A clarified and concentrated fruit juice preparation method

A technology of concentrated fruit juice and concentrated tank, which is applied in the field of food processing, can solve the problems that the technological process cannot get rid of the operation, cannot reflect the advantages of freezing and concentrating low-temperature dehydration, and accelerates the formation of crystal nuclei to form ice crystals. The effect of less equipment occupation and less equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

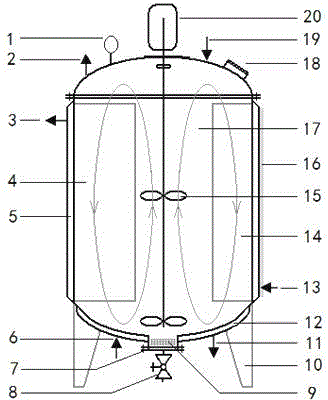

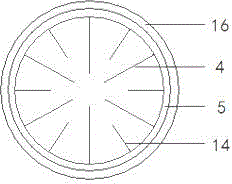

[0043] a. Freeze concentration tank 17 has an inner diameter of 100cm, a tank height of 200cm, and a tank capacity of 1500L. There are multiple heat-conducting plates 4 and 14 welded at intervals of 6cm on the side wall of the tank, wide heat-conducting plates (40cm*200cm) and narrow heat-conducting plates (25cm *200cm) welded alternately, 26 wide and narrow heat conduction plates each, the ratio of the surface area of the heat conduction plate to the side wall area of the tank is 10.76:1; there is a polyurethane insulation layer 16 on the outside, a tank foot 10 on the bottom, and a tank foot 10 on the upper part Observation hole 18;

[0044] B. evacuate the freeze concentration tank by the degassing air inlet 2, so that negative pressure is formed in the tank, and the apricot pulp with 1500kg soluble solids content is 13°Brix sucked into the freeze concentration tank from the feed hole 19, and the apricot pulp is carried out simultaneously outgassing. Dissolve 200g of p...

Embodiment 2

[0054] a. Freeze concentration tank 17 has an inner diameter of 80cm, a tank height of 100cm, and a tank capacity of 500L. A heat conduction plate 4, 14 is welded at an interval of 5.25cm on the side wall of the tank body, a wide heat conduction plate (30cm*100cm) and a narrow heat conduction plate (20cm*100cm ) alternately welded, 24 wide and narrow heat conduction plates each, the ratio of the surface area of the heat conduction plate to the inner wall area of the tank is 9.55:1.

[0055] b. evacuate the freeze concentration tank through the degassing air inlet 2, so that negative pressure is produced in the tank, suck 500kg from the feed hole 19, and the soluble solid content is 23°Brix grape pulp (containing pulp and skin) after crushing seeds), and remove the gas dissolved in the grape juice to avoid oxidative browning in subsequent processing.

[0056] c. Introduce refrigerant with a temperature of -10±1°C into the refrigerant jacket 5, turn on the propeller to stir ...

Embodiment 3

[0065] a. Freeze concentration tank (17) has an inner diameter of 120cm, a tank height of 90cm, and a tank capacity of 1000L. A heat conduction plate (4, 14) is welded at an interval of 6.25cm on the side wall of the tank body, a wide heat conduction plate (50cm*90cm) and a narrow heat conduction plate (30cm*90cm) welded alternately, 30 wide and narrow heat conduction plates each, the ratio of the surface area of the heat conduction plate to the inner wall area of the tank is 12.8:1.

[0066] b. vacuumize the freeze concentration tank through the degassing air inlet (2), so that negative pressure is generated in the tank, and 950 kg of soluble solid content is sucked from the feed hole (19) and the soluble solid content is 13.2 ° Brix broken beating melon pulp.

[0067] c. Introduce refrigerant with a temperature of -9±1°C into the refrigerant jacket (5), turn on the propeller stirring (15), lower the temperature of the melon pulp to -6°C, and promote the formation and grow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com