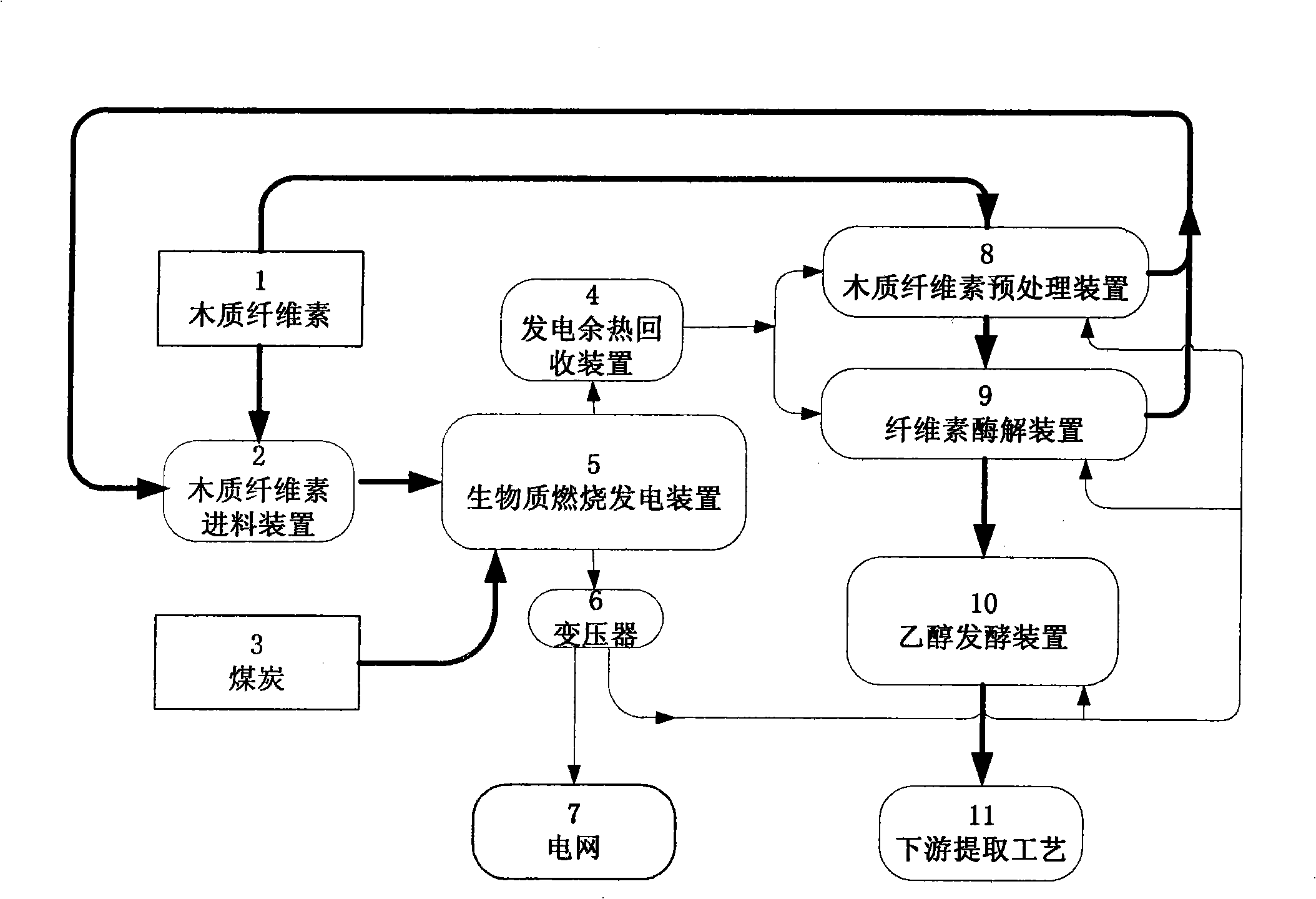

Coupling process for producing ethyl alcohol with fibre and generating power with biomass combustion

A technology of burning power generation and biomass, applied in the direction of biofuel, biosynthesis, microbial-based methods, etc., to solve processing problems, improve utilization efficiency, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Wheat straw is used as raw material for biomass combustion for power generation and fiber production for ethanol fermentation, in which the mass percentages of cellulose, hemicellulose and lignin are 34.8%, 35% and 18.5% respectively (reference for measurement methods: edited by Qu Weijun. Pulp and Papermaking Experiment. Beijing: China Light Industry Press, 1990). The direct combustion test was carried out in a small biomass boiler made by North China Electric Power University. The screw feed was used, the feed rate was 1t / h, and the power was 30kW. The single-stage backpressure power generation steam turbine STF426 (Zibo Sante Power Equipment Co., Ltd.) was used to generate electricity. The test was carried out for 2 hours, 3000kJ of electric power was obtained, 10MPa of waste heat steam was recovered, the steam volume was 1.5kg / h, and the power generation efficiency was 28%.

[0025] In the process of producing ethanol from fibers, wheat straw was crushed with a micr...

Embodiment 2

[0028] Wheat straw is used as raw material for biomass combustion for power generation and ethanol fermentation for fiber production, in which the mass percentages of cellulose, hemicellulose and lignin are 34.8%, 35% and 18.5%, respectively. The direct combustion test was carried out in a small biomass boiler made by North China Electric Power University. The pneumatic conveying device was used to feed the material. The feed rate was 3t / h and the power was 30kW. Power generation, the test was carried out for 2 hours, the obtained power was 17556kJ, the recovered waste heat steam pressure was 10MPa, the steam volume was 14kg / h, and the power generation efficiency was 35%.

[0029]In the process of producing ethanol from fibers, the wheat straw was pulverized with a micro-plant sample pulverizer FZ102, and passed through a 60-mesh sieve. Pass steam into the lignocellulose pretreatment device, temperature control is 100 ℃, add sulfuric acid (mass fraction is 4%), after processin...

Embodiment 3

[0032] Corn stalks are used as raw materials for biomass combustion power generation and ethanol fermentation for fiber production, and corn stalks and coal are co-combusted for biomass combustion power generation. The mass percent contents of cellulose, hemicellulose and lignin in corn stover were 39%, 19.5% and 15.1%, respectively. The combustion test was carried out in a small biomass direct-fired boiler made by North China Electric Power University. The pneumatic conveying device was used to feed the material. The mass ratio of corn stalks to coal was 1:1, the feed rate was 3t / h, and the power was 30kW under single-stage back pressure. The power generation steam turbine STF426 (Zibo Sangte Power Equipment Co., Ltd.) is used for power generation. The test was carried out for 2 hours, and the power obtained was 27556kJ. The steam pressure of recovered waste heat was 10MPa, the steam volume was 18kg / h, and the power generation efficiency was 32%.

[0033] Corn stalks in fiber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com