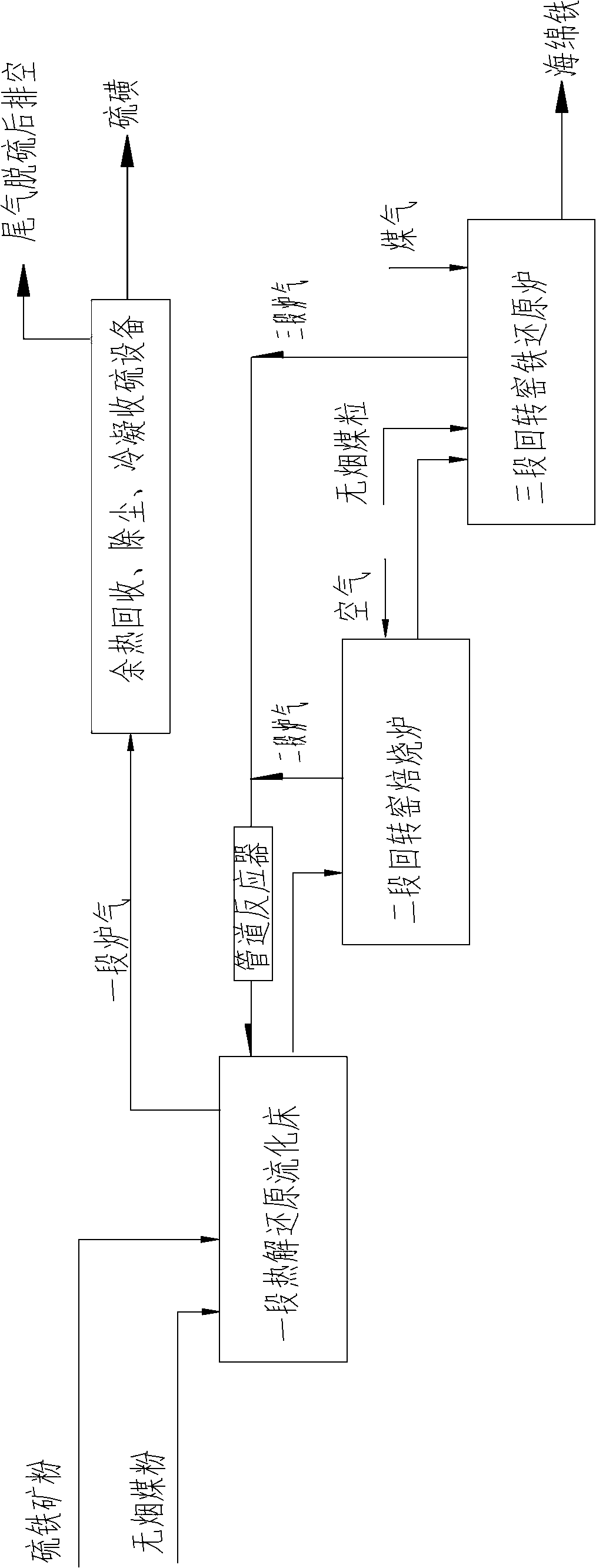

Method for producing sulfur by using pyrolysis-reducing united technique

A combined technology and pyrolysis technology, which is applied in the field of chemical raw material preparation, can solve the problems of insufficient resource utilization, high energy consumption, and difficult control, and achieve remarkable energy-saving effects, high comprehensive utilization rates, and reduction of carbon consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The main raw material that present embodiment adopts and main chemical composition thereof:

[0027] Pyrite: S 18.1%, Fe 23.4%, CaO+MgO 3.5%, SiO 2 31.1%,

[0028] Al 2 o 3 16.3%, As 0.032%;

[0029] Anthracite: C 固 70.5%, V f 10.3%, A f 17.7%

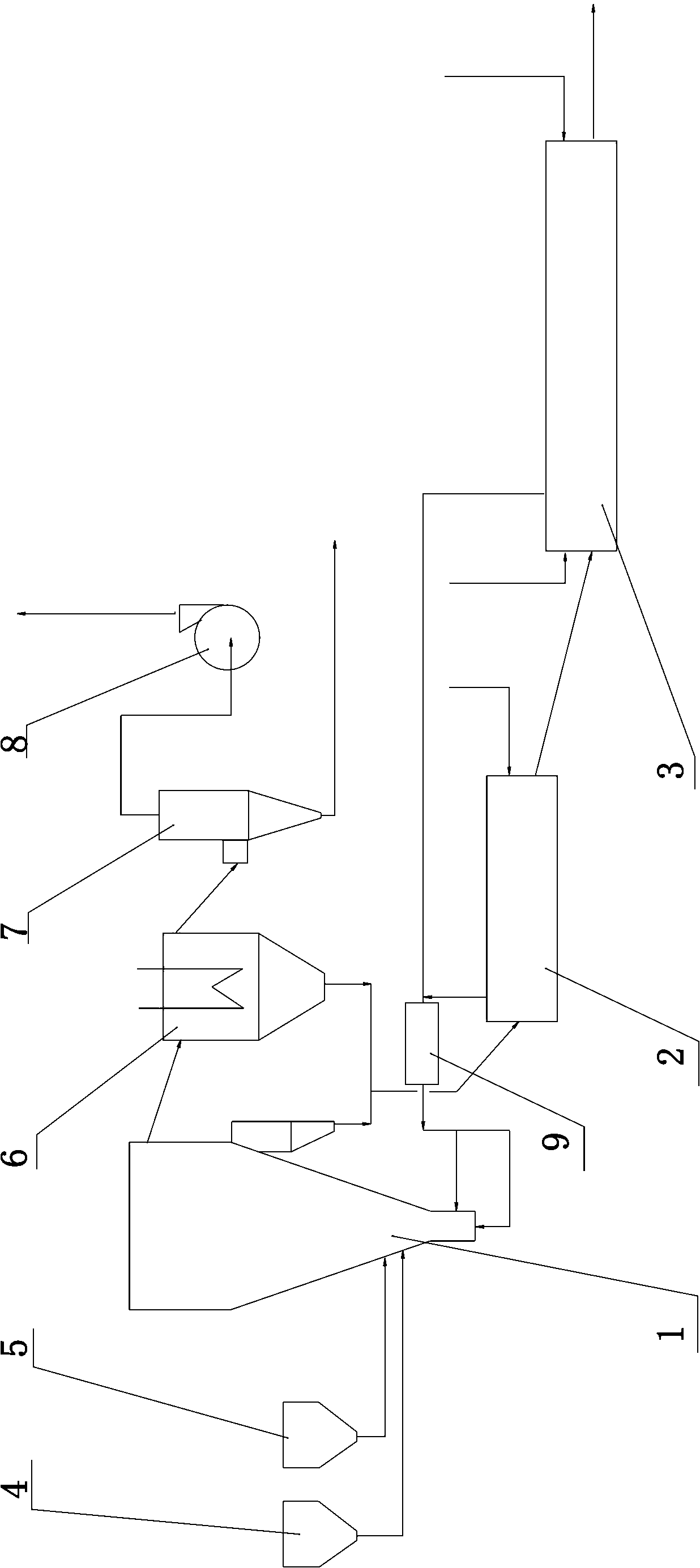

[0030]The pyrite ore with a sulfur content of 18.1% is processed into granular materials with a particle size of 2 mm or less through a crusher, and 280 kg of pyrite granular materials are sent into a section of pyrolysis reduction flow at a speed of 80 kg per hour by the pyrite feeder 5 In chemical bed 1; at the same time, 17.5 kg of anthracite coal powder with a particle size of 2 mm or less is fed by the coal feeder 4 at a rate of 5 kg per hour, and the pyrite is pyrolyzed and reduced at a temperature of 800-850 ° C to obtain a sulfur content of 9.6%. A total of 185 standard cubic meters of first-stage furnace gas, the first-stage furnace gas passes through the dust removal cooler 6 to remove most of the mine dust...

Embodiment 2

[0034] The main raw materials used in this test and their main chemical composition:

[0035] Pyrite: S 36.5%, Fe 35.2%, CaO+MgO 2.3%, SiO 2 17.1%,

[0036] al 2 o 3 3.7%, As 0.019%;

[0037] Anthracite: C 固 70.5%, V f 10.3%, A f 17.7%

[0038] The pyrite ore with a sulfur content of 36.5% is processed into granular materials with a particle size of 2 mm or less through a crusher, and 195 kg of pyrite granular materials are fed into a section of pyrolysis reduction flow at a speed of 80 kg per hour by the pyrite feeder 5 At the same time, 15 kg of anthracite coal powder with a particle size of 2 mm or less is fed by the coal feeder 4 at a rate of 6 kg per hour, and the pyrite is pyrolyzed and reduced at a temperature of 800-850 ° C to obtain a total sulfur content of 11.2%. 247 standard cubic meters of furnace gas;

[0039] The hot slag from the first-stage pyrolysis reduction fluidized bed 1 enters the second-stage rotary kiln roaster 2, and is roasted together w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com