Movable internal heating and external heating combined biomass pyrolysis charcoal and tar co-production system

A biomass pyrolysis and mobile technology, which is applied in the preparation of biofuels and liquid hydrocarbon mixtures, combined with direct and indirect heating for dry distillation, etc., can solve the problems of low heat transfer efficiency and low production efficiency, and improve heat exchange efficiency, ensure production efficiency, and facilitate the effect of promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

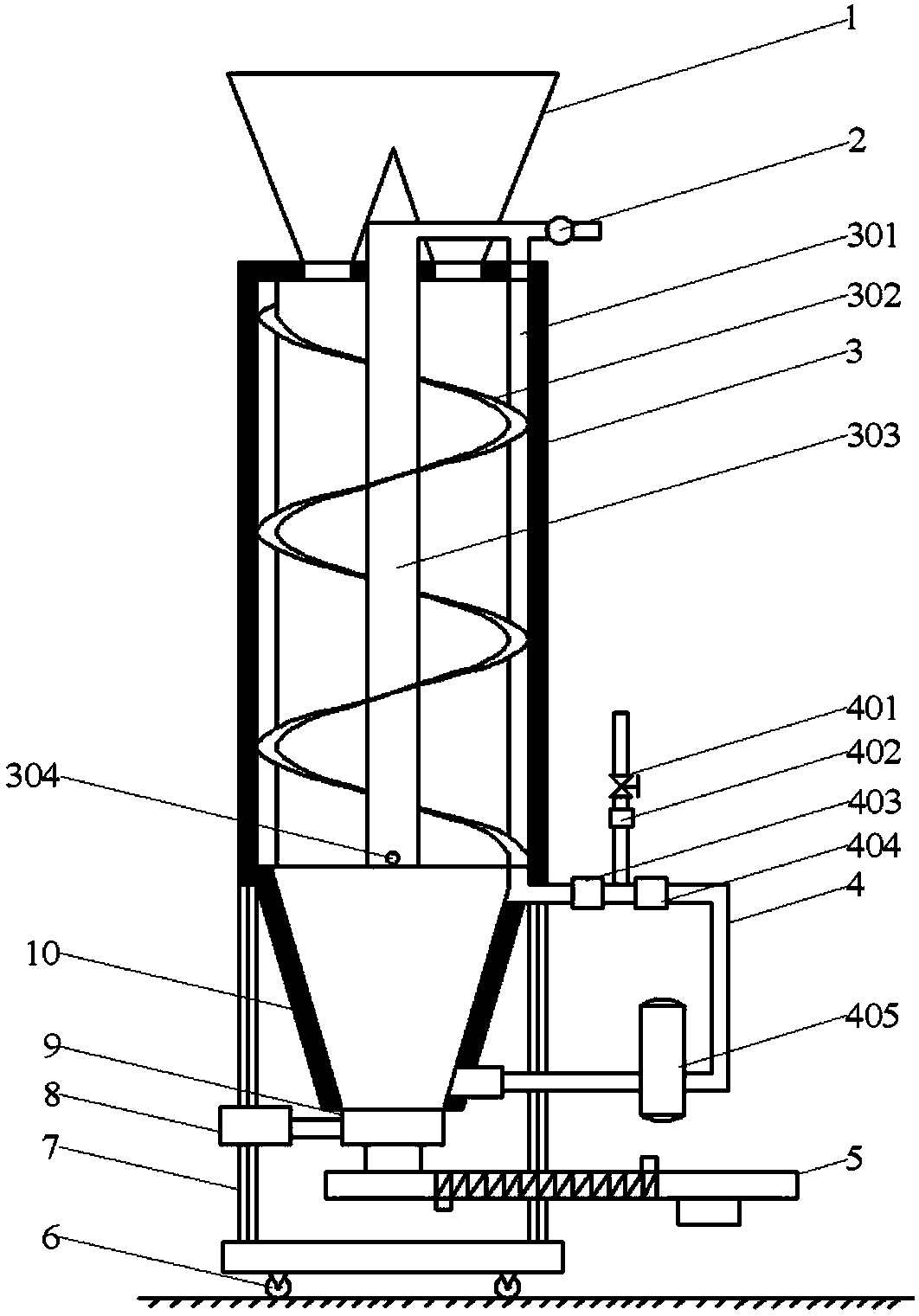

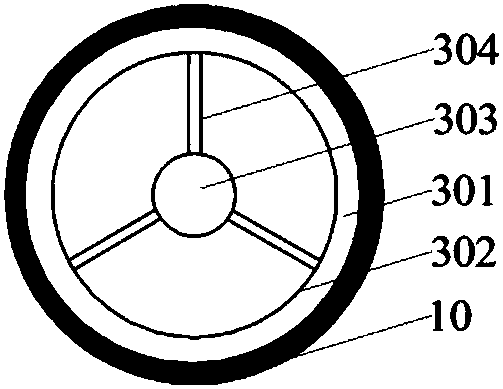

[0018] This embodiment is a mobile type combined internal and external heating biomass pyrolysis charcoal oil co-production pilot production system, the following will describe the embodiment of the present invention in conjunction with the accompanying drawings: The production system is a mobile type internal and external combination heating biomass pyrolysis charcoal oil co-production system The production system consists of a hopper (1), an induced draft fan (2), an external heating device (3), a pyrolysis gas backfire heating device (4), a water cooling device (5), a roller (6), a bracket (7), Composed of a motor (8), an air shutoff (9) and an insulation layer (10), the external heating device (3) provides an external heat source for drying the material, and the heat generated by the spontaneous combustion of the material provides an internal heat source for the pyrolysis of the material, realizing biomass Combination of internal and external heating for pyrolysis, the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com