Process for preparing nanometer calcium sulfate

A nano-calcium sulfate and preparation process technology, applied in the field of preparation of nano-calcium sulfate, can solve the problems of incapable of industrial production, low added value, and no use value of gypsum calcium sulfate, and achieve the effect of reducing preparation cost and preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

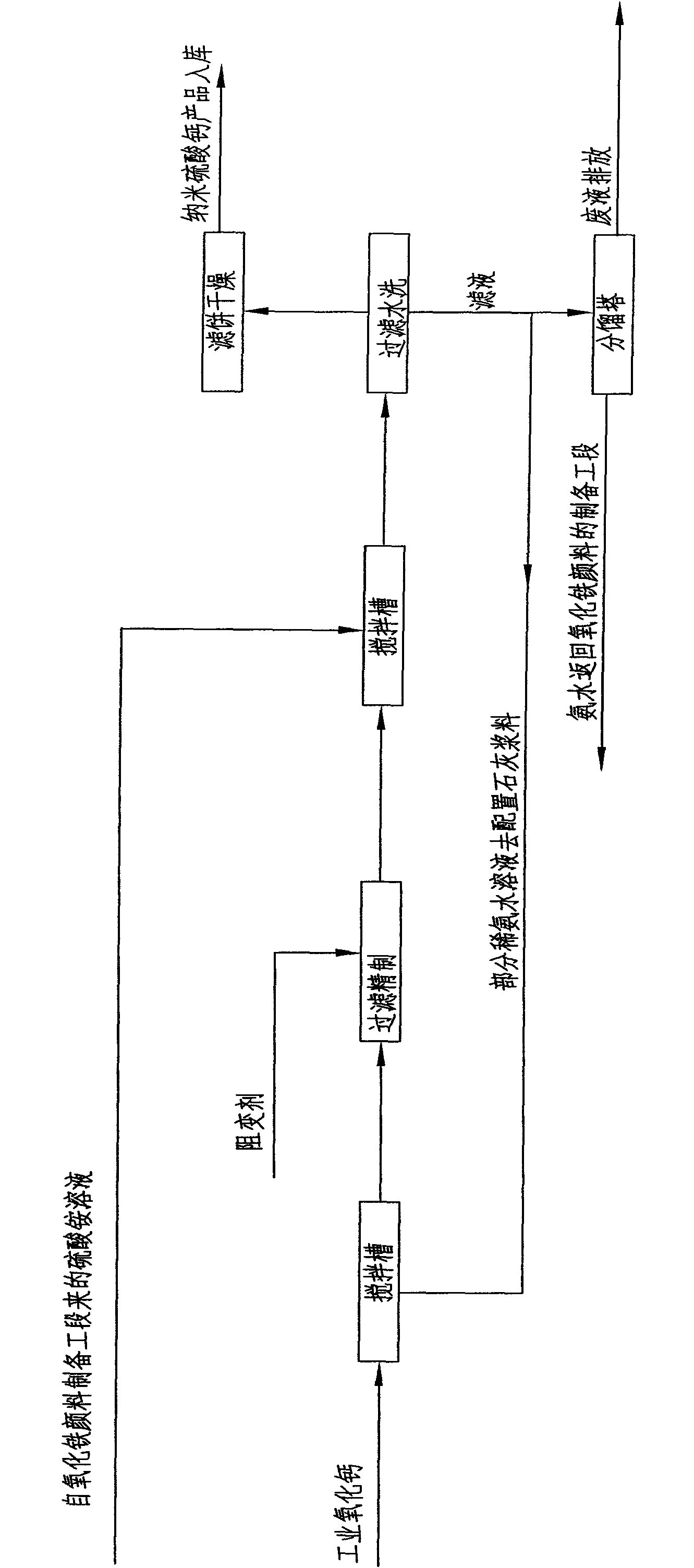

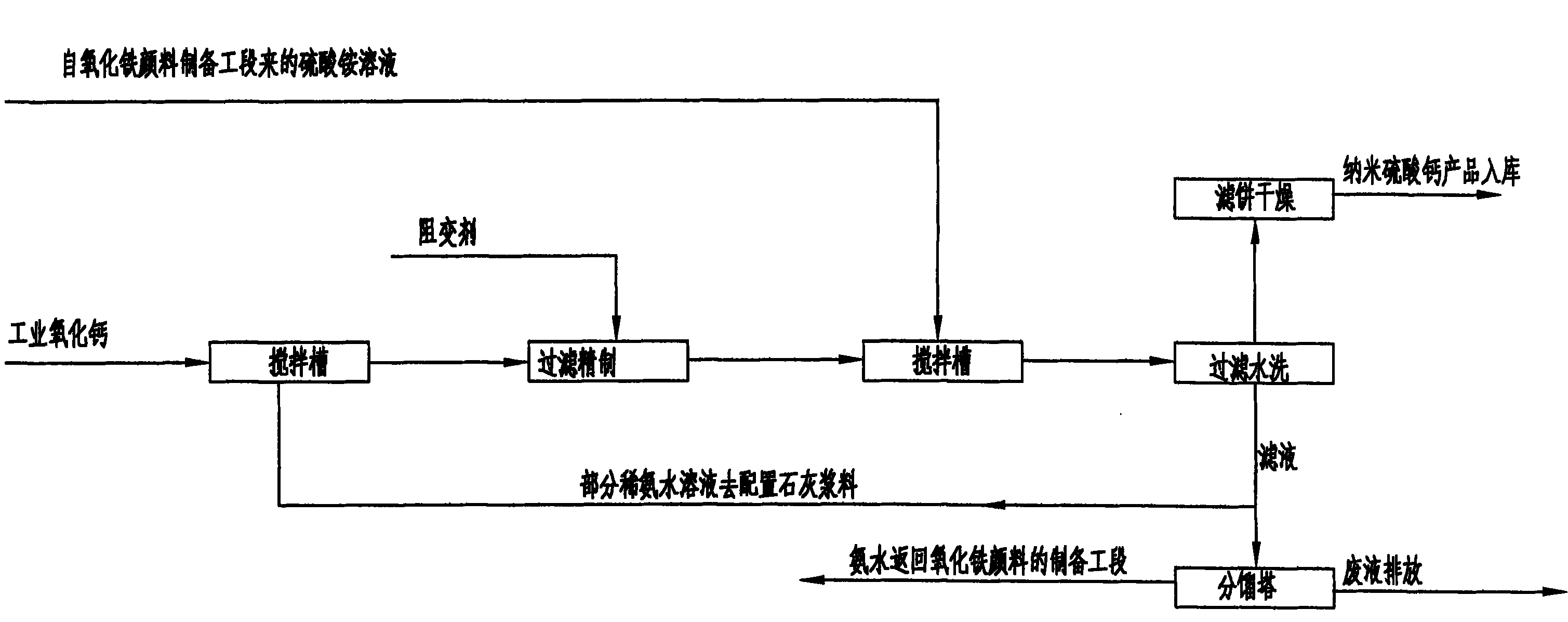

Image

Examples

Embodiment Construction

[0032] Raw materials for preparation: the concentration of ammonium sulfate solution from the iron oxide pigment preparation process is 25%; industrial lime calcium oxide, the calcium oxide content is greater than 95%.

[0033] 1. Take 210 kg of calcium oxide, add 80°C hot water, and prepare 1333 kg of calcium hydroxide emulsion with a calcium oxide content of 15%.

[0034] 2. Filter with a 200-mesh sieve to separate the coarse particles of impurities in the calcium hydroxide emulsion to obtain a refined calcium hydroxide emulsion.

[0035] 3. Take the anti-variable agent sodium stearate with an amount of 3% calcium oxide and mix it with the calcium oxide slurry to obtain a mixed slurry system containing the anti-variable agent.

[0036] 4. Take 1886 kg of ammonium sulfate solution with a concentration of 25%, add it into the calcium hydroxide slurry containing the resistive agent, stir at room temperature for 2 hours, and the reaction is completed to obtain the nanometer calc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com