Ore dressing method for metal containing secondary copper sulfide ores

A technology for copper sulfide ore and beneficiation method, applied in chemical instruments and methods, flotation, wet separation, etc., can solve the problems of undetected gold-bearing secondary copper sulfide ore beneficiation method, etc., to improve separation efficiency and hydrophobic selection. The effect of sexual ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

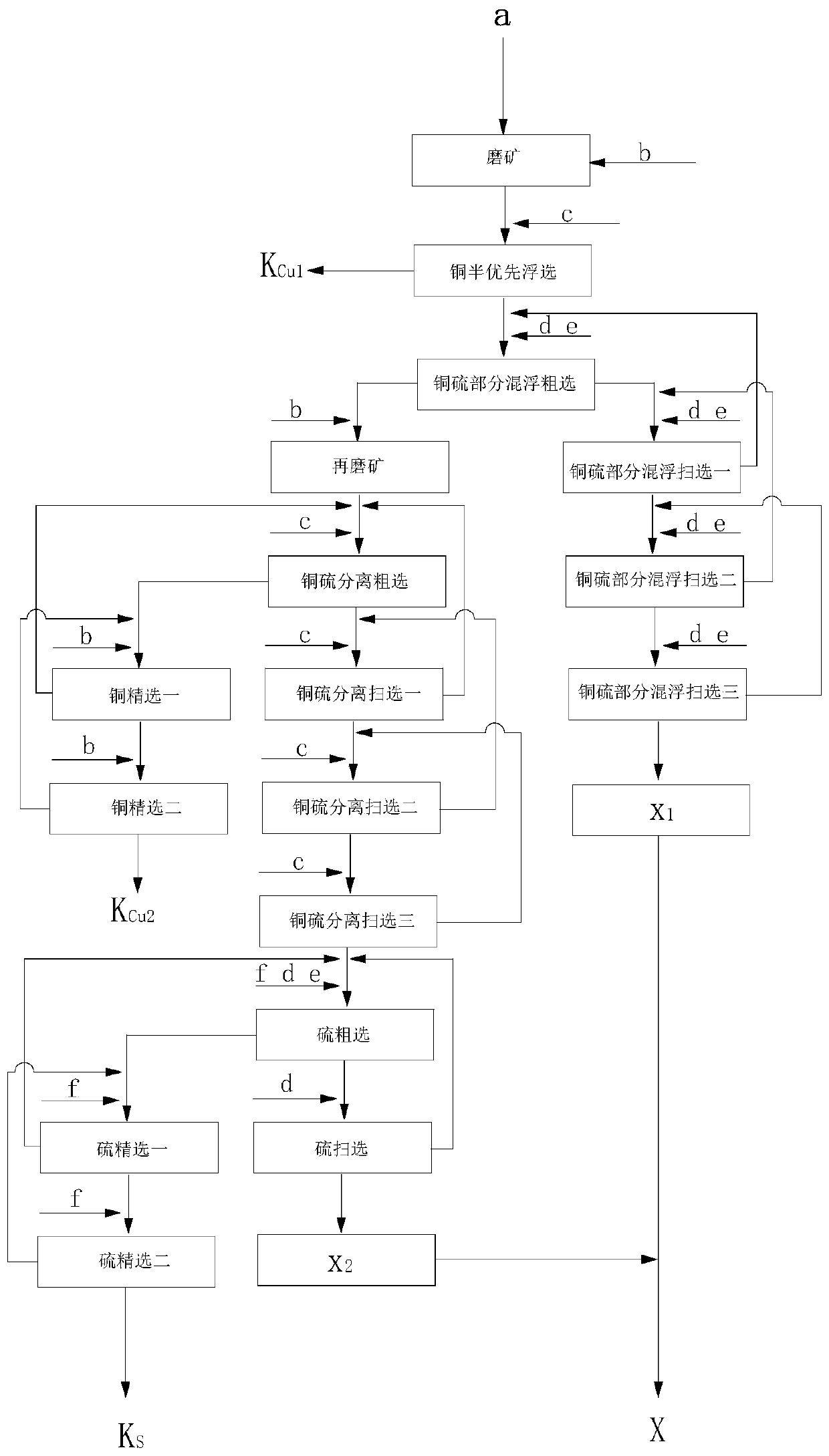

Image

Examples

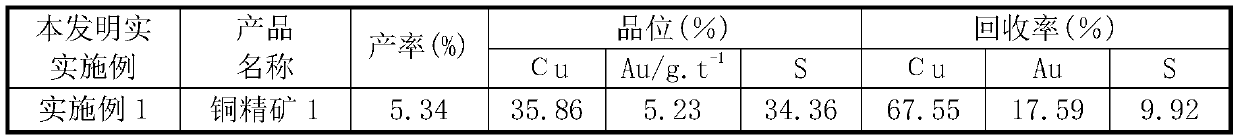

Embodiment 1

[0043] The raw ore contains Cu 2.83%, Au1.59g / t, S18.49%. The raw ore crushed to less than 2mm is mixed with water at a ratio of 2:1 and fed into the mill for grinding, and calcium oxide 2500g / t is added , grind the ore until the product fineness is -0.075mm, accounting for 50%, and the pH value of the slurry is 10.50; put the ground mineral into the hanging tank flotation machine, add the collector Z-200, the dosage is 30g / t, and stir for 2 minutes Carry out copper semi-priority flotation, concentrate (foam product) is copper concentrate 1(k Cu1 ), the tailings enter the copper-sulfur partial mixed flotation roughing operation; the collector butyl xanthate and the foaming agent terpineol oil are added to the copper semi-priority flotation tailings, and the dosages are 100g / t and 20g / t respectively. After stirring for 2 minutes and 1 minute, copper-sulfur partial flotation roughing is carried out. The concentrate (foam product) is copper-sulfur mixed concentrate, which enters ...

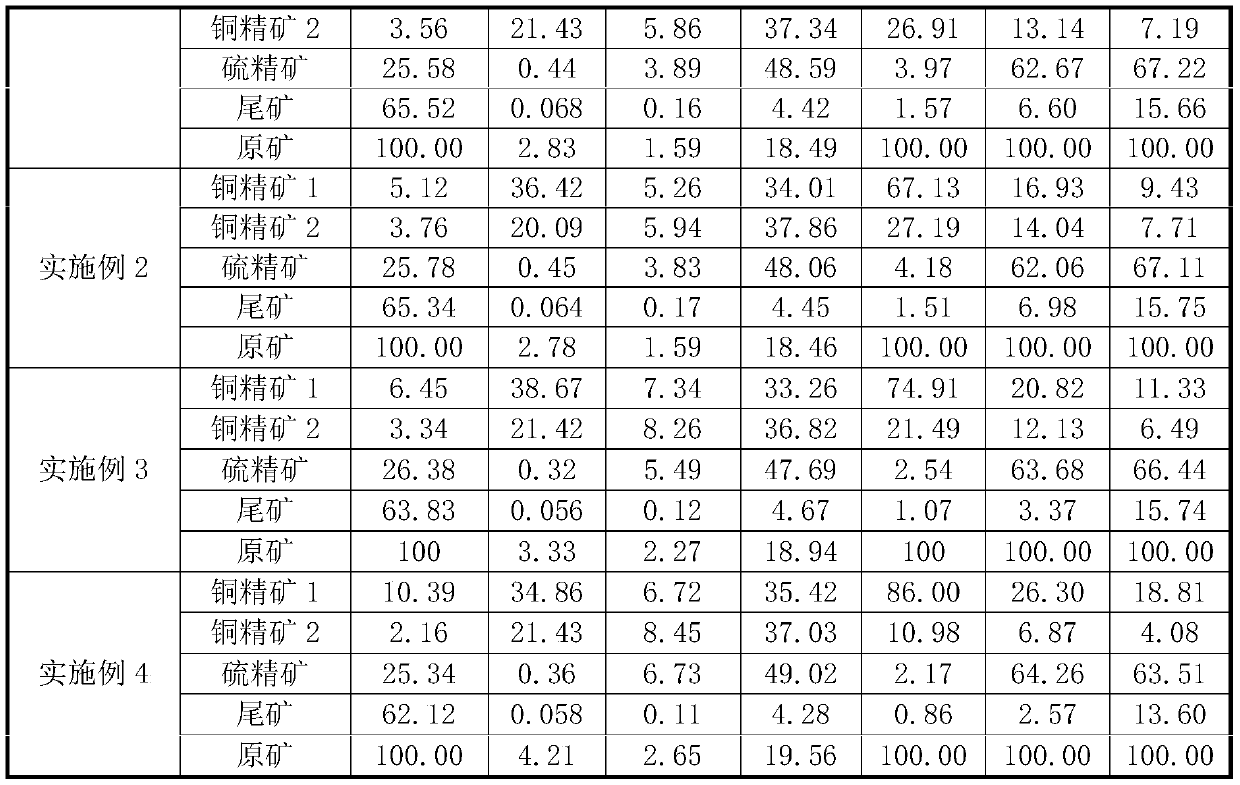

Embodiment 2

[0045] The raw ore contains 2.78% of Cu, 1.59g / t of Au, and 18.46% of S. The process steps, conditions, and medicament system are the same as in Example 1.

Embodiment 3

[0047] The raw ore contains 3.33% Cu, 2.27g / t Au, and 19.94% S, and the process steps, conditions and medicament system are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com