Preparation method of zanthoxylum seed oil

A technology of Zanthoxylum bungeanum seeds and kernels, which is applied in the direction of fat oil/fat production and fat generation, and can solve the problems of low usable value, high energy consumption, and hindering the practical application of Zanthoxylum bungeanum oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026]The invention discloses a method for preparing Zanthoxylum bungeanum seed oil, and those skilled in the art can learn from the content of this article and appropriately improve the process parameters to realize it. In particular, it should be pointed out that all similar replacements and modifications are obvious to those skilled in the art, and they are all considered to be included in the present invention. The method and application of the present invention have been described through preferred embodiments, and the relevant personnel can obviously make changes or appropriate changes and combinations to the method and application described herein without departing from the content, spirit and scope of the present invention to realize and Apply the technology of the present invention.

[0027] The reagents and raw materials used in the preparation method of the prickly ash seed oil provided by the invention can be purchased from the market.

Embodiment 1

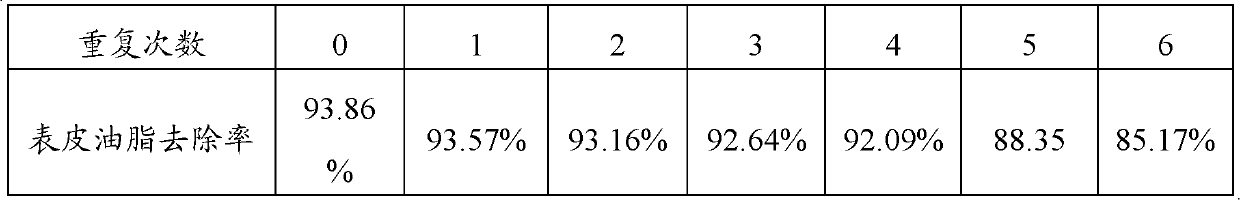

[0029] The selection of embodiment 1 Zanthoxylum bungeanum epidermis grease removal condition

[0030] Different sodium hydroxide concentrations were selected to detect the effect of sodium hydroxide concentration on the oil removal rate of pepper seed epidermis. The results are shown in Table 1.

[0031] Table 1 Effect of alkali concentration on oil removal rate of pepper seed epidermis

[0032] NaOH concentration

1.0%

1.2%

1.4%

1.6%

1.8%

2.0%

Cuticle Oil Removal Rate

70.18%

88.62%

93.86%

93.82%

93.66%

93.40%

[0033] It can be seen from the results in Table 1 that with the increase of the concentration of sodium hydroxide solution, the oil removal rate of the pepper seed epidermis increases, and when the concentration exceeds 1.4%, the removal rate remains basically unchanged. When pepper seeds are whole, the reaction between epidermal oil and sodium hydroxide solution actually in...

Embodiment 2

[0047] The removal of embodiment 2 Zanthoxylum bungeanum epidermis grease

[0048] Get 10g of Zanthoxylum bungeanum seeds containing kernels after water selection, sieving, and drying, put them in a 100ml three-necked bottle, add at least twice the volume of 1.4% sodium hydroxide aqueous solution (sodium hydroxide / water mass ratio), and feed N 2 , 60 ° C stirring reaction for 30 min. After the reaction is completed, cool naturally, separate the pepper seeds by suction filtration and wash them, the filtrate is rich in fatty acid sodium salt, has a certain emulsification ability for industrial kerosene and the ability to displace crude oil, and can be used as a raw material for industrial detergents; After the reaction, the oil removal rate of the pepper seed epidermis was 93.86%. The washed pepper seeds were dried in the air, sealed and stored for use in the preparation of kernel oil. The filtrate is rich in fatty acid sodium salt, has a certain emulsification ability for indu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com