Battery core flattening equipment for lithium battery production process

A production process and technology for lithium batteries, applied in non-aqueous electrolyte batteries, electrolyte battery manufacturing, final product manufacturing, etc., can solve the problem of cell thickness uniformity, poor stability, rigid cell flattening equipment, and affecting lithium batteries. Processing effect and other issues, to achieve the effect of reducing labor, uniform thickness, and easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

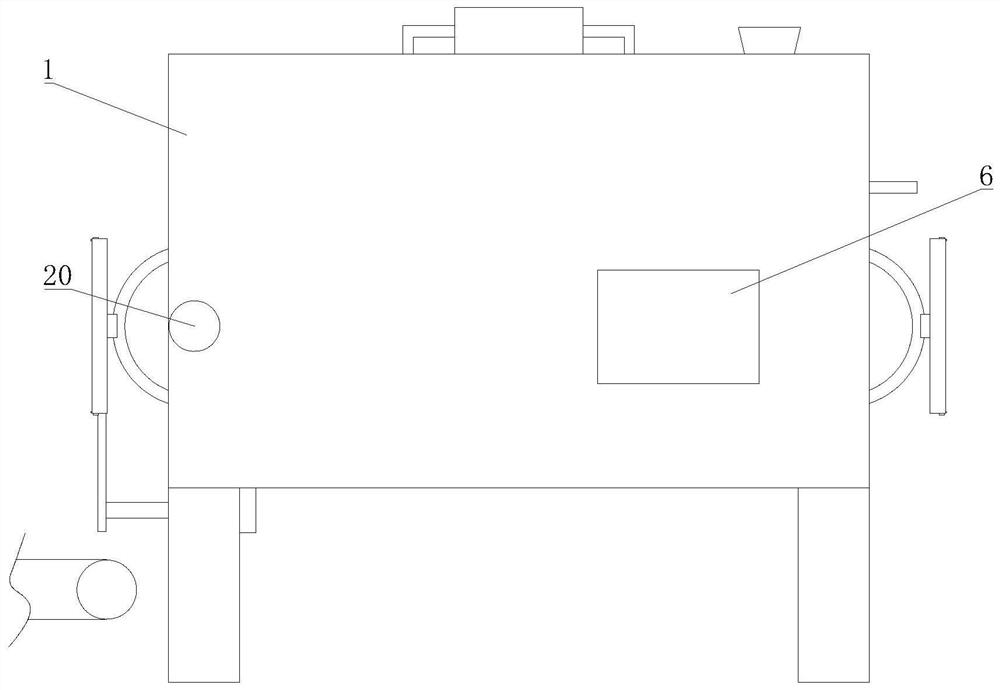

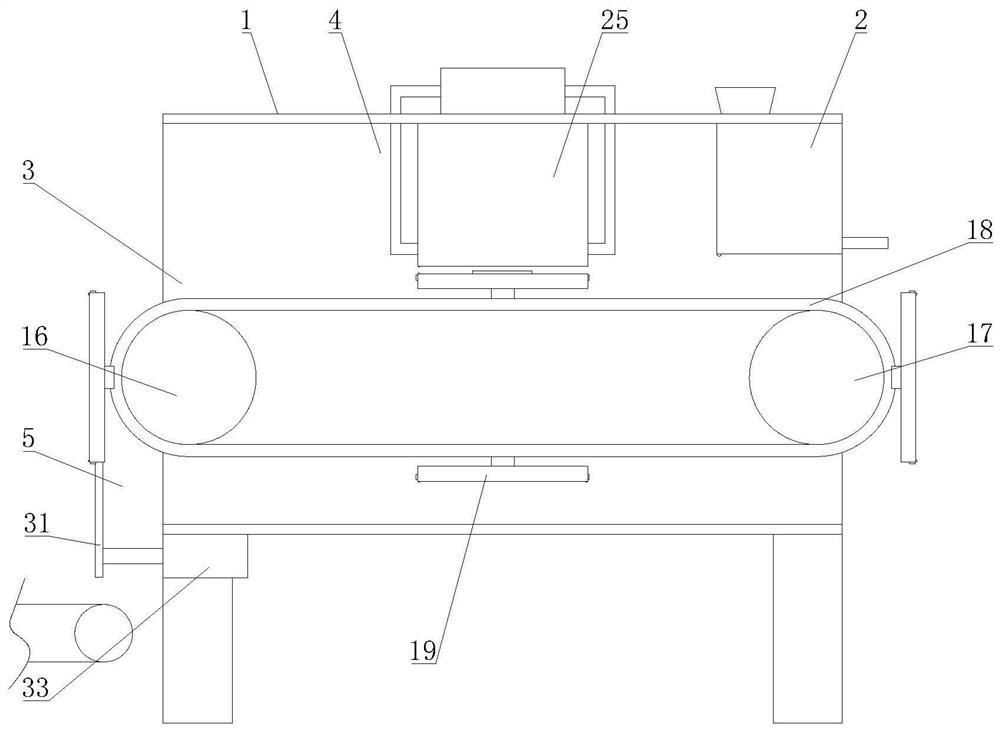

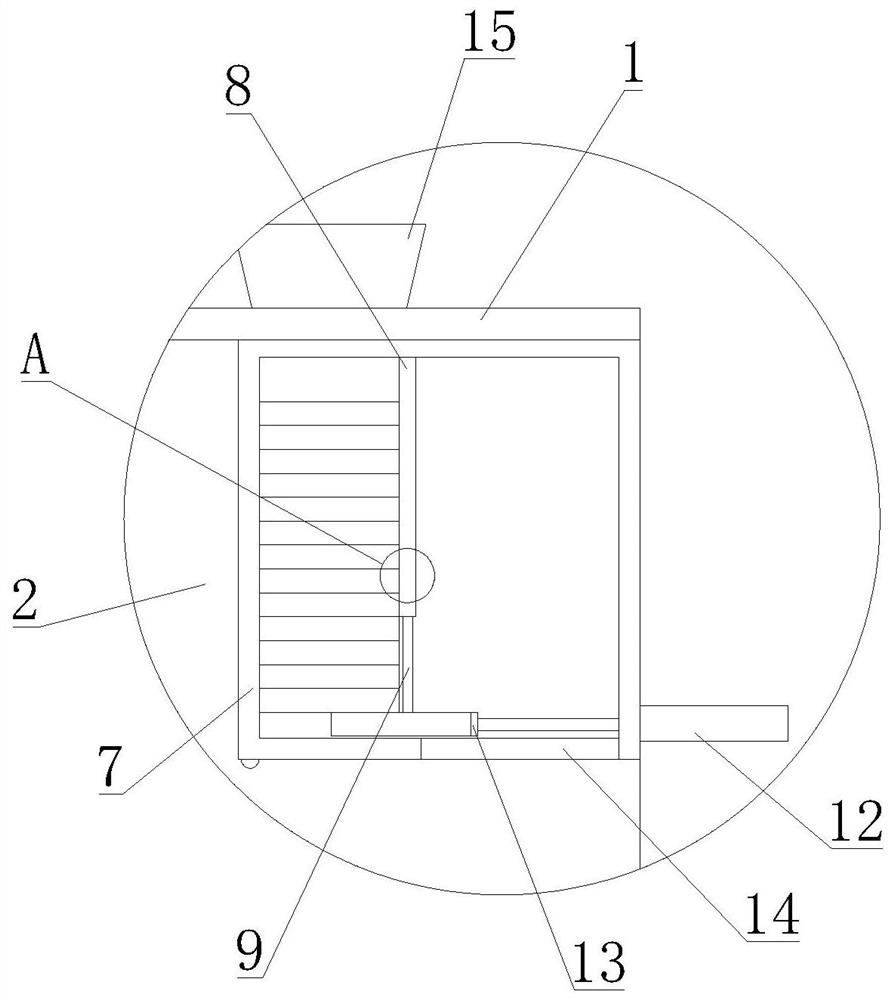

[0043] like Figure 1-7 As shown, a battery cell flattening device for lithium battery production process proposed by the present invention, working cabin 1, unloading assembly 2, feeding assembly 3, flattening assembly 4, unloading assembly 5, laser positioner assembly and control device 6; the left and right ends of the working cabin 1 are provided with a material outlet and a material inlet respectively; the feeding assembly 3 is arranged in the working cabin 1, and the two ends extend to the material outlet and the material inlet; Above the feeding end of the feeding assembly 3; the flattening assembly 4 is arranged in the working cabin 1; the unloading assembly 5 is arranged below the discharging end of the feeding assembly 3; the controller 6 communicates with the feeding assembly 2 and the feeding assembly 3. Flattening component 4, laser positioner component and unloading component 5; unloading component 2 includes material storage box 7, material partition plate 8, tele...

Embodiment 2

[0054] The present invention also provides a battery cell flattening method for lithium battery production process, the steps are as follows:

[0055] S1. According to production needs, select a suitable mold 23 and matching extrusion plate 27, and install them;

[0056] S2, through the feeding port 15, put a sufficient amount of electric cores into the storage box 7;

[0057] S3. According to the thickness of the raw material of the battery cell, adjust the telescopic plate 9 to move up and down, so that the amount of each blanking is accurate and stable;

[0058] S4, the conveyor belt 18 rotates, and the mold mounting part 19 moves along the processing direction;

[0059] S5. Through mutual induction between the first laser receiving part of the laser positioner assembly and the laser emitting part of the laser positioner assembly, the mold mounting part 19 moves below the material storage box 7, and the first driving cylinder 12 pushes the vacuum adsorption part 13 through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com