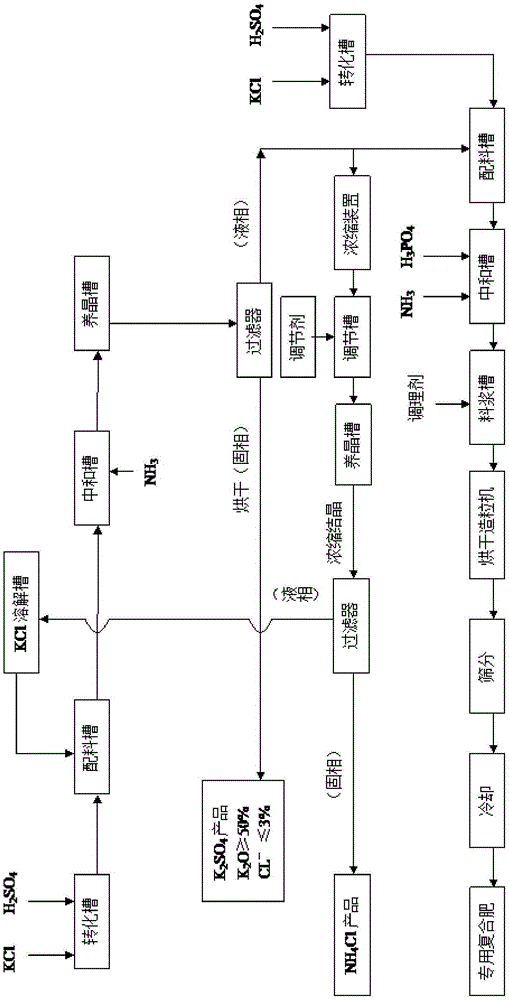

New process for production of potassium sulfate and co-production of compound fertilizer

InactiveCN105236448ATake advantage ofEfficient use ofAmmonium halidesAlkali metal sulfites/sulfatesAgricultural engineeringPotassium bisulfate

The invention discloses a fertilizer production process, which is characterized by including the steps of: (1) reacting potassium chloride with sulfuric acid in a conversion groove to generate potassium bisulfate and hydrochloric acid, then transferring the products into a first dosage bunker, adding potassium chloride and mixing the materials evenly, conveying the mixture into a neutralizing tank, introducing ammonia to carry out neutralization reaction, carrying out crystallization, filtration and solid phase drying to obtain potassium sulfate. The process provided by the invention avoids the high temperature hardening procedure, adopts low energy consumption crystallization technique, is energy saving and environment-friendly. At the same time, the mother solution in production can be directly subjected to concentration filter pressing so as to obtain a ammonium chloride product or be applied to production of special fertilizers, thus realizing the combined production process of a variety of fertilizers.

Owner:河北新宜化肥有限公司

Method for preparing polypeptide and astaxanthin from shrimp and crab processing waste

InactiveCN106591410AReduce pollutionIncrease added valuePeptide preparation methodsFermentationAstaxanthinBetaxanthins

The invention belongs to the field of comprehensive utilization of subsidiary agricultural products, and particularly relates to a method for preparing polypeptide and astaxanthin from shrimp and crab processing waste. The method particularly comprises the steps that the shrimp and crab processing waste serves as a raw material, cleaning and crushing are conducted, acid soaking is conducted, after enzymatic hydrolysis and centrifugation are conducted, supernatant is separated and concentrated through a membrane, and polypeptide is obtained; centrifugal sediments are dried, and astaxanthin is obtained after subcritical extraction and column chromatography isolation. Compared with traditional alkali extraction, the method has the advantages of being high in raw material utilization rate, energy-saving and environmentally-friendly in production process and high in product purity and additional value. By means of the method, comprehensive utilization of the shrimp and crab resource is promoted, the sources of the astaxanthin and polypeptide are enriched, and the positive economic value is achieved.

Owner:深圳市江牧实业有限公司

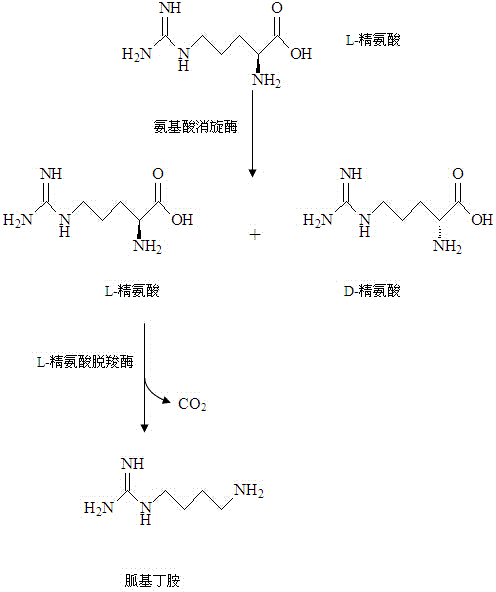

Method for coproducing D-arginine and gamatine through biotransformation

InactiveCN104152478ALow costLow priceMicroorganism based processesFermentationMolecular biologyTransformation systems

The invention discloses a method for coproducing D-arginine and gamatine through a biological method. The method comprises the following steps: synthesizing arginine racemase genes argR according to a designed primer, establishing an expression vector pET24a-argR and transferring the expression vector into an Escherichia coli strain, thus obtaining genetically engineered bacteria of the arginine racemase; establishing an expression vector pET24a-speA through a speA gene segment amplified by PCR, transferring the expression vector pET24a-speA into Escherichia coli, thus obtaining L-arginine decarboxylase genetically engineered bacteria; stirring and reacting a transformation system containing L-arginine and a wet vector for expressing the genetically engineered bacteria of the arginine racemase, thus obtaining an enantiomer of L-arginine and D-arginine; removing the arginine racemase, supplementing a wet vector for expressing L-arginine decarboxylase, and continuously reacting until the L-arginine is completely consumed; and finally, separating and purifying the D-arginine and gamatine in the reaction system. The catalyzing enzyme activity is high, the separation and purification operations are simple, the raw materials are cheap, the total production cost is low; and the method has high conversion rate, can realize large-scale production and is suitable for industrial application.

Owner:洛阳华荣生物技术有限公司

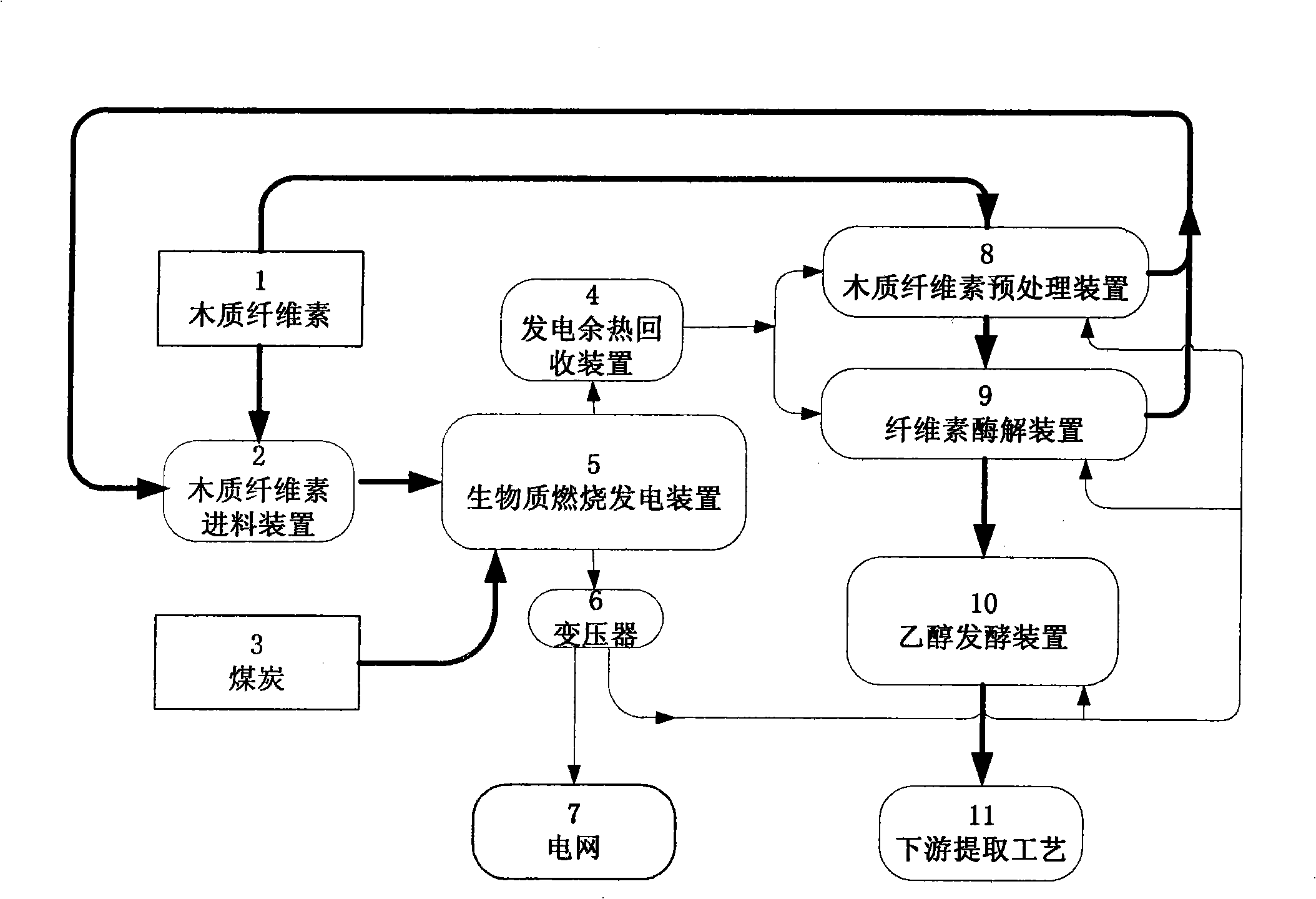

Coupling process for producing ethyl alcohol with fibre and generating power with biomass combustion

ActiveCN101402983ASolve processing problemsRealize resource utilizationBiofuelsSteam useDirect combustionPower grid

The invention discloses a coupling technology of cellulosic ethanol production and biomass combustion power generation, which belongs to the renewable energy technology field. The coupling technology takes lignocellulose as raw material for carrying out the cellulosic ethanol production and the biomass direct combustion or the mixed combustion power generation, the lignocellulose raw material separately passes through a lignocellulose feeding device to enter a biomass combustion power generation device for realizing the direct combustion power generation; or the lignocellulose raw material is mixed with coal for combustion, thus realizing the mixed combustion power generation and further realizing the combustion power generation of the lignocellulose; hot steam which is generated by the power generation technology is recovered through a waste heat recovery device and used for heating of the cellulosic ethanol production technology; the generated power enters a national power grid through a transformer or is supplied to the cellulosic ethanol production. Therefore, the coupling technology realizes the cellulosic ethanol production and the biomass combustion power generation. The biomass power generation efficiency achieves 28-32 percent and can provide the power.

Owner:STATE GRID ENERGY CONSERVATION SERVICE

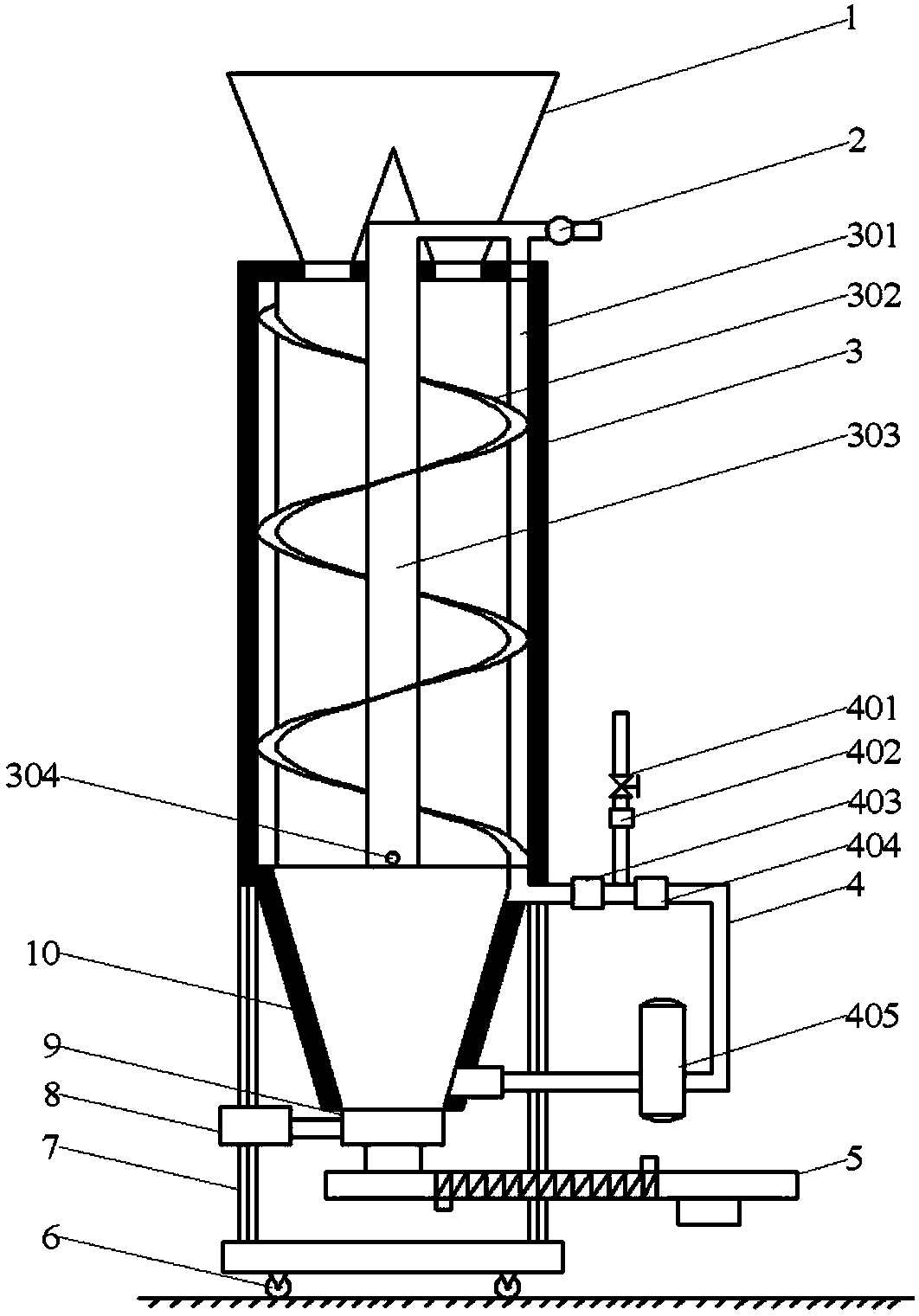

Movable internal heating and external heating combined biomass pyrolysis charcoal and tar co-production system

PendingCN107603646AImprove heat transfer efficiencyGuaranteed production efficiencyBiofuelsIndirect and direct heating destructive distillationTarBiomass

The invention discloses a movable internal heating and external heating combined biomass pyrolysis charcoal and tar co-production system, which mainly comprises a material hopper, an external source heating device, a pyrolysis gas backflash heating device, a water cooling device and rollers, wherein the external source heating device comprises a cyclone heat exchange chamber, a cyclone heat exchange plate, a heat exchange pipe and a three-way cross pipeline, the pyrolysis gas backflash heating device comprises an air regulation valve, an air flow rate meter, an igniter, a flame arrester and aflue gas purifier, the external source heating device provides an external heat source for material drying, the heat generated by the spontaneous combustion of the material provides an internal heat source for pyrolysis, the high temperature flue gas generated after the igniting of pyrolysis gas enters the external source heating device from the gas inlet at the side lower end of the external source heating device, dividing wall type countercurrent flow heat exchange is performed on the material so as to achieve the internal heating and external heating combination of the whole system, and therollers are arranged at the lower end of a bracket and is used for moving the whole system. The movable internal heating and external heating combined biomass pyrolysis charcoal and tar co-productionsystem of the present invention has advantages of convenient operation, convenient movement and high heat exchange efficiency.

Owner:ACADEMY OF PLANNING & DESIGNING OF THE MINIST OF AGRI

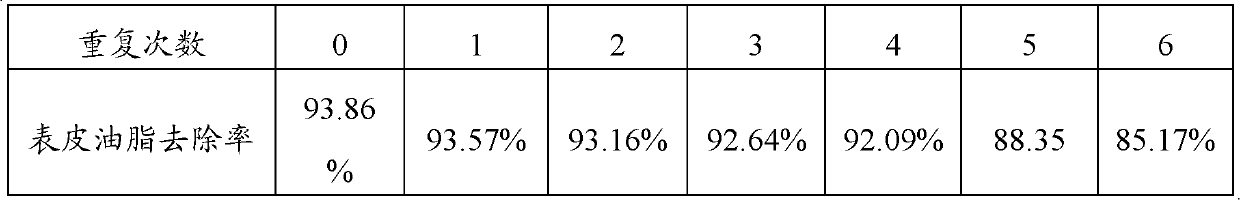

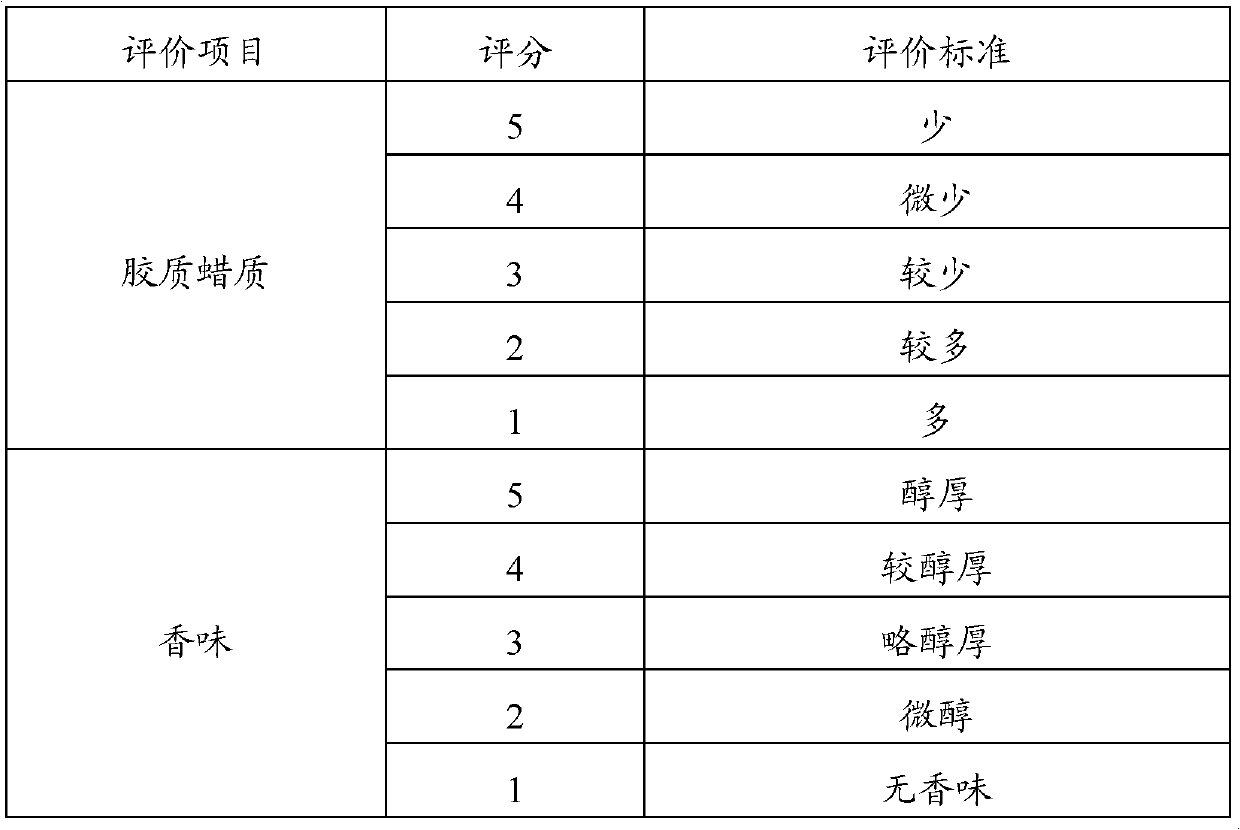

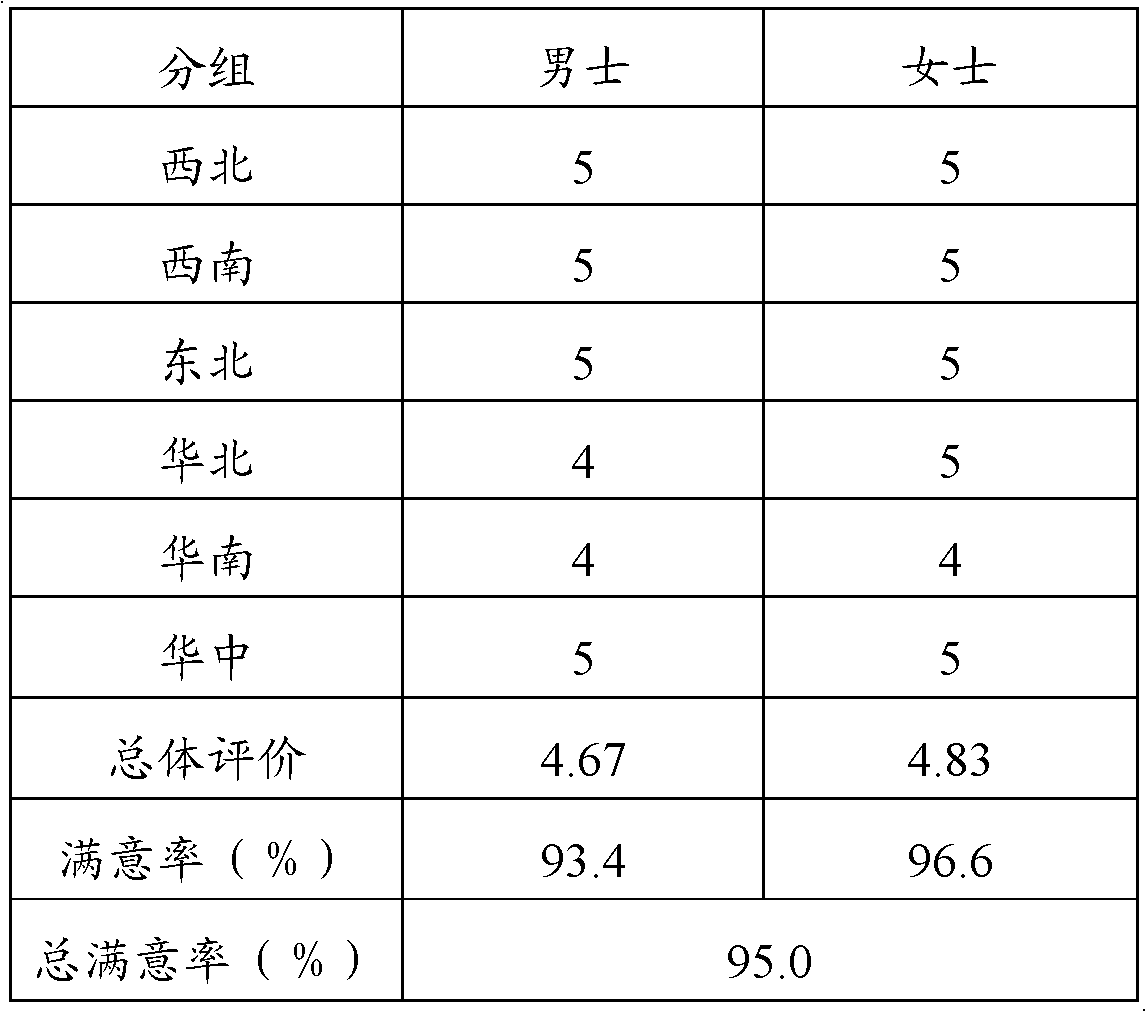

Preparation method of zanthoxylum seed oil

ActiveCN102604734AImprove oil yieldNo residueFatty-oils/fats productionOil and greaseZanthoxylum bungeanum

The invention relates to the field of oil material processing, in particular to a preparation method of zanthoxylum seed oil. The method comprises the following steps of: mixing zanthoxylum seeds and excessive sodium hydroxide solution of which the mass percentage is 1.2 to 2.0 percent; under the protection of nitrogen, heating the mixture to saponify the mixture; separating the mixture to obtain the zanthoxylum seeds without epidermis oil fat; and squeezing and refining the zanthoxylum seeds to obtain the zanthoxylum seed oil and also the aqueous solution of sodium aliphatate. The method has the advantages of simpleness in operation, low requirement on equipment, easiness in industrialization and the like. The obtained zanthoxylum seed oil is high in oil extraction rate, low in content of colloid and waxiness, and thick in fragrance, and does not have residual solvent. In addition, the obtained sodium aliphatate can serve as an industrial detergent raw material. Co-production of the zanthoxylum seed oil and the sodium aliphatate is also realized.

Owner:CHONGQING TECH & BUSINESS UNIV

Process for coupling producing bioloigical diesel oil and 1,3-propylene glycol

InactiveCN1276962CReduce or even eliminate poison inactivationSave on separation costsOrganic chemistryLiquid hydrocarbon mixture productionBiodieselMicrobial transformation

The present invention belongs to the field of bioengineering technology, and especially a kind of couple producing biological diesel oil and 1, 3-propylene glycol. The present invention features that the course of lipase catalyzed reaction between methanol or ethanol and fat to produce biological diesel oil and the course of biologically converting glycerin into 1, 3-propylene glycol are coupled via membrane filtering for simultaneous proceeding. The present invention has the effects of eliminating the suppression of short-chain alcohol and glycerin on lipase, prolonging the service life of immobilized enzyme, omitting the glycerin separating and extracting step, lowering the production cost, saving time, raising production efficiency and providing economic and feasible process for producing biological diesel oil and 1, 3-propylene glycol.

Owner:DALIAN UNIV OF TECH

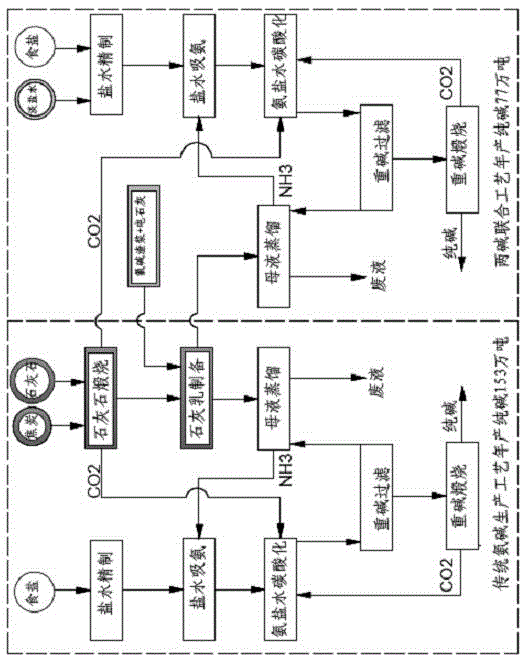

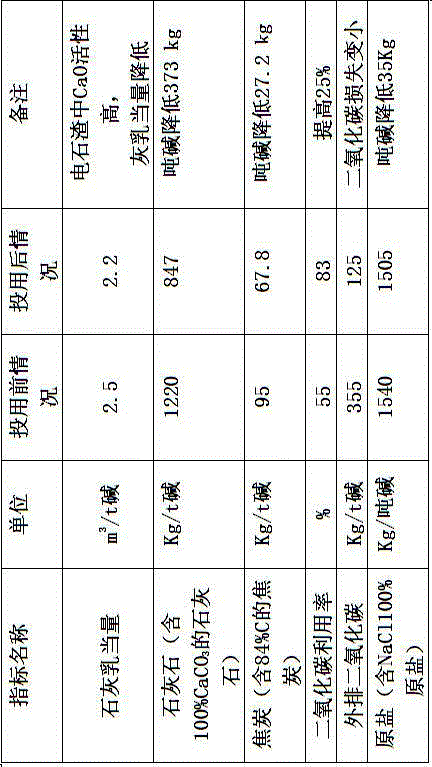

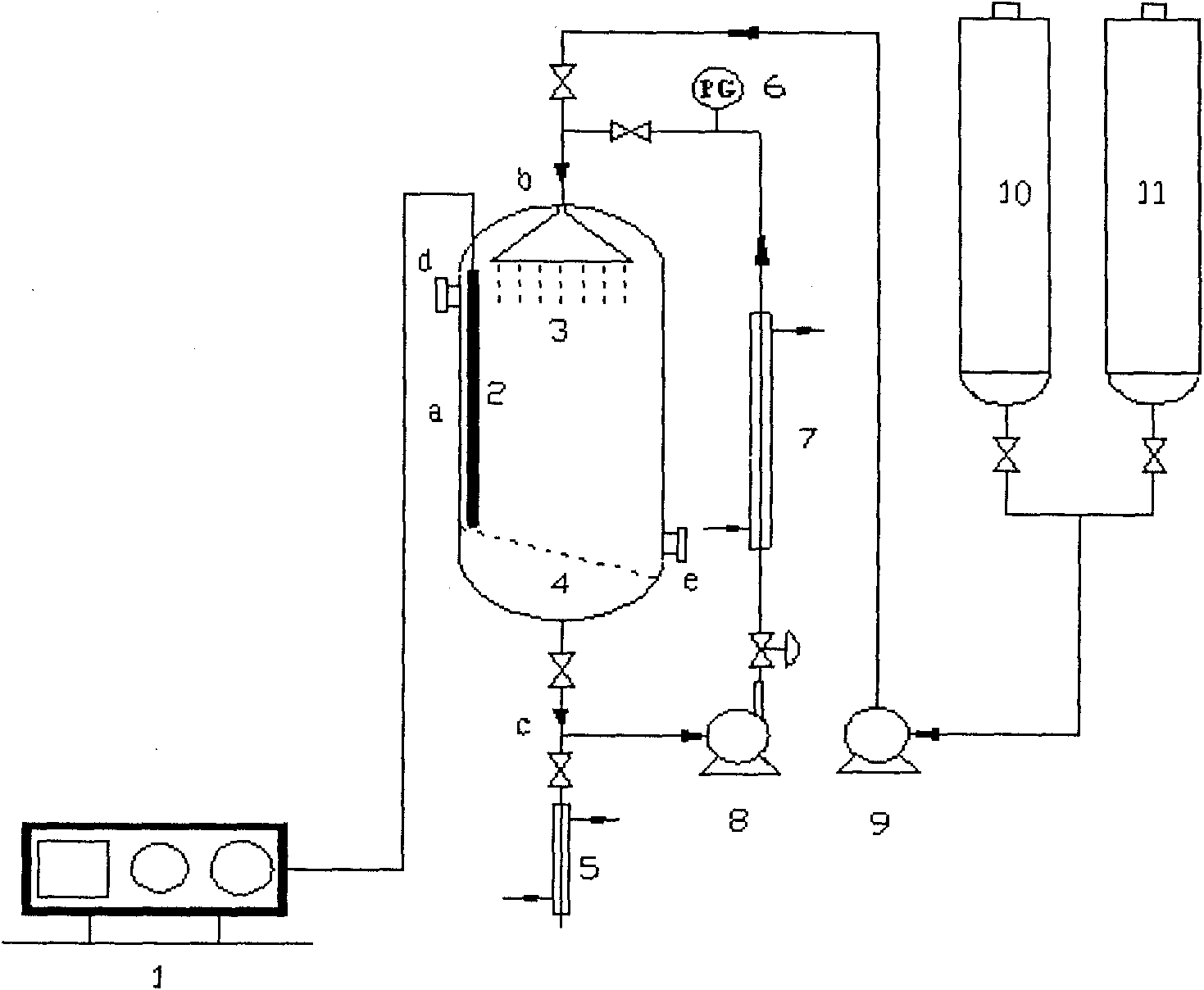

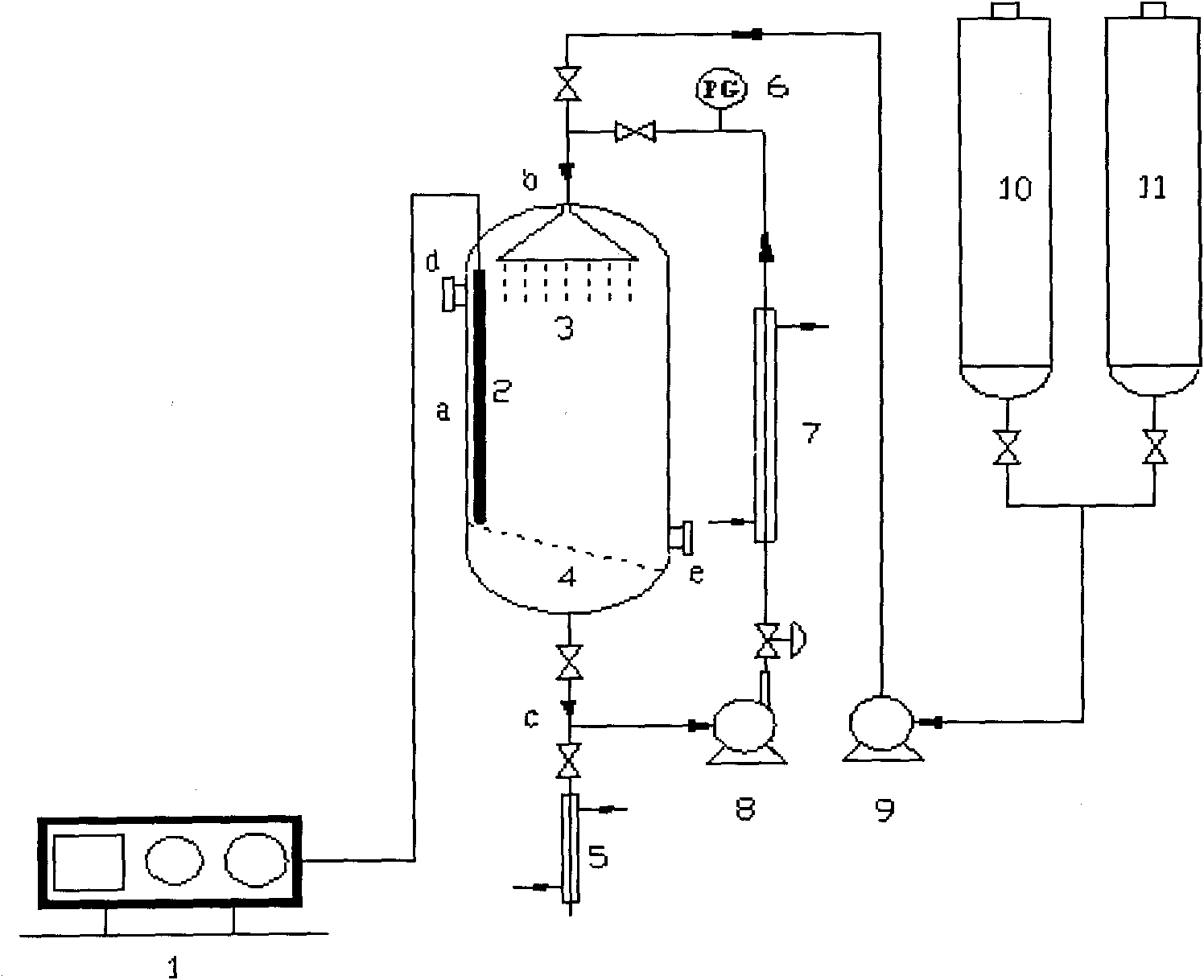

Method for producing sodium carbonate by utilizing chlor-alkali ammonia-alkali tailings

The invention relates to a method for producing sodium carbonate, in particular to a method for producing sodium carbonate by utilizing chlor-alkali ammonia-alkali tailings. Limestone burns to emit heat, and is resolved to generate carbon dioxide gas which is sent to a compressor; the acetylene sludge slurry of the chlor-alkali tailing and calcium carbide dust are mixed to prepare lime slurry; refined salt water is prepared through light salt brine after production of chlor-alkali and mirabilite; light ammoniacal brine is sent to an absorption tower to prepare ammoniacal brine; sodium bicarbonate slurry is sent to a filtering alkali vehicle for solid-liquid separation; the solid body is sent to a sodium bicarbonate calcination procedure; the liquid is sent to a mother liquid distillation procedure; the sodium bicarbonate is conducted by heating resolving in a sodium bicarbonate calcination furnace to generate sodium carbonate, and is sent to a sodium bicarbonate production and alkali cooling procedure; the generated carbon dioxide gas returns to a carbonizer. The method produces sodium carbonate by utilizing the carbon dioxide emitted by the ammonia-alkali and the acetylene sludge slurry emitted by the chlor-alkali, realizes combined production of the two alkalis, solves the problem of emission of the alkali wastes, reduces consumption of limestone and energy, improves the utilization ratio of the carbon dioxide, and improves the production of sodium carbonate through an ammonia soda process.

Owner:TANGSHAN SANYOU CHEM IND

Wet-method phosphoric acid staged extraction and purification process

ActiveCN102815685ARealize joint productionReduce the cost of high valuePhosphorus compoundsQuality levelMethyl isobutyl ketone

The invention relates to a wet-method phosphoric acid staged extraction and purification process, and belongs to the technical field of chemical engineering separation. According to the process, wet-method phosphoric acid with a P2O5 concentration of 50-65 wt% is extracted by using methyl isobutyl ketone; a first-level raffinate acid obtained through phase separation is extracted by using another solvent A; and phosphoric-acid-loaded methyl isobutyl ketone and phosphoric-acid-loaded solvent A are respectively subjected to back extraction for producing phosphoric acid and phosphate products, and are regenerated. The solvent A is a mixed solution of tributyl phosphate and a diluent. The diluent is selected from n-butanol, kerosene, n-hexane, and cyclohexane. According to the process provided by the invention, different solvents are adopted in different stages, such that the solvents can be used in extractions within appropriate P2O5 ranges thereof, and advantages in separation capacities or purification capacities are performed. Therefore, co-productions of phosphoric acid and phosphate products of different quality levels are realized. The cost in upgrading phosphorus resource values is reduced, wet-method phosphoric acid purification rate is improved, and conditions are provided for flexibly arranging productions according to resource status and market demands.

Owner:TSINGHUA UNIV

Method for cogenerating activated carbon and hydrogen by coal char gasification and methane reforming coupling technology

ActiveCN105800556AImprove gasification reactivityEasy to control the pore structureHydrogenHydrogen/synthetic gas productionCogenerationChemistry

The invention discloses a method for cogenerating activated carbon and hydrogen by a coal char gasification and methane reforming coupling technology. The method comprises the following steps: crushing coal char and mixing the coal char with a modifier evenly at the mass ratio of 1 to (0.1-10) to form a mixture; utilizing the mixture as a catalyst for steam reforming reaction of methane, wherein the conditions of regulating and controlling the steam reforming reaction of the methane are as follows: the temperature range is 500-950 DEG C; the pressure is 0-4MPa; and the molar ratio of the methane to steam is 1 to (1-6); collecting the gas generated by steam reforming reaction of the methane to obtain a hydrogen-rich gas; and controlling the standing time in the process of the steam reforming reaction of the methane to be 1-6 hours and then cooling the residues below 100 DEG C to obtain the activated carbon. According to the method, the targets of strengthening the gasification reactivity of the coal char and achieving targeted improvement of hydrogen yield and cogeneration of an activated carbon product can be achieved; and the method has the characteristics of being relatively wide in raw material application range, mild in technological conditions, high in hydrogen purity, low in equipment investment cost, convenient to operate, large-scale in production and the like.

Owner:NORTHWEST UNIV

Device and method for hydrolyzing plant hemicellulose by fermented citric acid wastewater

InactiveCN101787086AReduce processing costsSolve the sourceFermentationHigh concentrationWater storage tank

The invention relates to a device capable of effectively utilizing fermented citric acid wastewater to hydrolyze plant hemicellulose. The device is mainly composed of a circulating spray flushing and filtering reactor, an acid storage tank, a water storage tank and a heat exchanger; the method is characterized by comprising the steps: at first, mixing the citric acid wastewater with raw material of the plant hemicellulose for hydrolysis reaction at 100 to 200 DEG C to obtain hydrolyzate mainly containing pentose, and then adding cellulase into hydrolyzed residues for batch enzyme hydrolysis to obtain high-concentration dextrose for the fermentation of ethanol. The method for preparing fermentable sugar for ethanol by pretreating the raw material of the plant hemicellulose by using the fermented citric acid wastewater can not only sufficiently utilize the fermented citric acid wastewater to save water resource, but can also lower the cost for treating wastewater from fermented citric factory and the production cost of the fermentable sugar for cellulose ethanol.

Owner:NANJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com