Method for preparing polypeptide and astaxanthin from shrimp and crab processing waste

A technology of astaxanthin and waste, applied in the field of preparation of polypeptide and astaxanthin, to achieve the effect of reducing environmental pollution, mild conditions and good safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

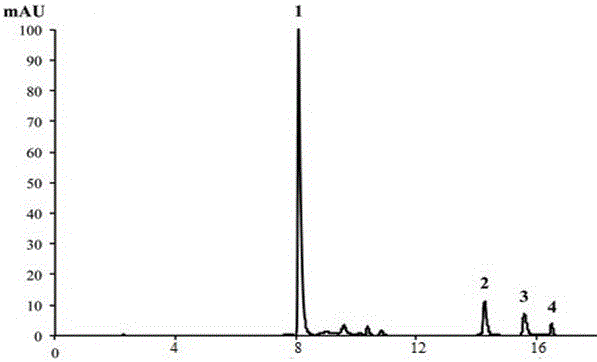

Image

Examples

Embodiment 1

[0047] A method for preparing polypeptide and astaxanthin from shrimp and crab processing waste, comprising the steps of:

[0048] 1) Raw material pretreatment:

[0049] Collect 10kg of shrimp shells, remove moldy shrimp shells, wash with tap water to remove sediment and seaweed, drain, crush and beat the slurry, pass the slurry through a 60-mesh sieve, and add a mixed solution of electrogenerated functional water and hydrochloric acid to make the pH of the system 1. After stirring at 150r / min for 6h, centrifuge at 3000r / min with a flat-panel centrifuge equipped with a 600-mesh filter cloth, collect the precipitate a, and store it at low temperature for later use.

[0050] 2) Material enzymatic hydrolysis:

[0051] Add the precipitate a to the electro-generated functional water with a pH of 8.5-9.0 at a material-to-liquid ratio of 1:10 (m / V), then add the complex protease at 3% of the enzyme amount, and stir at 300r / min at 40°C Hydrolysis 4h. After the enzymatic hydrolysis ...

Embodiment 2

[0057] A method for preparing polypeptide and astaxanthin from shrimp and crab processing waste, comprising the steps of:

[0058] 1) Raw material pretreatment:

[0059] Collect 20kg of crab shells, remove the moldy part, wash with tap water to remove sediment and seaweed, drain, crush and beat the slurry, pass the slurry through an 80-mesh sieve, add a mixed solution of electrogenerated functional water and hydrochloric acid, and make the pH of the system 0. After stirring at 200r / min for 6h, centrifuge at 3500r / min with a flat-panel centrifuge equipped with a 600-mesh filter cloth, collect the precipitate a, and store it at low temperature for later use.

[0060] 2) Material enzymatic hydrolysis:

[0061] Add the precipitate a to the electro-generated functional water with a pH of 9.0-10.0 at a material-to-liquid ratio of 1:15 (m / V), then add the complex protease at 5% of the enzyme amount, and stir at 50°C at a speed of 300r / min Hydrolysis 3h. After the enzymatic hydroly...

Embodiment 3

[0067] A method for preparing polypeptide and astaxanthin from shrimp and crab processing waste, comprising the steps of:

[0068] 1) Raw material pretreatment:

[0069] Collect 15 kg of shrimp shells, remove moldy shrimp shells, wash with tap water to remove sediment and seaweed, drain, crush and beat the slurry, pass the slurry through a 100-mesh sieve, and add a mixed solution of electrogenerated functional water and hydrochloric acid to make the pH of the system 2, After stirring at 200r / min for 9h, centrifuge at 3500r / min with a plate centrifuge equipped with an 800-mesh filter cloth, collect the precipitate a, and store it at low temperature for later use.

[0070] 2) Material enzymatic hydrolysis:

[0071] Add the precipitate a to the electro-generated functional water with a pH of 8.5-9.5 at a material-to-liquid ratio of 1:12 (m / V), then add the compound protease at 5% of the enzyme amount, and stir at 50°C at a speed of 300r / min Hydrolysis 6h. After the enzymatic h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com