New process for production of potassium sulfate and co-production of compound fertilizer

A production process and technology of potassium hydrogen sulfate, applied in the directions of alkali metal sulfite/sulfite, fertilization device, fertilizer mixture, etc., can solve the problems of low reaction efficiency and large reaction energy consumption, and achieve good water solubility and flexibility. The effect of good performance and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Preparation of Potassium Sulfate

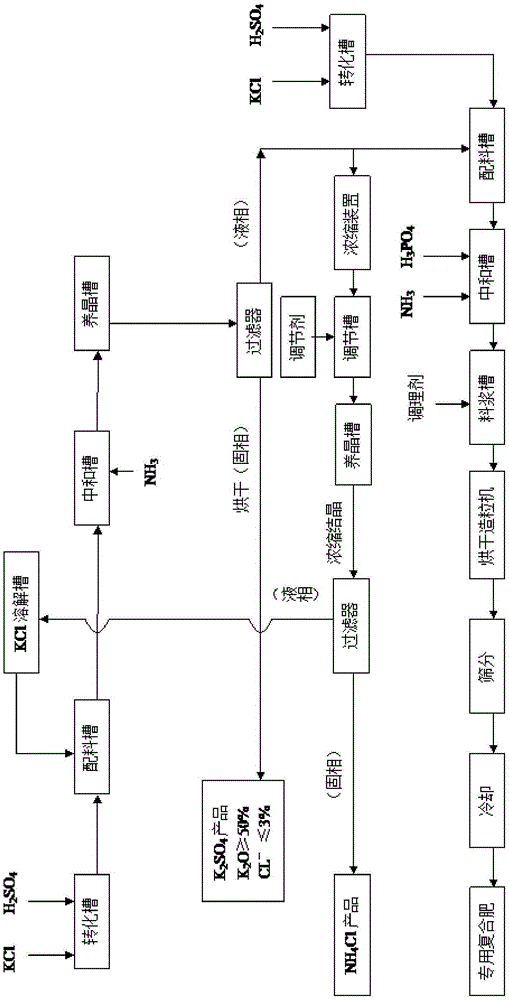

[0045] Such as figure 1 Shown, potassium sulfate production process. 5000kg of potassium chloride and 7200kg of sulfuric acid were placed in the conversion tank and reacted for 1 hour to generate potassium bisulfate and hydrochloric acid, then transferred to the first batching tank, added 7000kg of potassium chloride, mixed evenly, and transported to the neutralization tank. Pass through ammonia gas to neutralize the reaction until pH = 5-6, crystallize for 5 hours, filter, keep the mother liquor for later use, and dry in solid phase to obtain 13000 kg of potassium sulfate.

Embodiment 2

[0047] Combined production of compound fertilizer

[0048] Such as figure 1 Shown, prepare potassium sulfate by the processing method of embodiment 1, the mother liquor obtained by filtering is transferred in the second batching tank simultaneously. Prepare 2000 liters of potassium bisulfate and hydrochloric acid mixed solution with the reaction in the conversion tank, input the second batching tank, adjust the ratio of each component so that the molar ratio of potassium bisulfate, hydrochloric acid and potassium chloride meets the condition of 2:0.5:1 , then the material in the second batching tank is transported to the second neutralization tank, ammonia gas and phosphoric acid are added to the second neutralization tank for neutralization reaction, the amount of ammonia gas is adjusted according to pH, and the amount of phosphoric acid is added The material is controlled in the range of 20%, and when the pH of the solution is 3.5-4, the reaction is complete, transferred t...

Embodiment 3

[0050] co-production of potassium chloride

[0051] Such as figure 1 As shown, potassium sulfate is prepared by the process method of Example 1, and the mother liquor obtained by filtration is transferred to a concentration device, concentrated to 1.2-1.25g / ml, crystallized under stirring conditions for 5 hours, and press-filtered to obtain ammonium chloride product 1000kg. Preferably, the remaining filtrate of press filtration is returned to the potassium chloride dissolving tank for the dissolution of potassium chloride.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com