Energy-saving and environment-friendly automatic fatigue life testing machine for rubber transmission belt

An energy-saving, environmental-friendly, and fatigue-life technology, which is applied in the testing of mechanical components, testing of machine/structural components, and measuring devices, can solve problems such as low test efficiency, deviation, and poor stability of test loads, and reduce energy consumption, test The effect of high precision and high system integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

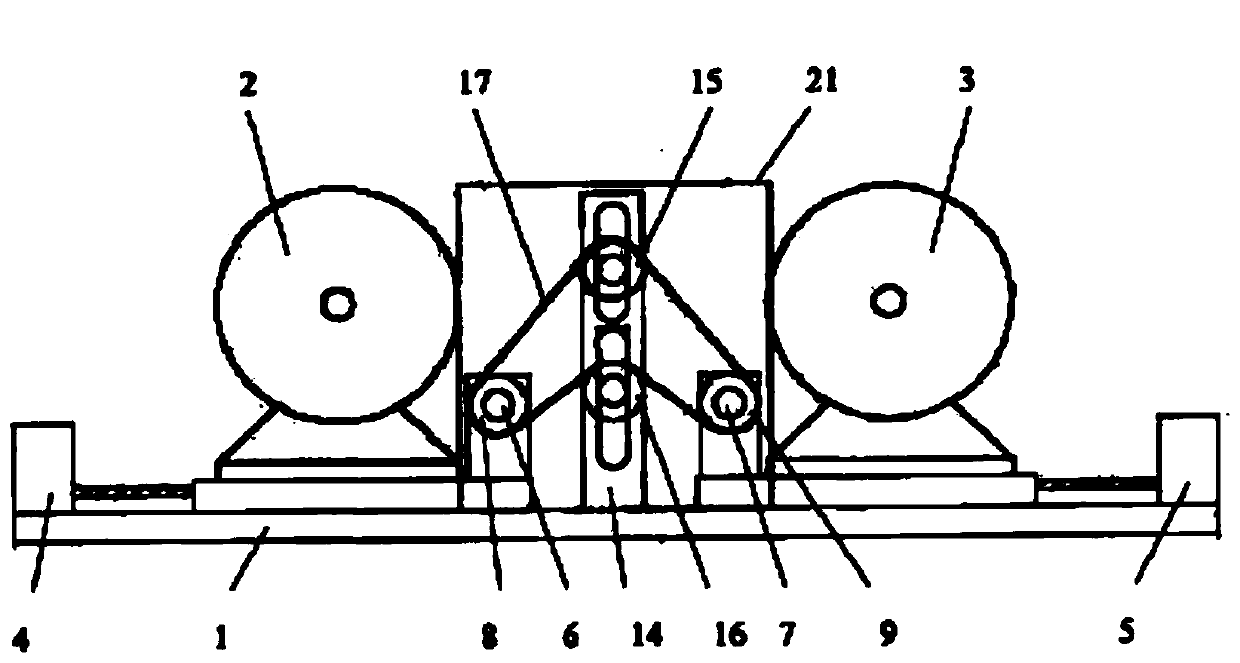

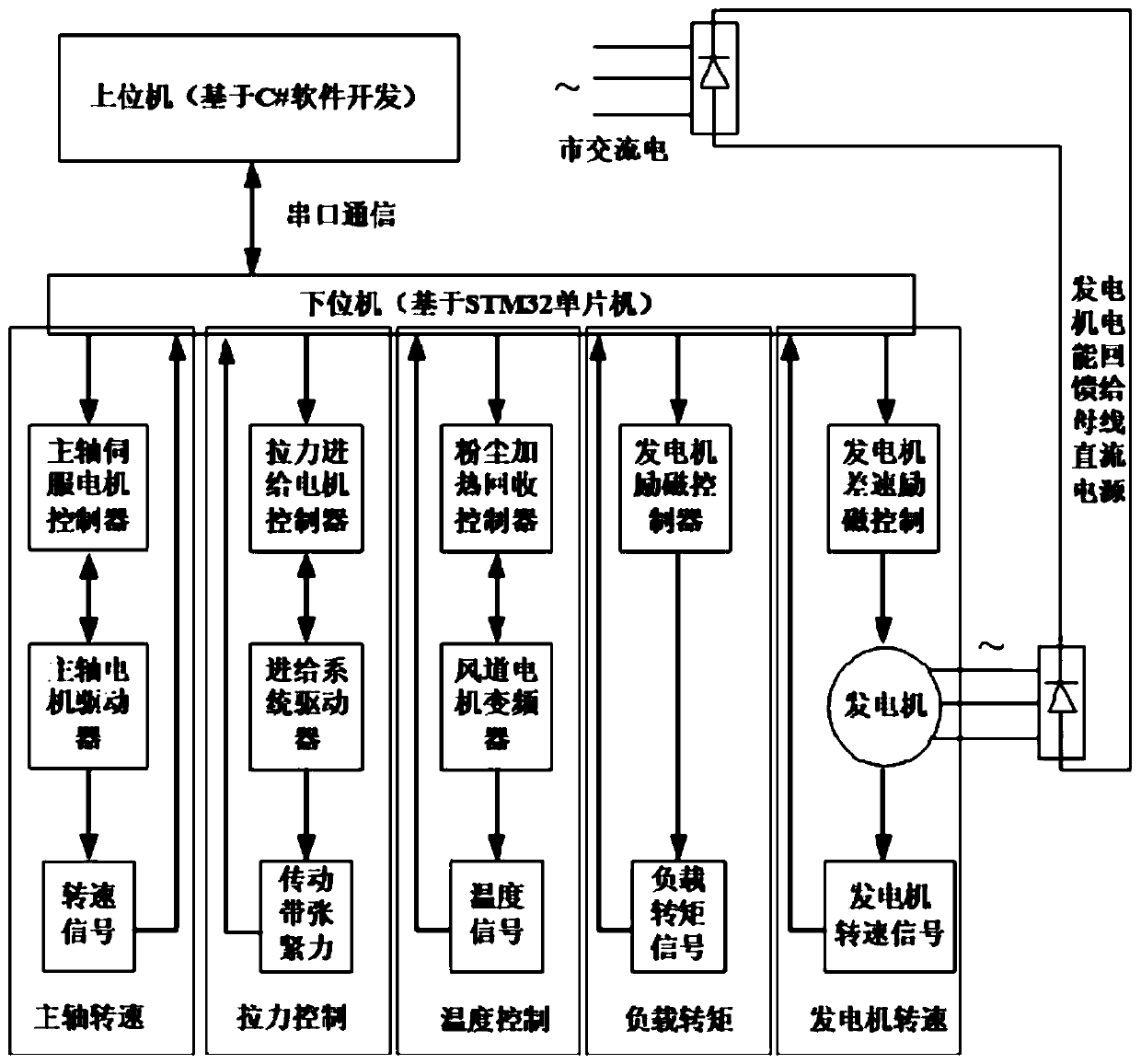

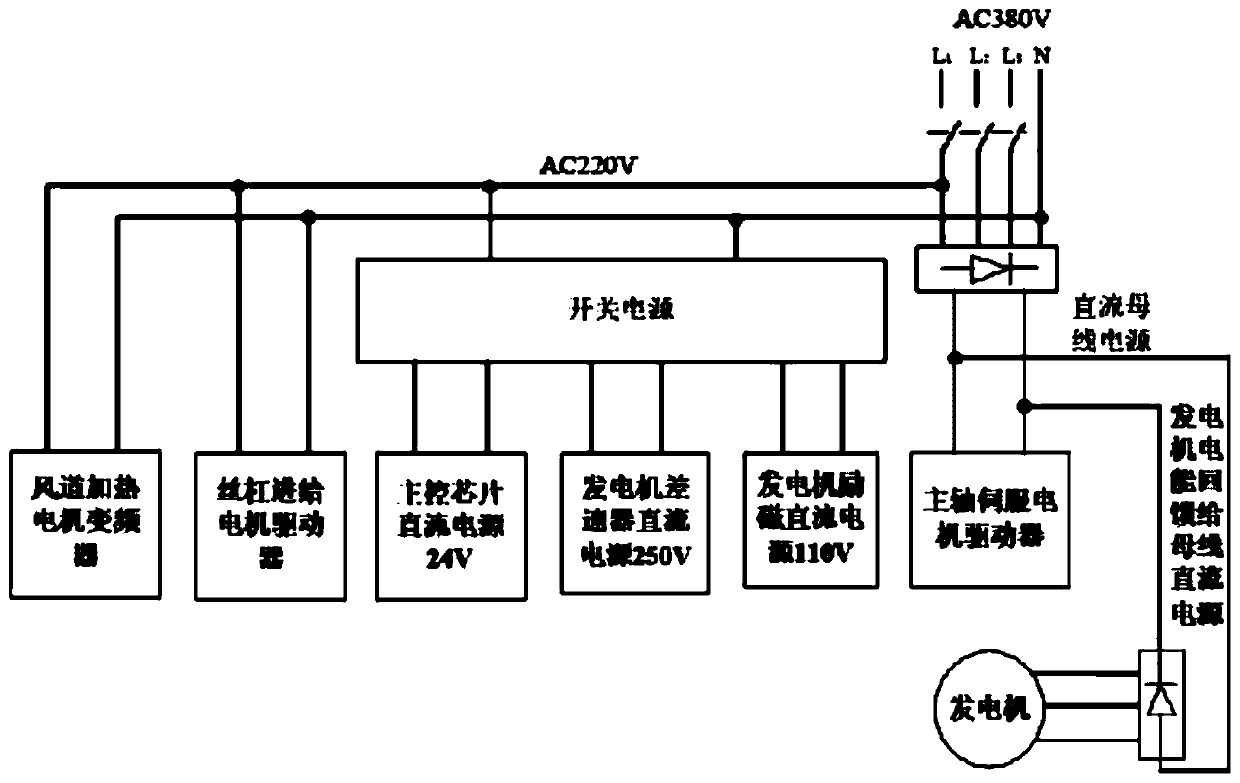

[0029] Such as Figure 1-11As shown, the present invention provides a technical solution: an energy-saving and environment-friendly automatic fatigue life testing machine for rubber transmission belts, comprising a base 1 on which a motor 2, a generator 3, a driving pulley tensioner 4 and a driven pulley tensioner are arranged. Tensioner 5, driven pulley tensioner 5 and drive pulley tensioner 4 use hydraulic devices to tension the drive belt between the motor pulley 10 and the power input pulley 11 and between the generator drive pulley 12 and the generator pulley 13 Tightness adjustment, the driving shaft 6 is provided on the driving wheel tensioner 4, the speed sensor 18 is provided on the driving shaft 6, the torque sensor 19 is provided on the driven shaft 7, and the tensioning wheel 15 is provided on the test belt tensioner. Force sensor 20, driven wheel tensioner 5 is provided with driven shaft 7, is provided with driving wheel 8 on driving shaft 6, is provided with driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com