Feeding quantity regulation and control system and method for combine harvester

A combine harvester and control system technology, applied to harvesters, agricultural machinery and implements, cutters, etc., can solve problems such as simultaneous control, measurement results are easily affected by light, and slow calculation speed, so as to achieve the effect of improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

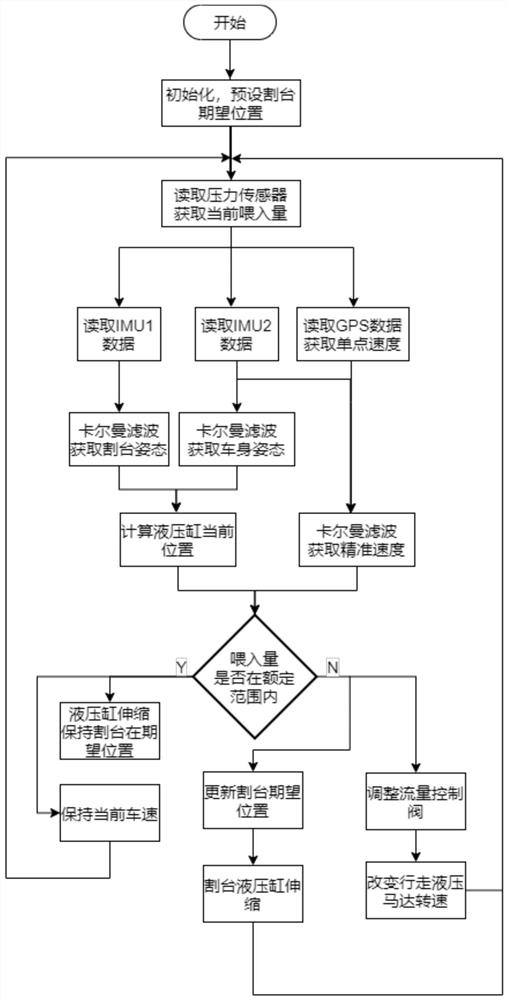

[0033] The present invention will be further described below with reference to the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereto.

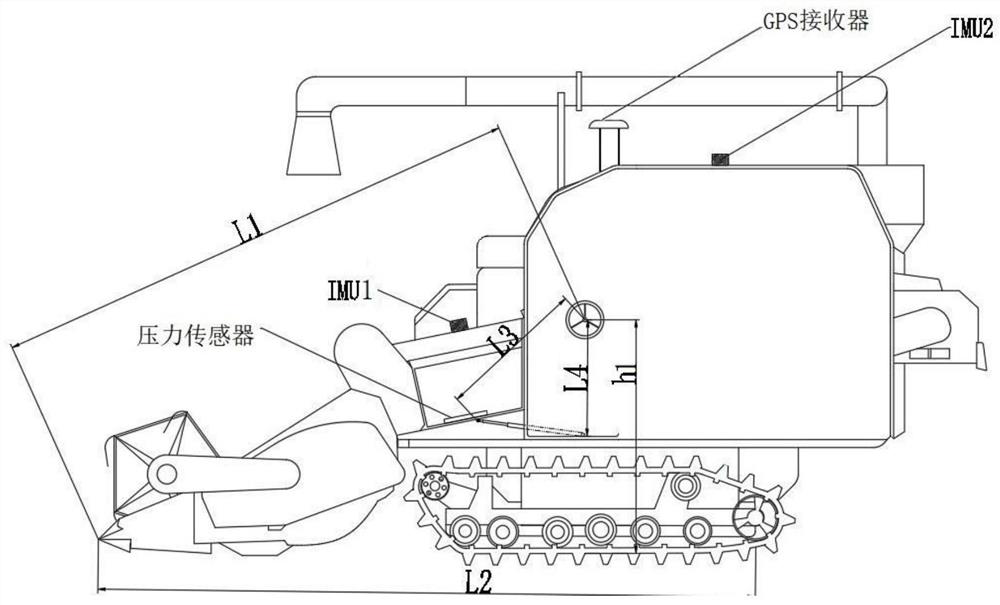

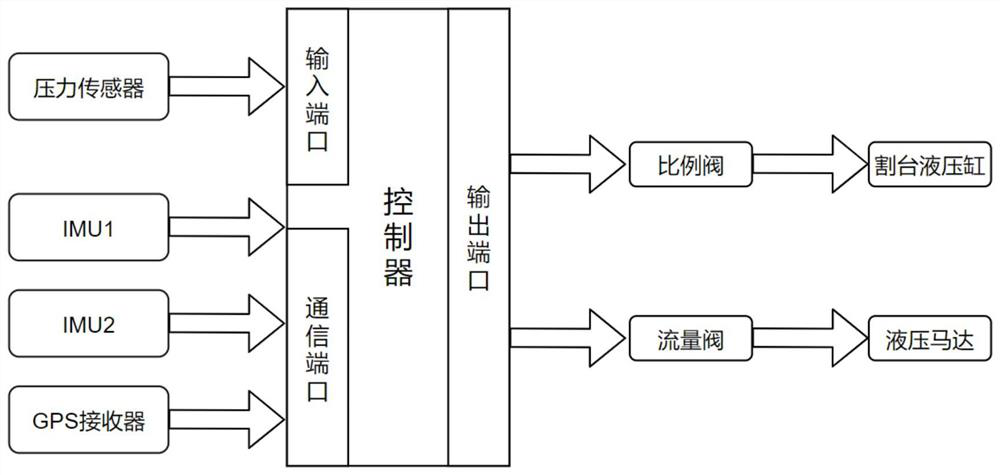

[0034] like figure 1 and figure 2 As shown, a combine harvester feed quantity control system includes an inertial measurement unit IMU1, an inertial measurement unit IMU2, a pressure sensor, a GPS receiver and a controller. Among them, IMU1 is installed at the outer casing of the inclined conveyor to detect the inclination of the header plane; IMU2 is installed above the granary and at the level of the car body. The raw data collected by the accelerometer and gyroscope of IMU2 is filtered by Kalman The horizontal attitude of the vehicle body is obtained, on the other hand, it is combined with GPS data, and the precise forward speed of the vehicle body is obtained after Kalman filtering; the GPS receiver is installed in the open space above the cab; the pressure sensor is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com