Coal-grading conversion poly-generation device and method for producing coal gas, tar and carbocoal on circulating fluid bed

A circulating fluidized bed and fluidized bed technology, used in coke ovens, petroleum industry, manufacturing of combustible gases, etc., can solve the problems of low coal utilization efficiency and pollution, and achieve high yield, simple process and low CO content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

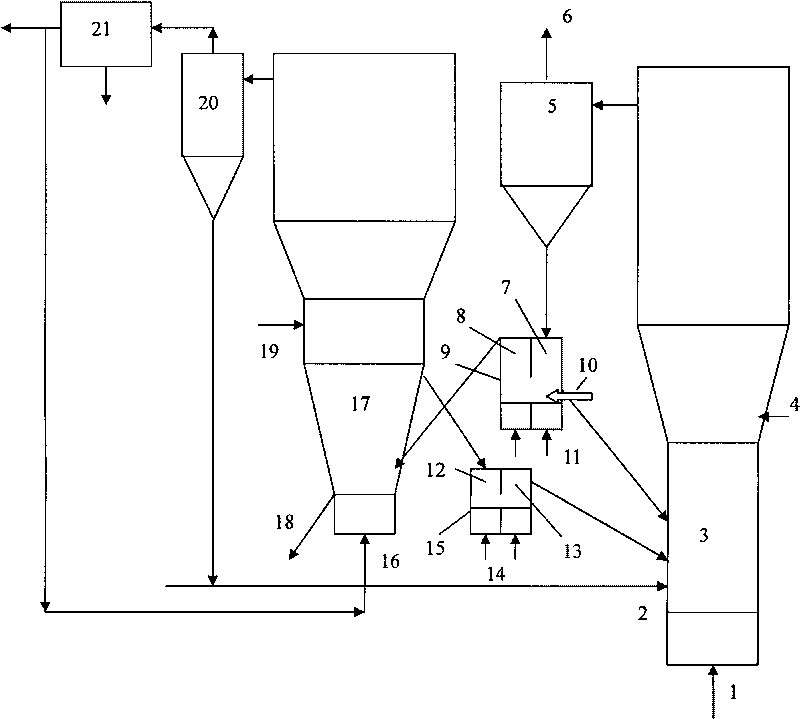

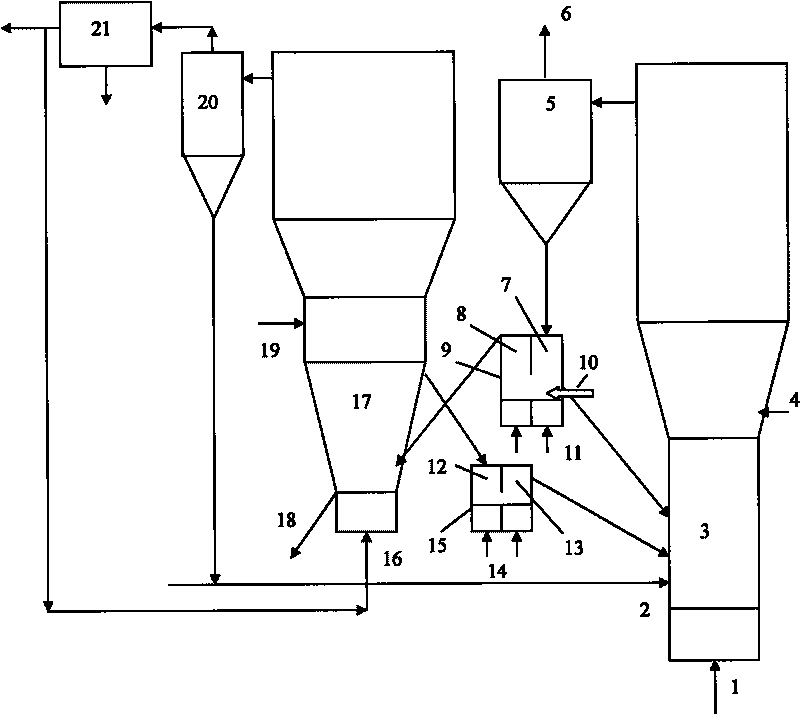

[0021] As shown in the accompanying drawings, the circulating fluidized bed coal staged conversion coal gas tar semi-coke polygeneration device includes a fluidized bed retort furnace 17 and a circulating fluidized bed gasification furnace 3; the fluidized bed retort furnace 17 has a small bottom and a large structure , the upper part of the fluidized bed carbonization furnace 17 is a dilute phase zone, the lower part of the fluidized bed carbonization furnace 17 is a dense phase zone, the bottom of the fluidized bed carbonization furnace 17 is provided with an air chamber, and the upper part of the circulating fluidized bed gasification furnace 3 It is a dilute-phase zone, and the lower part of the circulating fluidized bed gasifier 3 is a dense-phase zone, and the bottom of the circulating fluidized bed gasifier 3 is provided with an air chamber, and the dense-phase zone of the fluidized bed carbonization furnace 17 passes through the feeder 15 and The circulating fluidized b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com