Constant temperature heating system of hothouse

A heating system and greenhouse technology, applied in the field of constant temperature heating in agricultural greenhouses, can solve the problems of insufficient utilization of heat energy, large temperature differences in heating pipe networks, and high cost of high-pressure pumps, achieve stable and uniform hydraulic loads, increase working life, reduce The effect of dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

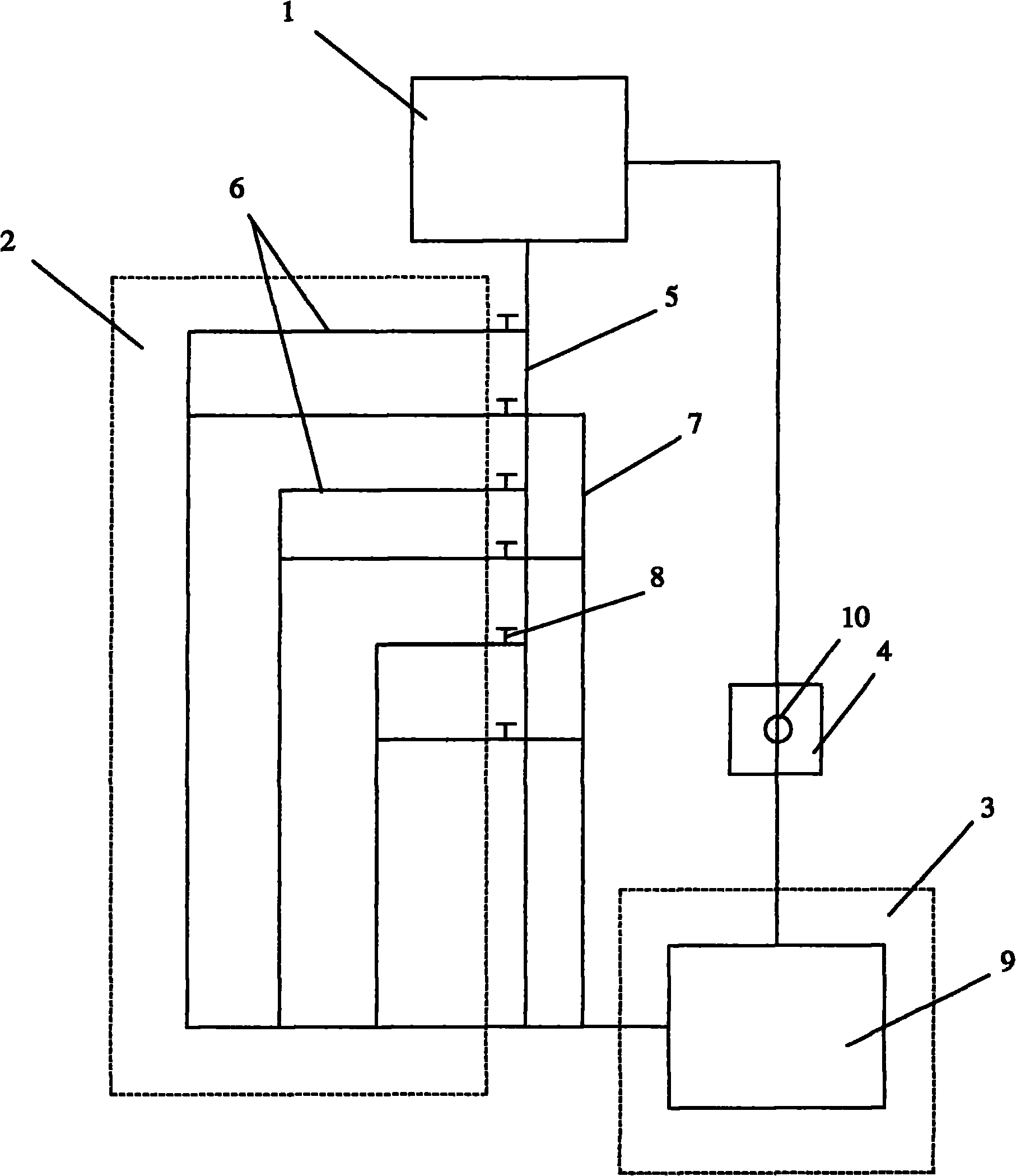

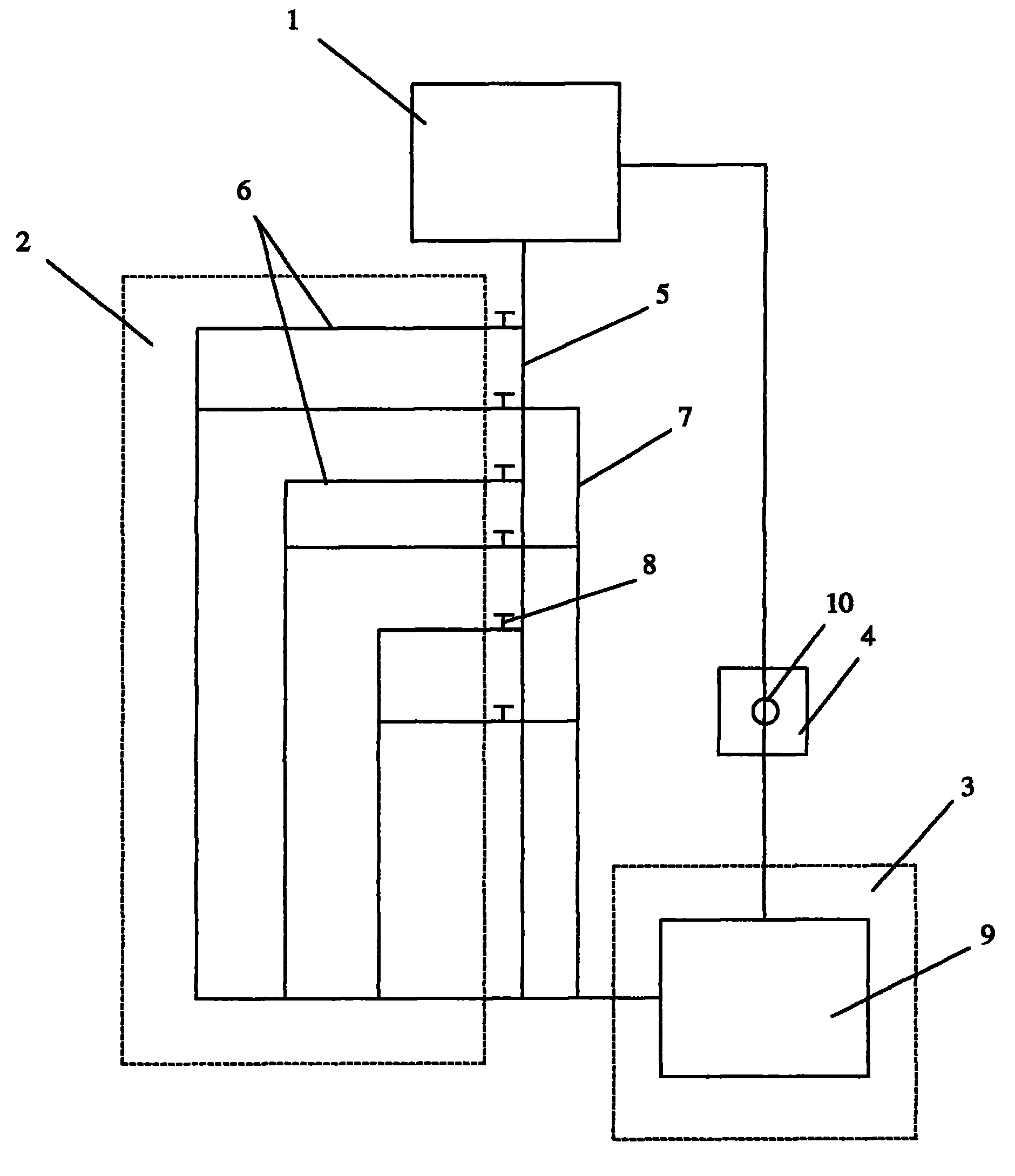

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

[0025] Such as figure 1 As shown, various heat sources are used to send the prepared or collected hot water to the water tower 1. The side wall of the water tower 1 is equipped with an insulation layer to prevent the heat dissipation and cooling of the hot water in the tower. The water tower 1 is much higher than the ground heating pipeline. The liquid height difference in the tower provides sufficient water delivery pressure.

[0026] The heat source of the greenhouse constant temperature heating system of the present invention may be various coal-fired or oil-fired boilers, or a solar water heating system, or utilize deep wells to exploit underground hot water. When the underground hot water is used as the heat source, since the underground hot water is rich in sulfur, if steel pipes are used, the corrosion will be severe, and the service life will be very short, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com