Polyester fabric treating agent

A polyester fabric and treatment agent technology, which is applied in fiber treatment, textiles and papermaking, fiber types, etc., can solve the problems of lack of stable performance, achieve significant energy saving and consumption reduction, prevent bonding, and ensure dyeing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

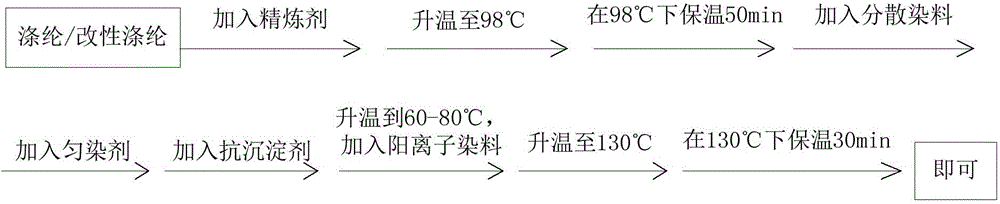

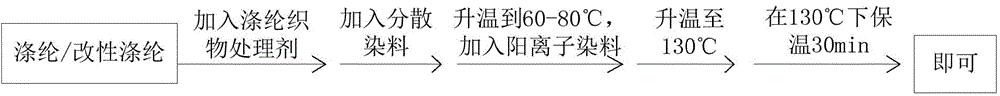

Method used

Image

Examples

Embodiment 1

[0029] In the present embodiment, the preparation method of the polyester fabric treatment agent is as follows: in parts by weight, first 40 parts of N-dodecyl dimethyl betaine, 15 parts of isomeric tridecyl alcohol polyoxyethylene ether (N EO =9), 1 part of citric acid, a mixture of 10 parts of water and 10 parts of ethanol and 24 parts of benzyl benzoate were mixed, then the temperature was raised to 70° C. and stirred at a speed of 80 r / min for 60 minutes, and then cooled to 45° C. Discharge.

Embodiment 2

[0031] The preparation method of the polyester fabric treatment agent in the present embodiment is as follows: in parts by weight, first 50 parts of 2-undecyl-N-acetoxy-N (2-hydroxyethyl) imidazoline, 20 parts of fatty alcohol polymer Oxyethylene ether (C=12~14, N EO =9), 0.5 parts of sodium citrate, a mixture of 5 parts of water and 4.5 parts of isopropanol and 20 parts of diethylene glycol dibenzoate were mixed, then, the temperature was raised to 65° C. and stirred for 60 minutes at a speed of 80 r / min , then cool down to 50°C, and discharge.

Embodiment 3

[0033] In the present embodiment, the preparation method of the polyester fabric treatment agent is as follows: in parts by weight, first 45 parts of cocamidopropyl dimethylamine ethylene glycol, 13 parts of fatty alcohol polyoxyethylene ether (C=16~18, N EO =25), 2 parts of gluconic acid, 10 parts of water and 5 parts of ethylene glycol monobutyl ether mixture and 25 parts of glycerol triacetate were mixed, then, the temperature was raised to 60°C and stirred at a speed of 80r / min for 60 minutes, and then Cool down to 40°C and discharge.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com