Novel energy-saving process for extracting and purifying panax notoginseng saponins

A new technology of Panax notoginseng saponins and new technology, which is applied in the field of extraction and purification of Panax notoginseng total saponins and energy-saving new technology, which can solve the problems of large steam consumption and loss, and achieve the effects of reducing consumption, significant effect, energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

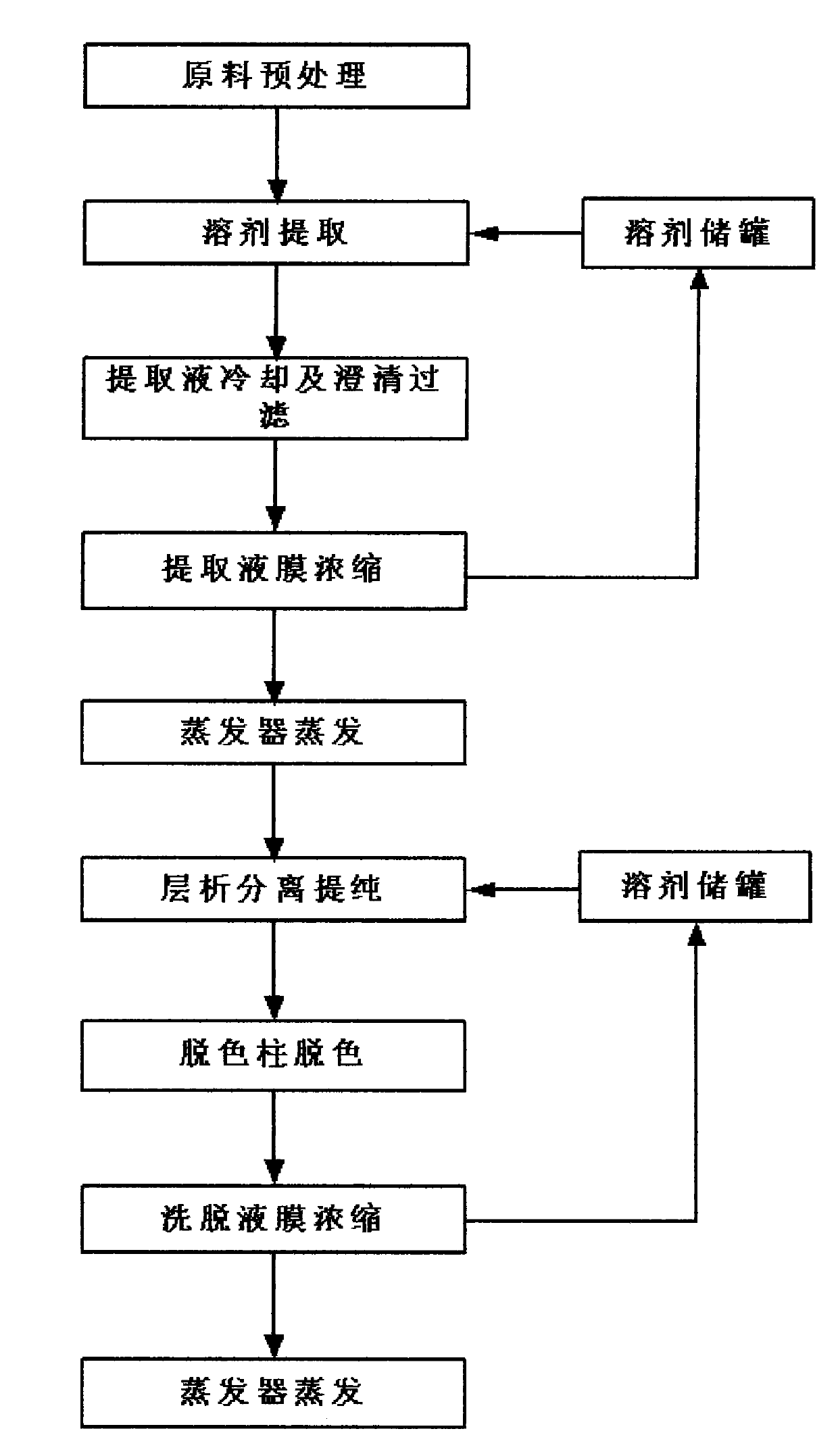

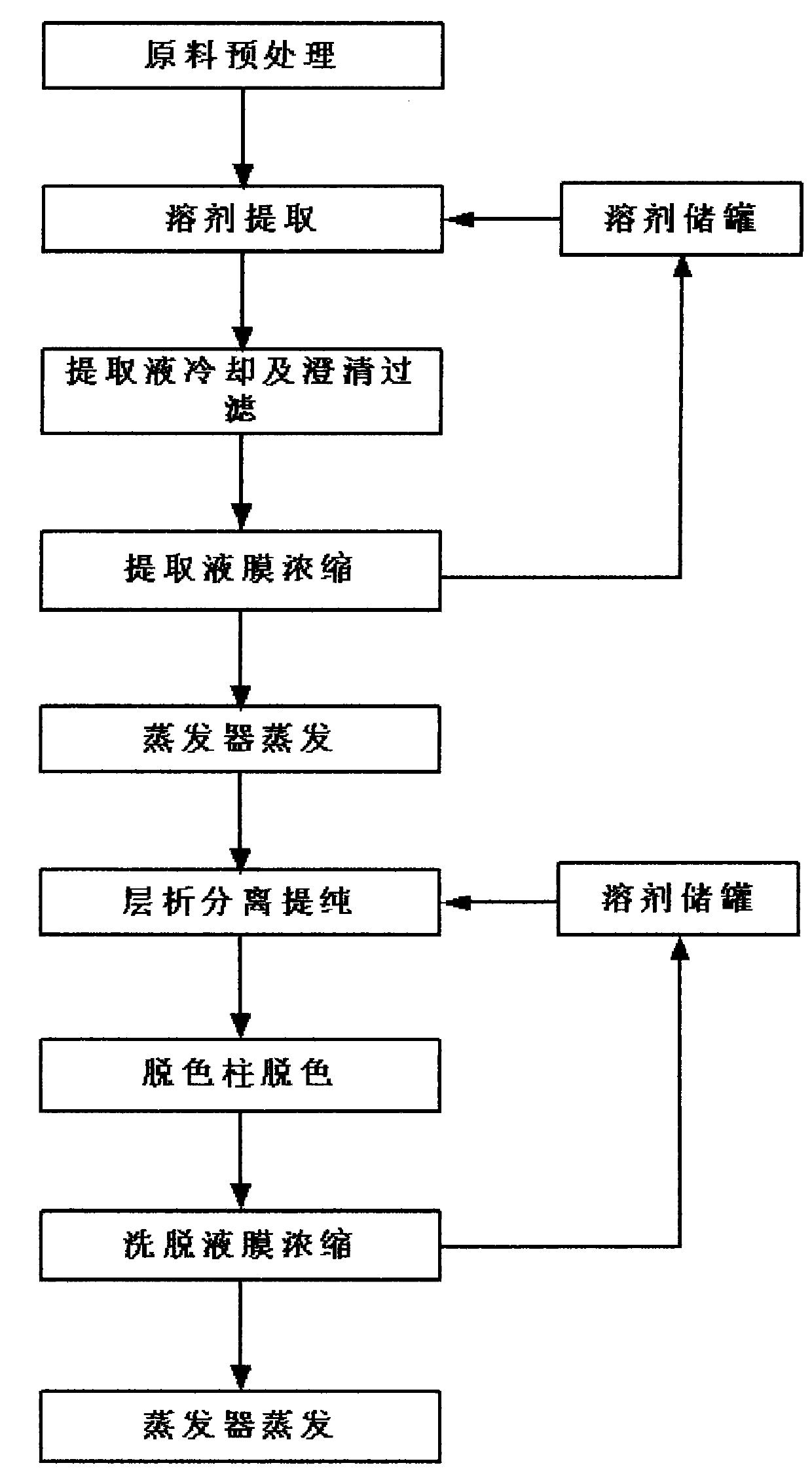

[0011] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited in any way, and any transformation made based on the teaching of the present invention falls within the protection scope of the present invention.

[0012] As shown in the accompanying drawings, the present invention includes raw material crushing, solvent extraction, cooling and clarification of the extract, film concentration of the eluent, chromatographic separation and purification, decolorization of the decolorization column, concentration of the film of the eluent, and evaporation by the evaporator, specifically including the following steps:

[0013] A. Wash, dry and pulverize the notoginseng raw material, put it into the extraction tank, add 5-10 times the amount of 70% ethanol solution, heat to about 75°C and reflux for extraction for about 3 hours;

[0014] B. Lead the cooled and clarified extract into a membrane concentr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com