Manufacturing method of thin strip continuously cast and cold rolled non-oriented electrical steel

A technology of grain-oriented electrical steel and manufacturing method, which is applied in manufacturing tools, heat treatment process control, heat treatment equipment, etc., and can solve problems such as difficulty in producing thin-gauge cold-rolled products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

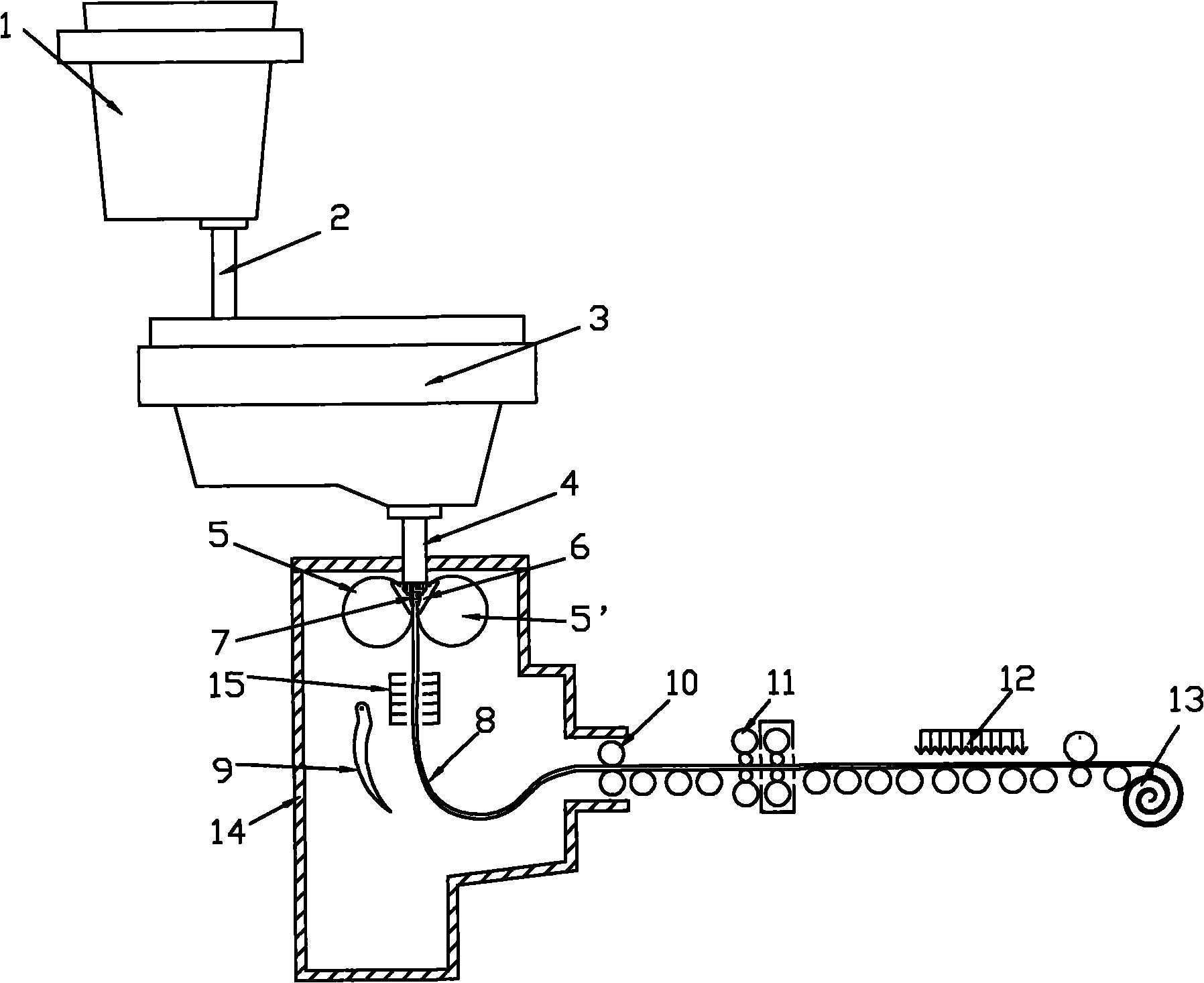

Method used

Image

Examples

Embodiment 1

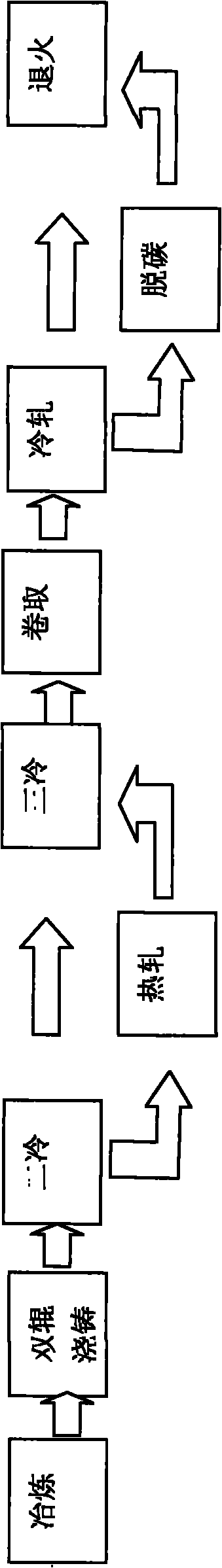

[0067] The molten steel is smelted in an electric furnace or a converter, and after the refining process, the molten steel that meets the A component requirements in Table 1 and the remainder is Fe is cast into a cast strip. Since the carbon content of this composition is less than 0.003%, it does not need to be decarburized. The technological process selection that embodiment A1 produces figure 2No hot rolling, no decarburization process in the flow process; the production process selection of embodiment A2 figure 2 There are hot rolling and non-decarburization processes in the process. The main process parameters and product performance are shown in A1 and A2 in Table 2.

Embodiment 2

[0069] The molten steel is smelted in an electric furnace or a converter. After the refining process, the molten steel that meets the B component requirements in Table 1 and the remainder is Fe is cast into a cast strip. Since the carbon content of this composition is less than 0.003%, it does not need to be decarburized. Process selection for B1 production figure 2 There is no hot rolling and no decarburization process in the process; B2 selection figure 2 There are hot rolling and no decarburization process, the main process parameters and product performance are shown in B1 and B2 in Table 2.

Embodiment 3

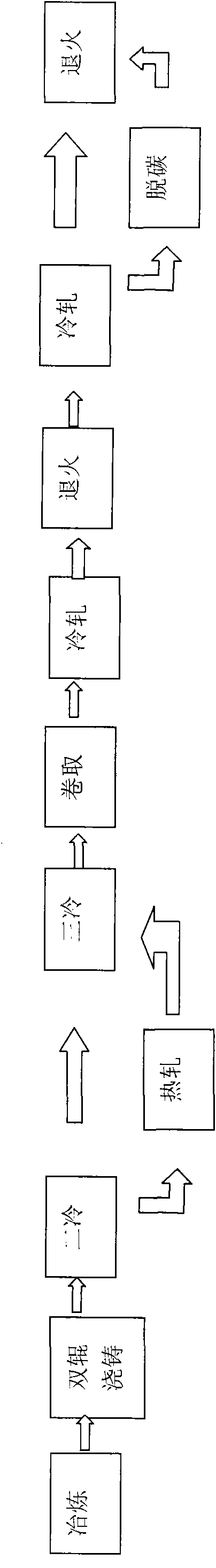

[0071] The molten steel is smelted in an electric furnace or a converter. After the refining process, the molten steel that meets the C component requirements in Table 1 and the balance is Fe is cast into a cast strip. Since the carbon content of this composition is less than 0.003%, it does not need to be decarburized. Process selection for C1 production figure 2 There is no hot rolling and no decarburization process in the process; C2 selection image 3 There are hot rolling and no decarburization process, the main process parameters and product performance are shown in C1 and C2 in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com