Patents

Literature

182results about How to "Significant energy saving and consumption reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

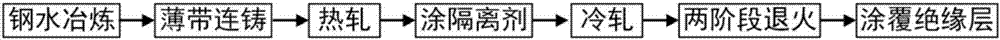

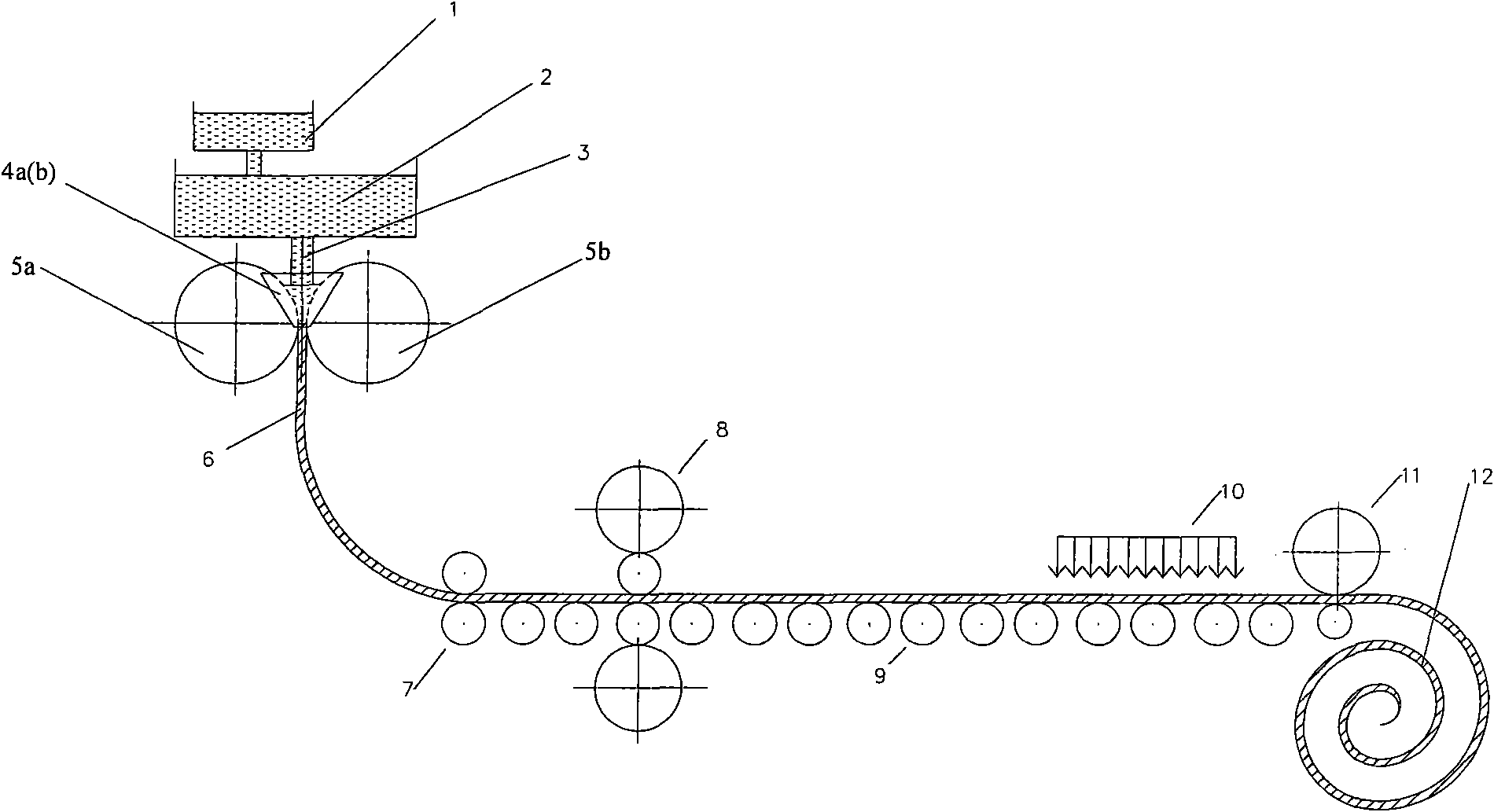

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367AMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

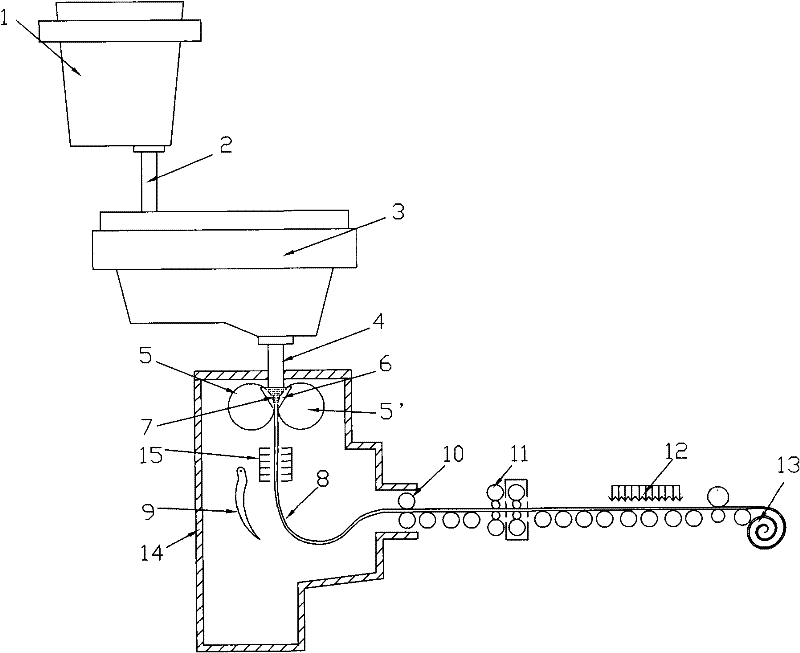

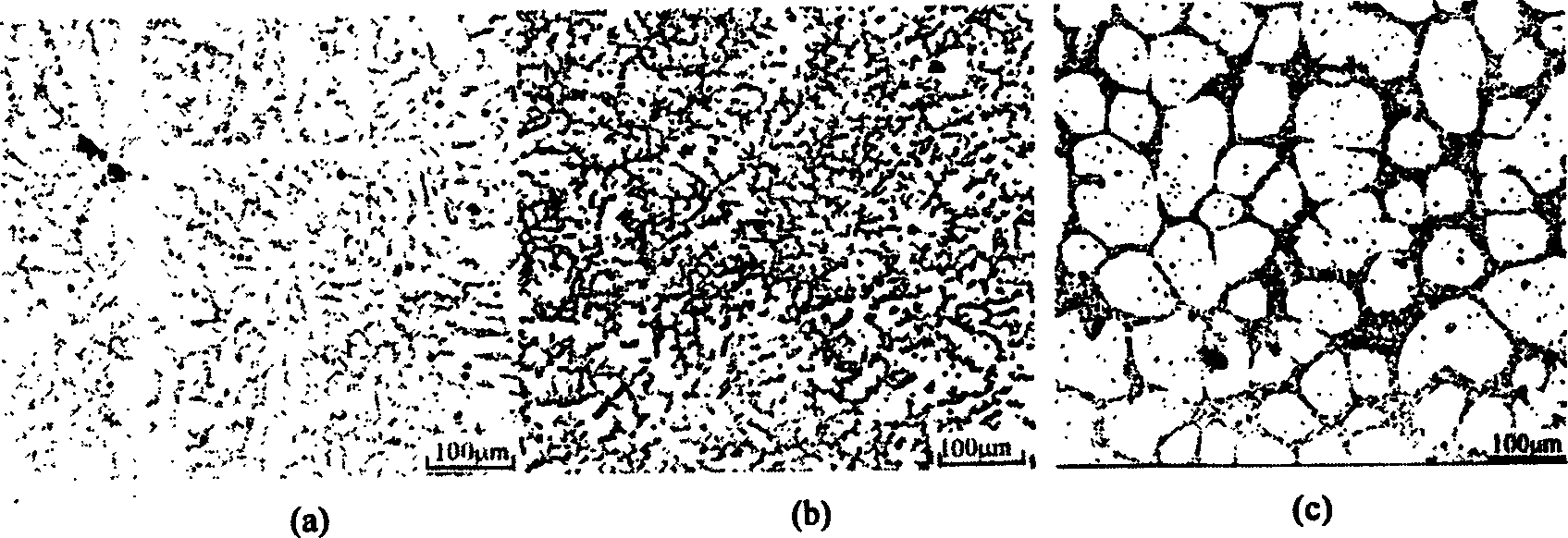

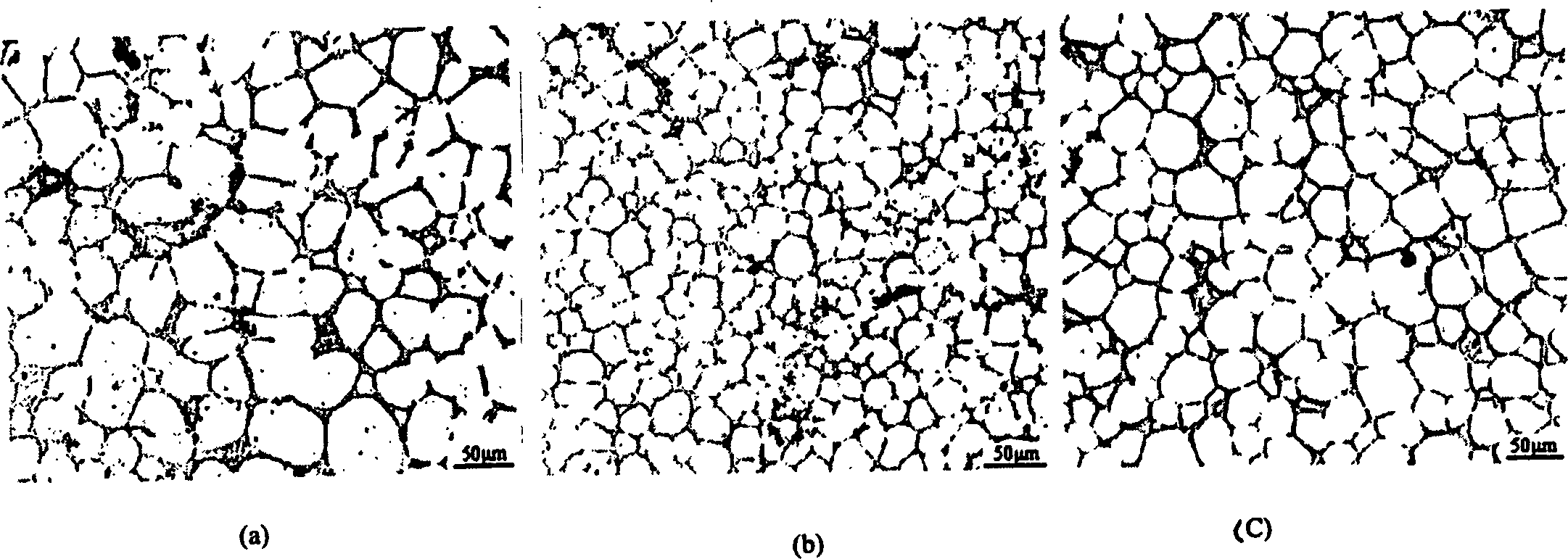

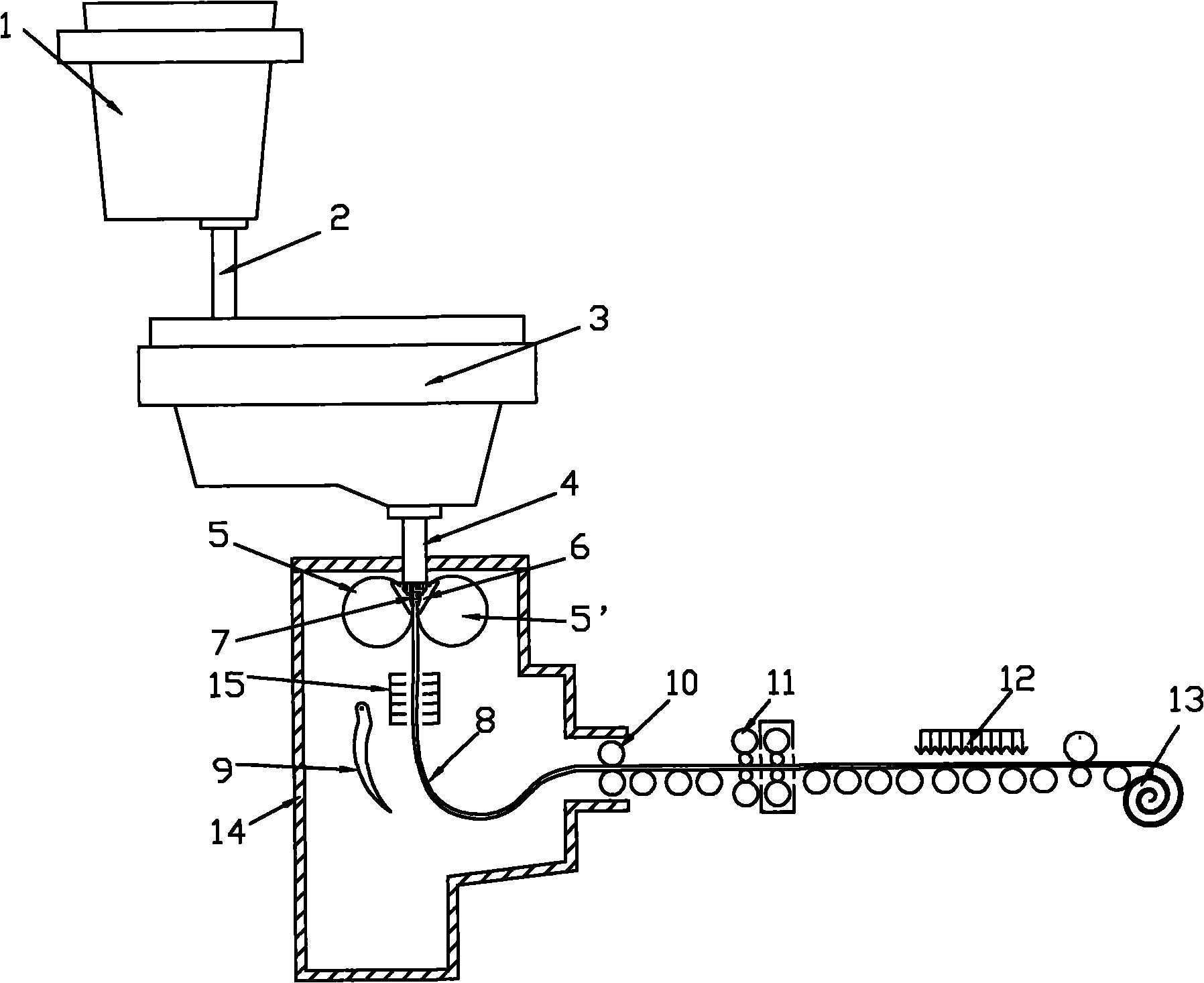

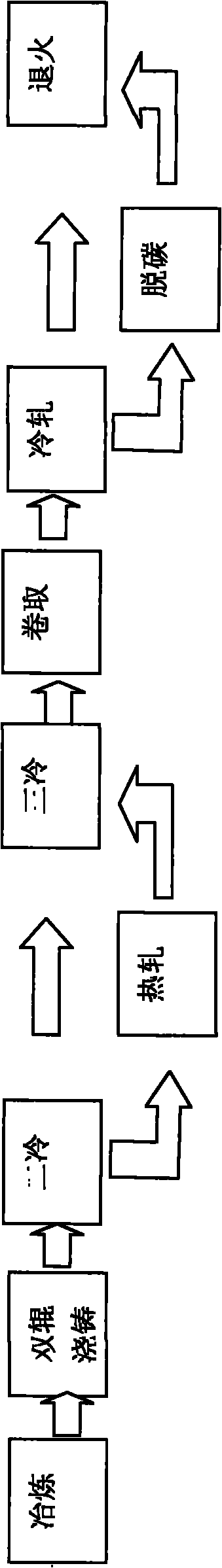

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time, hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improve the medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

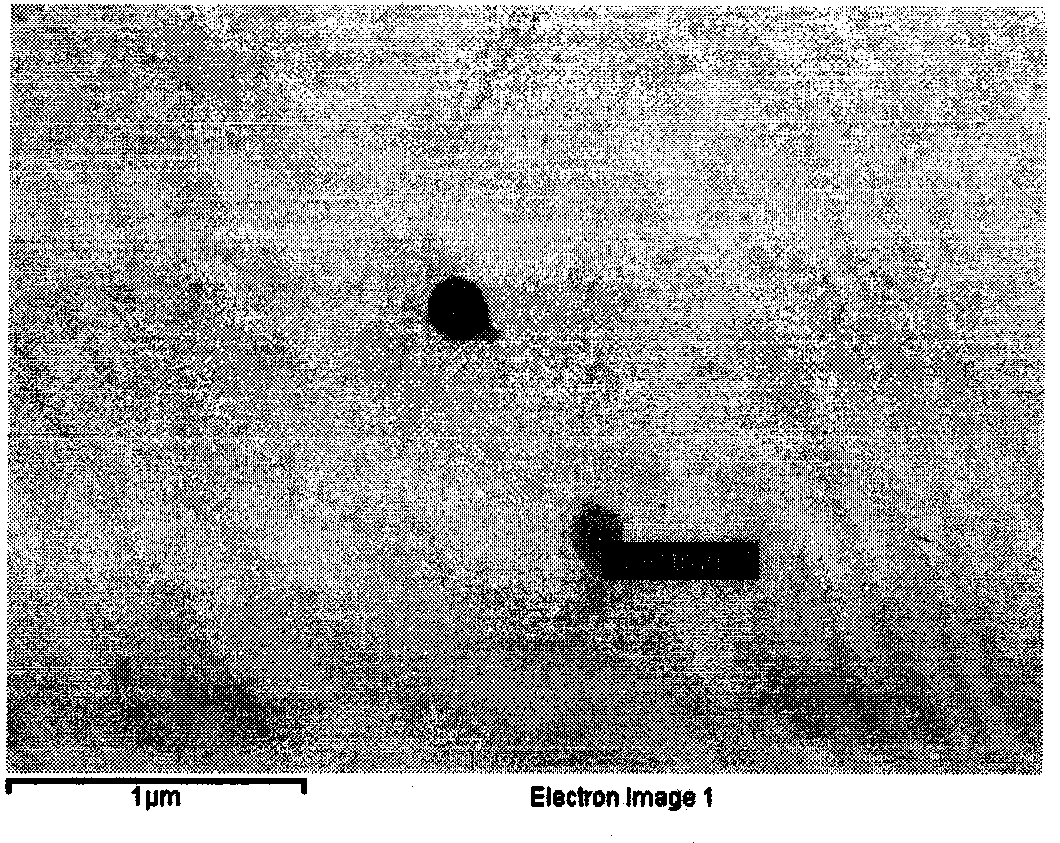

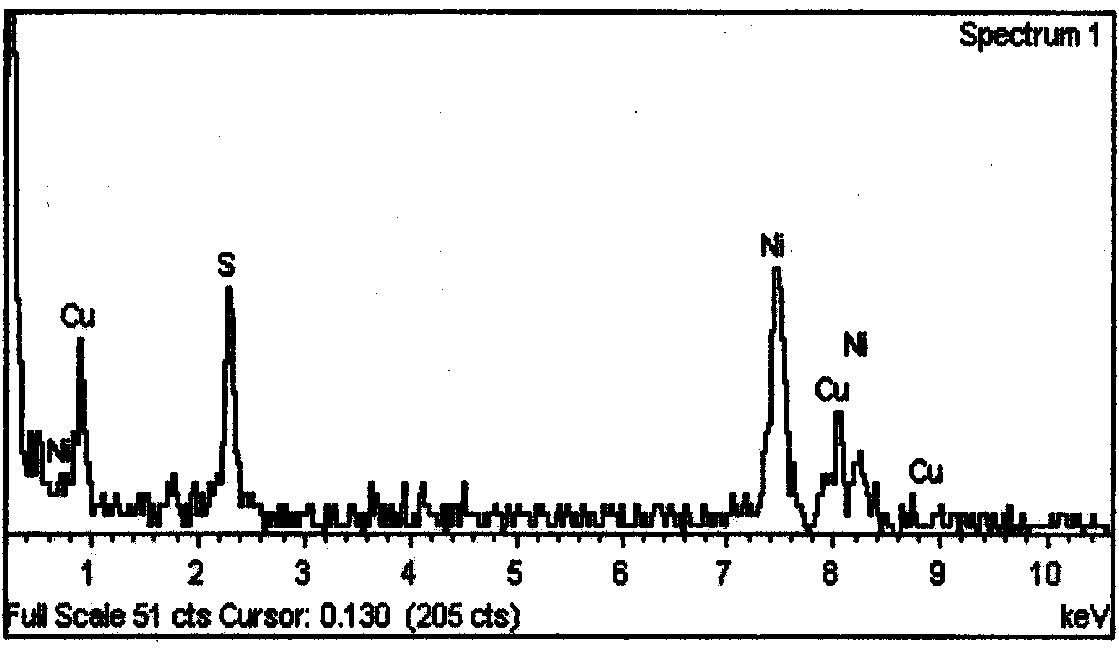

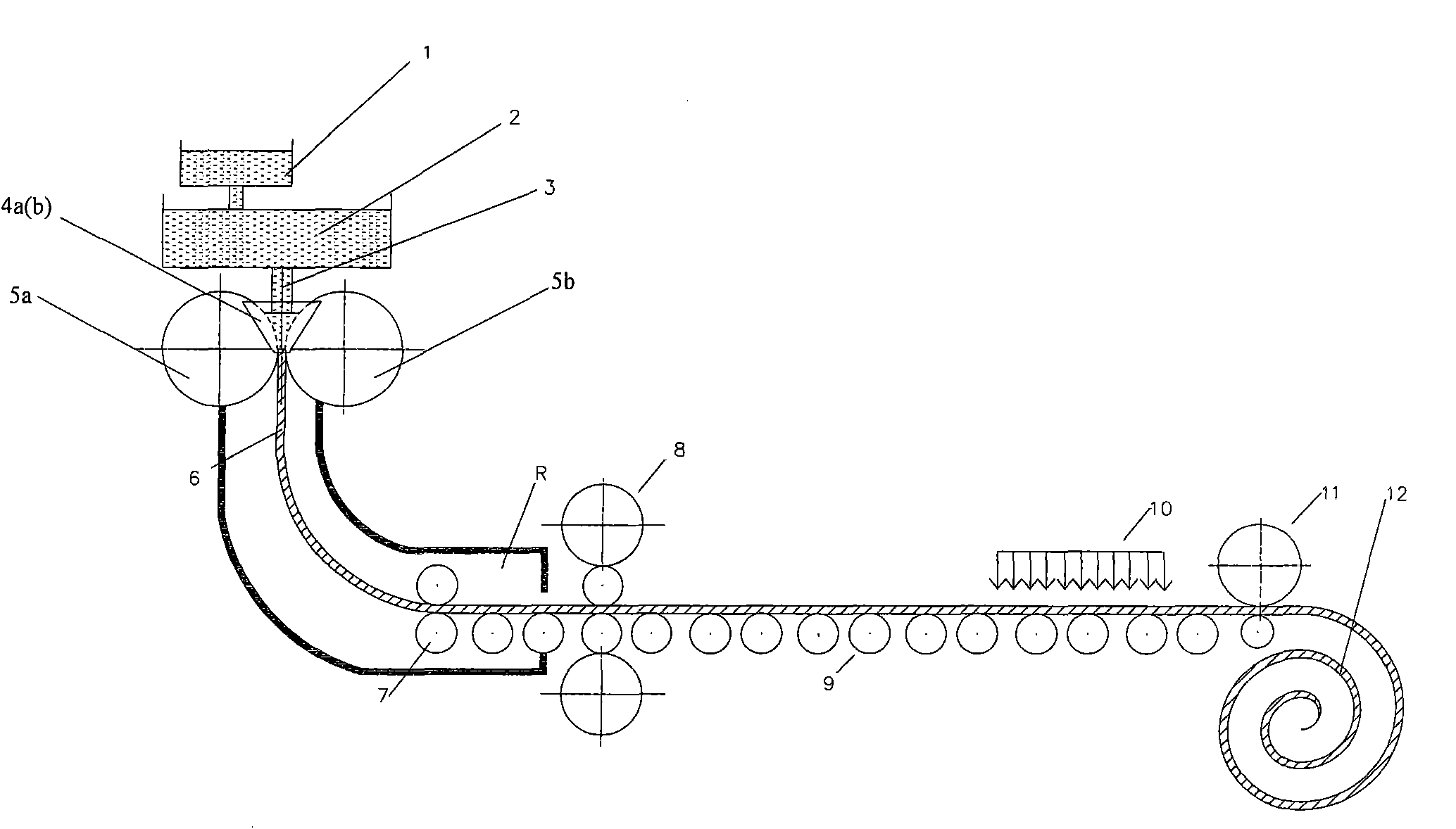

High-strength weather resisting steel with Cu2-xS dispersed precipitates and manufacturing method thereof

ActiveCN101928894AReduce steelmaking costsInhibition of segregationTemperature control deviceManufacturing convertersChemical compositionHigh intensity

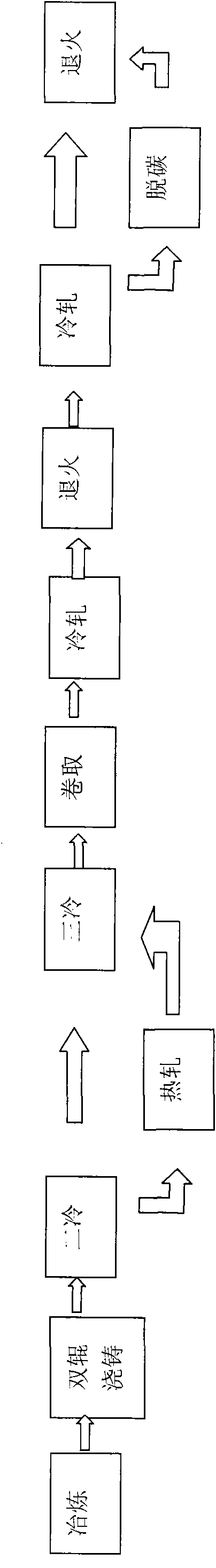

The invention relates to high-strength weather resisting steel with Cu2-xS dispersed precipitates, which comprises the following chemical components in percentage by weight: 0.04-0.08% of C, 0.20-0.40% of Si, 0.4-1.0% of Mn, 0.03-0.12% of P, not more than 0.2% of S, 0.01-0.06% of Al, 0.20-0.80% of Cu, 0.40-0.6% of Cr, 0.12-0.40% of Ni, 0.001-0.006% of Ca and the balance of Fe and inevitable impurities. The welding cold crack sensitivity coefficient Pcm is not more than 0.18%. A manufacturing method comprises the following steps of: acceleratedly cooling both sides of a cast belt formed by continuous casting by using a gas and adopting a thin belt continuous casting production technology, wherein the cooling rate is 150-200 DEG C / s; performing the entire double-roller continuous casting process in a closed chamber filled with protective atmosphere; and arranging one to two stands for online hot rolling, wherein the thickness of a finished steel belt reaches 0.6-2 mm. The desulfurization procedure in steel making process can be omitted, and the steel making cost is reduced. The segregation of copper elements is inhibited, meanwhile, a large quantity of dispersed Cu2-xS precipitates can be formed to achieve the effect of dispersion strengthening.

Owner:BAOSHAN IRON & STEEL CO LTD

Weathering steel and manufacturing method thereof

The invention discloses weathering steel, which comprises the following chemical compositions in percentage by weight: 0.06 to 0.12 percent of C, 0.20 to 0.40 percent of Si, less than or equal to 1.6 percent of Mn, 0.08 to 0.22 percent of P, less than or equal to 0.008 percent of S, 0.01 to 0.06 percent of Al, 0.20 to 0.80 percent of Cu, 0.40 to 0.75 percent of Cr, 0.12 to 0.40 percent of Ni, 0.001 to 0.006 percent of Ca and the balance of iron and inevitable impurity elements. The weathering steel is manufactured by a thin strip continuous casting process. The manufacturing process comprises the following steps of: performing deep desulfurization on molten steel, performing composite blowing on the top and bottom of a converter, performing RH vacuum circular degassing process, and simultaneously performing calcium treatment; performing twin-roll continuous casting, and making the temperature of the molten steel in a molten bath not lower than 1,535DEG C; controlling rolling in the reduction ratio of not less than 30 percent; controlling cooling at the speed 30 to 50 DEG C / s; and coiling at the temperature of between 600 and 650 DEG C. The weathering steel of which the texture is acicular ferrite has good weatherability and can be widely applied to structural materials.

Owner:BAOSHAN IRON & STEEL CO LTD

Process for producing 2,2-bis[2,4-diaminophenyloxy)phenyl]hexafluoropropane

InactiveCN101245023AShort timeSignificant energy saving and consumption reductionOrganic compound preparationAmino-hyroxy compound preparationHydrazine compoundFatty alcohol

The invention relates to a preparation method of 2,2-double(4-(2,4-diamino phenoxy)phenyl)hexafluoropropane, comprising the steps as following, after being put into the solvent system of the solution of palladium or carbon hydrazine hydrate and saturated fatty alcohol for reaction for 1 to 5 hours with the temperature of 70 to 85 DEG C, the 2,2-double(4-(2,4-dinitro phenoxy)phenyl)hexafluoropropane is filtered when being hot, mother liquor is cooled off, pure water is dripped in, crystal products are precipitated, filtered, and dried in vacuum, and crystals of the 2,2-double(4-(2,4-diamino phenoxy) phenyl) hexafluoropropane are gained. The method has the simple operation, needs no subsequent refining and purifying technique, takes little time, has the products with the high yield and the purity of more than 99 percent, and is suitable for industrial production.

Owner:DONGHUA UNIV

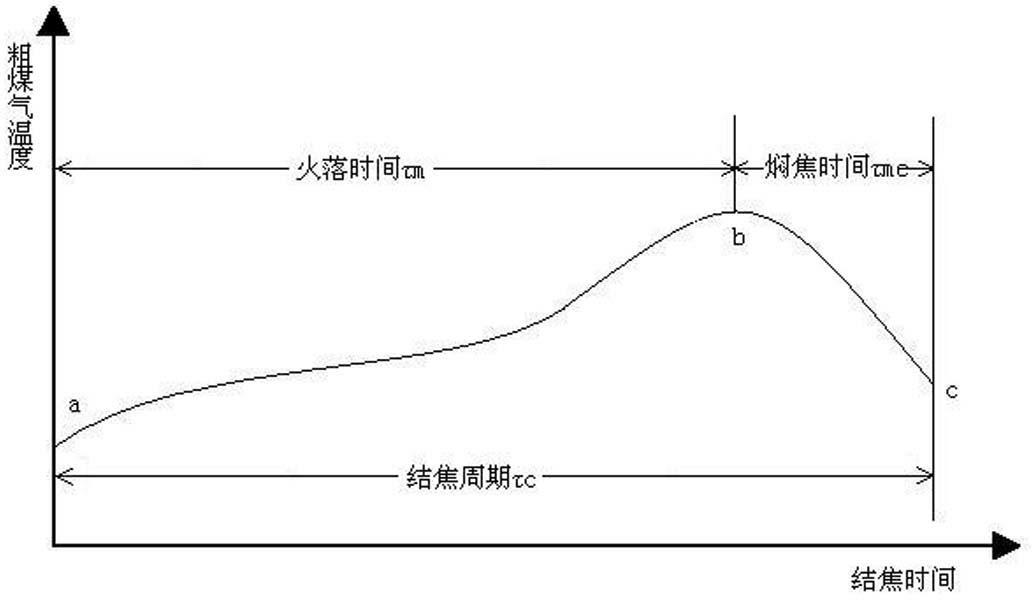

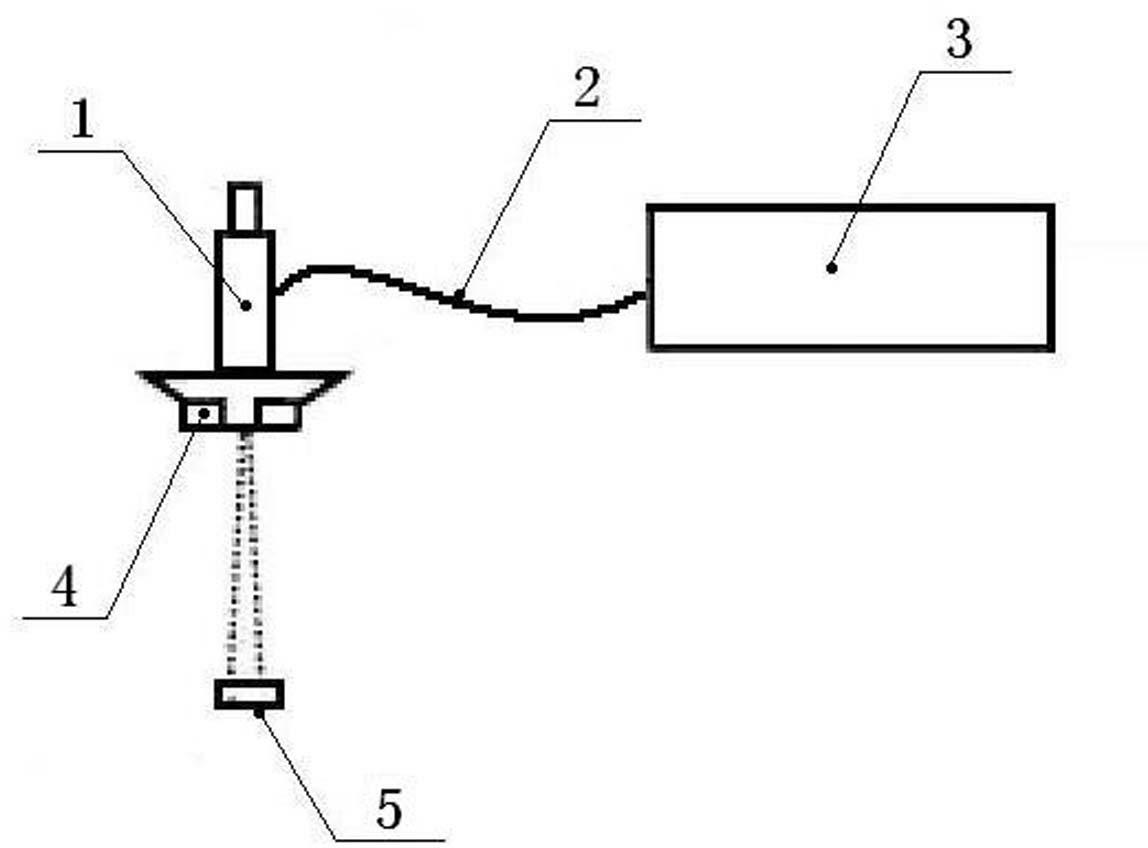

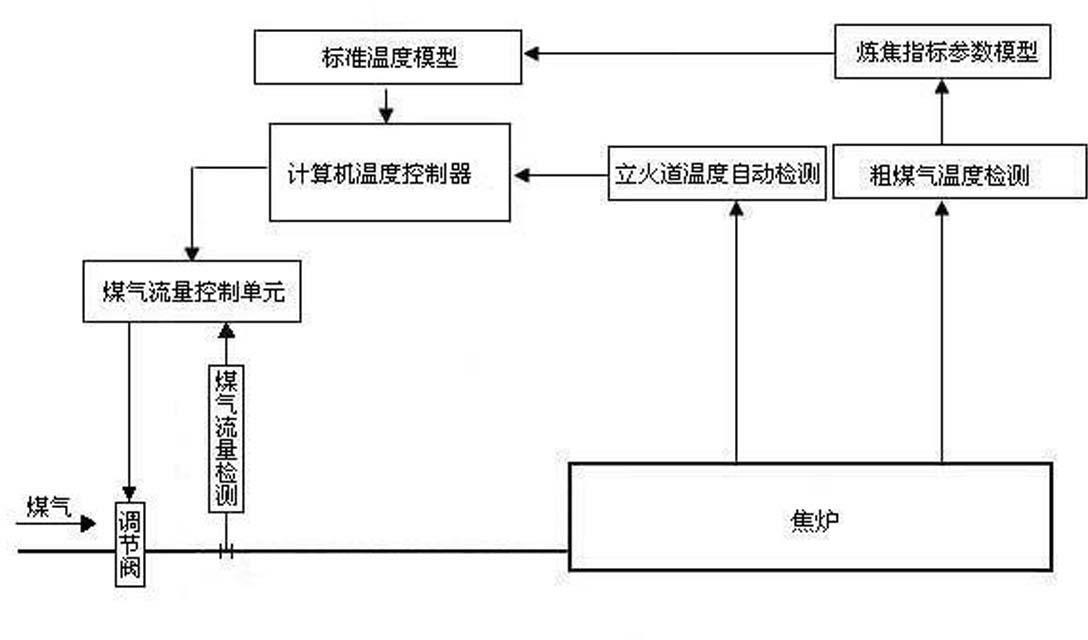

Method for heating and controlling temperature of coke oven

InactiveCN102517043AImprove the automation level of operation managementIncrease labor intensityCombustible gas coke oven heatingAuxillary controllers with auxillary heating devicesEconomic benefitsCoke oven

The invention relates to a method for heating and controlling temperature of a coke oven, which comprises the following steps: (1) detecting temperature of untreated gases of each coking chamber at a first coking period, obtaining an average coking index parameter 1 of the whole oven, and revising to obtain standard temperature Ts1 of the coke oven through the 1; (2) using the Ts1 as a standard temperature set value of a second coking period at the second coking period, measuring flue temperature to obtain an average flue temperature of the whole oven, determining heating coal gas flux so as to adjust temperature of the coke oven according to a deviation between the average flue temperature of the whole oven and the Ts1; and (3) detecting temperature of untreated gases of each coking chamber at the second coking period, obtaining an average coking index parameter 2, revising the Ts1 through the 2 to obtain standard temperature Ts2, using the Ts2 as a standard temperature set value of a third coking period, and processing later coking periods in the same manner. According to the method, the stability of the coke oven and coke quality index can be improved; and the system has low investment and long service life, and has significance in energy conservation and emission reduction of the coke oven, and obvious economic benefits.

Owner:TAIYUAN COAL GASIFICATION +1

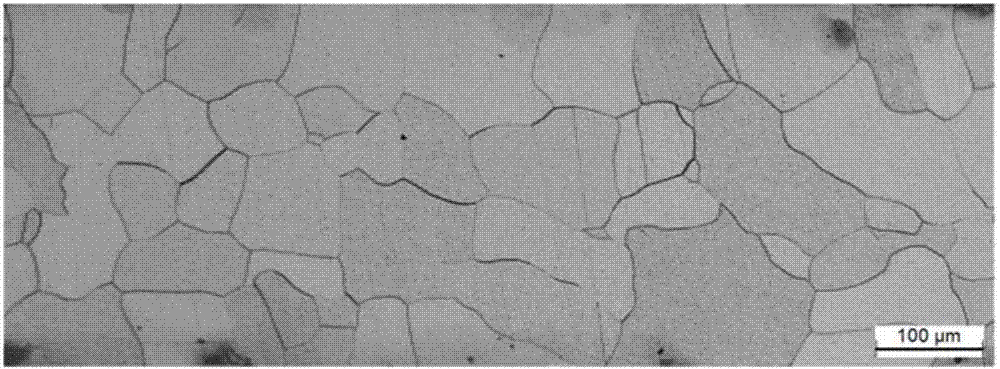

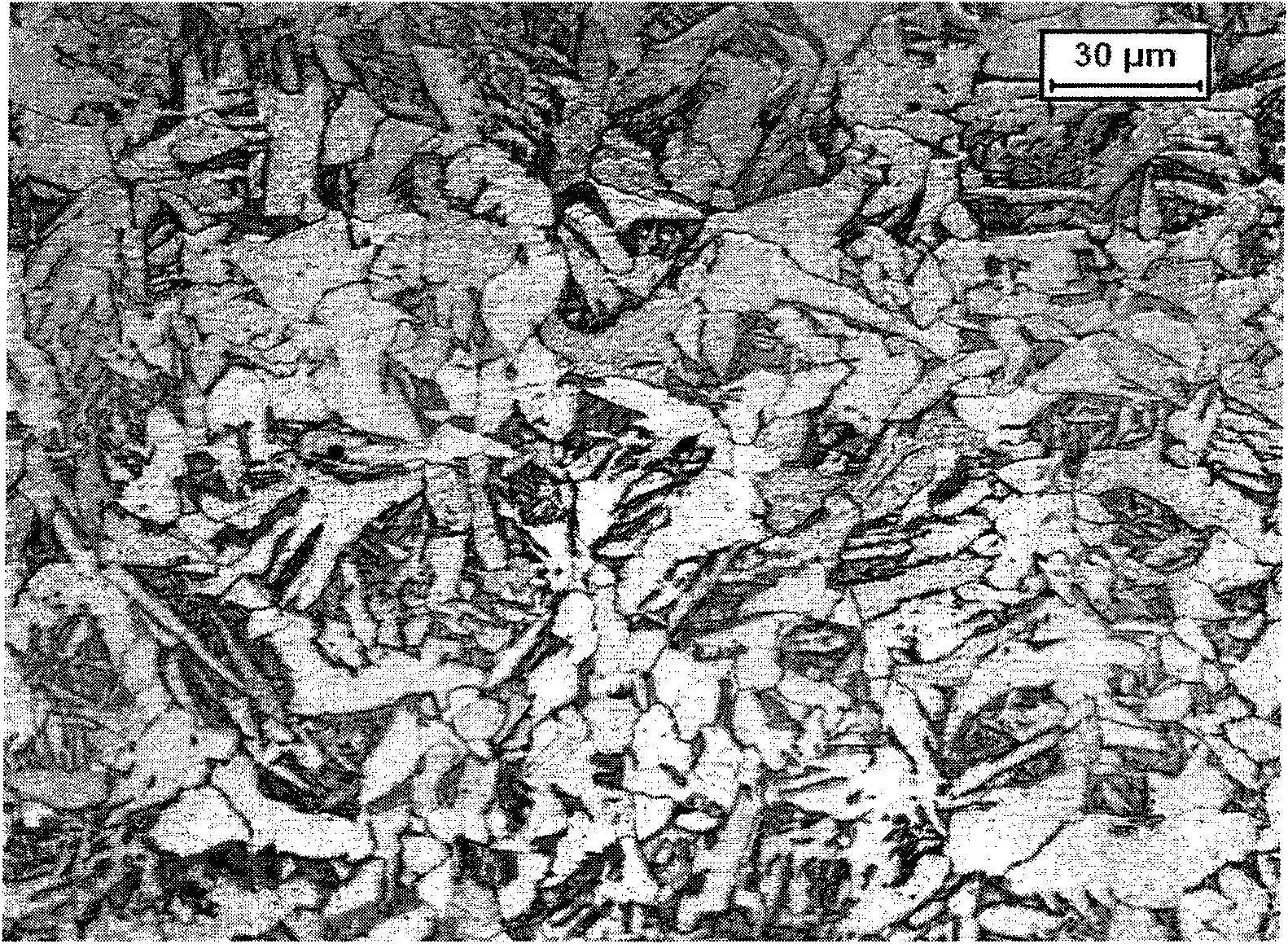

Method for preparing {100} surface developed-texture non-oriented silicon steel thin strip based on thin-strip continuous casting

The invention belongs to the technical field of metallurgy, in particular to a method for preparing a {100} surface developed-texture non-oriented silicon steel thin strip based on thin strip continuous casting. The method comprises the steps of smelting molten steel according to set components, wherein the set components comprise, by weight percentage, 0.002-0.005% of C, 2.2-3.5% of Si, 0.2-0.3% of Mn, less than or equal to 0.005% of Al, 0.08-0.20% of P, 0.002-0.005% of S and the balance Fe and inevitable impurities; (2) carrying out thin-strip continuous casting to form a cast strip with the thickness of 1.5-2.5mm; (3) carrying out one-pass hot rolling under an inert atmosphere condition; (4) carrying out single-stage multi-pass cold rolling on the hot rolled strip after clearing oxide skin of the hot rolled strip; (5) carrying out two-stage annealing on the cold rolled coil; and (6) applying an insulating layer to obtain a high-performance non-oriented silicon steel finished product. The method is based on the thin-strip continuous casting, the low-melting-point element P is added, the segregation characteristic of the P on the surface and the grain boundary is utilized, and therefore the intensity of {100} texture in the finished product plate can be enhanced. The method has the advantages that the technological process is short, the energy is saved, the consumption is reduced, and the anisotropy of the finished product plate can be obviously reduced.

Owner:NORTHEASTERN UNIV

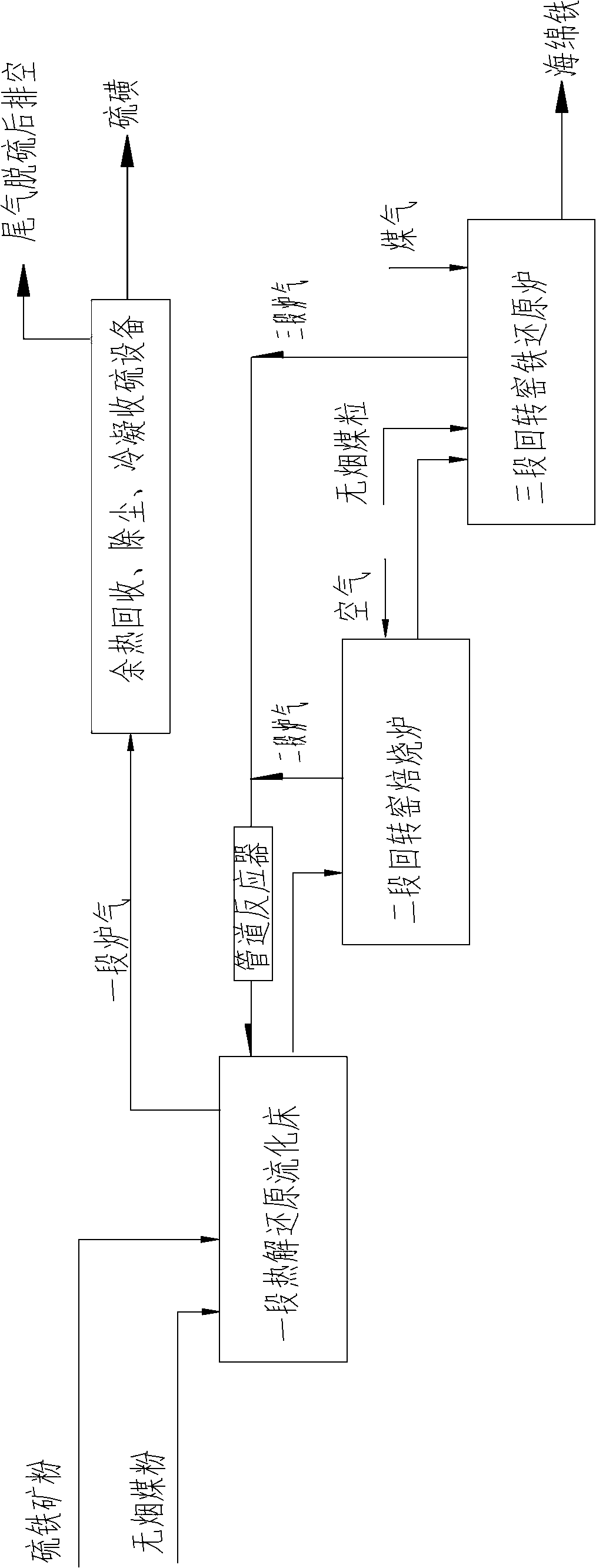

Method for producing sulfur by using pyrolysis-reducing united technique

ActiveCN103011090AIncrease profitIncrease concentrationEnergy inputSulfur preparation/purificationThermal energySlag

The invention discloses a method for producing sulfur and co-producing sponge iron by using a pyrolysis-reducing united technique, which comprises the following steps of: firstly carrying out first-step desulfurization-high temperature pyrolysis on sulfur-iron ores on a section of pyrolysis-reducing fluidized bed so as to generate sulfur steam and ferrous sulfide, wherein heat required by the pyrolysis process is mainly supplied by high-temperature flue gas from a pipe reactor and part of material combustion heat produced in the process; and 2, reducing iron oxide slag of a second-section furnace by using a coal-based rotary kiln direct reduction method, namely that on the basis of adopting a mature sponge iron production technology, fully using the high-order heat energy and high activity of the iron oxide slag discharged from the second-section furnace, therefore, effects of remarkably saving energy and reducing consumption as well as improving the production efficiency are achieved. The method is remarkable in energy saving effect, high in comprehensive utilization of mineral resources, environmental-friendly, and especially applicable to the large-scale development and utilization of sulfur-iron resources in sulfur resource-rich areas and the comprehensive utilization of high-sulfur fault coals; and meanwhile, the method also provides a new way for the comprehensive and efficient utilization of associated sulfur resources in the non-ferrous smelting industry.

Owner:新疆中驰恒谊环保科技有限公司

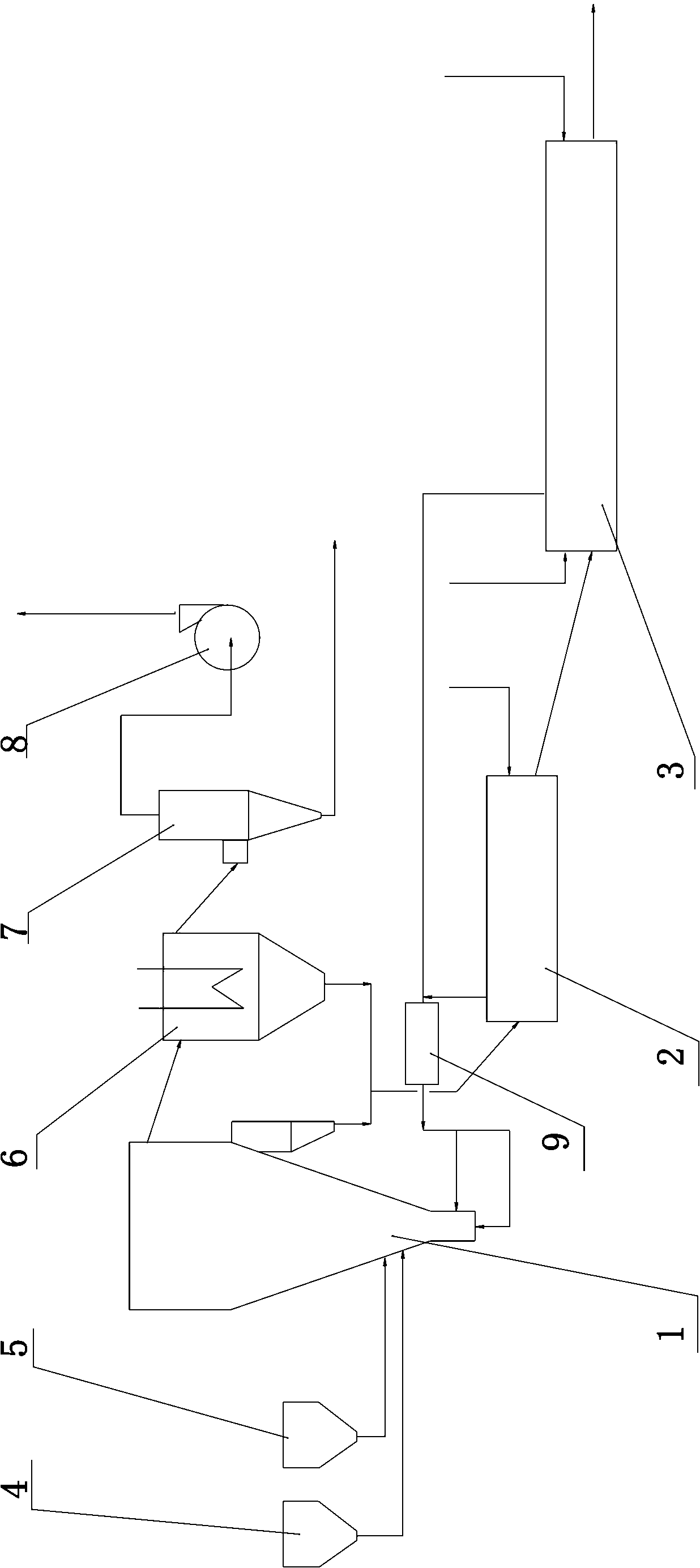

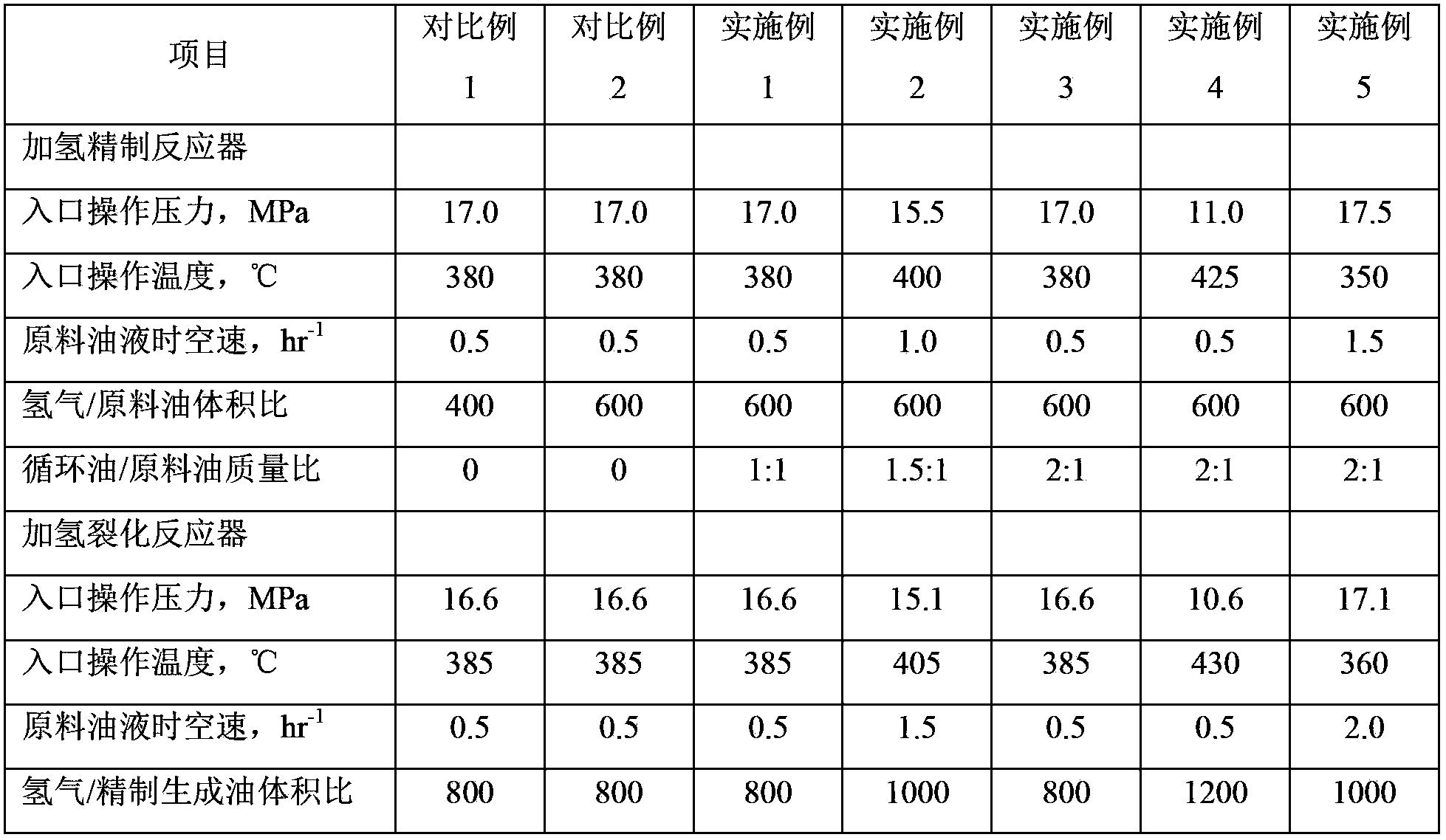

Coal tar hydrogenation system and coal tar hydrogenation method

ActiveCN103571533AExtend your lifeReduce adverse effectsTreatment with hydrotreatment processesHydrogenGas phase

The invention provides a coal tar hydrogenation system and a coal tar hydrogenation method. The method comprises a hydrogenation refining reactor, a separation unit and a hydrogenation cracking reactor, wherein the hydrogenation refining reactor is an up-flow fixed bed reactor, the hydrogenation cracking reactor is a down-flow fixed bed reactor, and the separation unit is a middle liquid separation tank; gas-liquid separation is performed on raw oil and hydrogen after a hydrogenation refining reaction, a part of liquid-phase heavy fractions is separated, one path is used as circulating oil and returned to perform the hydrogenation refining reaction again, and the other path is used as quenching oil after being cooled and added between catalyst bed layers for the hydrogenation refining reaction to play a role of cooling; and the other part of the liquid-phase heavy fractions is used as refined generated oil and mixed with hydrogen to perform a hydrogenation cracking reaction, and the obtained reaction product is combined with gas-phase light fractions after the gas-liquid separation to form the final product. The system and the method provided by the invention are low in equipment cost, simple to operate, capable of prolonging the life of the catalysts of the hydrogenation refining reactor and the hydrogenation cracking reactor, and suitable for raw oil with worse conditions.

Owner:CHINA PETROCHEMICAL CORP +1

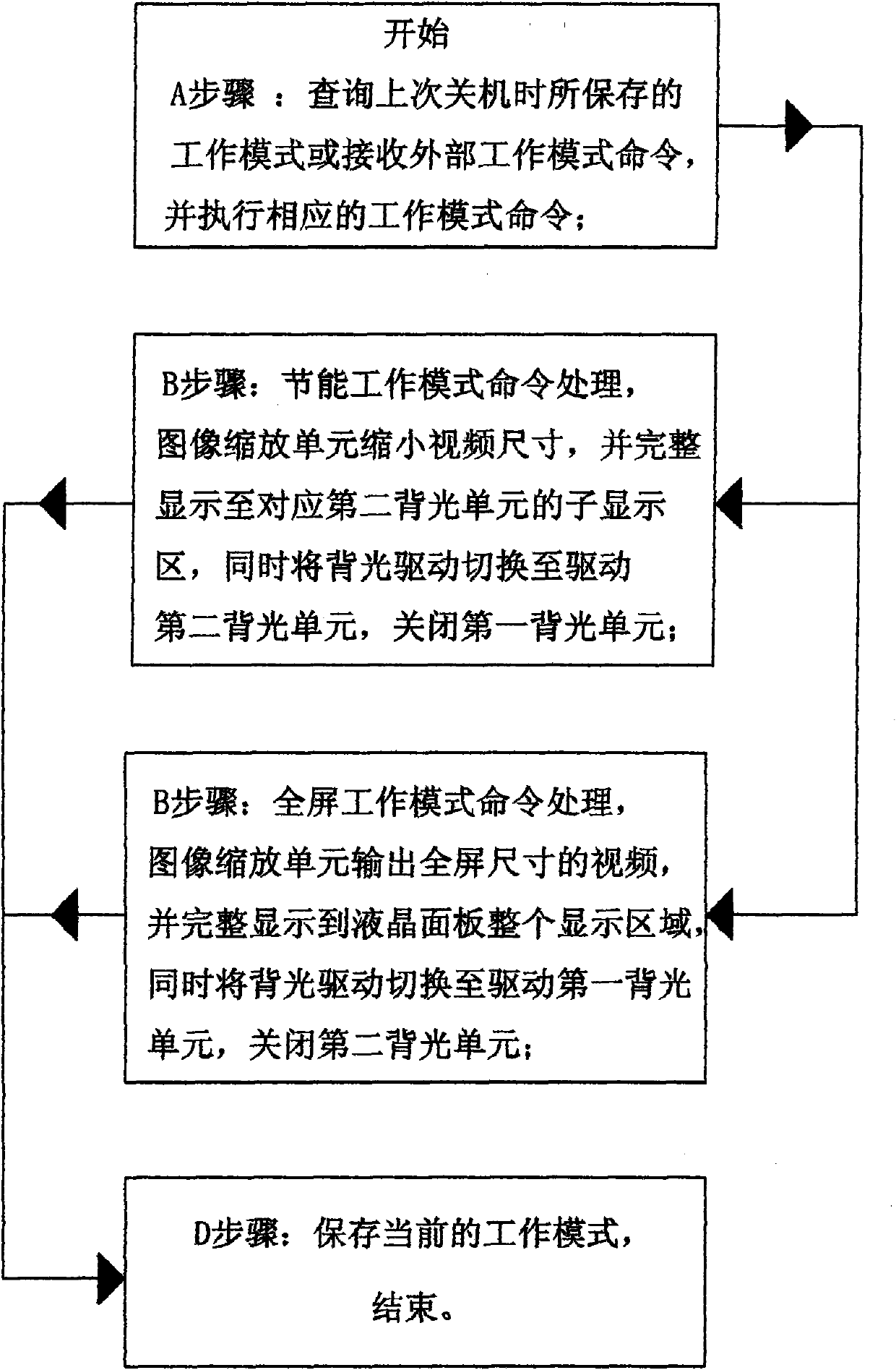

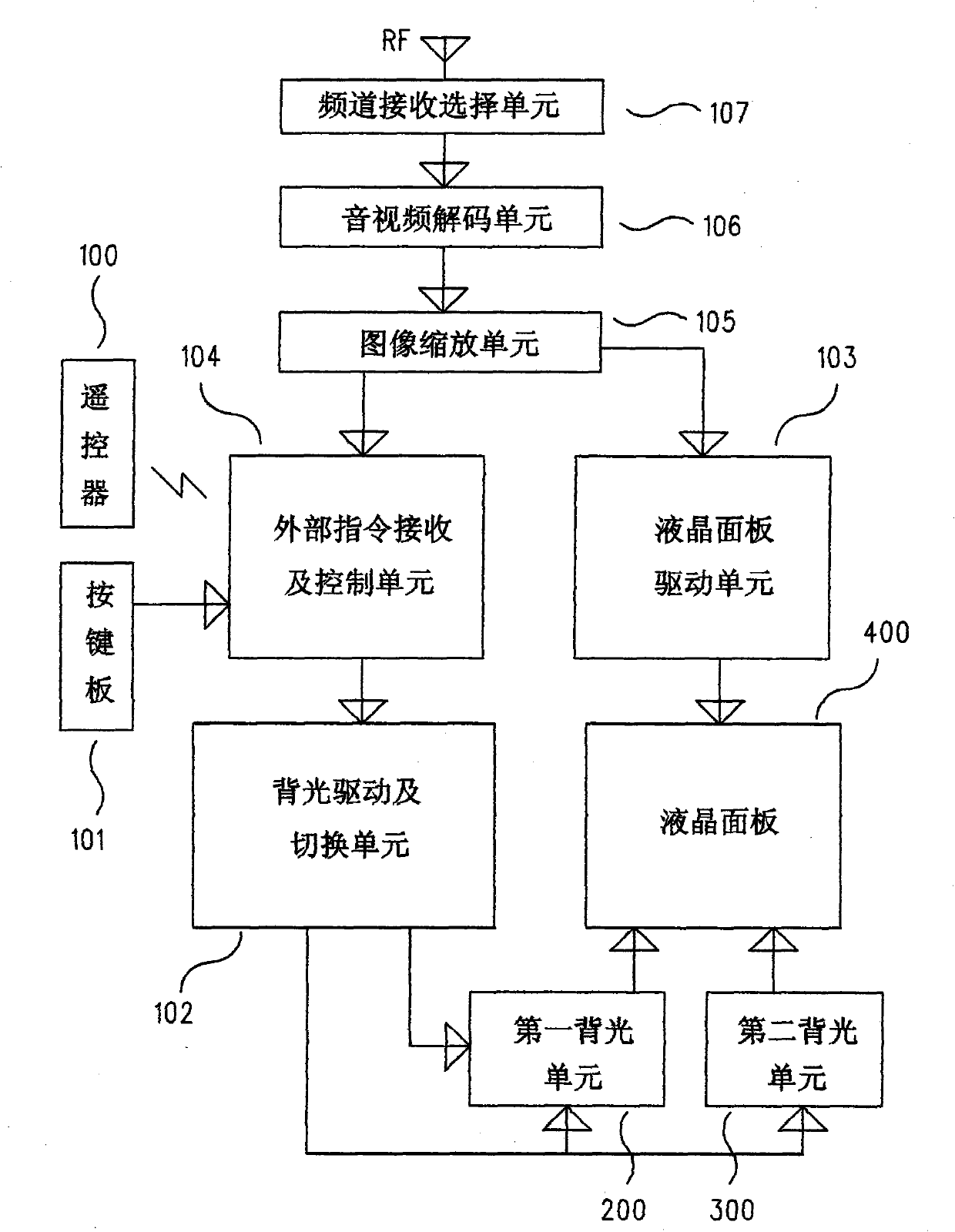

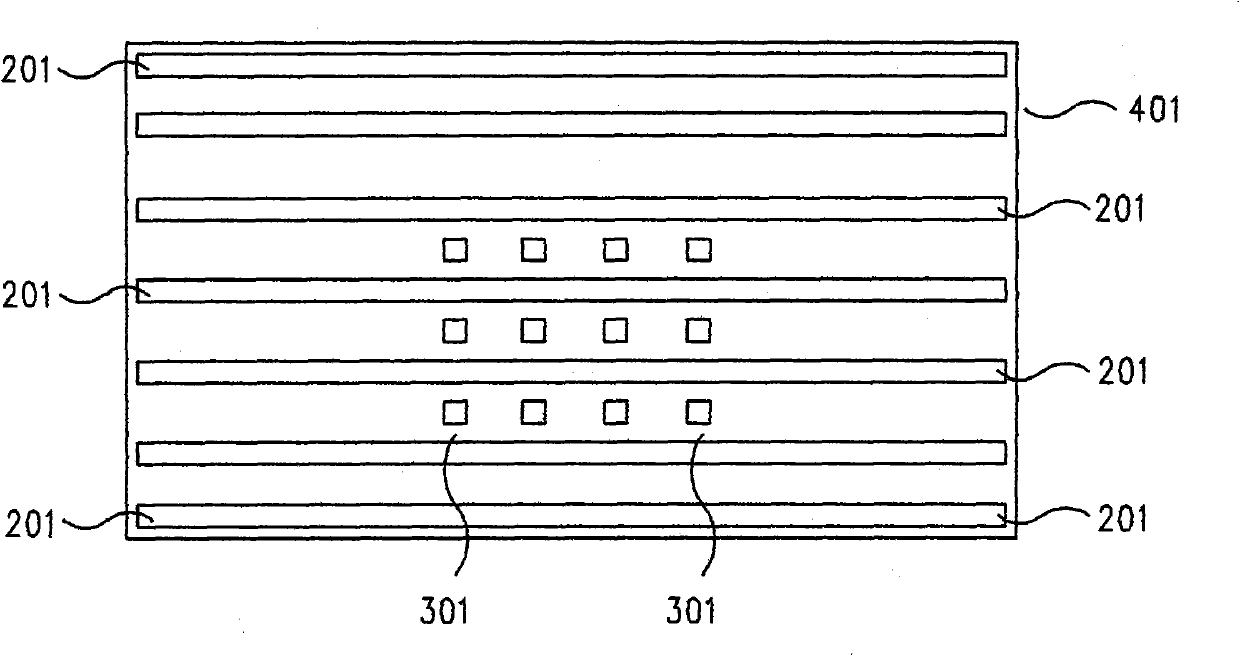

Liquid crystal display device and display control method thereof

InactiveCN101950546ADoes not affect consistencyExtend your lifeTelevision system detailsStatic indicating devicesLiquid-crystal displayComputer science

The invention discloses a liquid crystal display device and a display control method thereof. The liquid crystal display device comprises a television using a liquid crystal display. Two working modes comprising a full-screen mode and an energy-saving mode are provided, wherein in the energy-saving mode, an image is zoomed out and displayed on a sub display area in a liquid crystal panel, and the sub display area is lightened by a second backlight unit; and the full-screen mode is lightened by a first backlight unit. The method realizes the energy-saving mode without affecting the consistency of backlight lamps, and can prolong the service life of the liquid crystal display device at the same time.

Owner:张超

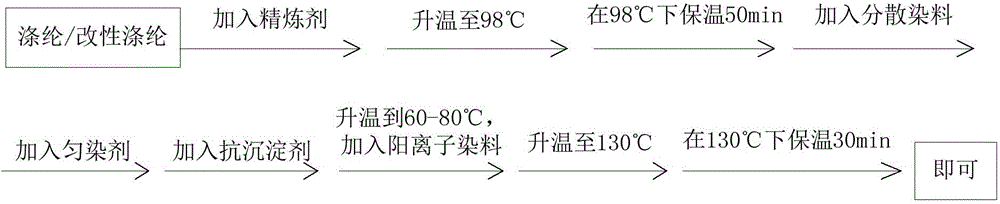

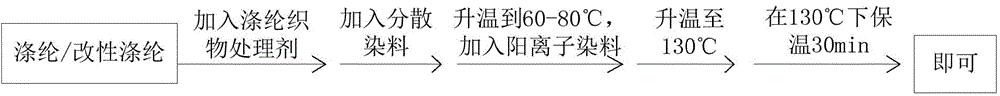

Polyester fabric treating agent

The invention discloses a polyester fabric treating agent. The polyester fabric treating agent is prepared from, by weight, 30-60 parts of an ampholytic surfactuant, 10-40 parts of an emulsifier, 0.1-2 parts of a stabilizer, 5-25 parts of solvent and 10-30 parts of an ester compound, wherein the sum of the weight parts of the components is 100. When the polyester fabric treating agent is used for one-bath dyeing of a polyester-modified polyester blended fabric, combination of anionic and cationic dyes can be prevented, the dyeing quality is guaranteed, and the technology is obviously simplified.

Owner:JIANGSU NEW REBA TECH CO LTD

A clarified and concentrated fruit juice preparation method

The present invention provides a clarified and concentrated fruit juice preparation method which includes the following steps: fruits are crushed and beat to prepare fruit pulp, the fruit pulp is sent into a freezing and concentrating equipment to conduct suspended crystallization and then conduct gradual layered crystallization until all the fruit pulp is frozen, the fruit flesh and other suspended particles can be effectively blocked in the ice layer with the help of filtering bed constituted by frozen ice particles, and the concentrated juice is separated out and clarified. The preparation method eliminates the necessary processes needed for the production of conventional clarified juice such as juice squeezing, filtrating, clarifying, etc. The preparations of fruit pulp to clarified concentrated juice are all conducted in a single freezing and concentrating device, the preparation occupies less devices, the technology process and operation were simple and convenient, the investment and operating costs are low, and the energy is saved and the consumption is reduced.

Owner:XINJIANG AGRI UNIV

Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

ActiveCN102041367BMeet needsReduce processHeat treatment process controlMelting tankElectrical steel

The invention relates to a manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel, comprising the following steps: smelting molten steel the temperature and components of which meet the requirements, casting the molten steel into a molten bath formed by a pair of water-cooling crystallizing rolls rotating at high speed, then cooling for the second time,hot rolling, cooling for the third time, coiling, cooling to room temperature, pickling, cold rolling, and finally annealing to obtain the cold rolled non-oriented silicon steel sheet with high magnetic induction and low iron loss. In the invention, the thin strip continuous casting process can eliminate the hot rolling thinning procedure in the traditional process, thus avoiding quality defect caused by the improper hot rolling process, simultaneously reducing the equipment loss, and reducing the maintenance and overhaul costs of equipment; the solidification process is controlled to improvethe medium axialite proportion of the casting strip, thus improving the corrugation defect of the product in the cold rolling process; and the range of components of the non-oriented silicon steel smelting is widened by the characteristic of quick solidification of the continuously cast thin strip, and the smelting cost is lowered. The invention has the advantages of short process flow, low energy consumption, high efficiency, low production cost, simple manufacturing method and obvious energy saving and consumption reducing effects.

Owner:BAOSHAN IRON & STEEL CO LTD

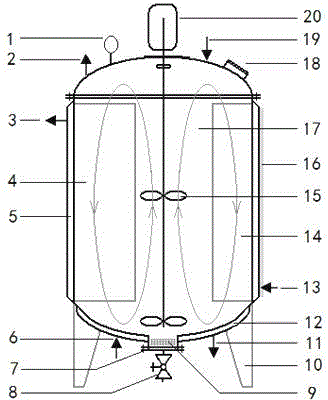

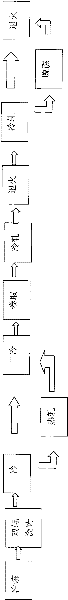

Extraction kettle apparatus for separating coal tar through mild extraction method

InactiveCN103275743AHigh recovery rateEmission reductionTar working-up by solvent extractionInsulation layerAgitator

The invention relates to an extraction kettle apparatus for separating coal tar, and concretely relates to an extraction kettle apparatus for separating coal tar through a mild extraction method. A strong magnetic stirrer is arranged in the center of a top cover, and a temperature measuring port, a pressure measuring port, a material inlet, an extractant inlet, a nitrogen inlet, a nitrogen outlet, a diffusing port, and valves connected with relevant tube ports are uniformly arranged in the circumference of the top cover respectively; an electric lift type lift tube lightweight component discharging system is arranged at the upper right side of the top cover; two hot steam heating coilers and corresponding hot steam inlets are arranged at the center outside a kettle; the material outlets of downward spreading valves are arranged at the outside surface portion of the kettle, and the downward spreading valves are respectively connected with a glass sight cup; three groups of sight glasses are arranged at the center outside the kettle; an interlayer heat insulation layer is arranged at the center outside the kettle; and a steam outlet, a material outlet and a valve are arranged at the bottom of the kettle. The apparatus has the advantages of simple operation, obvious energy saving and consumption reduction, high solvent recovery rate, easy automatic operation, low-carbon clean production, low investment cost, and less discharge of waste residues, the exhaust gas and wastewater.

Owner:ZAOZHUANG MINING GRP CO LTD +1

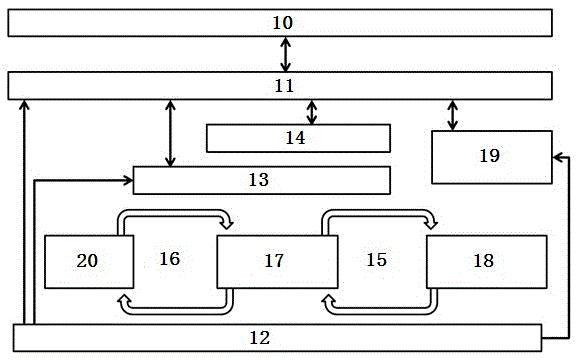

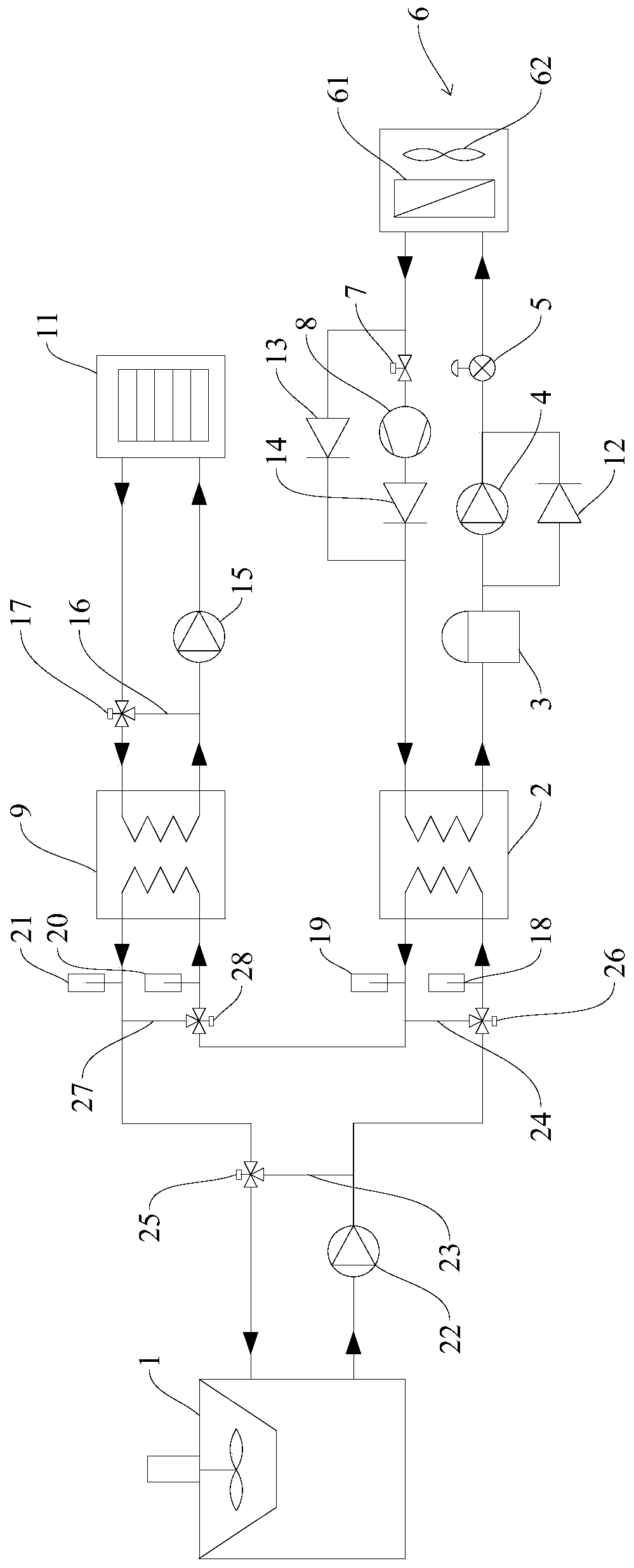

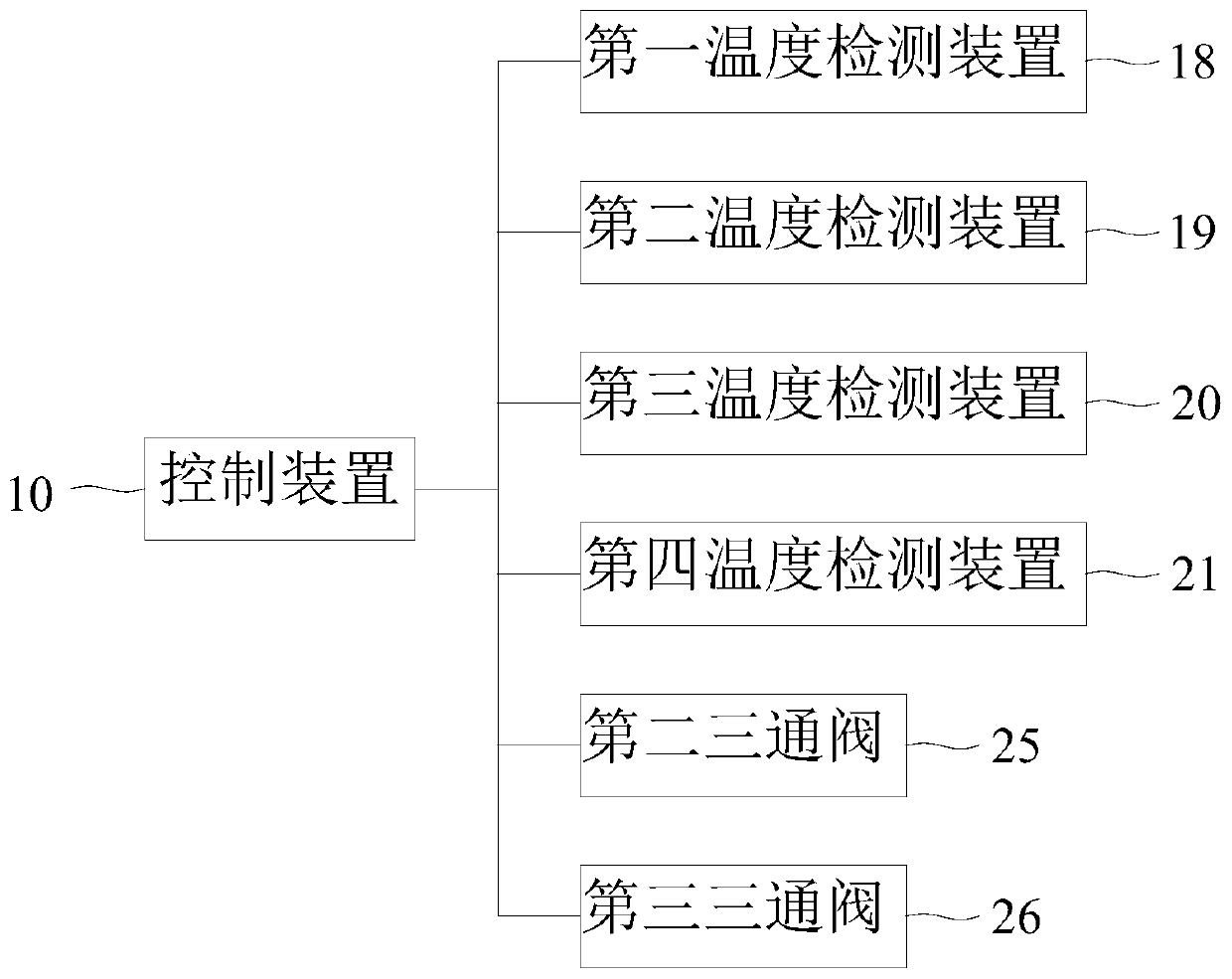

Heat balance adjusting method and intelligent monitoring system based on heat balance adjusting method

ActiveCN105650730AAchieve trafficAchieve temperatureLighting and heating apparatusCentral heating componentsIntelligent lightingMonitoring system

The invention relates to a heat balance adjusting method and an intelligent monitoring system based on the heat balance adjusting method. The heat balance adjusting method is characterized in that by adjusting the indoor temperature balance between terminal users, the balance of temperature flow between heat exchange stations and the balance between the heat needing amount of the heat exchange stations and the heat supply amount of a heat source, and rapid balance of the heat needing amount of the terminal users and the total heat supply amount is finally achieved; and the terminal users can rapidly obtain and keep the comfortable indoor temperature, a heating power company can adjust the heat supply amount in time, and the requirements of energy saving, consumption reduction and emission reduction are met.

Owner:WEIHAI PLOUMETER

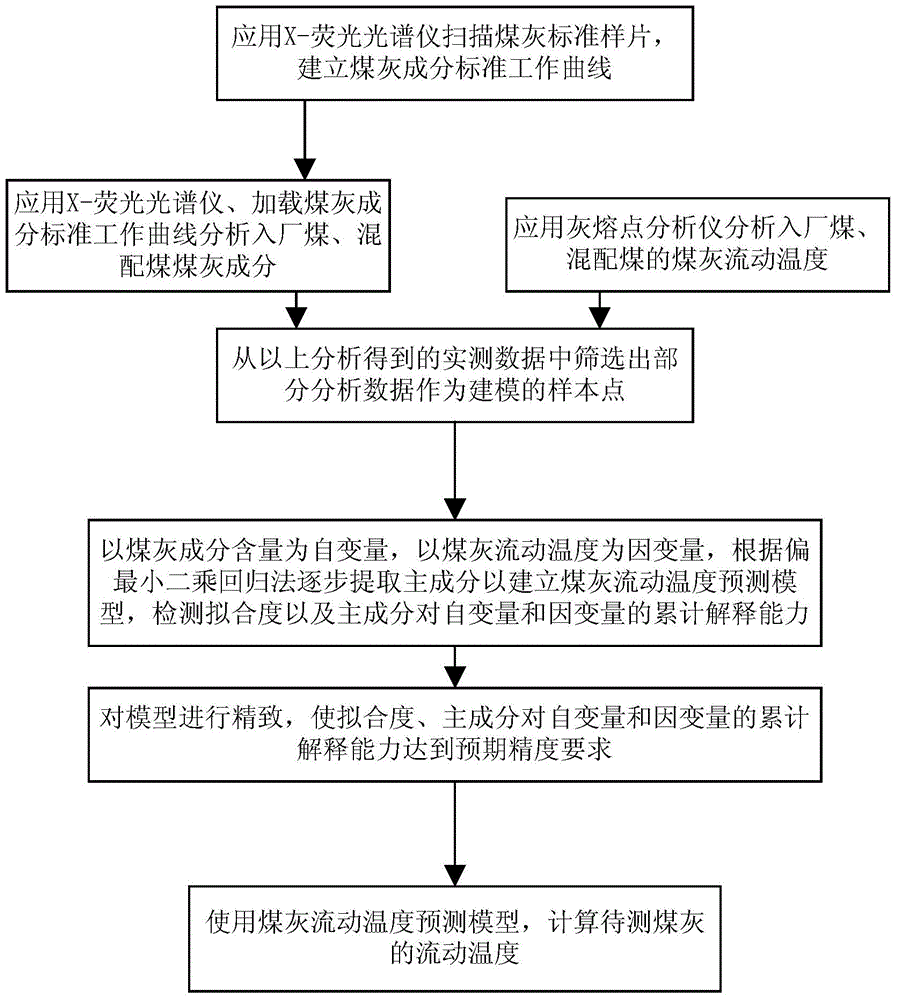

A method for predicting flowing temperature of coal ash

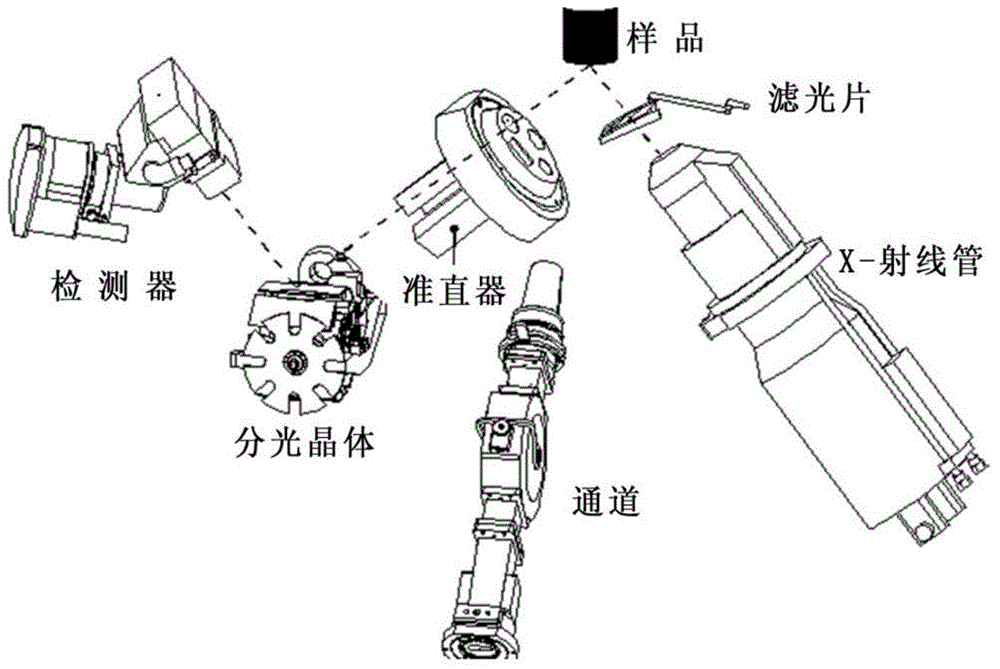

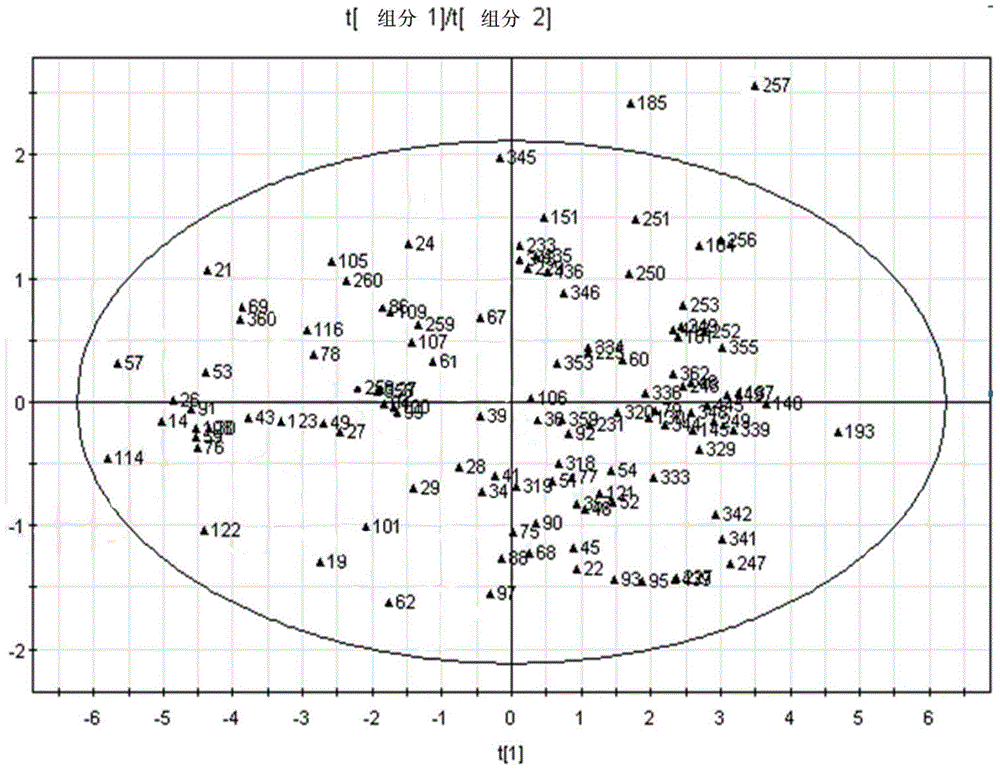

InactiveCN104408215AImprove accuracyMeet the needs of actual productionMaterial analysis using wave/particle radiationSpecial data processing applicationsData setCoal

The present invention provides a method for predicting a flowing temperature of coal ashes. The method includes substituting component content of the coal ash to be detected into a coal ash flowing temperature predicting model, to obtain a predicting value of the flowing temperature of the coal ash to be detected, wherein the coal ash flowing temperature predicting model is constructed by the following steps: analyzing the coal ash composition and the coal ash flowing temperature of the coal entering the factory or the mixed coal, and building a sample point data set using the obtained multiple groups of analyzed data, wherein each group of analyzed data includes the coal ash composition content and the corresponding coal ash flowing temperature; based on the sample point data set, using the coal ash composition content as an independent variable, using the coal ash flowing temperature as a dependent variable, and establishing the coal ash flowing temperature predicting model using a method of partial least-squares regression. The method solves the boundedness of complex analysis procedures and long analysis periods of a conventional coal ash flowing temperature measuring method. In addition, the method overcomes the ill effect of the multiple correlations on system modeling, narrows errors in model predicting, and increases robustness of the model.

Owner:DATANG INNER MONGOLIA DUOLUN COAL CHEM CO LTD

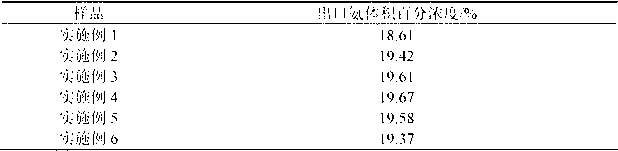

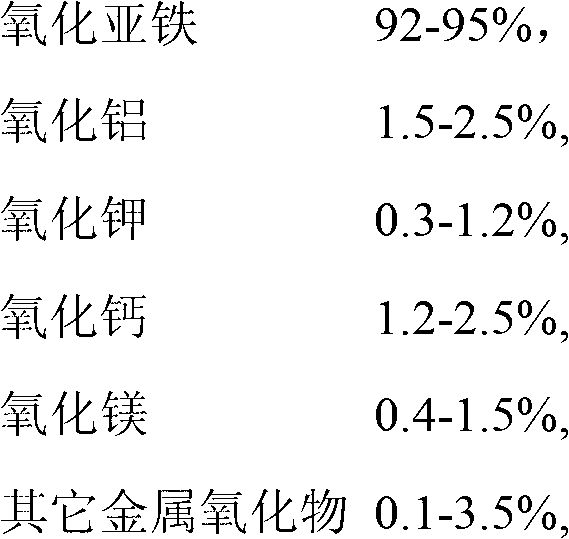

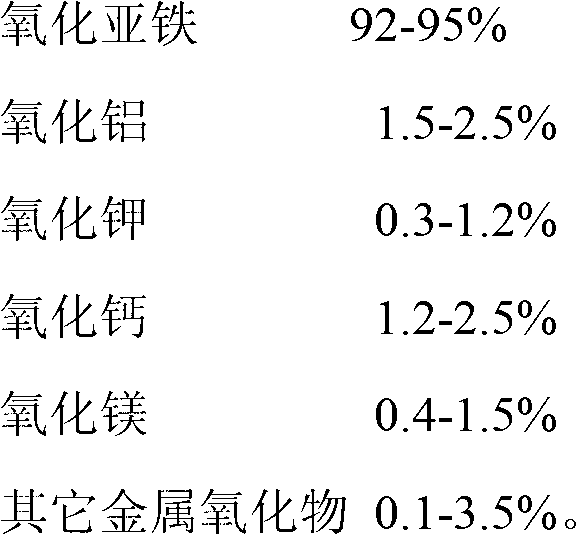

Ferrous oxide-based ammonia synthesis catalyst

ActiveCN102909030AHigh activityEnhanced adsorption and activationMetal/metal-oxides/metal-hydroxide catalystsBulk chemical productionHeat resistanceEconomic benefits

The invention discloses a ferrous oxide-based ammonia synthesis catalyst. The ferrous oxide is taken as a main phase component, and potassium oxide, calcium oxide, aluminum oxide, magnesium oxide and other metal oxides are used as auxiliary catalysts. The ferrous oxide-based ammonia synthesis catalyst is prepared by a melting method. The catalyst has high activity to catalyze nitrogen and hydrogenate to synthesize ammonia, easy to reduce, and great in heat resistance and antitoxic and has mechanical performances. The catalyst is suitable to be used in various sizes of ammonia synthesizing devices, and particularly suitable for a low-pressure and low-energy consumption ammonia synthesizing technique; and obvious energy saving, consumption reduction, efficiency increasing, cost saving and economic benefits are achieved.

Owner:ZHEJIANG UNIV OF TECH

Preparation method of polycrystalline silicon

InactiveCN104229802ASignificant energy saving and consumption reductionQuality improvementChemical industrySilicon compoundsElectric arc furnaceFluidized bed

The invention provides a preparation method of polycrystalline silicon, and belongs to the technical field of solar silicon wafer preparation. The preparation method is achieved by the following technical scheme: smelting and purifying silica sand to 98% in an electric arc furnace, and generating industrial silicon; crushing the industrial silicon and reacting by using anhydrous hydrogen chloride (HCl) in a fluidized bed reactor, so as to generate trichlorosilane (SiHCl3), wherein the reaction temperature is 300 DEG C, and a gaseous mixture (H2, HCl, SiHCl3, SiCl4 and Si) are formed by reaction; filtering silicon powder from the gaseous mixture; condensing SiHCl3 and SiCl4, returning gaseous H2 and HCl to reaction or discharging into atmosphere, and then decomposing condensates SiHCl3 and SiCl4; and purifying trichlorosilane; and carry out reducing deposition on the purified trichlorosilane with high-purity SiHCl3 in H2 atmosphere by adopting a high-temperature reduction process, thereby generating polycrystalline silicon. The preparation method of the polycrystalline silicon has the advantages of significant energy conservation and consumption reduction, low cost and good quality; by adopting a comprehensive utilization technique, the environment is not polluted; and the method has obvious competitive advantages.

Owner:潘龙祥

Constant temperature heating system of hothouse

ActiveCN101933447ASave electricitySave investment costClimate change adaptationGreenhouse cultivationGreenhouseEngineering

The invention provides a constant temperature heating system of a hothouse, comprising a heat source used for preparing hot water and a pipeline used for transporting the hot water to the hothouse to carry out heating. The constant temperature heating system of the hothouse is characterized by also comprising one or a set of water towers, wherein the water towers are used for storing the prepared hot water and supplying pressure needed by water transportation, the pipeline is a parallel water supply pipeline and comprises a main water feeding pipe and a plurality of branch water feeding pipes, wherein the branch water feeding pipes are all communicated with the main water feeding pipe, hierarchically supply heating to a located shed area and sequentially supplement heating for the branch water feeding pipe at the front according to the sequence of from far to near.

Owner:北京格瑞那环能技术有限责任公司

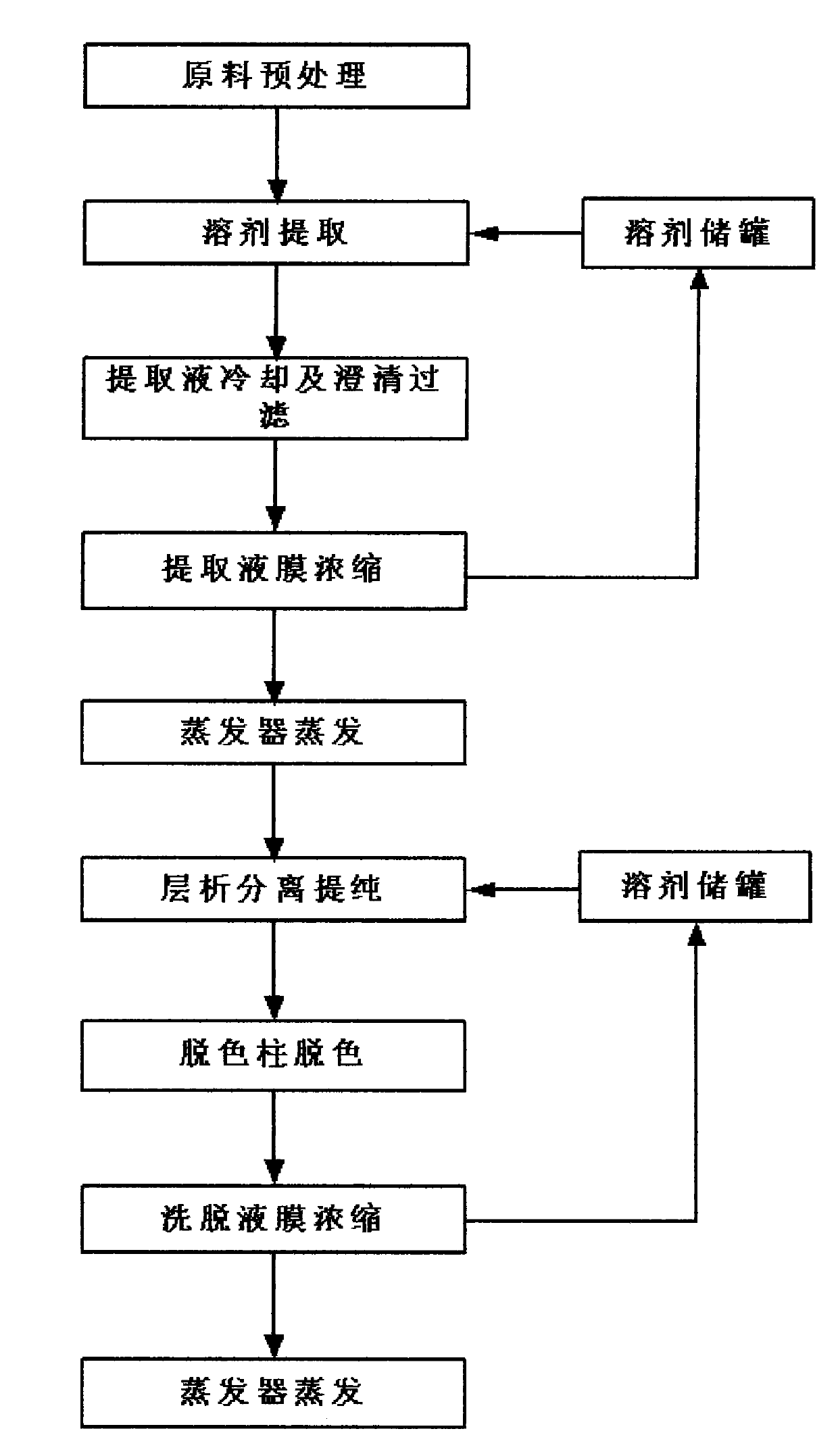

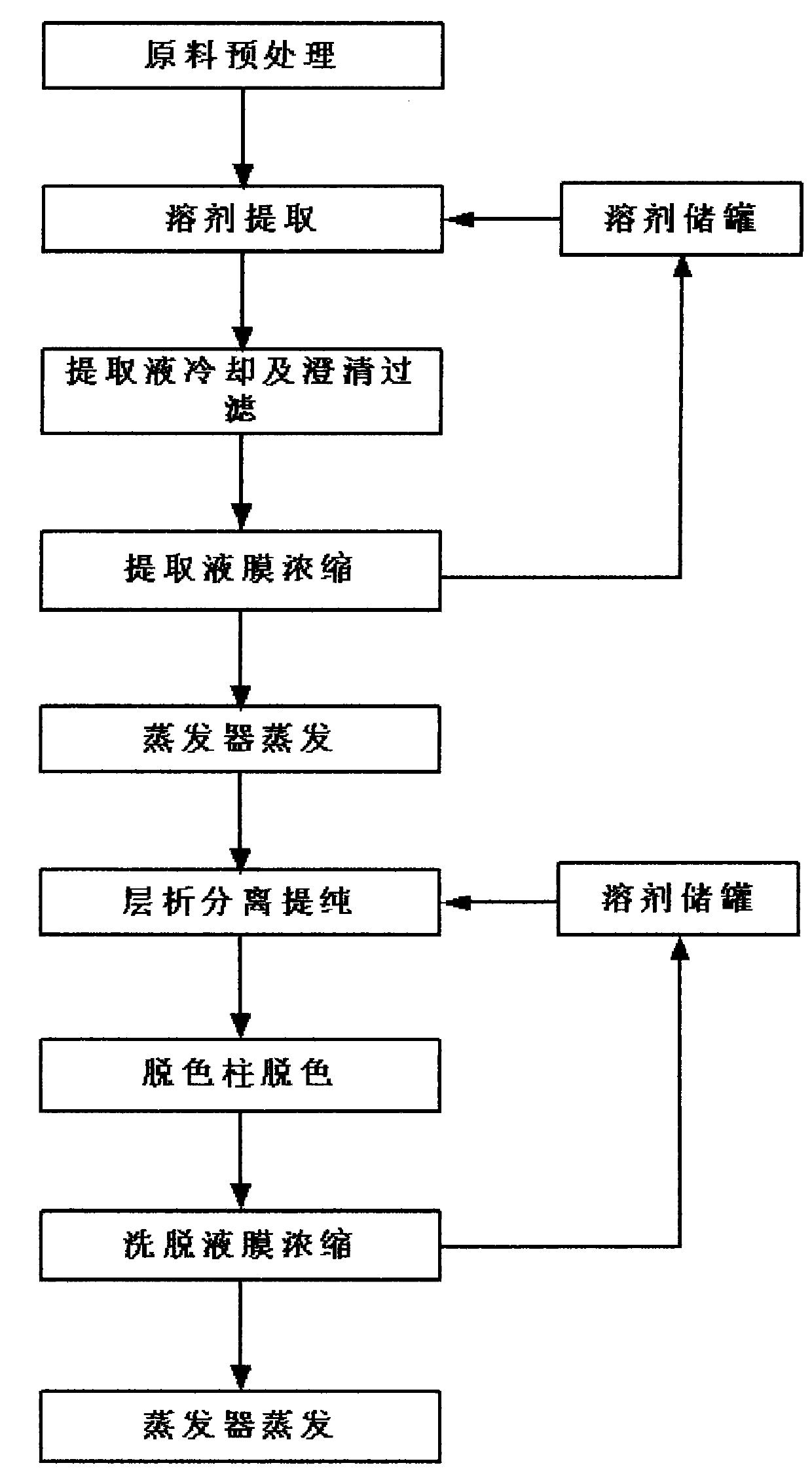

Novel energy-saving process for extracting and purifying panax notoginseng saponins

ActiveCN101947250AReduce consumptionSignificant energy saving and consumption reductionPlant ingredientsSolventChromatographic column

The invention discloses a novel energy-saving process for extracting and purifying panax notoginseng saponins, comprising: crushing raw materials, extracting solvent, cooling and clarifying extraction liquid, concentrating, chromatographically separating and purifying, decoloring, concentrating, evaporating, etc.; the steps are specifically as follows: pre-processing the pseudo-ginseng raw materials and then feeding into an extracting tank, adding 5-10 times of about 70% of ethanol solution, heating to 75 DEG. C, refluxing and extracting for about 3h; collecting the extraction liquid, cooling and clarifying, performing film concentration and recovering ethanol, stopping concentrating till amount of the permeated ethanol solution is 90% of that of the extraction liquid, evaporating the concentrated solution till to ethanol-free, transferring into a chromatographic column, absorbing the solution by the column, separating and purifying, eluting with 70% of ethanol solution, decoloring the eluent and then leading the eluent into a film concentrator to concentrate, directly feeding the concentrated solution into an evaporator to evaporate and recover the residual ethanol, finally preparing fine extract of the panax notoginseng saponins; through the film concentration process, concentration quantity of thermal evaporation is effectively reduced by 90%, comprehensive energy-saving rate reaches above 80%, absolute recovery rate of the solvent reaches above 90%, and solvent consumption is effectively reduced; thus, the process is evident in energy saving and consumption reducing.

Owner:云南活草堂生物科技有限公司

Printed synthetic leather and method for manufacturing same

InactiveCN102605635AImprove breathabilityGood resistance to extractionLamination ancillary operationsSynthetic resin layered productsCooking & bakingUltraviolet lights

The invention relates to a printed synthetic leather and a method for manufacturing the printed synthetic leather. The printed synthetic leather comprises a base cloth layer; the base cloth layer is coated with a water PU (polyurethane) foaming layer; and the surface of the water PU (polyurethane) foaming layer is printed directly to form a printed layer. The method for manufacturing the printed synthetic leather comprises the following steps: preparing a slurry; feeding the slurry into a foaming machine; adjusting the proportion of the slurry amount to the air intake to determine the size of needed foam holes; feeding a piece of base cloth, heating to iron, feeding, and putting into a baking oven to finish processing the base cloth; and finally printing directly on the surface of the synthetic leather taken out of the baking oven. The printed synthetic leather manufactured by adopting the method has good breathability and extraction resistance, can resist the irradiation of ultraviolet light, hydrolysis, cold bending and wear, can not become yellow, age and mildew and reaches the international advanced flame resistance standard. The process for manufacturing the printed synthetic leather is simple and has the advantages of saving energy and reducing consumption.

Owner:YIXING XINGUANG SYNTHETIC LEATHER

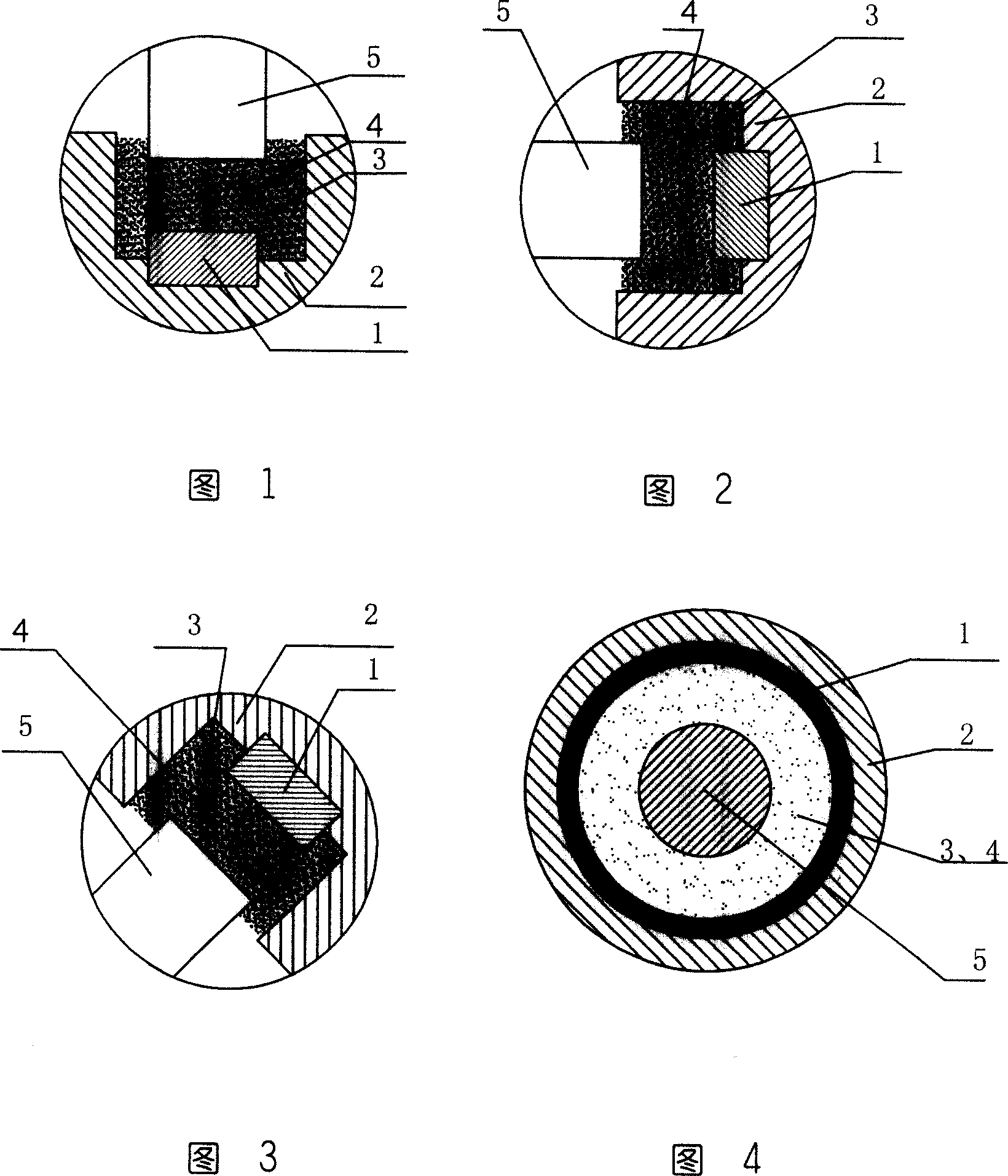

Magnetic field method for sealing air gap

InactiveCN101004220ASimple structureEasy maintenanceEngine sealsFurnace typesEngineeringElectrical and Electronics engineering

The present invention provides a magnetic field sealing method of air-gap. It is characterized by that on the air-gap of fixed body to be sealed a sealing groove correspondent to contact surface of mobile body is set, in the sealing groove bottom portion a magnetic field source is set, the groove interior is filled up with magnetic sealing medium to form magnetic field. The invented magnetic field flexible sealing theory is characterized by that in the air-gap to be sealed a magnetic field is created, the contact surface of said air-gap is filled up with magnetic sealing medium, under the action of magnetic field in the air-gap said magnetic sealing medium can be stably stored in the sealed air-gap, so that said sealed portion can obtain 'zero' leakage.

Owner:SHIJIAZHUANG RAILWAY INST

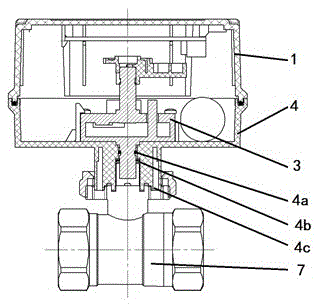

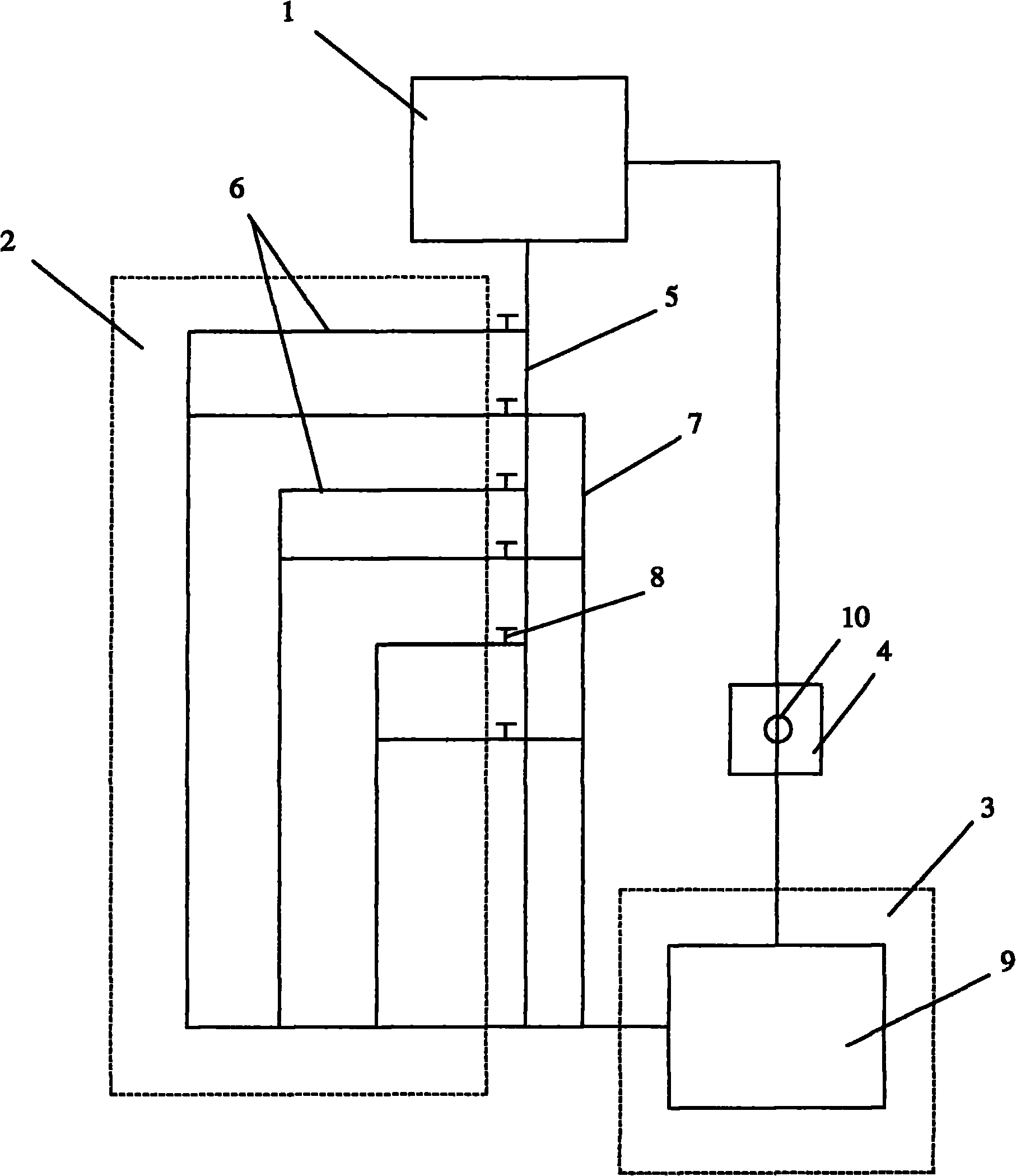

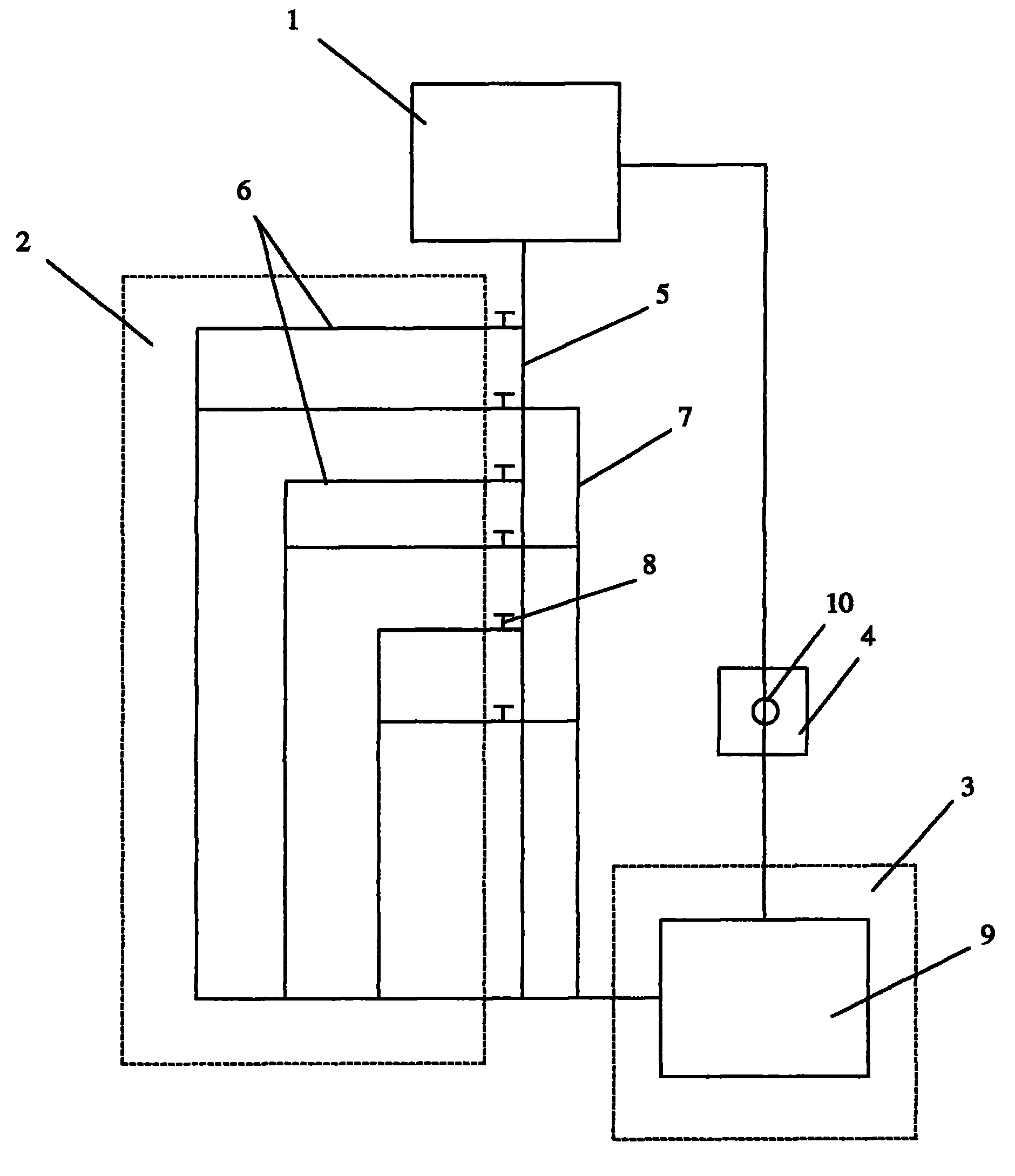

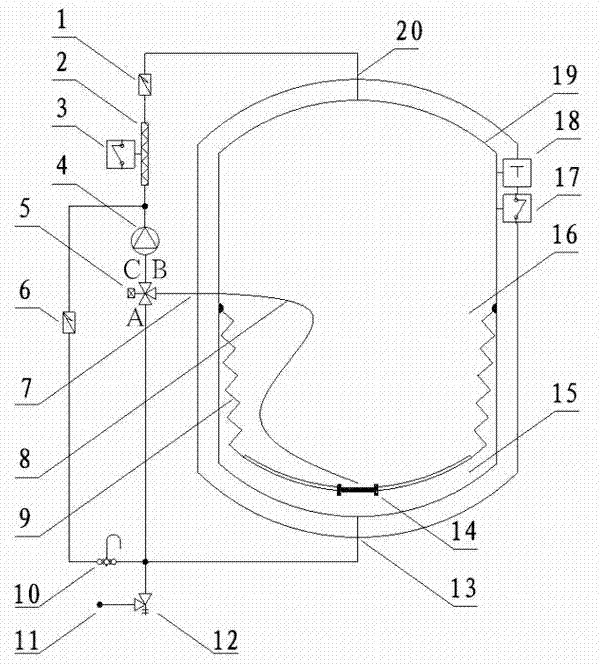

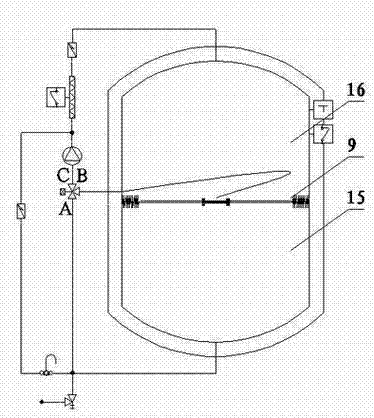

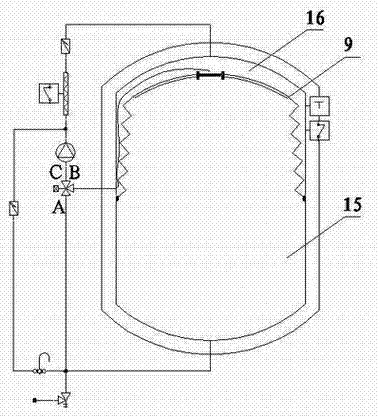

Electric water heater with high hot water output rate and constant-temperature water outlet function

Provided is an electric water heater with the high hot water output rate and the constant-temperature water outlet function. A diaphragm (9), a hot water circulating opening (7), a cold water opening (13) and a hot water opening (20) are formed in the middle of an inner container of a water heater body; a flow sensor (1), a heater (2), a water pump (4), a three-position three-way valve (5) and a flow sensor (6) are arranged outside the inner container of the water heater body; the inner container of the water heater body is divided by the diaphragm (9) into a cold water bin (15) and a hot water bin (16), and the cold water bin (15) and the hot water bin (16) are used for storing cold water and hot water respectively; the diaphragm (9) is of a flexible structure, and has three characteristics that pressure can be transmitted, the diaphragm can extend along with volume changes of the cold water and volume changes of the hot water in the inner container, and the diaphragm can be tightly attached to the inner wall of the inner container so that all the cold water or all the hot water can be pressed out; due to the fact that the cold water and the hot water are separated through the diaphragm (9), the cold water and the hot water cannot be blended, the constant-temperature water outlet function is achieved, and the effect that the hot water in the hot water bin (16) is completely output is achieved.

Owner:林子春

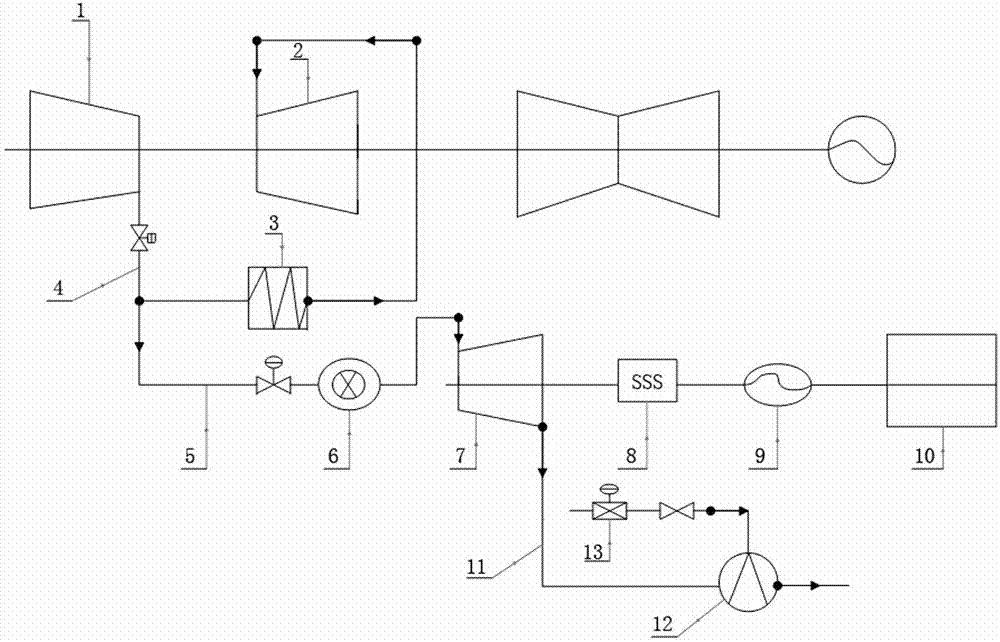

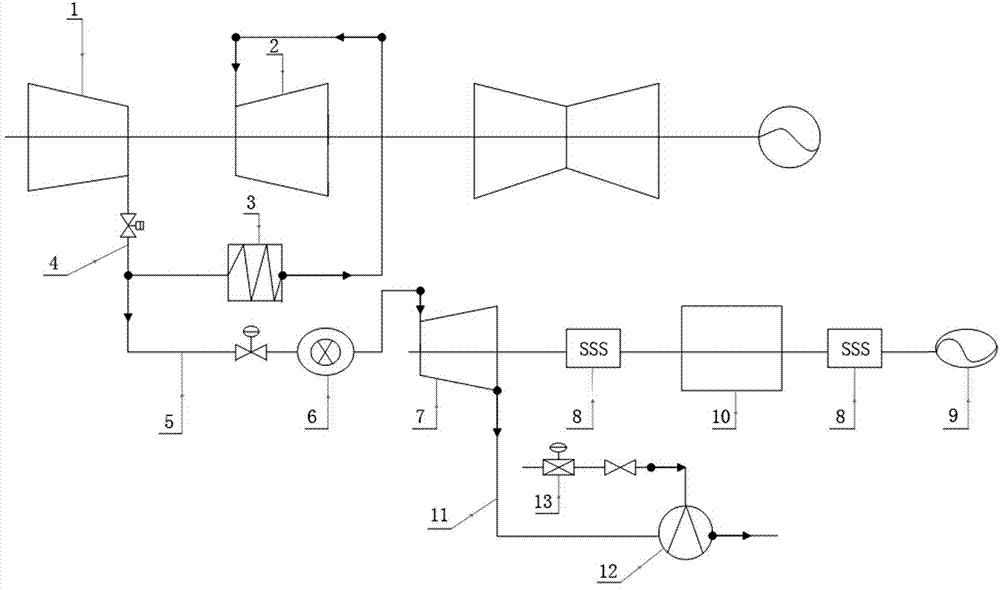

Back pressure machine work application device for supplying discharged steam of steam turbine high-pressure cylinder for industrial steam extracting system

InactiveCN104329128AReduce throttling lossReduce power consumptionSteam useCombined combustion mitigationIsolation valveEngineering

The invention provides a back pressure machine work application device for supplying discharged steam of a steam turbine high-pressure cylinder for an industrial steam extracting system. The back pressure machine work application device comprises an industrial steam extracting pipeline (5), an electric motor (9) and power equipment (10), wherein the industrial steam extracting pipeline (5) is provided with a back pressure machine steam inlet electric isolation valve, a back pressure machine main steam door and speed regulating steam door (6) and a steam supply temperature reducer (12), wherein the back pressure machine (7) and control equipment of the back pressure machine (7) are arranged between the back pressure machine main steam door and speed regulating steam door (6) and the steam supply temperature reducer (12), the back pressure machine (7) and the electric motor (9) are in coaxial arrangement at one side or two sides of the power equipment (10) and are connected with the power equipment (10) through an SSS clutch (8). Compared with the prior art, the back pressure machine work application device has the beneficial effects that the back pressure machine is additionally adopted, the partial industrially extracted steam is converted into effective applied work for outputting the power, in addition, the power equipment is dragged in a way of being coaxial with the electric motor, the industrial steam extracting throttling loss is reduced to the minimum degree, and the technical effects of obvious energy saving, consumption reduction, low carbon and environment protection are achieved.

Owner:HUADIAN POWER INTERNATIONAL CORPORATION LTD

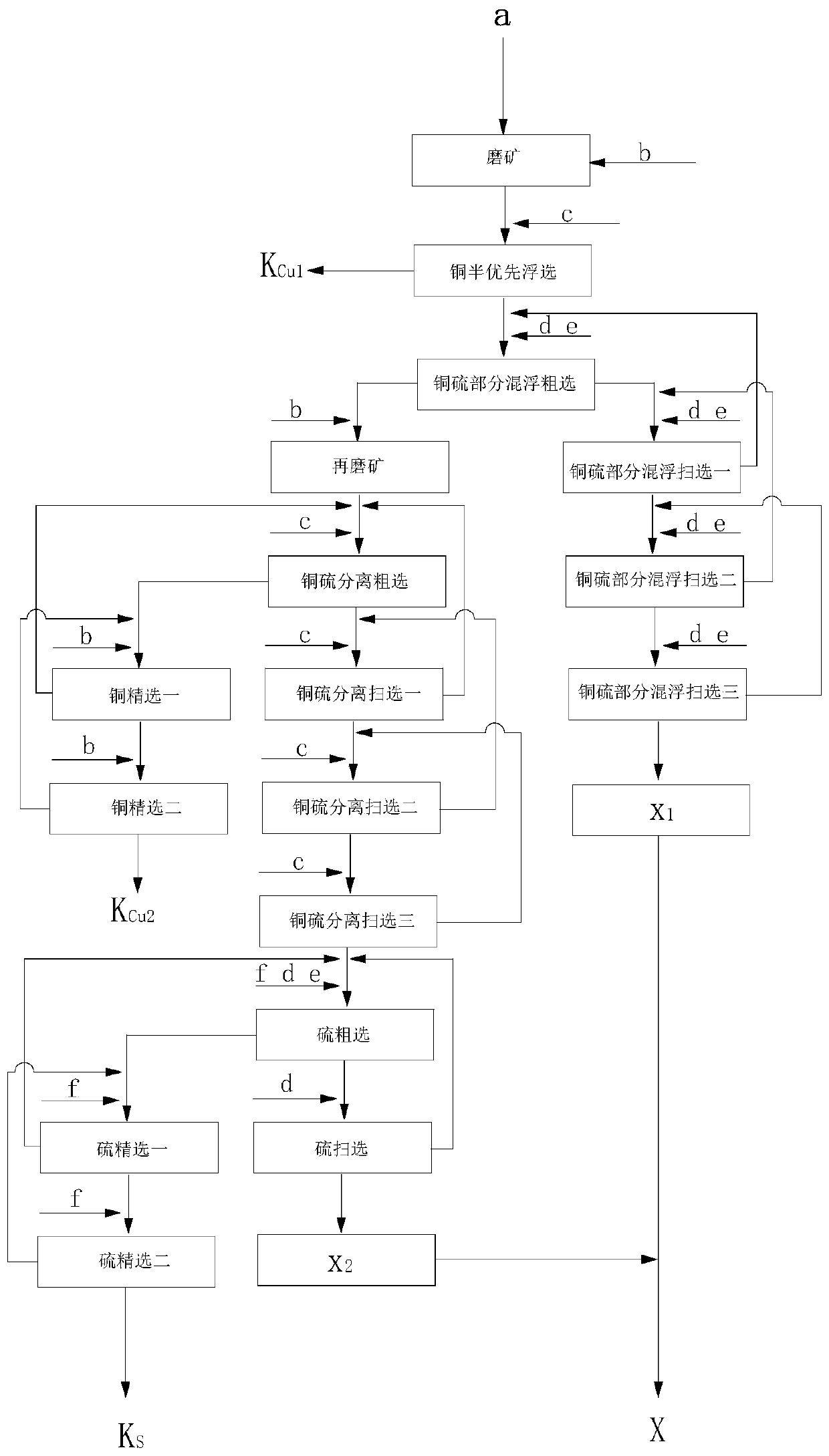

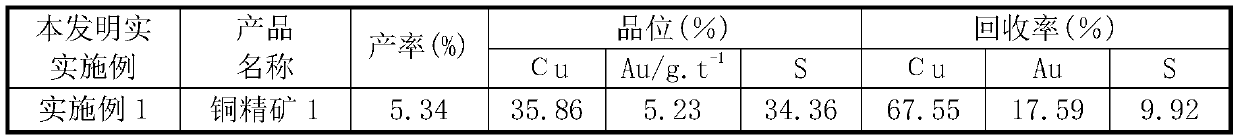

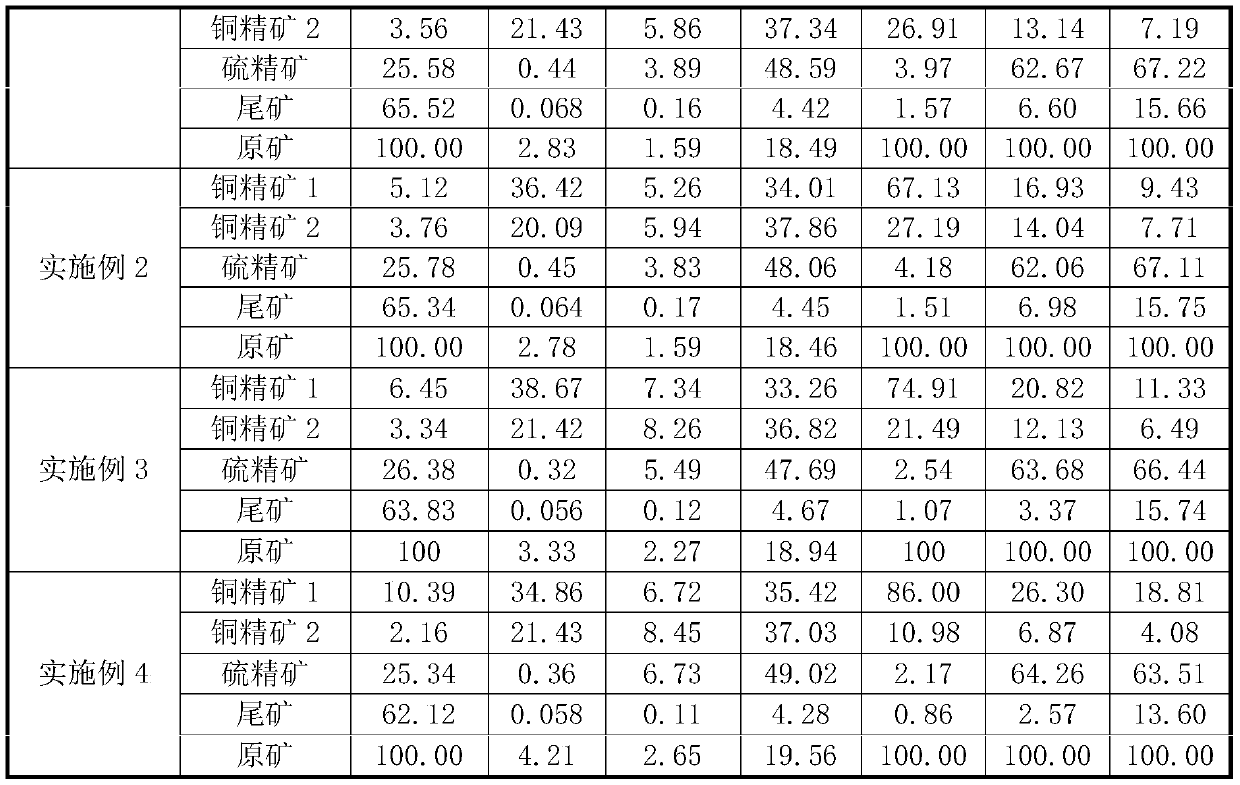

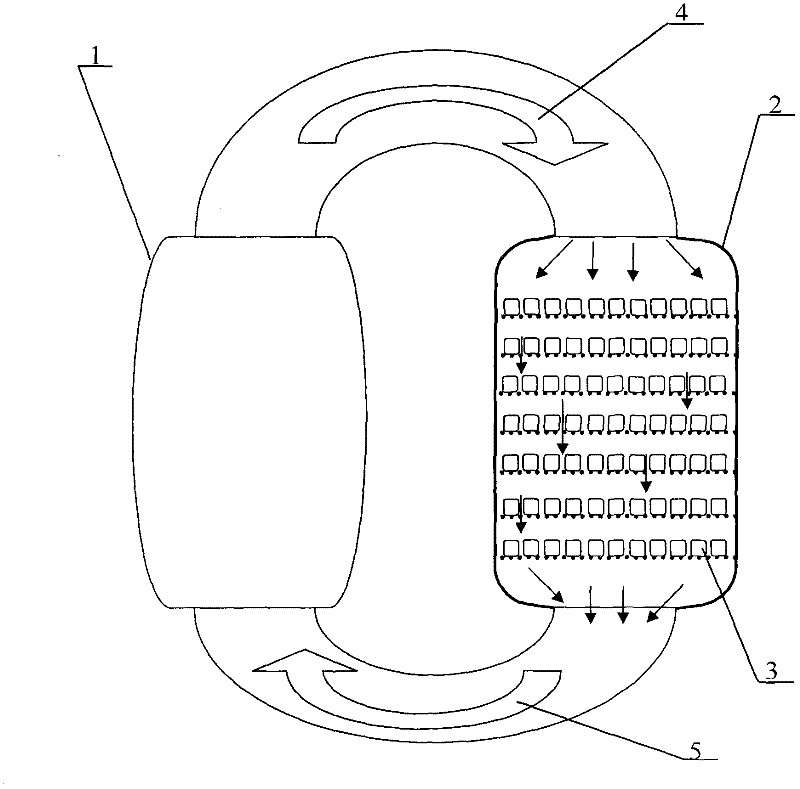

Ore dressing method for metal containing secondary copper sulfide ores

The invention relates to an ore dressing method for metal containing secondary copper sulfide ores. The method is characterized in half preferential copper floatation, branched Cu-S collective-selective floatation roughing, branch Cu-S separation roughing and differential reagent adding. Crude ores (a) are conventionally ground. Copper concentrate products 1 (KCu1) are obtained through half preferential copper floatation. Cu-S collective-selective floatation roughing is carried out in two paths: Cu-S collective-selective floatation scavenging and re-grinding Cu-S separation roughing. On one path, ore re-grinding and Cu-S separation roughing are carried out; and Cu-S separation roughing is carried out in two branches: on one branch, copper concentrate products 2 (KCu2) are obtained by carrying out secondary copper concentrating on copper crude ores and concentrates; and on the other branch, tailing third Cu-S separation scavenging, sulfur roughing and the sub-branches of carrying out secondary sulfur concentrating to obtain sulfur concentrate products (Ks) and carrying out sulfur scavenging to obtain tailings 2(X2) are carried out. On the other path, Cu-S collective-selective floatation scavenging is carried out, and tailings 1 (X1) are obtained through third collective-selective floatation scavenging. The method not only can realize Cu-S separation and ensure the grades and recycling rates of the copper concentrates and the sulfur concentrates, but also can reduce energy consumption, increase separation indexes and realize the early recycling of recyclable usable minerals in the ores. The method has the advantages of low ore grinding cost, simple reagent principles, stable and reliable technical process, great target mineral recycling effect, remarkable energy saving and consumption reduction and the like.

Owner:ZIJIN MINING GROUP

Processing and drying method of fructus momordicae

ActiveCN102578565AImprove the quality of hygieneMildew loss reductionFood preparationPlant ingredientsEngineeringEnergy consumption

The invention discloses a processing and drying method of fructus momordicae. The method comprises the step of removing 12.5%-100% of crusts, and the removal rate of fruit peels is not more than 90%. According to the method disclosed by the invention, the product quality can be improved significantly, and the prominent effects of energy consumption and consumption reduction are realized.

Owner:桂林三横王食品有限公司

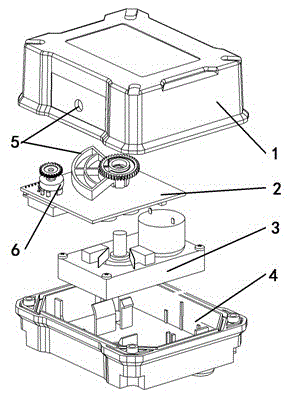

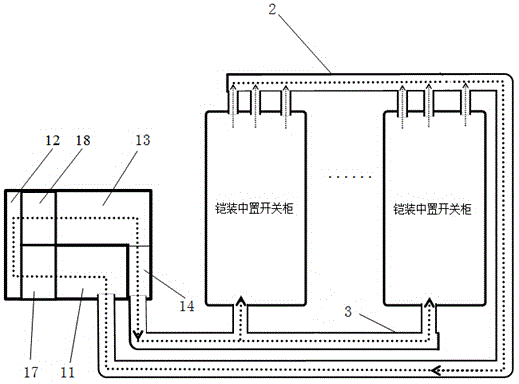

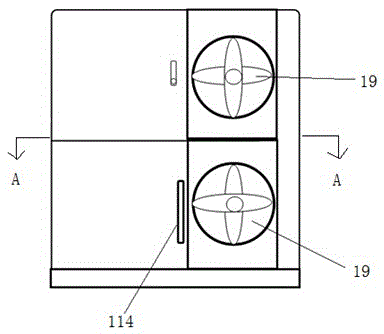

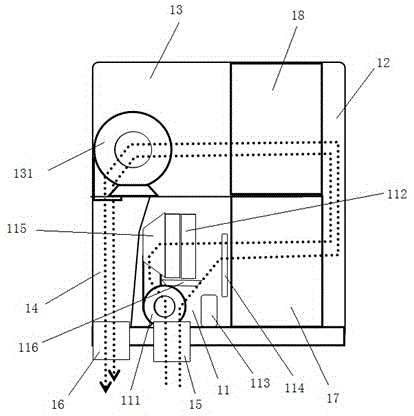

Intelligent adjustment system for metal-enclosed middle-arrangement switchgear of substation and adjustment method of intelligent adjustment system

ActiveCN105652931AImprove operational safety and reliabilityReduce operating and maintenance costsSimultaneous control of multiple variablesPower gridEngineering

The invention relates to an intelligent adjustment system for a metal-enclosed middle-arrangement switchgear of a substation and an adjustment method of the intelligent adjustment system. The intelligent adjustment system comprises a main machine device, an input pipe and an output pipe, the main machine device comprises a box body and a temperature adjustment device and a humidity adjustment device arranged in the box body, the box body is provided with an air input opening and an air output opening, the air input opening is connected with the air output end of the metal-enclosed middle-arrangement switchgear through the input pipe, and the air output opening is connected with the air input end of the metal-enclosed middle-arrangement switchgear through the output pipe. The intelligent adjustment system has the functions of removing moisture, adjusting the temperature and preventing electric equipment from getting dirty, and wet and hot air in the switchgear is sucked through a sealed pipe, so that moisture is removed, the temperature is controlled and dirt in the air in the switchgear is removed, and safety and reliability of operation of the power grid are really improved.

Owner:TONGLING POWER SUPPLY CO OF STATE GRID ANHUI ELECTRIC POWER CO +1

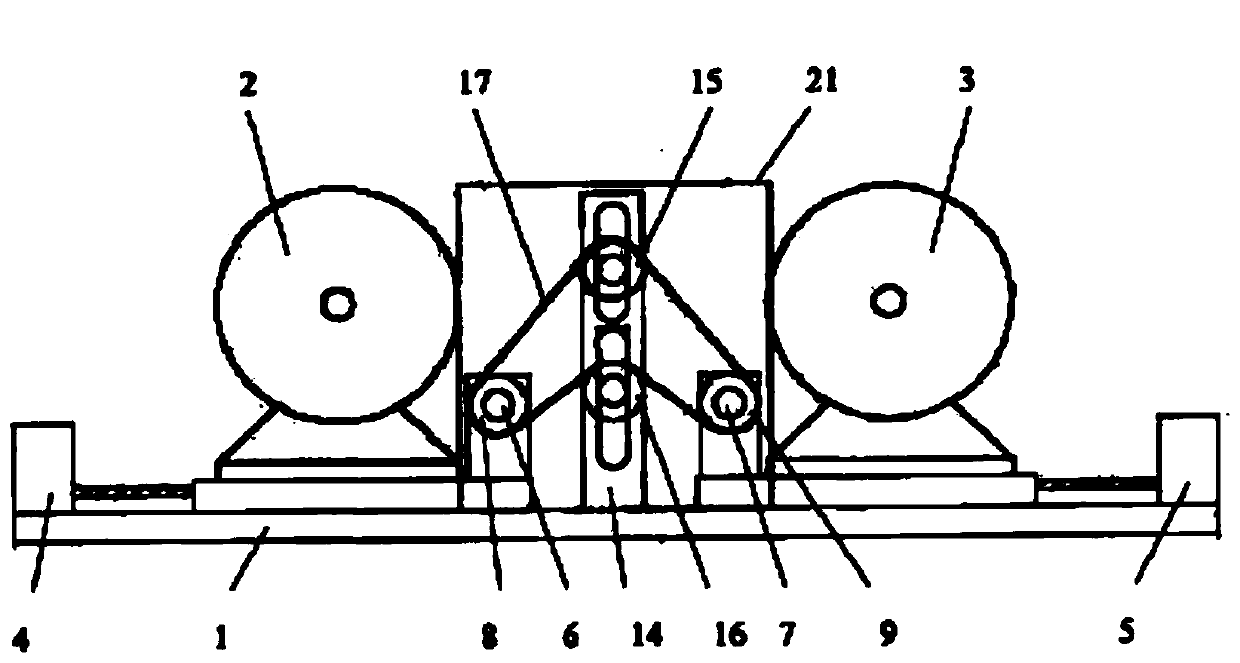

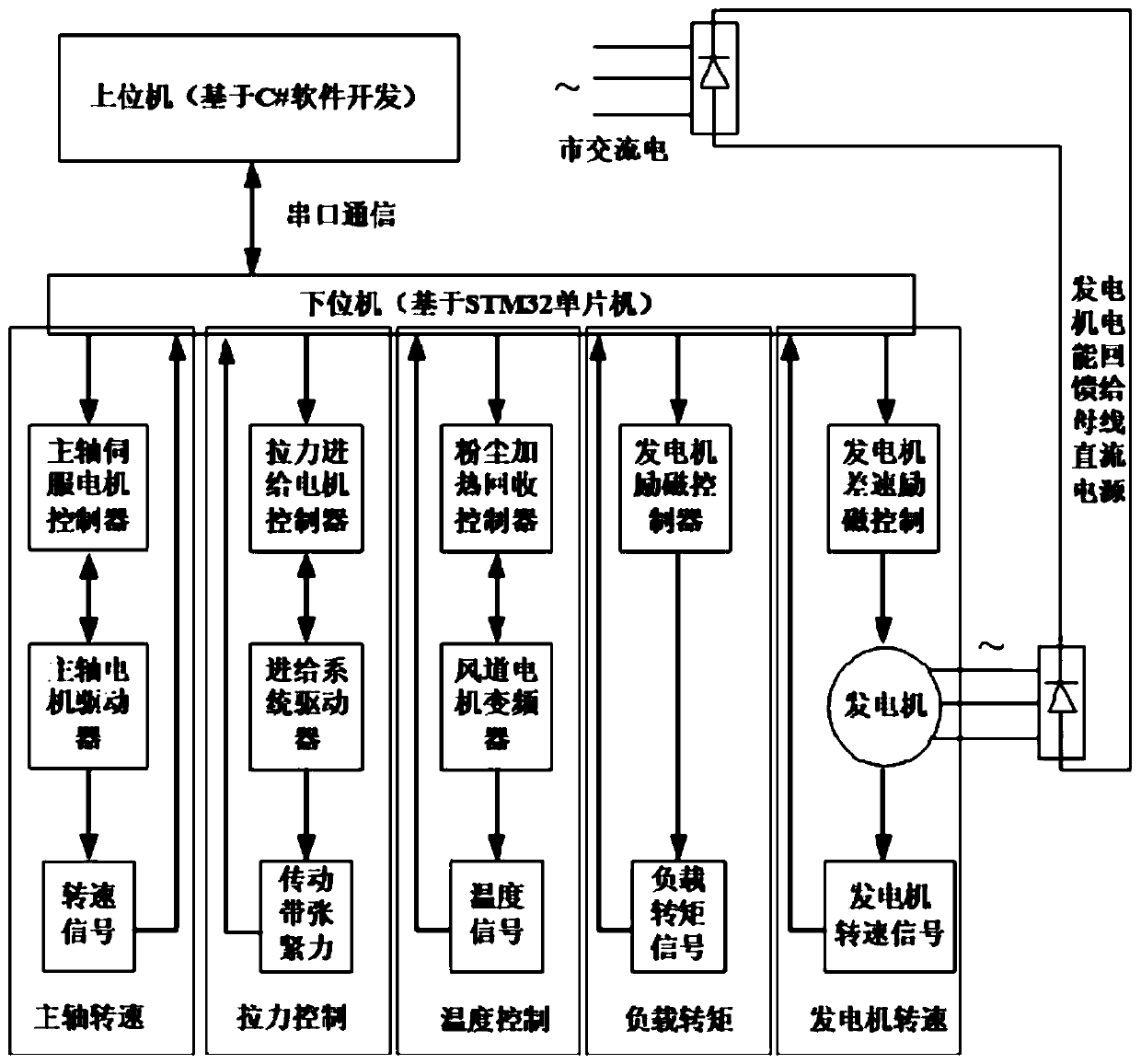

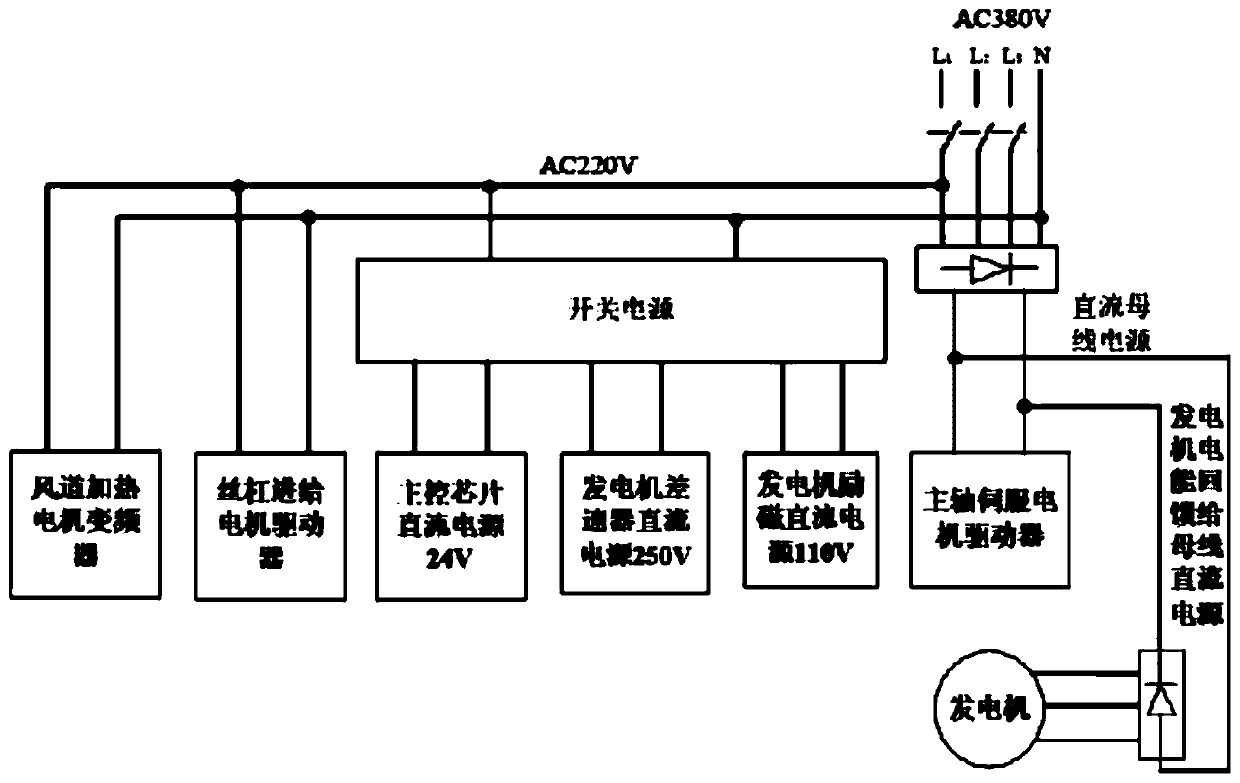

Energy-saving and environment-friendly automatic fatigue life testing machine for rubber transmission belt

ActiveCN111426471AImprove test accuracyReduce energy consumptionMachine part testingAutomatic controlDrive wheel

The invention relates to the technical field of conveyor belt fatigue testing machines. The invention further discloses an energy-saving and environment-friendly automatic fatigue life testing machinefor a rubber transmission belt. A tested rubber transmission belt is arranged at a spindle motor; an electromagnetic differential mechanism is arranged at the end, away from the spindle motor, of thetransmission belt; an output shaft of the electromagnetic differential mechanism is connected with a generator rotor serving as a load; a linear feeding device is arranged between a driving wheel anda driven wheel; and a tension sensor is installed on the feeding device. According to the invention, overall control scheme design is carried out on the testing system; the composition and the principle of a test bed measurement and control system are respectively introduced; in combination with test requirements and functions of the test system, hardware model selection of the test machine measurement and control system and a software part of the measurement and control system are designed to complete automatic control and man-machine interaction operation of the test system; and design of the transmission belt fatigue life test system which is energy-saving, environment-friendly and high in test precision is realized.

Owner:浙江省三门县王中王电机焊接设备有限公司 +1

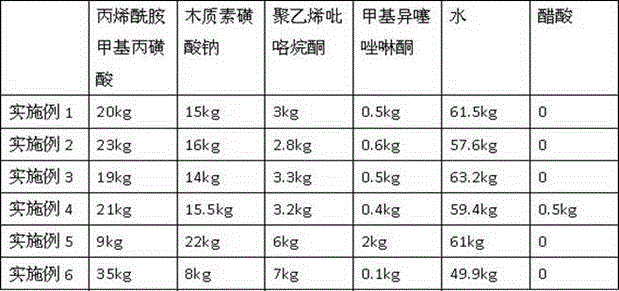

Acrylic color fixing agent and preparation method thereof

InactiveCN105926329AThe effect of removing floating color is obviousFloating effect is obviousDyeing processYarnFiber

The invention provides an acrylic color fixing agent, comprising the following components according to parts by weight: 10-30 parts of acrylamido methylpropanesulfonic acid, 10-20 parts of sodium lignosulfonate, 1-5 parts of polyvinylpyrrolidone, 0.2-1 part of methylisothiazolinone, and 40-70 parts of water. The invention also provides a preparation method of the acrylic color fixing agent, comprising: mixing well the components according to a matching ratio and reacting at high temperature. Fiber treated with the acrylic color fixing agent of the invention has high color fastness; the acrylic color fixing agent has high affinity to a dye not reacted with the fiber; the impact on color of yarn or fabric color-fixed with the acrylic color fixing agent is low; water can be effectively saved for a dyeing plant, and production efficiency can be effectively improved; the acrylic color fixing agent is a special surfactant and is free of bubbles.

Owner:广东博科纺织科技有限公司

Method for preparing semisolid slurry for ultralow temperature casting magnesium alloy

The method for preparing semisolid slurry for magnesium alloy ultralow temp. casting includes the processes and steps of melting magnesium, adding compound fire-resisting elements, adding alloy elements, heat-insulating and standing still and semicontinuous casing. Said invention utilizes the addition of compound fire-resisting elements to implement magnesium alloy smelting free from covering agent, and utilizes the pouring process which is made under the condition of the temperature of liquid phase line or the temperature below liquid phase link at a certain cooling rate after properly standing still to implement that its interior has no dirt inclusion or porosity.

Owner:NORTHEASTERN UNIV

Tandem-type liquid-gas dual-channel data center refrigerating system

ActiveCN110381698ARaise the inlet and outlet water temperatureReduce investmentCooling/ventilation/heating modificationsCooling towerData center

The invention provides a tandem-type liquid-gas double-channel data center refrigeration system, and belongs to the technical field of data center refrigeration. The system comprises a cooling tower,a first heat exchanger and a second heat exchanger, wherein the secondary side of the first heat exchanger and the secondary side of the second heat exchanger are circularly communicated to form a natural heat dissipation system; the primary side of the first heat exchanger, a liquid storage tank, a fluorine pump, an air conditioner terminal, an electromagnetic valve and a compressor are circularly communicated to form an air cooling system; a first one-way valve connected in parallel with the fluorine pump and a second one-way valve connected in parallel with a series pipeline of the electromagnetic valve and the compressor are also arranged in the air cooling system; the primary side of the second heat exchanger is circularly communicated with the liquid cooling server cabinet to form aliquid cooling system; and the air cooling system and the liquid cooling system respectively exchange heat with the natural heat dissipation system through the first heat exchanger and the second heatexchanger. The system provided by the invention is small in occupied space and low in energy consumption.

Owner:厦门华睿晟智能科技有限责任公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Process for producing 2,2-bis[2,4-diaminophenyloxy)phenyl]hexafluoropropane Process for producing 2,2-bis[2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/e309efc1-da50-47d2-9e4c-55c6337bcad6/s2008100349568e00011.PNG)

![Process for producing 2,2-bis[2,4-diaminophenyloxy)phenyl]hexafluoropropane Process for producing 2,2-bis[2,4-diaminophenyloxy)phenyl]hexafluoropropane](https://images-eureka.patsnap.com/patent_img/e309efc1-da50-47d2-9e4c-55c6337bcad6/s2008100349568d00021.PNG)