Back pressure machine work application device for supplying discharged steam of steam turbine high-pressure cylinder for industrial steam extracting system

An industrial steam extraction and back pressure machine technology, which is applied in the direction of steam engine devices, machines/engines, mechanical equipment, etc., can solve the problems of reduced suction capacity, poor operation stability of auxiliary machines, and reduced suction coefficient of pressure matching devices, etc., to achieve The effect of reducing throttling loss, reducing throttling loss, and reducing power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

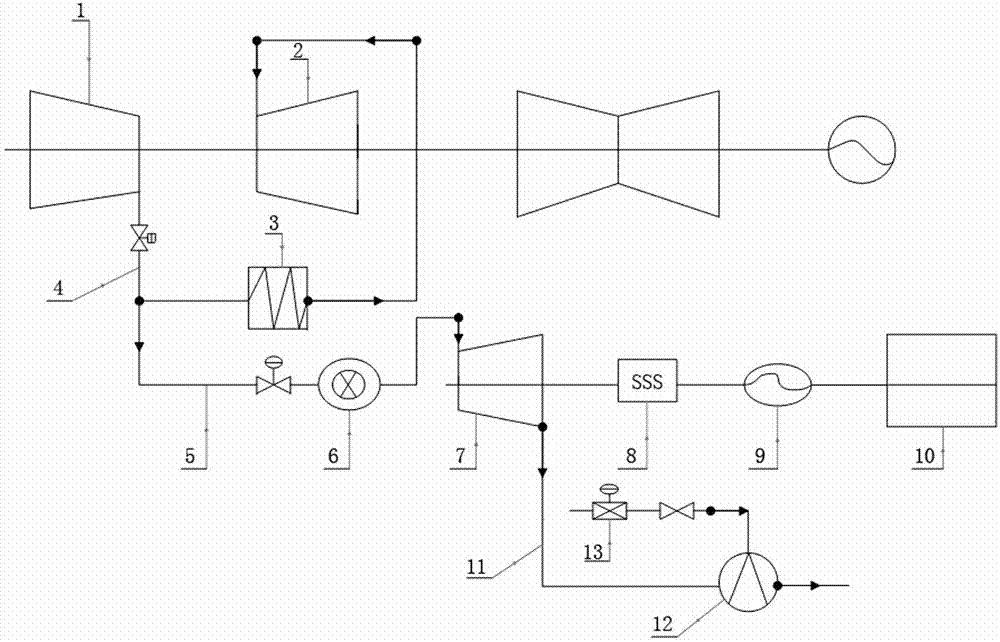

[0058] Such as figure 1 As shown, the back pressure machine working device used for steam turbine high-pressure cylinder exhaust for industrial steam extraction system includes industrial steam extraction pipeline 5, motor 9 and power equipment 10, and said industrial steam extraction pipeline 5 is provided with a back pressure machine to enter Steam electric isolation valve, back pressure machine main steam valve and speed regulating valve 6 and steam supply desuperheater, between the back pressure machine main steam valve and speed regulating valve 6 and the steam supply desuperheater The back pressure machine 7 and its control equipment, the back pressure machine 7 and the electric motor 9 are coaxially arranged on one side of the power equipment 10 and connected to the power equipment 10 through the SSS clutch 8, including the steam turbine high-pressure cylinder 1 , the steam turbine high-pressure cylinder 1 is provided with a high-pressure cylinder exhaust pipeline 4, an...

Embodiment 2

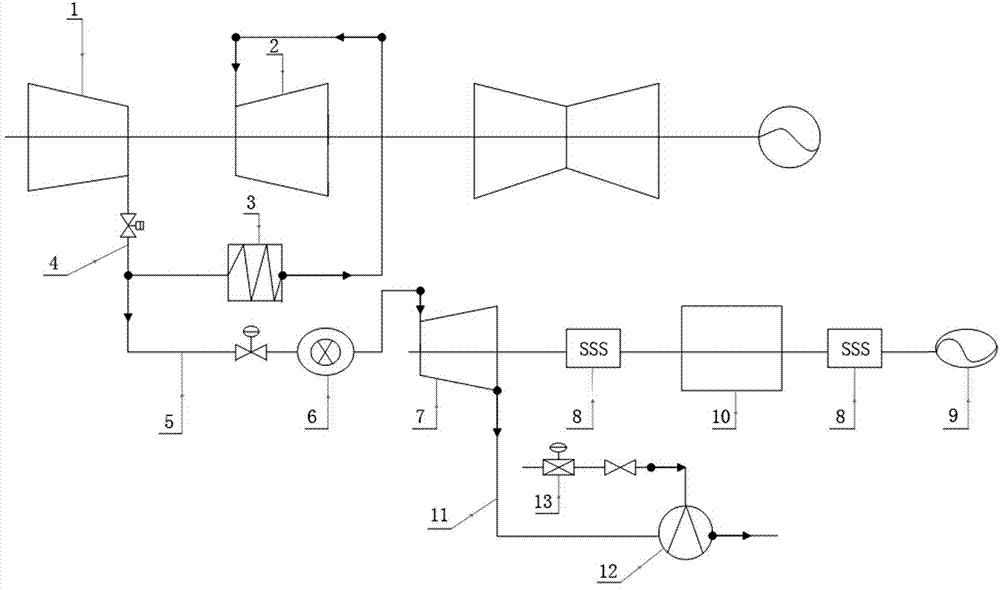

[0063] Such as figure 2 As shown, the working device of the back pressure machine used for steam turbine high-pressure cylinder exhaust for industrial steam extraction system is similar to Embodiment 1, the difference is that the back pressure machine 7 and the motor 9 are coaxially arranged on the Two sides of the power equipment 10 are respectively connected with the power equipment 10 through SSS clutches 8 .

[0064] figure 2 Shown is the technical scheme in which the back pressure machine 7 and the motor 9 are respectively arranged on both sides of the power equipment 10. The back pressure machine 7 and the motor 9 are connected to the power equipment 10 through the SSS clutch 8 respectively. When the rated output of the motor 9 is reached, the back pressure machine 7 and the motor 9 work at the same time; when the output of the back pressure machine 7 reaches the rated output of the motor 9, the SSS clutch connected between the motor 9 and the power equipment will be ...

Embodiment 3

[0066] The working device of the back pressure machine used in the steam turbine high-pressure cylinder exhaust steam supply system is similar to that of Embodiment 1 or 2, except that the high-pressure cylinder exhaust check valve adopts a lifting check valve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com