Method for preparing nuclear-grade sponge zirconium and nuclear-grade sponge hafnium

A nuclear-grade sponge zirconium and nuclear-grade technology, which is applied in the field of preparing nuclear-grade zirconium sponge and nuclear-grade hafnium sponge, can solve the problem that the zirconium-hafnium extraction and separation device cannot be produced normally, does not meet the national environmental protection requirements, and the product quality cannot reach high-purity oxygen Zirconium chloride quality standards and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

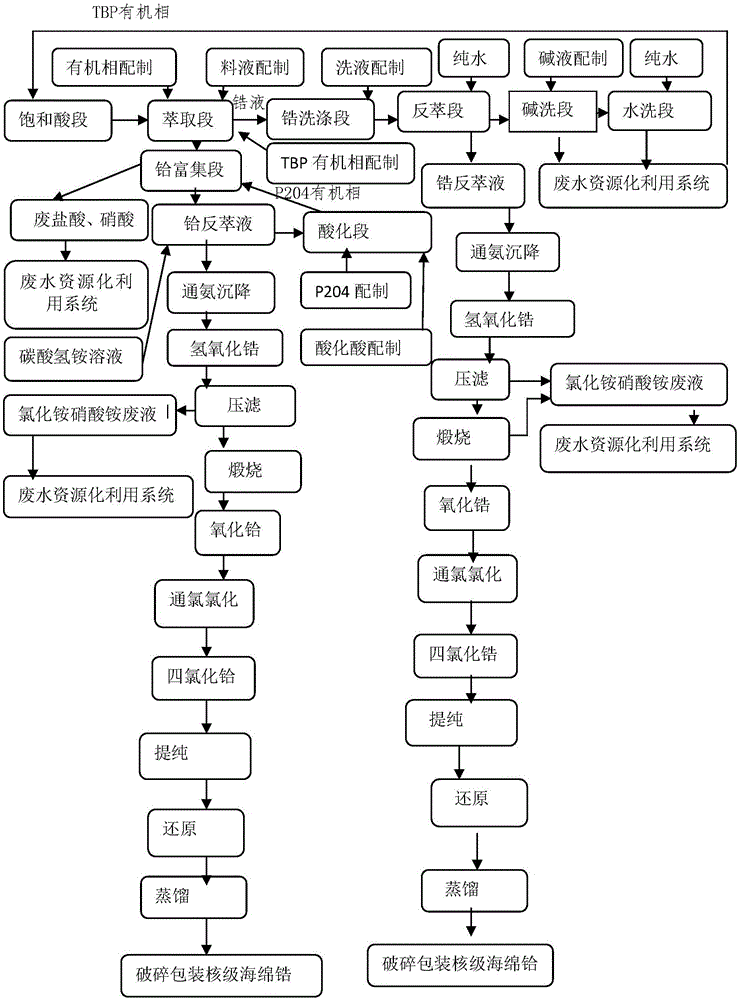

[0051] The processing device and process method of nuclear-grade zirconium sponge and nuclear-grade hafnium sponge (see figure 1 )

[0052] 1. Preparation of each stage of extraction

[0053] Feed solution preparation: measure and dissolve the zirconium oxychloride in the raw material, hydrolyze the zirconium tetrachloride, control the ZrO2 concentration in the feed liquid of the two obtained solutions to 80-95g / l, filter through a ceramic membrane filter, and use nitric acid and hydrochloric acid to prepare a qualified feed liquid with 8N acidity;

[0054] Preparation of lotion: use recovered hydrochloric acid, nitric acid mixture, hydrochloric acid, and nitric acid to prepare a mixed pickling solution with 5N acidity;

[0055] TBP organic phase preparation: 60% tributyl phosphate (TBP) and 40% kerosene by weight percentage, prepare TBP organic phase;

[0056] Saturated acid preparation: nitric acid is prepared into TBP saturated acid with 6N acidity;

[0057] Alkaline p...

Embodiment 2

[0203] Obtaining of the above-mentioned embodiment raw material: the method for producing high-purity zirconium oxychloride

[0204] 1. Boiling chlorination reaction

[0205] Zircon sand, silicon powder, petroleum coke and chlorine gas, the ratio is 0.8~1.2:0.1~0.4:0.4~0.5:2.8~3.0, and chlorine gas is introduced into the chlorination furnace at a gas velocity of 0.06~0.16m / s. The boiling chlorination reaction is carried out at 650-1100°C, which is an autothermal reaction, and the temperature of the expansion section is controlled at 380-500°C to generate zirconium tetrachloride and silicon tetrachloride.

[0206] Chlorination reaction equation:

[0207] ZrSiO 4 +4C+4Cl 2 =ZrCl 4 +SiCl 4 +4CO (1)

[0208] ZrSiO 4 +2C+4Cl 2 =ZrCl 4 +SiCl 4 +2CO 2 (2)

[0209] Si+2Cl 2 = SiCl 4 (3)

[0210] 2. Condensation and separation of the mixed gas after the reaction

[0211] The mixed gas after the reaction enters the fourth-stage condenser, and is cooled by circulating w...

Embodiment 3

[0230] Preparation of silica by gas phase method:

[0231] 1. Fumed silica synthesis and treatment

[0232]The refined silicon tetrachloride from the high-purity zirconium oxychloride process enters the silicon tetrachloride vaporizer for vaporization, and is vaporized with hot water in the vaporizer. The vaporization temperature is controlled at 70-80°C, and the hydrogen and air from the hydrochloric acid electrolysis device are heated The device is preheated to 120-130°C, and the three gases enter the reaction gas homogenizer for homogenization. The ratio of silicon tetrachloride: hydrogen: air (molar ratio) is 1:2-4:9-11, Enter the multi-layer burner on the upper part of the silica high-temperature reactor, form a stable flame after burning, and generate gas-phase silicon dioxide and hydrogen chloride water vapor in the silica high-temperature reactor, and the temperature in the silica high-temperature reactor is controlled at 800~1000℃, after passing through the reaction-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com