Gas turbine combustion chamber with pre-mixing low-swirl nozzle

A gas turbine and combustor technology, applied in the direction of combustors, continuous combustion chambers, combustion methods, etc., can solve the problems of increased nitrogen oxide emissions, and achieve the effects of reducing the formation of NOx, lowering the combustion temperature, and lowering the temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

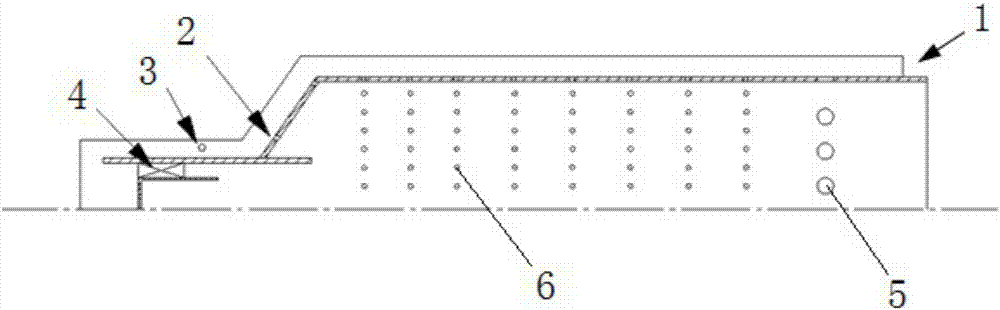

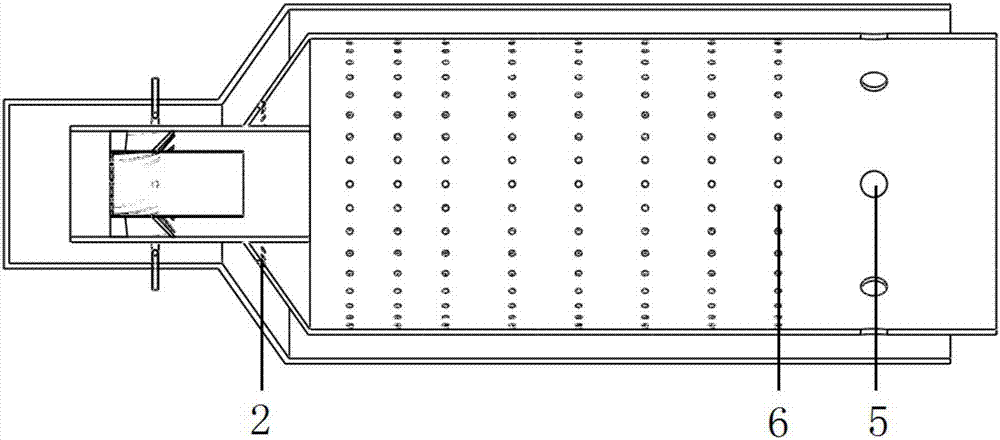

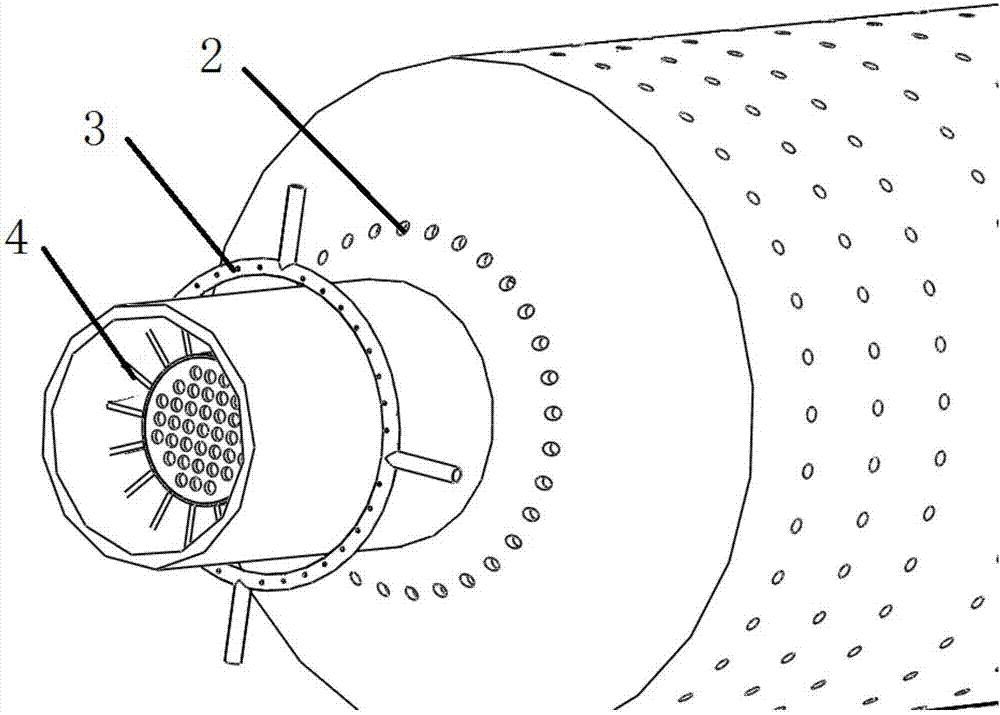

[0023] Such as Figure 1 to Figure 11 As shown, a gas turbine combustor of a premixed low-swirl nozzle includes a combustor casing and a combustion cylinder arranged in the combustion chamber casing, and an air intake cavity is formed between the combustion chamber casing and the combustion cylinder; the air intake cavity The front end is closed, and the rear end has an air inlet 1; the combustion tube is divided into a swirl area with a swirler 4 inside, a jet part with a jet hole 2 processed on the head, and a barrel part from front to back; The barrel part is the rear mixing zone with the mixing hole 5 processed on the outer wall and the front main combustion zone with the cooling hole 6 processed on the outer wall, the main combustion zone is close to the side of the jet part; the diameter of the swirl zone is less than The diameter of the cylinder part, the jet part and the swirl area and the cylinder part are in an oblique transition; an annular fuel pipe is arranged bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com