Magnesium oxide neutralization system and method for acid waste water from smelting flue gas

A technology for acid wastewater and smelting flue gas, applied in the chemical industry, can solve the problems that affect the continuous and stable operation of the acid wastewater treatment system, block the magnesium oxide dosing device, and easily generate new wastes, etc. The effect of reducing neutralization reaction time and stable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

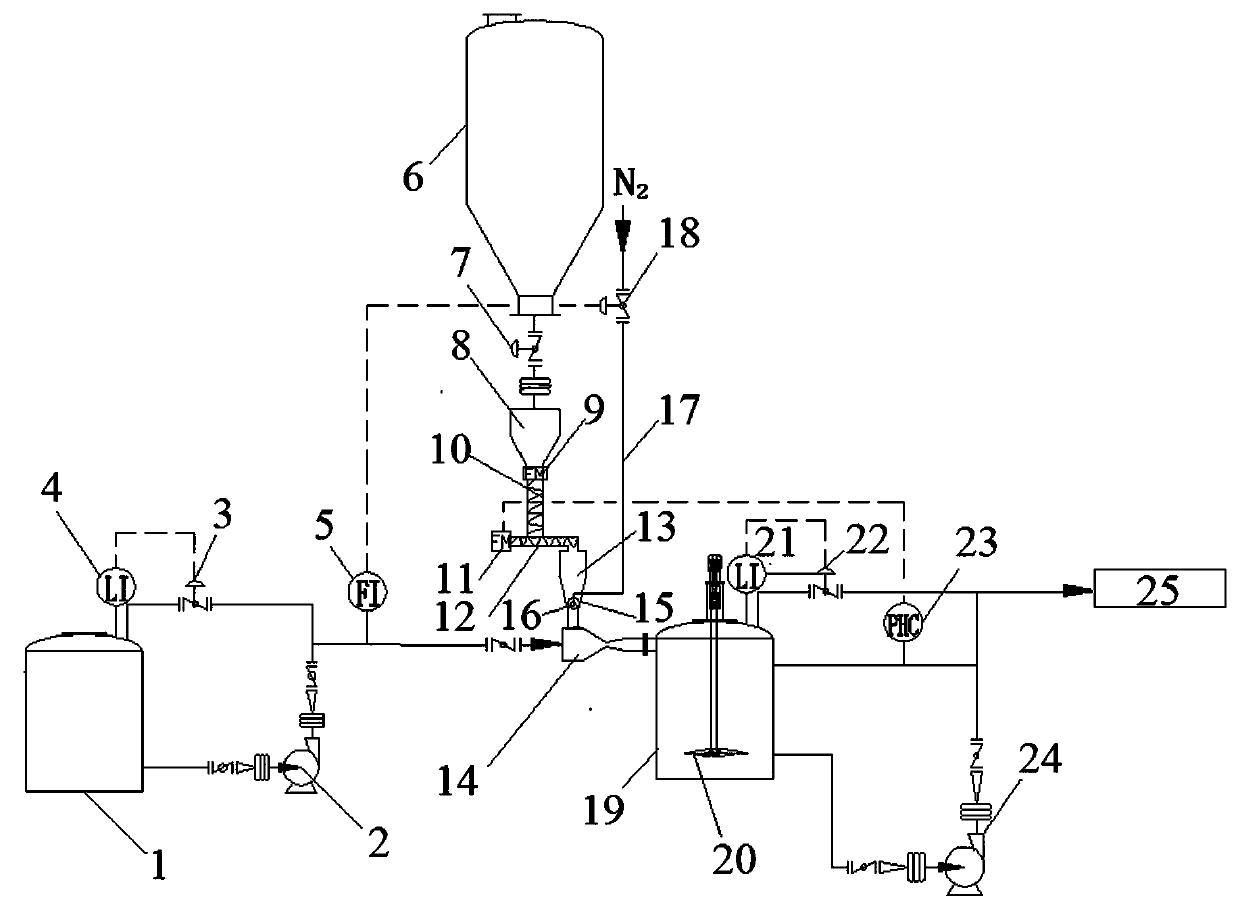

[0026] Such as figure 1 As shown, a magnesium oxide neutralization system for smelting flue gas acidic acid wastewater includes an acid water buffer tank 1, which is provided with a first liquid level gauge 4, and the bottom of the acid water buffer tank 1 passes through two A group of acid water buffer pumps 2 (one open and one standby) are respectively connected to an inlet of the acid water buffer tank 1 and the injector 14, and the pipeline between the acid water buffer pump 2 and the acid water buffer tank 1 is provided with a first Return valve 3, the first return valve 3 is interlocked with the first liquid level gauge 4, and the outlet of the acid water buffer pump 2 is provided with a flow meter 5; A nitrogen purging device is provided, and the nitrogen purging device includes a nitrogen delivery pipeline 17 provided with an automatic nitrogen valve 18, and a spiral nozzle 16 located in the lower hopper 13. 18 is interlocked with the flow meter 5; the inlet of the l...

Embodiment 2

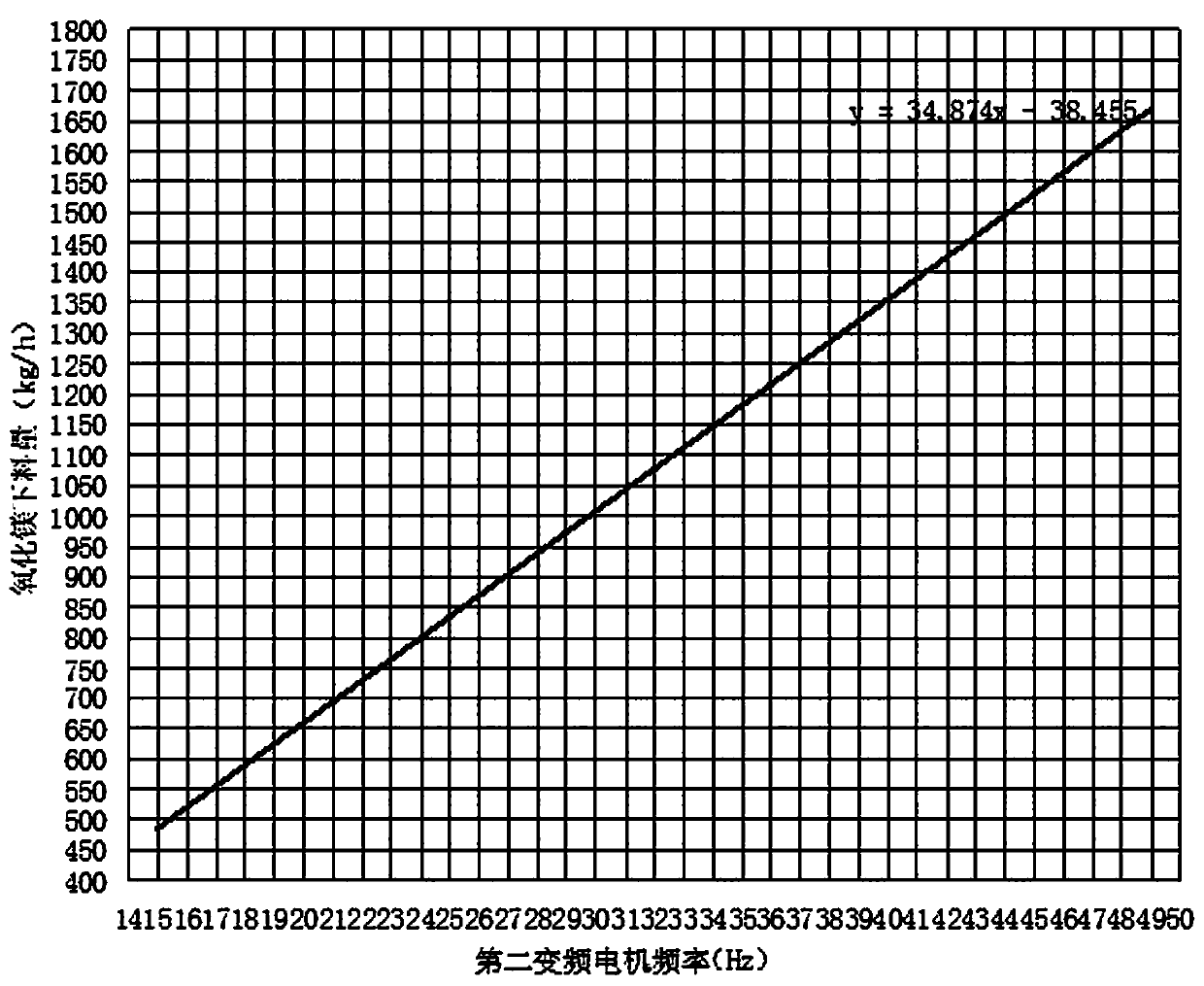

[0029] In this embodiment, the magnesium oxide neutralization system of acid waste water from smelting flue gas is the same as in Example 1, and it is applied to acid waste water from smelting flue gas during abnormal production (acidity: 61.17-166.38g / L, average acidity 119.27 g / L, flow rate: 20-28m 3 / h, average flow 22m 3In the neutralization of / h), due to the large change in the acidity of the acidic wastewater, by detecting the acidity of the acidic wastewater in the acidic water buffer tank 1, the amount of magnesium oxide added is calculated to be 1566kg / h. The linear relationship of the amount of magnesia feeding determines that the frequency of the second variable frequency motor 11 is 46 Hz, which specifically includes the following steps: opening the automatic feeding valve 7, so that the magnesia solid powder in the magnesia storage tank 6 flows into the feeding storage tank 8 through a soft connection ; Send the acid waste water in the acid water buffer tank 1 i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com