Acrylic color fixing agent and preparation method thereof

A color-fixing agent and acrylic fiber technology, applied in the field of textile printing and dyeing auxiliaries, can solve the problems of perspiration fastness and water fastness reduction, difficult to improve, etc., achieve the effects of short time, increase production efficiency, and obvious effect of removing floating color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

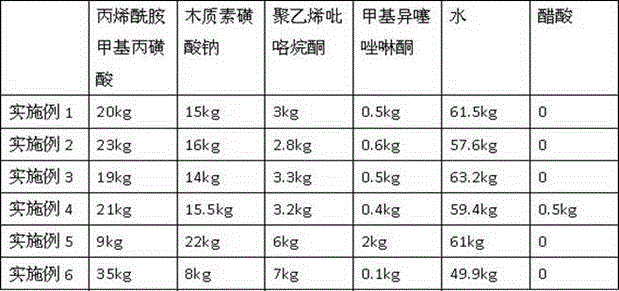

Examples

Embodiment Construction

[0019] The following examples facilitate a better understanding of the present invention, but do not limit the present invention. The experimental methods in the following examples are regarded as conventional methods unless there are special circumstances.

[0020]

[0021] After testing, the above embodiments 1-4 all belong to the preparation method of the present invention, and are acrylic fiber fixatives with a dark brown liquid appearance and a pH value of 8-9 (10% aqueous solution). According to the liquor ratio of 10:1, fix the acrylic fiber at a general temperature of 60 °C for 30 minutes. It is found that it has a strong affinity for dyes that have not reacted with the fiber, and can completely strip the free dye and stably disperse it in the fixed color. In the bath, it is discharged with the waste liquid, and at the same time, this product can form a film on the surface of acrylic fiber. Therefore, the color treated by this product has excellent fastness; the yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com