Biorefinery method of wood fiber material

A technology of lignocellulosic raw materials and biorefining, which is applied in the fields of cellulose raw material pulping, lignin derivatives, fiber raw material treatment, etc., to achieve the effect of good cellulase enzymatic hydrolysis performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

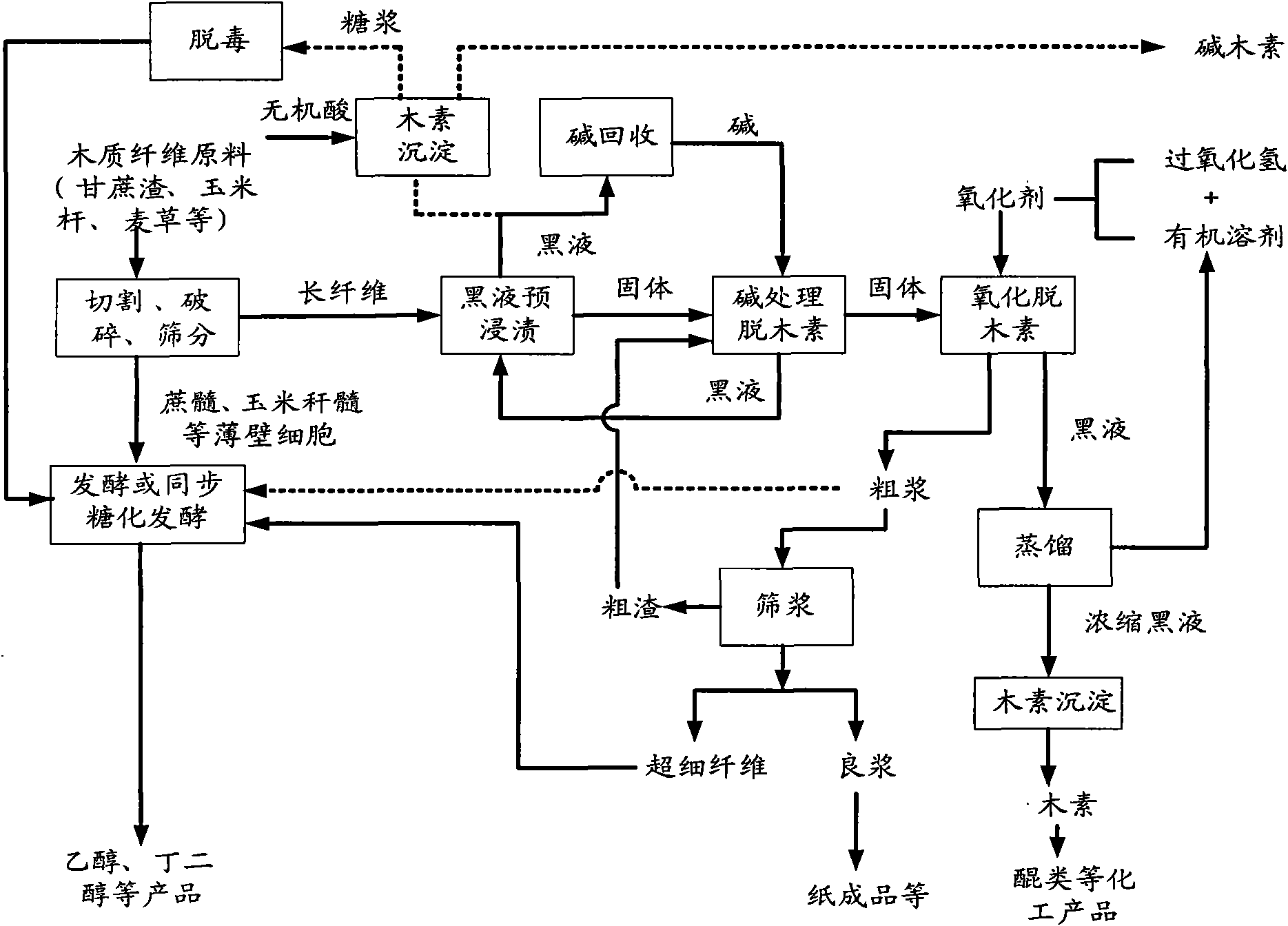

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1: The lignocellulosic raw material used is bagasse, and the place of origin is Nanning, Guangxi. The bagasse is air-dried and sieved to remove the smaller size marrow cells, and the part whose particle size is larger than 40 mesh sieve aperture is selected as the raw material. With reference to "Pulp and Paper Analysis and Detection" (Shi Shulan. Pulp and Paper Analysis and Detection. Beijing: China Light Industry Publishing House, 2003.), the bagasse components are analyzed by relevant measurement methods in the book, and the analysis results are: the bagasse Among them, the ash content is 1.38%, the hot water extract is 5.16%, the 1% NaOH extract is 34.20%, the benzene-alcohol extract is 3.17%, the cellulose content is 44.98%, and the cellulose content is 76.76% %, the acid-insoluble lignin content is 18.45%, and the acid-soluble lignin content is 1.80%.

[0037] The liquid-solid ratio of the pretreatment lye and bagasse is 6:1, wherein the mass of sodium...

Embodiment 7

[0043]Embodiment 7: The lignocellulosic raw material used is the same as above. The liquid-solid ratio of the pretreatment lye and the bagasse is 3:1, wherein the mass of sodium hydroxide in the pretreatment lye is 10% of the mass of the bagasse. Put bagasse in a digester, add pretreatment lye and mix evenly, then raise the temperature to 90°C, and keep it warm for 1.5h. After the pretreated solid is washed with water, it is extruded to remove water until the water content is about 75%, and a peracetic acid solution having a quality equal to that of the initial bagasse is added, wherein the quality of the peracetic acid is 15% of the initial bagasse, After mixing evenly, raise the temperature to 75°C and keep it warm for 2h. The obtained pulp was washed and then dried. The solid yield of coarse pulp was 59.4%, the Kappa value was 2.8, the slurry ratio was 1.6%, the intrinsic viscosity of pulp was 940ml / g, and the ISO whiteness was 62.68%. The pulp is enzymatically hydrolyzed...

Embodiment 8

[0044] Embodiment 8: The lignocellulosic raw material used is the same as above. The bagasse is pre-impregnated with the black liquor obtained in the preceding examples, the concentration of residual alkali in the black liquor is 5 g / L, the liquid-solid ratio of the black liquor to bagasse is 3:1, and the pre-impregnation conditions are: temperature 60°C, time 1h . After pre-impregnation, the bagasse is placed in a digester for alkaline treatment. The liquid-solid ratio of the pretreatment lye and the initial bagasse is 1:1, wherein the mass of sodium hydroxide in the pretreatment lye is 11% of the mass of the bagasse. , add pretreatment lye and mix evenly, then raise the temperature to 90°C, and keep it warm for 1.5h. After the alkali-treated solid is washed with water, it is extruded to remove water until the water content is about 75%, and a peracetic acid solution having a quality equal to that of the initial bagasse is added, wherein the quality of the peracetic acid is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com