Biomass powder feeder

A feeder and biomass technology, applied in the directions of transportation, packaging, loading/unloading, etc., can solve the problems of easy overhead, easy blockage of the feeder, uneven feeding amount, etc., and achieve uniform and stable feeding. The effect of stable material quantity and strong adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

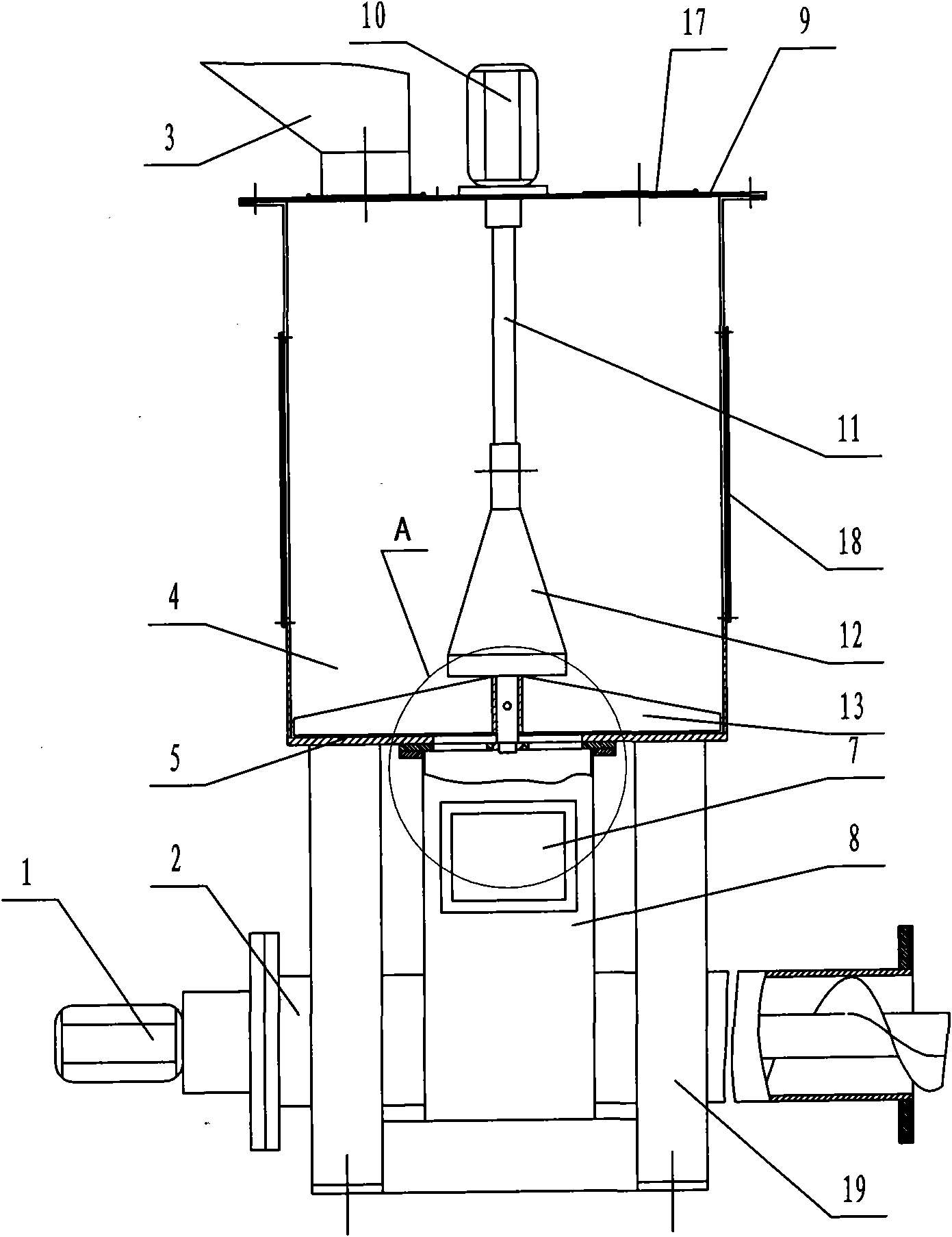

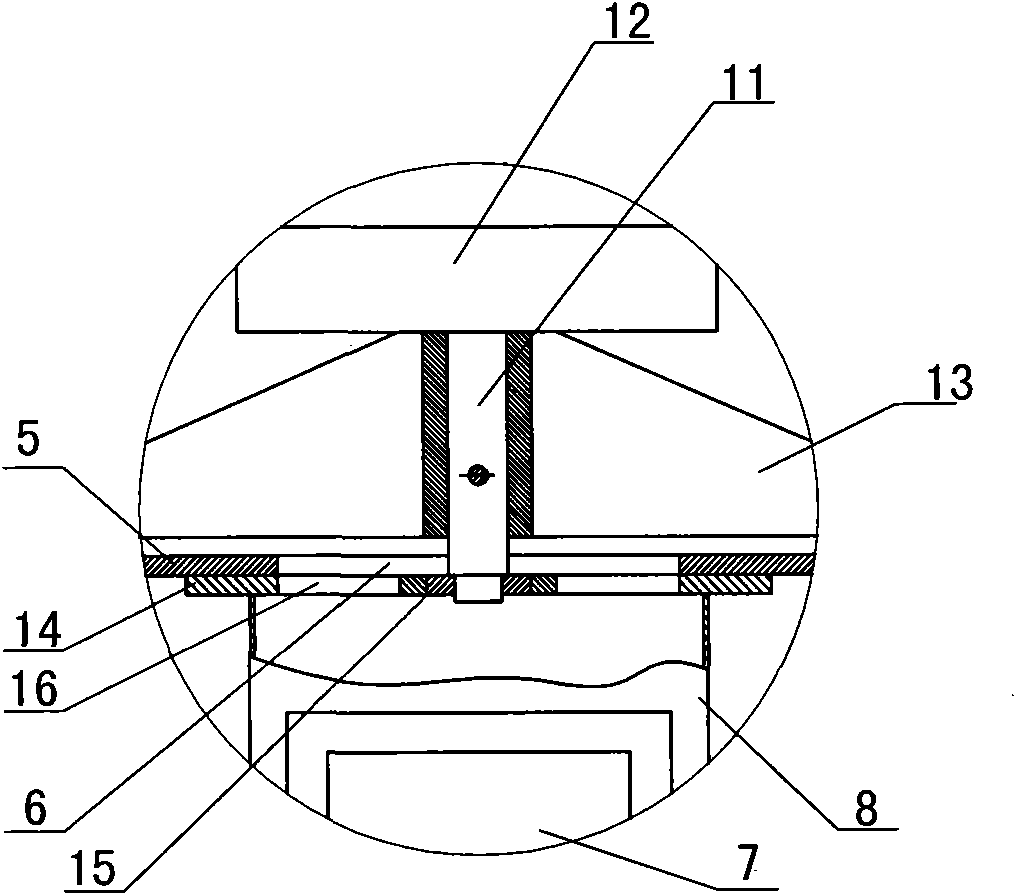

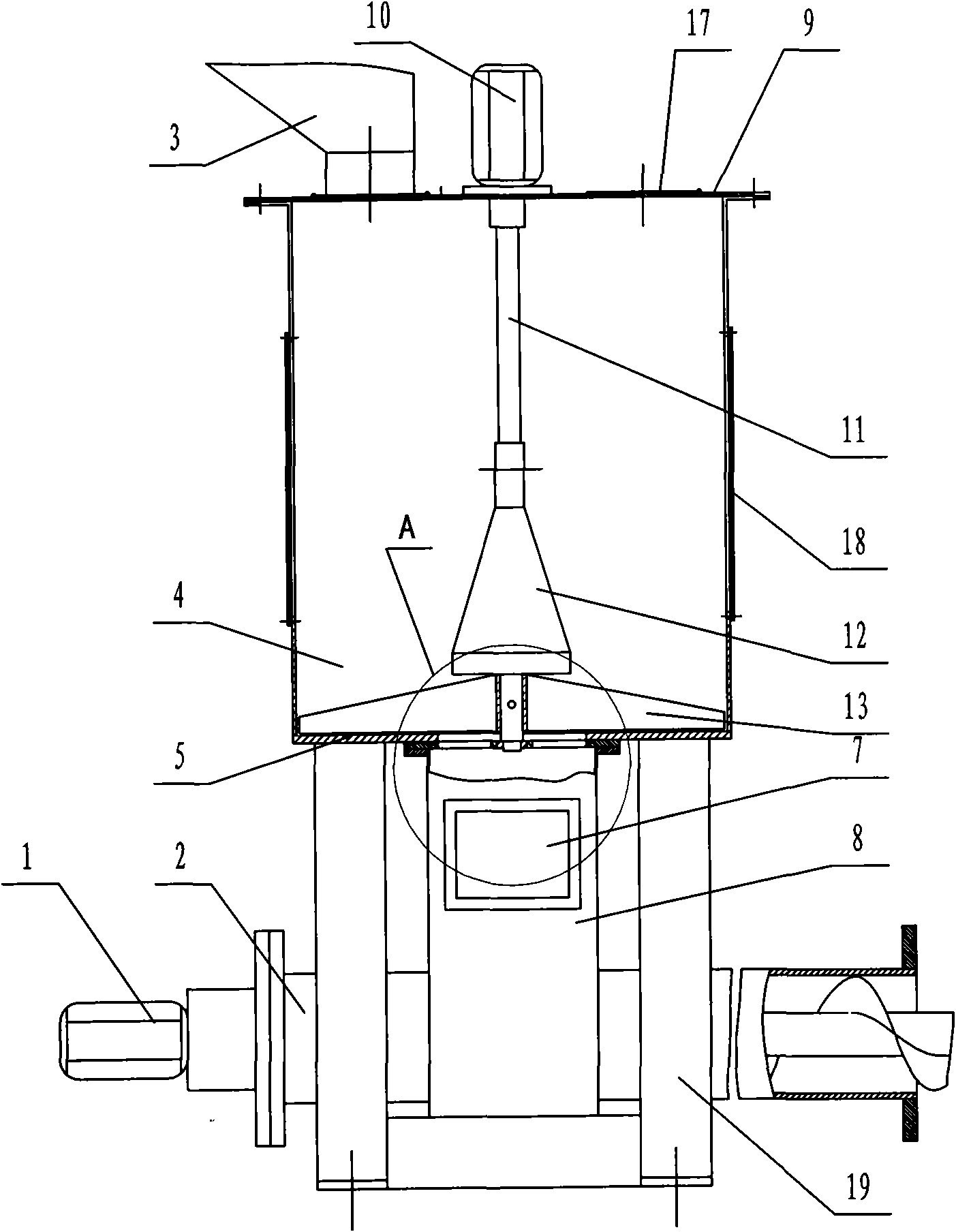

[0016] exist Figure 1-2 In the shown embodiment: the conveying device adopts the reduction motor 1 to directly drive the screw auger 2, the connecting cylinder 8 provided with the blanking observation window 7 is perpendicular to the screw auger 2, and the bottom of the connecting cylinder 8 is connected to the screw auger 2 Connected; the top of the connecting cylinder 8 is fixed with a support plate 14, the center of the support plate 14 is provided with a bearing sleeve 15, and the support plate 14 is located around the bearing sleeve 15 and is evenly distributed with blanking holes 16; the bottom 5 of the barrel 4 is fixedly installed on the On the support plate 14 of the connecting cylinder 8, the two are coaxial, the top of the material cylinder 4 is provided with a hopper 3, the center of the cylinder bottom 5 is provided with a round hole 6, and the speed regulating motor 10 is installed on the top cover plate 9 of the material cylinder 4 , the upper end of the rotati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com