Method for producing sodium carbonate by utilizing chlor-alkali ammonia-alkali tailings

A technology for ammonia-alkali tailings and chlor-alkali tailings, applied in carbonate preparations and other directions, can solve the problems of geographical environment pollution, narrow scope of use, inability to handle, etc., to improve utilization rate, increase production, and reduce limestone and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing and embodiment:

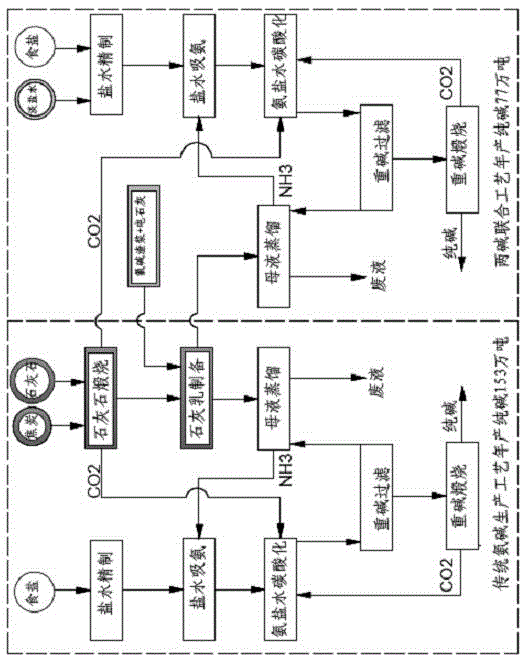

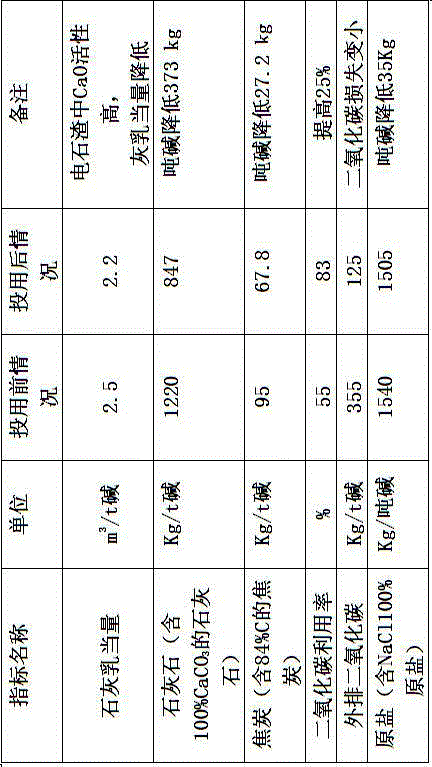

[0026] A kind of method utilizing chlor-alkali tailings and ammonia-soda tailings to produce soda ash, see attached figure 1 The process shown in , the concentration of calcium carbide slurry at 1.75 mol / l is about 250m 3 / h (300t / h), digested and mixed with about 31 tons of calcium carbide to obtain a concentration of 1.875mol / l thick slag slurry 300m 3 / h (366 tons / h), pumped to the desulfurization tower of the soda ash company to remove divalent sulfur ions or elemental sulfur, (the active ingredient of calcium carbide slurry is calcium oxide, and the digestion reaction between calcium carbide slurry and calcium oxide is actually used The water contained in it reacts with calcium oxide, the equation is: CaO+H 2 O—Ca(OH) 2 ); then sent to the ash machine and the quicklime from the lime kiln is mixed and digested in the ash machine to ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com