Process for coupling producing bioloigical diesel oil and 1,3-propylene glycol

A technology of biodiesel and propylene glycol, which is applied in the field of bioengineering, can solve the problems of unfavorable conditions and high salt content in glycerin, and achieve the effects of prolonging the service life, eliminating the poisoning and inactivation of lipase, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

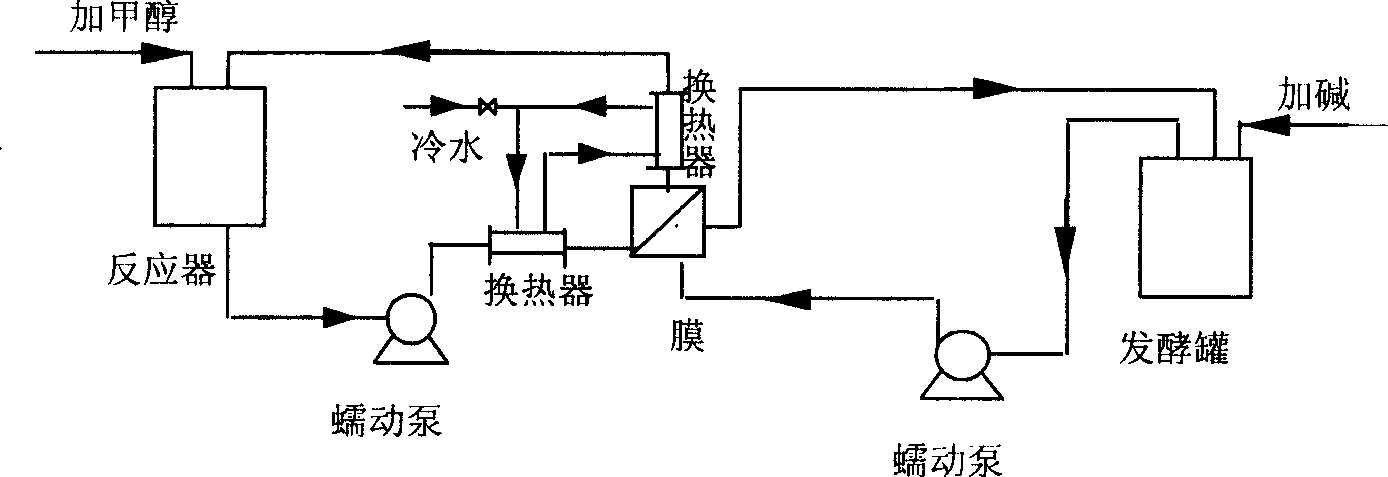

Image

Examples

Embodiment 1

[0020] 1) Strain and enzyme: The fermented strain is Klebsiella pneumoniae, which is a facultative anaerobic bacterium, purchased from China General Microorganism Culture Collection Center (CGMCC), and the strain preservation number is 1.1736 . Immobilized lipase Novozym 435 was purchased from Novo Nordisk, from Candidaantarctica, immobilized on a macroporous acrylic resin.

[0021] 2) Culture medium: There are two kinds of seed medium and fermentation medium, which are described as follows:

[0022] A. Seed medium (1L):

[0023] Glycerin: 20g K 2 HPO 4 ·3H 2 O: 4.454g

[0024] K H 2 PO 4 : 1.3g (NH4) 2 SO 4 : 2.0g

[0025] MgSO 4 ·7H 2 O: 0.2g Yeast powder: 1.0g

[0026] CaCO 3 : 2.0g Trace elements TE1: 2mL

[0027] 2% CaCl 2 Solution: 1 mL 0.5% FeSO 4 Solution: 1mL

[0028]Composition of trace element TE1 (1L):

[0029] Saturated hydrochloric acid: 0.9mL ZnCl 2 : 70mg

[0030] MnCl 2 4H 2 O: 100mgH 3 BO 3 : 60mg

[0031] CoCl 2 ·6H 2 O: 200mg NiC...

Embodiment 2

[0049] 1) 1,3-propanediol fermentation strain, culture medium and fermentation process are the same as embodiment 1.

[0050] 2) Add 2kg of rapeseed oil into the reactor, add 320g of immobilized lipase Novozym 435 at the same time, heat to 45°C, add 11g of ethanol (the molar ratio of alcohol to oil is 0.1:1) to start the reaction, and the stirring speed during the reaction is 170r / min, ethanol is added dropwise, and the dilution rate is 0.01h -1 , add ethanol 380g altogether, use the pump to force the reaction solution to circulate, pass through the hollow fiber membrane, the other side of the membrane is 1,3-propanediol fermentation broth.

[0051] 3) The hollow fiber membrane is a cellulose acetate ultrafiltration membrane with a cut-off molecular weight of 10kDa and a surface area of 0.5m 2 , the operating pressure is 0.13Mpa, the temperature is 38°C, the tube side of the membrane is the esterification reaction liquid, and the volume ratio of the flow rate to the enzyme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com